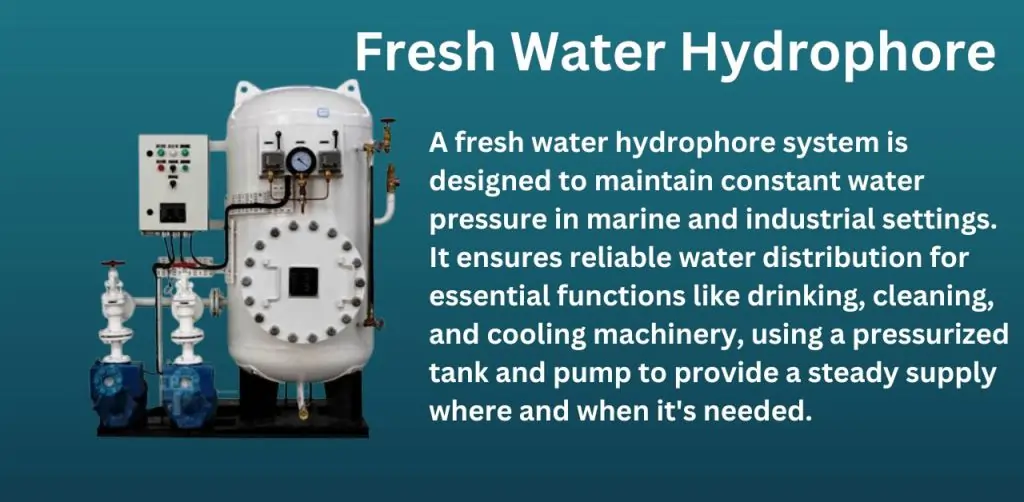

Fresh Water Hydrophore

A fresh water hydrophore system is a vital component in marine and industrial settings, designed to maintain consistent water pressure for distribution. It stores water in a pressure tank and uses a pump to pressurize the system, ensuring a steady supply when needed. In ships, this system is essential for providing fresh water for various needs, including drinking, cooking, and cleaning, while also supporting essential machinery cooling processes.

Maintaining a reliable fresh water supply is crucial for operational efficiency and crew well-being in marine environments. This post will cover the fundamentals of how a fresh water hydrophore system works, its key components, types, and the best practices for installation, maintenance, and troubleshooting. You’ll also learn about common problems and solutions, safety measures, and when to upgrade your system to the latest technologies. Whether you’re in the maritime industry or an industrial setting, this guide will provide valuable insights into optimizing your hydrophore system.

What is a Fresh Water Hydrophore System?

A fresh water hydrophore system is a specialized setup used to maintain constant water pressure in ship and industrial water distribution systems. It consists of a pressure tank, a pump, and control mechanisms that work together to ensure a reliable supply of fresh water to various outlets onboard or within a facility.

Definition and Basic Working Principle

The hydrophore system works by storing water in a sealed tank. A pump pressurizes the tank, which pushes water through the distribution lines when a tap or valve is opened. As water is used and pressure drops, the pump activates to repressurize the system, ensuring consistent flow.

Role of the Hydrophore in Maintaining Water Pressure

On ships, the hydrophore system is critical for providing fresh water for daily operations such as drinking, cooking, and cleaning, as well as for cooling essential machinery. By regulating water pressure, it prevents fluctuations, ensuring that fresh water is always available as needed.

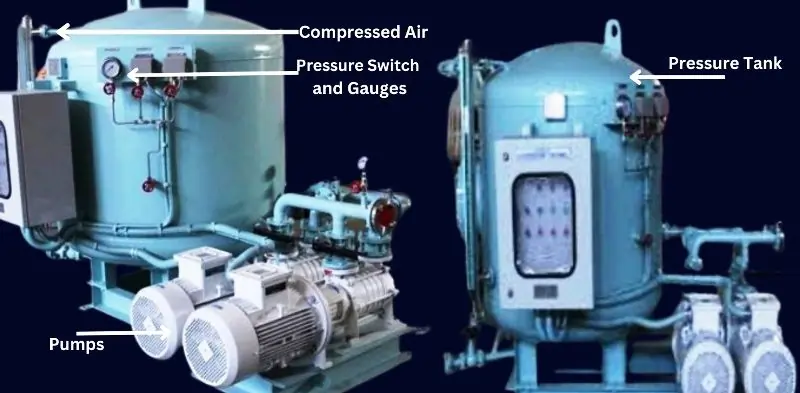

Key Components of a Fresh Water Hydrophore System

A fresh water hydrophore system is made up of several key components, each playing a vital role in maintaining water pressure and ensuring smooth operation. Here’s a breakdown of the essential parts:

Pressure Tank: Functions and Features

The pressure tank is the core of the hydrophore system. It stores water and maintains the pressure required for distribution. The tank is typically designed to handle high-pressure conditions and is equipped with features that prevent over-pressurization, ensuring safe and efficient operation.

Hydrophore Pump: Types and Operation

The pump is responsible for pressurizing the water in the tank. There are two main types: single-pump and multi-pump systems. Single-pump systems are suitable for smaller applications, while multi-pump systems provide redundancy and increased capacity, especially in larger marine or industrial setups.

Pressure Switch and Gauges: Role in System Regulation

Pressure switches and gauges are critical for monitoring and regulating water pressure. The pressure switch automatically controls the pump, turning it on or off depending on pressure levels, while gauges display real-time pressure readings to ensure system stability.

Air Compressor or Air Bladder: Function in Pressure Maintenance

The air compressor or air bladder helps maintain the required pressure within the system. In systems using an air bladder, the bladder compresses to maintain pressure as water is used. In air compressor-driven systems, the compressor adds air to keep pressure levels consistent. Both methods ensure that water is available at the correct pressure when needed.

How the Fresh Water Hydrophore System Works

The fresh water hydrophore system operates through a well-organized process that ensures a consistent water supply at the right pressure. Here’s a step-by-step look at how the system functions:

Step-by-Step Process of Water Storage, Pressurization, and Distribution

- Water Storage: The system begins by storing water in a pressure tank, which acts as a reservoir. This water is either pumped from a freshwater tank or directly from a shore supply in marine applications.

- Pressurization: Once the water is stored in the hydrophore tank, a pump is activated to pressurize the tank. This ensures that water is readily available to flow through the system when needed.

- Distribution: When a tap, valve, or outlet is opened, the pressurized water is distributed to the desired location. As water flows out and the pressure drops, the system automatically kicks in to repressurize and maintain the flow.

Explanation of the Automated Pressure Control Mechanism

The system uses a pressure switch to monitor water pressure levels inside the tank. When the pressure drops below a set level, the switch activates the pump to repressurize the tank. Once the desired pressure is reached, the switch turns off the pump, maintaining energy efficiency while ensuring that the water supply remains uninterrupted. This automated control mechanism allows the system to operate seamlessly without constant manual intervention.

Types of Fresh Water Hydrophore Systems

There are various types of fresh water hydrophore systems designed to meet the specific needs of different marine and industrial settings. Each system type has distinct features and advantages based on its application and operational requirements.

Single Pump System: Description and Use Cases

A single pump hydrophore system uses one pump to pressurize the water tank. It is ideal for smaller vessels or industrial setups where the water demand is moderate. This system is cost-effective and simpler to maintain, making it suitable for environments with lower water consumption and limited space for equipment.

Multi-Pump System: Benefits in Larger Vessels or Systems

A multi-pump hydrophore system uses two or more pumps to manage water pressure. This setup is beneficial for larger vessels or systems that require a continuous and high-volume water supply. The key advantage is redundancy—if one pump fails, the other can continue to operate, ensuring uninterrupted water pressure. Additionally, multi-pump systems can balance the load, reducing wear and tear on individual pumps and enhancing overall system longevity.

Air-Operated vs. Bladder-Type Hydrophores: Pros and Cons

- Air-Operated Hydrophore: This system uses compressed air to pressurize the water tank. It’s reliable for larger applications but requires regular air maintenance to prevent air leakage and pressure loss.

- Pros: Durable, suitable for high-demand settings.

- Cons: Requires frequent maintenance of the air compressor.

- Bladder-Type Hydrophore: In this system, an air-filled bladder inside the tank compresses as water is pumped in. It maintains pressure more efficiently and requires less maintenance.

- Pros: Low maintenance, more efficient in smaller systems.

- Cons: Limited capacity compared to air-operated systems, not ideal for high water demand setups.

Fresh Water Hydrophore Installation & Setup

Installing a fresh water hydrophore system on ships requires careful planning and precision to ensure optimal performance. This section outlines key factors to consider during installation and setup.

Space and Location Considerations on Ships

When installing a hydrophore system, selecting the right location is crucial. The system should be placed in a dry, well-ventilated area with easy access for maintenance and inspections. It’s typically installed in the ship’s engine room or near water storage tanks to minimize piping lengths, ensuring efficient water distribution. Additionally, the area must accommodate both the system’s components and any required safety features, such as pressure relief valves.

Piping and Connection Requirements

Proper piping is essential to maintain steady water flow and pressure. Use high-quality, corrosion-resistant pipes suitable for marine environments. Ensure that the piping is correctly sized to match the system’s capacity and water demand. Secure connections and fittings are crucial to prevent leaks and pressure loss, and all connections must be properly sealed and tested for strength. Adequate provisions should also be made for drainage and venting.

Initial Setup and Testing Procedures

Once installed, the hydrophore system must undergo a thorough testing process. Start by filling the pressure tank with water and running the pumps to pressurize the system. The pressure switch and gauges should be calibrated to ensure the system activates at the desired pressure levels. Finally, check all connections for leaks and run a full test cycle to ensure smooth water distribution. The system should be tested under different load conditions to verify consistent performance before being put into service.

Hydrophore Maintenance Best Practices

Regular maintenance is essential to ensure the long-term reliability and efficiency of a fresh water hydrophore system. Proper upkeep helps avoid system failures and costly repairs.

Regular Inspections and Checks

To keep the system in optimal condition, regular inspections should be carried out, focusing on:

- Pressure Levels: Check the system’s pressure gauges to ensure the water pressure is within the recommended range. Inconsistent pressure could indicate issues with the pump or tank.

- Air Cushion or Bladder Integrity: For air-operated systems, verify that the air cushion is intact and maintaining pressure. In bladder-type systems, inspect the bladder for any signs of wear or damage.

- Tank Integrity: Regularly inspect the hydrophore tank for signs of corrosion, leaks, or cracks that could compromise system performance.

Common Issues and Troubleshooting Tips

- Leaks: Inspect all pipes, fittings, and tank connections for leaks. If a leak is detected, seal it immediately to avoid pressure drops and water loss.

- Low Pressure: If the system is not maintaining pressure, check the pump’s operation. It could be a sign of pump failure or a malfunctioning pressure switch. Ensure that air pressure levels in air-operated systems are within normal ranges.

- Pump Failure: If the pump isn’t functioning, examine the electrical connections and motor. A faulty pressure switch or air compressor could also cause pump malfunction.

How to Clean and Service Hydrophore Components

Periodically, the tank and associated components should be cleaned to prevent sediment buildup. To do this:

- Drain the Tank: Shut off the system and drain the water tank completely.

- Clean the Interior: Use a non-abrasive cleaner to scrub the interior of the tank, removing any buildup or debris that could affect performance.

- Service the Pump and Valves: Check and clean the pump, pressure switch, and valves, ensuring they are free from blockages and functioning properly. Replace any worn-out parts as needed.

Common Problems and Their Solutions

| Problem | Causes | How to Fix |

|---|---|---|

| Pressure Fluctuations | – Air cushion issues in air-operated systems – Faulty pressure switch – Water leaks | – Check air cushion/bladder for integrity – Replace or recalibrate the pressure switch – Inspect piping and fittings for leaks |

| Pump Overrunning | – Faulty pressure switch – Low water levels in the tank – Air leaks in the system | – Inspect and replace faulty pressure switch – Ensure adequate water supply in the tank – Detect and seal any air leaks |

| Air Leaks | – Worn seals or fittings – Damaged bladder in air-operated systems | – Perform a pressure test to identify leaks – Replace worn seals and fittings – Check and repair or replace the air bladder as needed |

Safety Measures for Fresh Water Hydrophore Systems

| Safety Measure | Description |

|---|---|

| Pressure Relief Valves | Pressure relief valves prevent over-pressurization in the system, automatically releasing excess pressure to protect the tank and piping from damage. Regular testing and maintenance of these valves are essential to ensure they function properly. |

| Emergency Procedures for Failures | In case of system failure, shut off the power supply to the pump and close the inlet valve to prevent further water or air flow. Follow emergency protocols to depressurize the tank and identify the cause of failure. Having backup systems or manual overrides in place can ensure a steady water supply during emergencies. |

| Compliance with Maritime Safety Standards | Fresh water hydrophore systems must meet international maritime safety standards, including proper installation, pressure regulation, and regular inspections. This ensures the system operates safely and effectively in marine environments. Documentation of maintenance and safety checks is also important for regulatory compliance. |

Hydrophore Important Formulas:

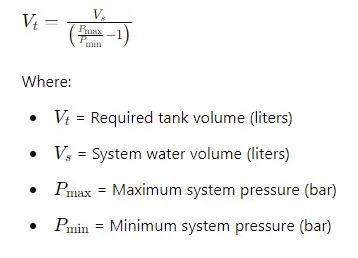

Hydrophore Tank Sizing Formula

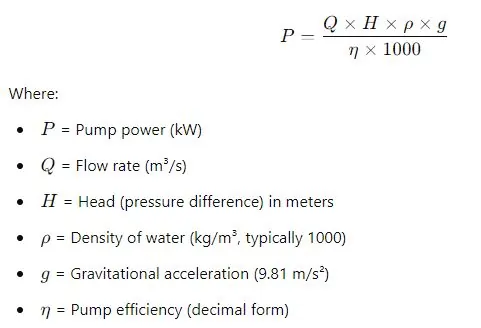

Pump Power Calculation:

This formula calculates the power required by the pump to maintain the desired water pressure in the hydrophore system.

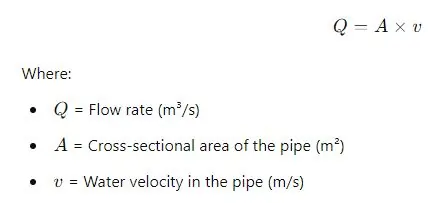

Flow Rate Calculation:

To determine the flow rate required to meet the system demand:

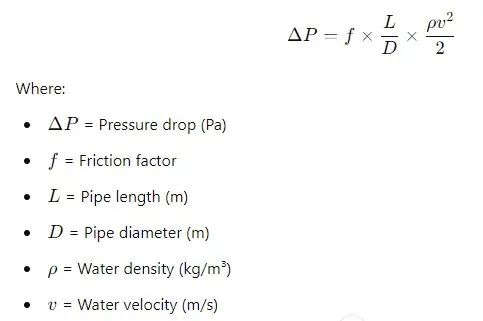

Pressure Drop Calculation:

This formula helps calculate the pressure drop due to friction in the piping system, which affects the performance of the hydrophore system.

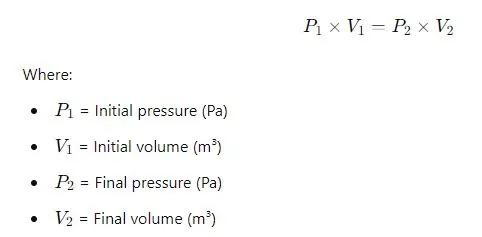

Tank Pressure Calculation (Ideal Gas Law):

For air-operated hydrophore systems, the ideal gas law can estimate the air pressure needed to maintain system balance:

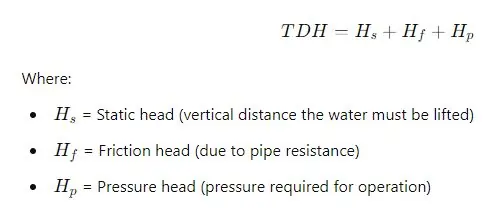

Total Dynamic Head (TDH):

This is an important parameter in pump sizing, calculating the total height the pump must lift the water.

Upgrading Your Fresh Water Hydrophore System

As technology advances, upgrading your fresh water hydrophore system can provide significant improvements in efficiency, reliability, and control. Here’s when and how to consider upgrading:

When to Consider Upgrading

An upgrade should be considered when the current system struggles to meet demand, experiences frequent breakdowns, or operates inefficiently. Signs such as reduced water pressure, frequent pump failures, or difficulty maintaining a steady water supply indicate that the system may be outdated. Additionally, if the system’s components are beyond their recommended lifespan, it’s time to explore an upgrade.

New Technologies and Trends in Hydrophore Systems

Modern hydrophore systems are now equipped with more energy-efficient pumps, enhanced pressure control mechanisms, and eco-friendly designs. Recent trends include the use of variable frequency drives (VFDs) for better pump control, reducing energy consumption and wear on components. Furthermore, advanced materials in pressure tanks improve durability and reduce the need for frequent maintenance.

Benefits of Automation and Remote Monitoring

Automation and remote monitoring are revolutionizing hydrophore systems. Automated systems allow for real-time adjustments to water pressure based on usage demands, reducing manual intervention and improving efficiency. Remote monitoring technologies enable operators to track system performance from anywhere, receiving instant alerts for any anomalies. These features minimize downtime, extend system life, and offer significant cost savings by preventing failures before they happen.

How to Charge a Fresh Water Hydrophore

Charging a fresh water hydrophore system involves filling the pressure tank with water and ensuring the system is correctly pressurized for optimal performance. Here’s a step-by-step process:

1. Check the System

Before charging the hydrophore, inspect the system to ensure all components—pressure tank, pump, valves, and gauges—are in good condition. Ensure the pump is functioning and the air cushion or bladder in the tank is intact.

2. Fill the Pressure Tank

Begin by filling the hydrophore tank with fresh water. If the tank is empty, open the inlet valve and allow water to flow into the system. Monitor the water level until it reaches the appropriate fill level, usually indicated by the system’s gauges.

3. Start the Pump

Once the tank is filled with water, activate the hydrophore pump. The pump will pressurize the water inside the tank, ensuring it is ready to distribute water on demand. Monitor the pressure gauge to ensure that the system reaches the desired pressure level.

4. Monitor and Adjust the Pressure

The pressure switch automatically regulates the pressure in the tank. If necessary, adjust the pressure settings to match the system’s operational requirements. Ensure the pressure remains within the recommended range for consistent water flow.

5. Check for Leaks and Proper Operation

After charging the system, inspect all connections, valves, and fittings for leaks. Ensure the pump cycles correctly—activating when water is drawn and stopping once the desired pressure is reached.

Sea Water Hydrophore System

A sea water hydrophore system is designed to maintain constant pressure for sea water distribution on ships and offshore installations. It is essential for ensuring the availability of pressurized sea water for various applications such as firefighting, cooling systems, cleaning, and sanitation onboard.

Definition and Working Principle

The sea water hydrophore system operates similarly to the fresh water system, but instead of using fresh water, it pressurizes sea water. The system consists of a pressure tank, pumps, and automated controls. Sea water is pumped into the tank, and the pressure is maintained to ensure a consistent supply throughout the vessel. When the water is used, the pump activates to restore pressure, ensuring continuous availability.

Role of Sea Water Hydrophore in Marine Operations

The system is critical for maintaining operational efficiency on ships, particularly for non-potable water requirements. It plays a vital role in cooling machinery, fire suppression, and general cleaning. By regulating pressure, the hydrophore system ensures that sea water is distributed effectively to all necessary points without the need for manual intervention, improving both safety and functionality onboard.

Sea water hydrophore systems are specifically designed to withstand the corrosive properties of saltwater, using materials like corrosion-resistant alloys and special coatings to ensure longevity and reliability in harsh marine environments.

FAQ on “Fresh Water Hydrophore”

Q: What is a fresh water hydrophore?

A: It’s a system that maintains water pressure for distribution on ships and industrial settings.

Q: How does a hydrophore pump work?

A: It pressurizes water in a tank to ensure a steady supply when needed.

Q: What is the main use of fresh water?

A: Fresh water is primarily used for drinking, cleaning, and cooling machinery.

Q: What is the quality of freshwater?

A: Freshwater should be clean, potable, and free from harmful contaminants.

Conclusion

In conclusion, a fresh water hydrophore system plays a crucial role in maintaining consistent water pressure in marine and industrial applications. Understanding its components, operation, and maintenance practices ensures the system runs efficiently and reliably. By upgrading to modern technologies and following safety measures, you can optimize performance and extend the system’s life, making it an essential asset for any ship or facility.