Miniature Circuit Breaker

MCB Breaker, or Miniature Circuit Breakers, are essential components in modern electrical systems, designed to protect circuits from overloads and short circuits. These devices play a crucial role in ensuring the safety and efficiency of residential, commercial, and industrial electrical installations. By automatically disconnecting the circuit when excessive current flows through it, MCB Breakers prevent potential electrical hazards, equipment damage, and fire risks.

In this blog post, we aim to provide a comprehensive guide on Miniature Circuit Breaker, covering the basics of how they work, the different types available, and detailed installation tips. Whether you’re an electrical professional or a homeowner looking to enhance your knowledge, this guide will equip you with valuable insights to choose the right MCB for your needs, install it correctly, and maintain it for optimal performance. Join us as we explore the top seven basics, types, and installation tips for MCB Breakers.

Understanding MCB Breakers: The Basics

What is an MCB Breaker?

An MCB (Miniature Circuit Breaker) is a type of electrical switch designed to automatically protect an electrical circuit from damage caused by overcurrent or short circuit. It is an essential component in modern electrical systems, providing reliable and efficient protection for various applications.

How MCB Breakers Work

MCB Breakers operate by detecting excessive current flow through the circuit. When the current exceeds a predefined limit, the MCB interrupts the circuit, cutting off the electrical flow to prevent damage to the wiring and connected devices. This automatic disconnection helps to mitigate risks associated with electrical overloads and short circuits.

Benefits of MCB Breakers in Electrical Systems

MCB Breakers serve several critical functions in electrical systems:

- Enhanced Safety: They prevent electrical fires and equipment damage by promptly disconnecting circuits in the event of overcurrent.

- Reliability: MCBs are more reliable and durable compared to traditional fuses, as they can be reset and reused multiple times.

- Convenience: They offer easy and quick restoration of power by simply resetting the breaker, eliminating the need to replace fuses.

- Protection: MCBs safeguard both the electrical infrastructure and the connected devices, ensuring a longer lifespan and reduced maintenance costs.

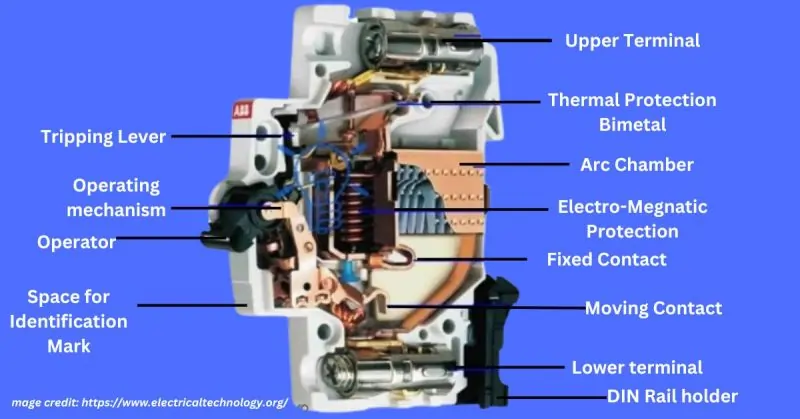

Detailed Components of MCB Breakers

Upper Terminal

- Function: Connects the incoming electrical supply to the MCB.

- Importance: Ensures a secure and reliable connection to the circuit.

Thermal Protection Bimetal

- Function: Detects prolonged overcurrent by bending due to heat.

- Importance: Triggers the breaker to trip and disconnect the circuit, preventing damage from sustained overcurrent.

Arc Chamber

- Function: Extinguishes the electrical arc formed during the interruption.

- Importance: Protects the MCB and surrounding components from damage by safely dissipating the arc.

Electro-Magnetic Protection

- Function: Provides instantaneous protection against short circuits.

- Importance: Utilizes an electromagnet to trip the breaker immediately, ensuring rapid response to high current spikes.

Fixed Contact

- Function: Serves as the stationary contact point within the MCB.

- Importance: Works with the moving contact to either complete or break the circuit, enabling or stopping the flow of electricity.

Moving Contact

- Function: Moves to either make or break contact with the fixed contact.

- Importance: Operates during the tripping and resetting of the breaker, crucial for the MCB’s operation.

Lower Terminal

- Function: Connects the outgoing electrical supply from the MCB.

- Importance: Ensures the circuit is properly connected to the load, maintaining the flow of electricity to the designated area.

DIN Rail Holder

- Function: Secures the MCB onto a standard DIN rail.

- Importance: Facilitates easy installation and removal of the breaker, ensuring stable and accessible mounting.

Tripping Lever

- Function: Mechanism that physically disconnects the moving contact.

- Importance: Allows manual resetting of the breaker after a trip, providing control and safety.

Operating Mechanism

- Function: Internal mechanism that operates the moving contact.

- Importance: Ensures precise and reliable tripping action, critical for the proper functioning of the MCB.

Operator

- Function: The external switch used to manually turn the MCB on or off.

- Importance: Provides user control over the circuit breaker, allowing easy operation and reset.

Space for Identification Mark

- Function: Designated area for labeling the MCB.

- Importance: Helps identify the breaker and its circuit in an electrical panel, aiding in maintenance and troubleshooting.

Types of MCB Breakers

Overview of Different Types of MCB Breakers

| Type | Characteristics | Applications |

|---|---|---|

| Type B MCB | Trips between 3 to 5 times the full load current. | Residential or light commercial installations (e.g., lighting and socket circuits). |

| Type C MCB | Trips between 5 to 10 times the full load current. | Commercial and industrial environments with moderate surge currents (e.g., small motors, fluorescent lighting). |

| Type D MCB | Trips between 10 to 20 times the full load current. | Heavy industrial applications with high inrush currents (e.g., large motors, transformers). |

Specifications and Ratings of Each Type

| Type | Tripping Current | Common Ratings |

|---|---|---|

| Type B MCB | 3 to 5 times the rated current. | 6A, 10A, 16A, 20A, 32A. |

| Type C MCB | 5 to 10 times the rated current. | 6A, 10A, 16A, 20A, 32A, 40A. |

| Type D MCB | 10 to 20 times the rated current. | 10A, 16A, 20A, 32A, 40A, 63A. |

How to Choose the Right MCB for Your Needs

- Identify the Application: Determine whether the MCB will be used in a residential, commercial, or industrial setting. Residential settings typically use Type B, while commercial and industrial settings may require Type C or D.

- Consider the Load Type: Evaluate the type of devices or machinery that will be connected. For lighting and general circuits, Type B is sufficient. For circuits with motors or fluorescent lighting, Type C is more appropriate. For high inrush current devices, Type D is necessary.

- Check the Current Rating: Ensure the MCB’s current rating matches the expected load of the circuit to prevent nuisance tripping or insufficient protection.

- Assess the Surge Current: Determine the potential surge current of the connected devices to choose an MCB that can handle the inrush without tripping unnecessarily.

- Review Regulatory Requirements: Make sure the selected MCB complies with local electrical codes and standards to ensure safety and legality.

Installation Guide for MCB Breakers

Step-by-Step Instructions for Installing an MCB Breaker

- Turn Off the Main Power Supply Ensure the main power supply to the distribution board is turned off to prevent any electrical hazards.

- Prepare the Distribution Board Open the distribution board cover and locate the slot where the MCB will be installed. Ensure the slot is clear of any debris or obstructions.

- Mount the MCB Breaker Align the MCB with the DIN rail holder in the distribution board. Snap the MCB onto the DIN rail, ensuring it is securely fixed in place.

- Connect the Incoming Supply Strip the insulation from the end of the incoming supply wire. Insert the stripped wire into the upper terminal of the MCB and tighten the screw to secure the connection.

- Connect the Outgoing Load Wire Strip the insulation from the end of the outgoing load wire. Insert the stripped wire into the lower terminal of the MCB and tighten the screw to secure the connection.

- Check All Connections Ensure all connections are tight and secure to prevent any loose wiring. Double-check that there are no exposed wires or loose strands.

- Label the MCB Use the designated space for the identification mark to label the MCB according to its connected circuit.

- Close the Distribution Board Cover Carefully close the cover of the distribution board, ensuring it is properly secured.

- Turn On the Main Power Supply Restore the main power supply to the distribution board. Switch the MCB to the “ON” position and test the connected circuit to ensure proper operation.

Tools and Materials Needed for Installation

- Screwdriver (flathead or Phillips, depending on the screws used)

- Wire stripper

- Insulated pliers

- MCB Breaker

- Electrical tape

- Labels for identification

- DIN rail (if not already installed in the distribution board)

Common Installation Mistakes to Avoid

- Not Turning Off the Main Power Supply Always ensure the main power supply is turned off before beginning any electrical work to prevent electric shock.

- Loose Connections Ensure all wire connections are tight and secure to prevent arcing and overheating.

- Incorrect Wire Stripping Strip the correct amount of insulation from the wires; too much exposed wire can cause shorts, and too little can result in a weak connection.

- Improper Mounting Make sure the MCB is securely mounted on the DIN rail to avoid it becoming loose over time.

- Neglecting to Label the MCB Properly label the MCB to identify its connected circuit, which aids in future maintenance and troubleshooting.

- Using Incorrect Tools Use the appropriate tools to ensure a safe and efficient installation process.

Comparing Different MCB Brands and Models

Overview of Popular MCB Brands and Models

1. Schneider Electric

- Popular Models: Acti9, Easy9

- Features: High performance, advanced safety features, easy installation.

- Applications: Residential, commercial, and industrial.

2. Siemens

- Popular Models: 5SY, 5SP

- Features: Robust design, reliable performance, comprehensive protection.

- Applications: Commercial and industrial environments.

3. ABB

- Popular Models: S200, S800

- Features: Wide range of ratings, high breaking capacity, space-saving design.

- Applications: Residential, commercial, industrial.

4. Legrand

- Popular Models: DX3, RX3

- Features: Versatile applications, enhanced safety, easy to integrate.

- Applications: Residential and light commercial.

5. Eaton

- Popular Models: FAZ, C Series

- Features: Compact size, high reliability, excellent protection.

- Applications: Residential, commercial, industrial.

Comparison of Performance, Durability, and Value for Money

| Brand | Performance | Durability | Value for Money |

|---|---|---|---|

| Schneider Electric | High performance with advanced features. | Highly durable with long lifespan. | Offers good value due to superior quality and features. |

| Siemens | Reliable performance suitable for heavy-duty applications. | Very durable, suitable for harsh environments. | Competitive pricing with strong performance. |

| ABB | Excellent performance across a wide range of ratings. | Highly durable, especially in industrial settings. | Slightly higher cost but justified by quality and reliability. |

| Legrand | Versatile with reliable performance for general use. | Durable enough for most residential and light commercial applications. | Cost-effective with good safety features. |

| Eaton | Consistent and reliable performance. | Durable and compact design. | Affordable with solid protection capabilities. |

Customer Reviews and Expert Recommendations

Schneider Electric

- Customer Reviews: Users praise the ease of installation and the advanced safety features. Highly recommended for residential use.

- Expert Recommendations: Preferred for projects requiring reliable performance and advanced protection.

Siemens

- Customer Reviews: Appreciated for its robustness and reliability in industrial applications. Some mention the higher initial cost.

- Expert Recommendations: Recommended for heavy-duty and industrial environments where durability is key.

ABB

- Customer Reviews: High marks for performance and reliability, especially in demanding settings. A bit on the pricier side.

- Expert Recommendations: Ideal for industrial projects needing a wide range of ratings and high breaking capacity.

Legrand

- Customer Reviews: Users like its versatility and safety features. Seen as a good balance between cost and performance.

- Expert Recommendations: Suitable for residential and light commercial applications with budget constraints.

Eaton

- Customer Reviews: Noted for its compact size and reliability. Highly regarded for value and protection.

- Expert Recommendations: Best for those seeking affordable and dependable protection in various settings.

Troubleshooting and Maintenance Tips for MCB Breakers

| Issue | Troubleshooting Steps | Maintenance Tips | Signs of Replacement |

|---|---|---|---|

| MCB Trips Frequently | 1. Check for overloads and reduce the load on the circuit. 2. Inspect for short circuits or faulty wiring. 3. Ensure all connections are tight and secure. 4. Test with a known good MCB to rule out a faulty breaker. | – Regularly check and tighten all connections. – Monitor circuit loads to prevent overloads. – Perform periodic insulation resistance tests. | – Frequent tripping without an apparent cause. – Visible damage or discoloration. – MCB fails to reset or stay in the ‘on’ position. |

| MCB Does Not Trip During Faults | 1. Test the MCB with a known fault condition. 2. Verify that the breaker is correctly rated for the circuit. 3. Inspect the MCB for internal damage or wear. 4. Replace the MCB if it does not respond correctly. | – Schedule routine testing of MCB functionality. – Ensure MCBs are rated appropriately for their circuits. – Clean the distribution board to prevent dust buildup. | – Failure to trip under fault conditions. – Loose or unresponsive operating lever. – Signs of wear or internal damage. |

| MCB Cannot Be Reset | 1. Ensure the fault condition is cleared before resetting. 2. Check for internal mechanical obstructions. 3. Inspect the tripping mechanism for damage. 4. Replace the MCB if it cannot be reset. | – Regularly inspect the tripping mechanism. – Lubricate moving parts as needed. – Test reset functionality during maintenance checks. | – Persistent failure to reset. – Broken or damaged reset mechanism. – Unusual stiffness or looseness in the lever. |

| MCB Feels Hot to Touch | 1. Measure the current flowing through the MCB. 2. Check for loose connections or high-resistance joints. 3. Ensure adequate ventilation in the distribution board. 4. Replace if overheating persists. | – Keep the distribution board well-ventilated. – Regularly inspect for loose or corroded connections. – Monitor temperature of MCBs during regular checks. | – Consistently hot to touch without load. – Visible signs of overheating or burning. – Deformation of the MCB casing. |

| Noise from MCB | 1. Listen for humming or buzzing sounds indicating loose connections. 2. Tighten all terminal screws securely. 3. Replace the MCB if noise persists after securing connections. | – Ensure all connections are tight and secure. – Inspect for signs of electrical arcing. – Schedule regular auditory inspections. | – Persistent noise despite troubleshooting. – Evidence of internal arcing or damage. – Visible wear on internal components. |

Safety Standards and Certifications for MCB Breakers

Key Safety Standards and Certifications

MCB Breakers must comply with several key safety standards and certifications to ensure their reliability and effectiveness. These standards include:

- IEC 60898: This international standard specifies the requirements for circuit breakers intended for protection against overcurrents in household and similar installations.

- UL 489: This standard applies to molded-case circuit breakers and their accessories, providing guidelines for performance, testing, and marking.

- BS EN 60898: A British and European standard that sets the criteria for MCBs used in low voltage electrical installations.

- IS/IEC 60898: The Indian standard equivalent to IEC 60898, ensuring that MCBs meet specific safety and performance criteria.

The Role of MCBs in Protecting Electrical Circuits

MCBs play a critical role in safeguarding electrical circuits from overloads and short circuits. By automatically disconnecting the circuit when an overcurrent condition is detected, MCBs prevent:

- Electrical Fires: Overloads can cause wires to overheat, potentially leading to fires. MCBs mitigate this risk by tripping the circuit.

- Equipment Damage: Short circuits can damage electrical devices and appliances. MCBs protect these components by interrupting the current flow immediately.

- Personal Injury: By preventing electrical faults, MCBs reduce the risk of electric shocks and other injuries.

How to Ensure Compliance with Safety Standards

- Choose Certified MCBs: Always select MCBs that comply with recognized international and national standards, such as IEC, UL, and BS.

- Proper Installation: Follow manufacturer guidelines and local electrical codes during installation to ensure the MCBs function correctly.

- Regular Inspections: Conduct periodic inspections and maintenance to ensure that the MCBs are in good working condition and have not deteriorated over time.

- Stay Informed: Keep up-to-date with the latest safety standards and industry best practices to ensure ongoing compliance and safety.

FAQ on “Miniature Circuit Breaker”

Q: What is an MCB?

A: An MCB is an automatic switch that protects circuits from overcurrent.

Q: How does an MCB work?

A: It trips to disconnect the circuit when detecting excessive current

Q: Where are MCBs used?

A: MCBs are used in residential, commercial, and industrial systems.

Q: What are the benefits of MCBs over fuses?

A: MCBs are reusable, more reliable, and provide faster protection.

Conclusion

In this comprehensive guide, we’ve explored the fundamentals of Miniature Circuit Breakers (MCBs), their various types, installation procedures, and essential maintenance tips. Understanding the importance of MCBs in safeguarding electrical systems helps ensure the safety, reliability, and efficiency of your circuits.

By choosing the right type of MCB for your specific needs, following proper installation practices, and adhering to regular maintenance routines, you can prevent potential electrical hazards and extend the lifespan of your electrical components. Additionally, familiarizing yourself with common issues and troubleshooting techniques empowers you to address problems swiftly and effectively.

We hope this guide has provided you with valuable insights into MCB Breakers, enabling you to make informed decisions and maintain optimal performance in your electrical systems. Stay safe, stay informed, and continue to explore advancements in electrical safety technology. If you have any questions or experiences to share, please leave a comment below. Thank you for reading!