Ultrasonic Sensor

Ultrasonic sensors are versatile devices that use sound waves to measure distance, detect objects, and monitor various conditions. Their non-contact nature and high precision make them indispensable in many sectors. In this blog post we will explore the seven powerful trends where ultrasonic sensors are making significant impacts: marine applications, automotive safety systems, smart manufacturing, healthcare innovations, consumer electronics, environmental monitoring, and industrial processes. Each trend showcases the sensor’s adaptability and importance in modern technology. Staying updated with these trends is crucial for industry professionals to leverage the latest advancements and maintain a competitive edge in their respective fields.

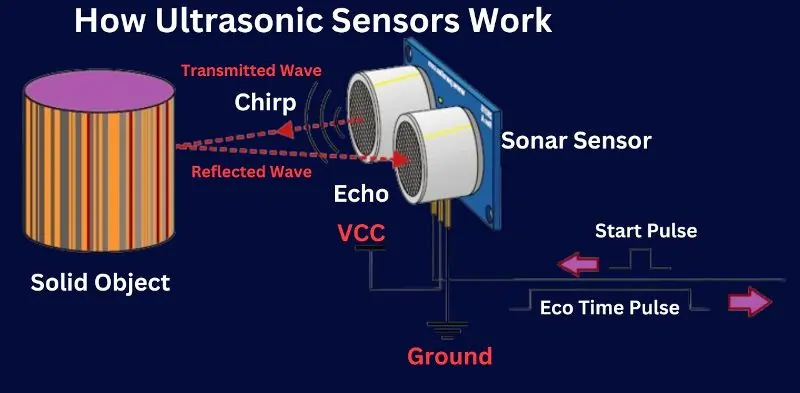

How Ultrasonic Sensors Work

SONAR Sensor

The core of an ultrasonic sensor is the SONAR sensor, which emits ultrasonic waves and measures their reflections to detect objects and distances.

Start Pulse

The sensor’s operation begins with a start pulse, a short burst of energy that triggers the emission of ultrasonic waves.

Chirp

The emitted ultrasonic wave, or chirp, is a high-frequency sound wave beyond the audible range of humans.

Transmitted Wave

The chirp travels through the air as the transmitted wave. This wave moves away from the sensor and towards the environment.

Solid Object

When the transmitted wave encounters a solid object, such as a wall or another surface, it reflects back towards the sensor.

Reflected Wave

The wave that bounces back from the object is known as the reflected wave. This wave carries information about the distance and position of the object.

Echo

The reflected wave is received by the sensor as an echo. The time it takes for the echo to return to the sensor is critical for calculating distances.

Eco Time Pulse

The sensor measures the time interval between the start pulse and the reception of the echo. This duration, known as the eco time pulse, is used to determine the distance to the object based on the speed of sound.

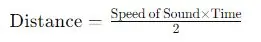

Formula: Distance Calculation

The distance to the object can be calculated using the formula:

Here, the speed of sound in air is approximately 343 meters per second, and the time is the duration of the eco time pulse.

Ground and VCC

The ultrasonic sensor operates with electrical connections including ground (GND) and VCC (Voltage Common Collector). The ground provides a return path for the electrical current, while VCC supplies the necessary power to the sensor.

Functionality

- The sensor emits a start pulse which triggers the transmission of the chirp.

- The transmitted wave travels through the air and reflects off a solid object.

- The reflected wave returns to the sensor as an echo.

- The time taken for the echo to return (eco time pulse) is measured.

- Using the speed of sound, the sensor calculates the distance to the object based on the time taken for the echo to return.

Marine Applications of Ultrasonic Sensors

NDT Testing of Engine and Machinery Components

Ultrasonic sensors are pivotal in Non-Destructive Testing (NDT) methods, which allow for the inspection of engine and machinery components without disassembly. These sensors send high-frequency sound waves into materials and measure the reflections to detect internal flaws such as cracks, voids, or corrosion. Ensuring the integrity of critical marine components without the need to take them apart is crucial for maintaining the operational readiness and safety of marine vessels.

Key applications of NDT using ultrasonic sensors in marine engineering include:

- Crankshaft and Cam Shaft Crack Detection: Detecting cracks in these vital components ensures the engine’s performance and longevity.

- Con Rod Serrations Crack Detection: Early identification of cracks in connecting rod serrations prevents catastrophic engine failures.

- Engine Bed Plate and Bearings Saddles Crack Detection: Monitoring these areas helps in maintaining the engine’s structural integrity and performance.

- Other Engine Parts Inspection: Regular inspection of pistons, cylinder heads, and cylinder liners using ultrasonic sensors helps in identifying wear and potential failure points.

- Boiler Wall Thickness Measurement: Ultrasonic sensors measure the thickness of boiler walls to detect thinning caused by corrosion, ensuring the safety and efficiency of the boiler system.

- Cylinder Head Wall Thickness Detection: Detecting reduced wall thickness due to cold corrosion helps in timely maintenance, preventing engine damage.

Underwater Object Detection and Navigation

Ultrasonic sensors play a key role in identifying and navigating around underwater obstacles. This capability is essential for both commercial and military marine vessels, helping them avoid collisions and navigate safely through complex underwater environments. Submarines and Autonomous Underwater Vehicles (AUVs) rely on ultrasonic sensors for real-time obstacle detection and path planning. Case studies have shown successful implementations of these sensors in avoiding underwater hazards and enhancing navigational accuracy, significantly improving the safety and efficiency of underwater missions.

Submarine and Surface Vessel Communication

Enhancing communication reliability between submarines and surface vessels in challenging underwater conditions is another vital application of ultrasonic sensors. These sensors facilitate secure communication by transmitting ultrasonic waves through water, which is less susceptible to interference compared to traditional radio waves. Examples of this application include secure data transmission for coordinated maneuvers and real-time sharing of navigational data, critical for both military operations and commercial underwater exploration.

Hull Inspection and Maintenance

Regular hull inspections are essential for maintaining the safety and longevity of marine vessels. Ultrasonic sensors are used to detect structural issues such as cracks, corrosion, and material thinning in ship hulls. These inspections help prevent catastrophic failures and extend the service life of the vessels. Real-world examples include the routine inspection of commercial shipping fleets and military vessels, where ultrasonic sensors provide detailed assessments of hull integrity, enabling timely maintenance and repairs.

Ultrasonic sensors’ ability to perform precise, non-invasive measurements makes them indispensable in the marine industry, ensuring safety, enhancing navigational capabilities, and maintaining the structural integrity of critical components.

Automotive Applications of Ultrasonic Sensors

Safety and Assistance Features

Ultrasonic sensors are integral to modern automotive safety and assistance systems. They enhance driver awareness and vehicle safety through several key applications:

- Parking Assistance: Ultrasonic sensors detect obstacles around the vehicle during parking maneuvers, providing auditory or visual alerts to the driver. This helps in preventing collisions with other vehicles, objects, or pedestrians.

- Collision Avoidance: These sensors are used in collision avoidance systems to detect imminent obstacles and automatically apply brakes or steer the vehicle to avoid a crash.

- Blind Spot Detection: Ultrasonic sensors monitor the vehicle’s blind spots and alert the driver when another vehicle is detected in these areas, significantly reducing the risk of accidents during lane changes.

Autonomous Driving Systems

Ultrasonic sensors play a crucial role in Advanced Driver Assistance Systems (ADAS) and the development of self-driving vehicles. They provide essential data for:

- Proximity Detection: In autonomous vehicles, ultrasonic sensors help detect nearby objects, ensuring safe navigation in complex environments.

- Parking Automation: They enable automated parking systems by precisely measuring distances to surrounding obstacles, allowing the vehicle to park itself without driver intervention.

- Enhanced Safety Features: Ultrasonic sensors are part of the sensor fusion technology in ADAS, working alongside cameras, LiDAR, and radar to create a comprehensive perception of the vehicle’s surroundings.

Case Studies

Leading automotive companies are at the forefront of integrating ultrasonic sensors into their vehicles:

- Tesla: Tesla’s Autopilot system uses a network of ultrasonic sensors for enhanced safety and parking assistance, contributing to its advanced self-driving capabilities.

- BMW: BMW incorporates ultrasonic sensors in its Parking Assistant Plus system, which assists drivers in parking by providing a 360-degree view and detecting obstacles around the vehicle.

- Mercedes-Benz: The Mercedes-Benz DISTRONIC PLUS system utilizes ultrasonic sensors for adaptive cruise control and collision avoidance, maintaining safe distances from other vehicles on the road.

Smart Manufacturing and Industry 4.0 with Ultrasonic Sensors

Automation and Efficiency

Ultrasonic sensors are revolutionizing automation in manufacturing by providing precise, non-contact measurement capabilities. They enhance automation and efficiency through various applications:

- Distance Measurement: Ultrasonic sensors measure distances accurately, enabling automated systems to position components correctly, ensuring precision in assembly lines.

- Object Detection: These sensors detect the presence or absence of objects, which is crucial for automated material handling systems, robotic arms, and conveyor systems. They help in preventing collisions and ensuring smooth operations.

- Level Sensing: In liquid and bulk material handling, ultrasonic sensors are used to measure levels in tanks and silos, automating the filling and dispensing processes and ensuring optimal inventory management.

Industry 4.0 Integration

Ultrasonic sensors play a significant role in the digitalization and IoT landscape, essential components of Industry 4.0:

- Data Collection: Ultrasonic sensors collect real-time data on various parameters, such as distance, presence, and level, feeding this data into IoT systems for monitoring and analysis.

- Predictive Maintenance: By continuously monitoring the condition of machinery and components, ultrasonic sensors help predict failures before they occur, reducing downtime and maintenance costs.

- Enhanced Connectivity: These sensors integrate with other smart devices and systems, creating a connected ecosystem that enables more efficient and flexible manufacturing processes.

Core Components of Industry 4.0:

- Internet of Things (IoT): Devices and machines are interconnected through the internet, allowing for seamless communication and data exchange.

- Big Data and Analytics: Large volumes of data are collected from various sources, analyzed in real-time to enhance decision-making and optimize processes.

- Artificial Intelligence (AI) and Machine Learning: AI algorithms and machine learning models are used to automate complex tasks, predict maintenance needs, and improve production efficiency.

- Cyber-Physical Systems (CPS): The integration of physical processes with digital technologies enables machines to communicate and cooperate with each other and humans in real-time.

- Cloud Computing: Storing and processing data on remote servers allows for greater scalability, flexibility, and accessibility of information.

- Advanced Robotics and Automation: The use of robots and automated systems to perform tasks with high precision and efficiency.

- Augmented Reality (AR) and Virtual Reality (VR): These technologies are used for training, maintenance, and design processes, providing immersive and interactive experiences.

- Additive Manufacturing (3D Printing): Producing complex components with 3D printing technologies, reducing material waste and enabling customization.

Objectives of Industry 4.0:

- Increased Productivity: Through automation and real-time data analytics, processes become more efficient, reducing downtime and increasing output.

- Improved Quality: Continuous monitoring and predictive maintenance ensure higher product quality and consistency.

- Flexibility and Customization: Manufacturers can quickly adapt to changing demands and offer personalized products.

- Enhanced Supply Chain Management: Real-time tracking and data sharing improve logistics, inventory management, and overall supply chain efficiency.

- Sustainability: Optimizing resource use and reducing waste contribute to more sustainable manufacturing practices.

Examples of Industry 4.0 Applications:

- Smart Factories: Factories equipped with interconnected machines and sensors that communicate and optimize production processes autonomously.

- Predictive Maintenance: Using IoT and AI to predict equipment failures before they occur, minimizing downtime and repair costs.

- Digital Twins: Creating digital replicas of physical assets to simulate and analyze their performance, improving design and operational efficiency.

Real-world Applications

Several factories have successfully implemented ultrasonic sensors to improve their manufacturing processes:

- Automotive Manufacturing: In automotive assembly lines, ultrasonic sensors are used to ensure precise positioning of parts and components, enhancing the accuracy and speed of assembly processes.

- Food and Beverage Industry: Ultrasonic sensors are employed to monitor the levels of liquids in tanks and ensure the accurate filling of bottles and containers, optimizing production efficiency and reducing waste.

- Pharmaceutical Manufacturing: These sensors are used in pharmaceutical plants to measure the level of liquids and powders in mixing and storage tanks, ensuring consistency and quality in production.

- Textile Industry: In textile manufacturing, ultrasonic sensors help in controlling the position of fabrics and detecting any misalignment, ensuring high-quality output.

Healthcare Innovations Using Ultrasonic Sensors

| Category | Description |

|---|---|

| Medical Imaging and Diagnostics | Ultrasonic sensors are widely used in non-invasive medical imaging procedures such as ultrasound scans. These procedures help visualize internal organs, tissues, and blood flow, aiding in the diagnosis and monitoring of various medical conditions without the need for invasive surgery. |

| Monitoring Systems | Precise and reliable data from ultrasonic sensors are crucial for patient monitoring systems. These sensors measure physiological parameters like blood flow, heart rate, and fetal health, ensuring continuous and accurate monitoring, which is vital for effective patient care. |

| Technological Advancements | The latest innovations in ultrasonic sensor technology include the development of miniaturized and portable devices, improved imaging resolution, and advanced signal processing techniques. These advancements enhance the accuracy and capabilities of ultrasonic sensors, making them more effective for various healthcare applications. |

Consumer Electronics and IoT Using US

| Category | Description |

|---|---|

| Gesture Recognition and Proximity Sensing | Ultrasonic sensors are used in smartphones and home automation devices to detect hand gestures and proximity. This allows users to control their devices through simple gestures without physically touching them, enhancing convenience and interactivity. |

| Enhancing User Experience | Ultrasonic sensors improve user interactions with electronic devices by providing more intuitive and responsive control mechanisms. For instance, they enable touchless control features, improve screen auto-brightness adjustments, and enhance the accuracy of virtual assistants in recognizing user commands. |

| IoT Integration | The growth of smart home technologies heavily relies on ultrasonic sensors. These sensors play a crucial role in IoT ecosystems by enabling smart home devices to detect occupancy, measure distances, and interact seamlessly with other connected devices, contributing to a more automated and intelligent living environment. |

Environmental and Safety Monitoring Using US

| Category | Description |

|---|---|

| Water and Air Quality Monitoring | Ultrasonic sensors are used in environmental applications to monitor water levels, detect contaminants, and measure air quality. They provide real-time data that helps in maintaining safe and healthy environmental conditions. |

| Smart City Infrastructure | In smart city infrastructure, ultrasonic sensors contribute to urban safety and efficiency by monitoring infrastructure health, detecting hazardous conditions, and enabling automated responses to environmental changes. |

| Case Examples | Various projects utilize ultrasonic sensors for environmental monitoring, such as flood warning systems that measure water levels in rivers and reservoirs, and air quality monitoring systems that detect pollution levels in urban areas. |

Industrial Applications of Ultrasonic Sensor

| Category | Description |

|---|---|

| Material Handling and Logistics | Ultrasonic sensors enhance efficiency and safety in industrial settings by accurately detecting the position and movement of materials on conveyors, ensuring precise handling, reducing errors, and preventing collisions. |

| Level and Distance Measurement | Ultrasonic sensors are critical in various industrial processes for measuring levels of liquids and solids in tanks and silos, and for distance measurement in manufacturing and warehousing, ensuring accurate inventory management and process control. |

| Future Trends | Future trends predict advancements in ultrasonic sensor technology, such as increased integration with AI and IoT, improved accuracy and sensitivity, and the development of more robust and compact sensors for diverse industrial applications. |

FAQ on Ultrasonic Sensor

Q: What is an ultrasonic sensor?

A: It measures distance using sound waves.

Q: How does an ultrasonic sensor work?

A: It emits sound waves and measures the echo time.

Q: What are common applications of ultrasonic sensors?

A: They are used in cars, industry, and healthcare.

Q: What are the advantages of using ultrasonic sensors?

A: They offer non-contact and precise measurements.

Conclusion

Ultrasonic sensor are transforms various industries with their versatile applications and precise measurement capabilities. From enhancing safety and efficiency in automotive and industrial settings to revolutionizing healthcare and environmental monitoring, these sensors are integral to modern technology. As we continue to advance into the era of Industry 4.0, the role of ultrasonic sensor will only grow, driving innovation and improving processes across multiple sectors. Staying updated with the latest trends and advancements in ultrasonic sensor technology is crucial for leveraging their full potential and maintaining a competitive edge.