Exhaust Valves

Exhaust valves play a critical role in the operation of marine engines, ensuring that exhaust gases are efficiently expelled after the combustion process. These valves directly impact the engine’s performance, fuel efficiency, and overall longevity. By maintaining proper sealing and timing, exhaust valves help the engine run smoothly, preventing power loss and excessive wear. However, due to their constant exposure to high temperatures and pressures, exhaust valves are prone to carbon buildup, wear, and even failure over time.

Regular maintenance and overhauling of these components are essential to prevent costly engine breakdowns and ensure long-term reliability. Properly cared for, exhaust valves can greatly extend the lifespan of a marine engine and maintain its efficiency at optimal levels. This post will explore the importance of exhaust valves, the overhauling process, and why consistent attention to their condition is crucial for keeping marine engines in peak performance.

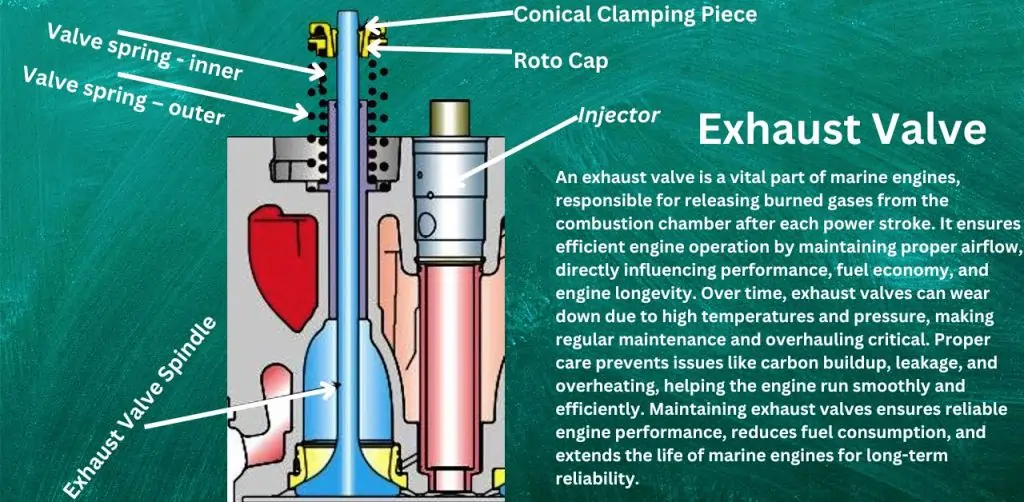

What is an Exhaust Valve?

An exhaust valve is a critical component of an internal combustion engine that controls the expulsion of exhaust gases from the combustion chamber after the combustion process is complete. It opens at precise intervals to allow the burnt gases to escape, making room for fresh air-fuel mixture for the next cycle.

Function of Exhaust Valves in Marine Engines

In marine engines, the exhaust valve plays a key role in the combustion cycle by facilitating the removal of exhaust gases from the cylinder, ensuring efficient engine performance. Proper functioning of the exhaust valve is essential for maintaining engine power, fuel efficiency, and reducing emissions.

Key Components of an Exhaust Valve

- Valve Seat: Provides a sealing surface for the valve.

- Valve Spindle: The moving part that opens and closes the valve.

- Cage: Holds the valve assembly in place, ensuring stability and proper alignment. These components must work together effectively to maintain the engine’s operational efficiency and longevity.

Types of Exhaust Valves

Marine engines utilize various types of exhaust valves to control the expulsion of exhaust gases efficiently. The two main types of exhaust valves used in marine engines are Caged Exhaust Valves and Uncaged Exhaust Valves. Each type offers specific advantages and disadvantages depending on the engine’s design and operational needs.

Caged Exhaust Valves

Caged exhaust valves feature a removable cage that contains the valve, making maintenance and overhauling easier. The entire valve assembly, including the spindle and seat, can be removed as a single unit during maintenance.

- Advantages:

- Simplified maintenance process due to easy removal and reinstallation.

- Reduces downtime during overhauls.

- Disadvantages:

- Slightly larger size, which may require more space in the engine design.

Uncaged Exhaust Valves

Uncaged exhaust valves are integrated into the cylinder head, making them more compact but requiring more time and effort for maintenance.

- Advantages:

- More compact design, saving space in the engine.

- Potentially lighter, which can reduce overall engine weight.

- Disadvantages:

- Maintenance and overhauls are more complex and time-consuming, often requiring partial engine disassembly.

Common Problems with Exhaust Valves

| Problem | Description | Effects | Prevention |

|---|---|---|---|

| Carbon Buildup | Accumulation of carbon deposits on the valve and seat due to incomplete combustion. | Reduces sealing efficiency, leading to power loss and poor fuel economy. | Regular cleaning during maintenance, proper fuel mixture adjustment. |

| Exhaust Valve Leakage | Caused by improper seating, carbon buildup, or wear on the valve seat or spindle. | Loss of compression, increased exhaust emissions, and decreased engine performance. | Routine inspection for wear, proper seating during overhauls. |

| Overheating Issues | Excessive heat due to poor cooling or improper valve timing. | Causes warping of the valve and loss of material, leading to improper sealing and wear. | Ensure proper cooling, maintain correct valve timing, and regular inspection. |

| Valve Seat and Spindle Damage | Wear or cracks in the valve seat and spindle due to excessive temperatures or stress. | Leads to misalignment, loss of compression, and engine inefficiency. | Routine inspection, timely replacement of worn parts, proper lubrication. |

Video Credit: https://www.youtube.com/hashtag/dieselengine

What is the Procedure for Overhauling of Caged Exhaust Valve?

Overhauling a caged exhaust valve is essential for maintaining the efficiency and longevity of marine engines. Below is a step-by-step guide that outlines the entire process, from preparation to testing.

1. Preparation

- Tools and Safety Precautions: Ensure you have the necessary tools such as valve lifters, torque wrenches, and cleaning equipment. Follow all safety protocols, including wearing protective gear (gloves, goggles).

- Engine Shutdown and Cooling: Shut down the engine and allow sufficient time for cooling to prevent injuries or damage to the components.

2. Disassembly

- Steps to Safely Remove the Caged Exhaust Valve:

- Disconnect any components obstructing access to the valve.

- Carefully unbolt the cage assembly and extract it using a valve lifter.

- Inspection of Cage, Valve Spindle, and Seat:

- Once disassembled, inspect the cage, valve spindle, and seat for any visible wear or damage.

3. Cleaning and Inspection

- Cleaning of Carbon Deposits:

- Remove carbon deposits from the valve, seat, and spindle using appropriate cleaning agents and tools.

- Detailed Inspection for Wear, Cracks, and Damage:

- Inspect all parts for wear, cracks, corrosion, and any signs of damage that may affect valve operation.

4. Machining and Reconditioning

- Valve Grinding or Lapping:

- Perform valve grinding or lapping to restore the sealing surface of the valve to ensure proper sealing during operation.

- Seat Reconditioning if Necessary:

- If the valve seat is damaged or worn, recondition it to restore a smooth, flat surface.

5. Reassembly

- Replacing Worn Components:

- Replace any components, such as seals, gaskets, or springs, that show signs of wear.

- Reassembly of the Exhaust Valve:

- Carefully reassemble the valve components, ensuring everything is properly aligned and torqued to specifications.

6. Testing

- Pressure and Leak Testing:

- Conduct a pressure test to ensure the valve seals correctly and there are no leaks.

- Final Inspection Before Putting Back into Operation:

- Perform a final visual and functional inspection before reinstallation, verifying the valve is in optimal condition for operation.

Importance of Regular Exhaust Valve Overhaul

Regular overhauling of exhaust valves is essential for maintaining the performance and reliability of marine engines. Given the harsh conditions exhaust valves endure, such as high temperatures and pressure, routine maintenance ensures these vital components function efficiently.

Why Regular Overhauling is Critical for Engine Efficiency

Exhaust valves play a significant role in expelling gases from the combustion chamber, which directly affects the engine’s power and fuel consumption. Over time, carbon buildup, wear, and valve leakage can reduce sealing efficiency, leading to power loss and higher fuel consumption. Regular overhauling helps maintain a proper seal, ensuring that the engine runs smoothly and efficiently.

Recommended Overhaul Intervals for Marine Engines

The recommended overhaul intervals for exhaust valves in marine engines typically vary based on engine type and usage. As a general guideline, it is recommended to perform an overhaul every 8,000 to 10,000 hours of operation or as advised by the engine manufacturer. Regular inspections between major overhauls can help identify potential issues early.

Long-Term Benefits of Proper Exhaust Valve Maintenance

- Enhanced Engine Performance: Properly maintained exhaust valves ensure optimal engine performance by preventing gas leakage and improving combustion efficiency.

- Extended Engine Life: Regular overhauls reduce the risk of severe damage to the valve components, which can lead to costly repairs or engine failures.

- Reduced Fuel Consumption: Efficient exhaust valve function minimizes fuel wastage, leading to better fuel economy.

- Lower Maintenance Costs: Timely maintenance helps avoid more extensive and expensive repairs by addressing issues early.

FAQs on Exhaust Valve

Q: What is an exhaust valve?

A: A valve lets out burned gases from the engine cylinder.

Q: What causes exhaust valves to burn?

A: They burn when they don’t seal properly.

Q: Why do exhaust valves break?

A: They can break due to detonation, poor-quality parts, or improper valve adjustment.

Q: What are exhaust valves made of?

A: They are made from chrome nickel silicon alloy steel.

Conclusion

Exhaust valves are crucial components in marine engines, responsible for the efficient expulsion of exhaust gases, which directly impacts engine performance, fuel efficiency, and longevity. Their proper functioning ensures smooth operation, while issues like carbon buildup or valve wear can lead to significant engine problems. Regular maintenance and timely overhauling of exhaust valves are essential to prevent failures, optimize performance, and extend the engine’s lifespan. By following a consistent maintenance schedule, marine engineers can minimize costly repairs, reduce downtime, and ensure that their engines continue to operate at peak efficiency for years to come. Proper care of exhaust valves is an investment in the long-term reliability and safety of marine vessels.