Air Conditioning System

Air conditioning systems are crucial for maintaining comfortable indoor environments on ships and marine vessels. In marine applications, these systems regulate temperature, humidity, and air quality in crew living quarters, control rooms, and critical equipment areas, ensuring a safe and productive working environment. With varying sea conditions and temperature extremes, reliable air conditioning becomes indispensable for both comfort and operational efficiency onboard.

Proper maintenance is key to ensuring the longevity and efficiency of marine air conditioning systems. Conducting regular checks from start to stop helps detect potential issues early, preventing costly breakdowns and maintaining optimal system performance. Routine inspections, such as checking refrigerant levels, airflow, and system components, help ensure that the air conditioning system remains energy-efficient while providing a stable environment at sea. Neglecting these checks can lead to increased fuel consumption, reduced system reliability, and higher operational costs—making regular maintenance essential for marine vessels.

Types of Air Conditioning Systems

Air conditioning systems come in various forms, each suited for different environments and needs. Understanding the differences helps in selecting the best system for your specific requirements. Here are the main types of air conditioning systems:

1. Central Air Conditioning

Central air conditioning systems are ideal for large homes or buildings. They use a network of ducts to distribute cooled air throughout multiple rooms, providing uniform cooling. These systems are efficient for maintaining a consistent temperature across large spaces but require significant installation and upfront costs.

2. Split Air Conditioning Systems

Split systems are common in residential and small commercial applications. They consist of an indoor unit and an outdoor compressor. These systems are efficient, quiet, and flexible, allowing for targeted cooling in specific areas without the need for ductwork.

3. Window Air Conditioning

Window units are compact, cost-effective options for single-room cooling. They are installed directly into a window or a hole in an external wall and are ideal for small spaces.

4. Portable Air Conditioning

Portable air conditioners are convenient, movable units that require minimal installation. They are perfect for cooling single rooms or spaces where a permanent installation isn’t feasible. However, they are generally less efficient than other types.

5. Ductless Mini-Split Systems

Ductless mini-splits are ideal for homes without existing ductwork. These systems provide zoned cooling, where different rooms can be cooled independently. They are energy-efficient, easy to install, and offer precise temperature control.

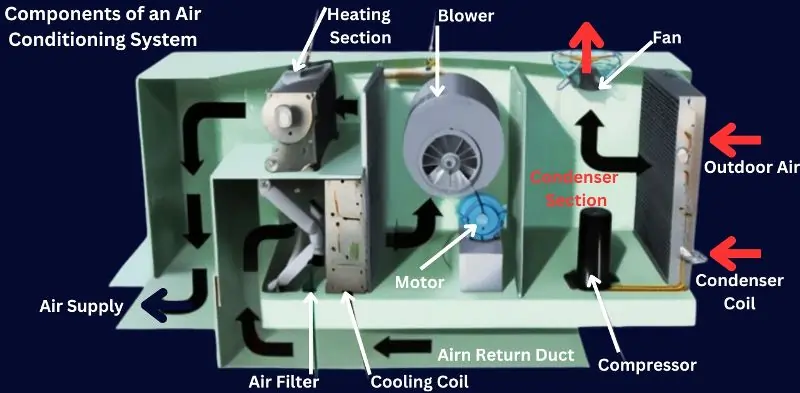

Components of an Air Conditioning System

Air conditioning systems consist of various components that work together to provide cooling, heating, and air circulation. Each part plays a crucial role in maintaining indoor comfort. Here’s a breakdown of the essential components:

1. Heating Section

The heating section provides warmth during colder months by using a heat exchanger. In some systems, it works in tandem with the cooling functions to maintain a balanced indoor environment.

2. Blower

The blower circulates air throughout the system and into the conditioned space. It pushes air through the air ducts or directly into the room, depending on the system type.

3. Fan

The fan helps move air over the evaporator or condenser coils. It plays a critical role in dissipating heat from the refrigerant.

4. Outdoor Air

Outdoor air is drawn into the system to replace stale indoor air. This helps in ventilation and maintaining air quality indoors.

5. Condenser Coil

The condenser coil releases the heat absorbed by the refrigerant in the cooling process. It is located in the outdoor unit and dissipates heat to the surroundings.

6. Compressor

The compressor is the heart of the air conditioning system. It compresses the refrigerant, increasing its pressure and temperature before it enters the condenser coil.

7. Air Return Duct

The air return duct pulls air from the room and directs it back to the air conditioner for cooling or heating. It helps in the continuous circulation of air.

8. Cooling Coil

The cooling coil, also known as the evaporator coil, absorbs heat from the indoor air, cooling it before it’s circulated back into the room.

9. Air Filter

The air filter removes dust, debris, and other particles from the air before it enters the system. Regular cleaning or replacement of the filter is essential for efficient operation.

10. Air Supply

The air supply consists of the ducts or vents that distribute cooled or heated air throughout the building or room.

11. Condenser Section

The condenser section houses the condenser coil and fan. It is responsible for cooling the refrigerant and expelling heat from the system.

12. Motor

The motor drives the compressor and fans. It ensures the continuous operation of the air conditioning system, allowing the movement of air and the flow of refrigerant.

How Does an Air Conditioning System Work?

Air conditioning systems function through a series of steps that involve transferring heat from inside a space to the outside, thus cooling the indoor environment. The process is centered on the cooling cycle, with the refrigerant and system components playing a vital role in this heat transfer. Here’s a step-by-step explanation of how an air conditioning system works:

1. Warm Air is Drawn into the System

The air conditioning cycle begins when warm indoor air is pulled into the system through the air return duct. This air passes through the air filter to remove dust and debris before moving further into the system.

2. Refrigerant Absorbs Heat

As the warm air passes over the cooling coil (evaporator coil), the refrigerant inside the coil absorbs the heat. The refrigerant, in its cold liquid state, evaporates as it absorbs heat from the indoor air, cooling the air in the process.

3. Cooled Air is Circulated Back Indoors

After the refrigerant absorbs the heat, the blower pushes the now cooled air through the air supply ducts, circulating it throughout the room or building to reduce the temperature.

4. Compressor Increases Refrigerant Pressure

The refrigerant, now in gas form after absorbing heat, travels to the compressor. The compressor compresses the refrigerant gas, raising its pressure and temperature, preparing it for the next phase of heat dissipation.

5. Heat is Released Outside

The high-pressure refrigerant gas moves to the condenser coil in the outdoor unit. Here, the fan blows outdoor air over the condenser coil, allowing the refrigerant to release the absorbed heat to the outside environment. The refrigerant condenses back into a high-pressure liquid.

6. Refrigerant Returns to Cooling Coil

Once the refrigerant releases the heat, it returns to the cooling coil in a low-pressure liquid state, ready to repeat the process of absorbing heat from the indoor air.

Role of Refrigerant and Components in Heat Transfer

The refrigerant is crucial in transferring heat. It alternates between a liquid and gas state, absorbing heat from the indoor air in the evaporator coil and releasing it in the condenser coil. Key components like the compressor, blower, and fans work together to move the refrigerant and air, ensuring continuous cooling.

Air Conditioning System Checks from Start to Stop Position

| Stage | Checks to be Done |

|---|---|

| Pre-start Checks | – Check refrigerant levels. – Inspect for any visible leaks. – Ensure proper electrical connections. – Verify the thermostat settings. – Inspect air filters for cleanliness. |

| Start-up Checks | – Monitor the compressor and fan operation. – Ensure there are no unusual noises. – Check the airflow from vents. – Inspect the condenser and evaporator coil for proper functionality. |

| Running Checks | – Monitor the temperature control for consistent cooling. – Ensure the compressor and condenser fan run smoothly. – Check for any system vibrations. – Monitor refrigerant pressures and system efficiency. |

| Shutdown Checks | – Inspect system performance before turning off. – Check for any delays in shutdown or compressor short cycling. – Perform a quick inspection of air filters and coils for wear or dirt accumulation. – Record any unusual sounds or behaviors noticed during the stop process. |

Common Problems in Air Conditioning Systems

| Problem | Description | Impact |

|---|---|---|

| Low Refrigerant Levels | Insufficient refrigerant reduces the system’s ability to cool effectively. | – Poor cooling performance – Increased energy consumption – Potential compressor damage |

| Clogged Filters | Dust and debris buildup in filters restricts airflow and reduces system efficiency. | – Reduced airflow – Increased strain on system components – Poor indoor air quality |

| Thermostat Malfunctions | Faulty thermostats can cause incorrect temperature readings, leading to improper system operation. | – Inconsistent cooling – System may fail to turn on or off properly |

| Compressor Issues | Compressor failure or malfunction prevents the refrigerant from circulating properly throughout the system. | – No cooling or heating – Expensive repairs – Possible system shutdown |

Best Practices for Air Conditioning Maintenance

Proper maintenance of an air conditioning system is essential for ensuring its efficiency, longevity, and performance. By following these best practices, you can prevent common issues and keep your system running smoothly throughout the year.

1. Scheduled Filter Cleaning and Replacement

Air filters play a vital role in maintaining good air quality and system efficiency by trapping dust and debris. It’s important to clean or replace filters on a regular basis, typically every 1-3 months, depending on usage and environmental factors. Dirty filters restrict airflow, reduce efficiency, and can lead to system strain.

2. Regular Condenser and Evaporator Coil Maintenance

Both the condenser and evaporator coils are essential for effective heat exchange in the system. Over time, these coils can collect dirt, which reduces their ability to absorb and dissipate heat. Regular cleaning of these coils helps maintain optimal cooling performance and reduces energy consumption.

3. Checking Refrigerant Levels and System Pressure

Maintaining the correct refrigerant levels and system pressure is crucial for efficient operation. Low refrigerant levels can lead to poor cooling, increased energy usage, and potential damage to the compressor. Routine checks help ensure the system is properly charged and operating at the right pressure.

4. Inspecting and Cleaning Ductwork for Dust and Debris

Over time, ductwork can accumulate dust, dirt, and debris, reducing the efficiency of air circulation and indoor air quality. Regular inspection and cleaning of ducts help improve airflow, enhance cooling efficiency, and prevent blockages that can strain the system.

Innovations in Air Conditioning Technology in 2024

In 2024, air conditioning technology continues to evolve with advancements focused on improving energy efficiency, automation, and environmental sustainability. Here are some of the key innovations making an impact this year:

1. Energy-Efficient Systems

Energy efficiency remains a top priority in air conditioning innovation. Modern systems in 2024 use advanced compressors, variable-speed motors, and energy-efficient designs to reduce power consumption while delivering effective cooling. These systems are designed to meet stricter energy regulations and help reduce operational costs for both residential and commercial users.

2. Smart Thermostats and Automation

Smart thermostats and automation technologies have revolutionized how air conditioning systems are controlled. These devices allow users to manage and monitor their air conditioning systems remotely via smartphones or smart home systems. Features like scheduling, learning user preferences, and real-time energy usage data help optimize cooling, leading to greater energy savings and convenience.

3. Eco-Friendly Refrigerants

A shift toward eco-friendly refrigerants has been a major innovation in 2024. New refrigerants, such as R-32 and other low global warming potential (GWP) options, are replacing older, environmentally harmful refrigerants like R-410A. These eco-friendly alternatives are designed to minimize the environmental impact while maintaining high system performance.

4. Hybrid Air Conditioning Systems

Hybrid air conditioning systems combine traditional cooling methods with newer, renewable energy solutions such as solar power. These systems are designed to reduce reliance on conventional electricity sources, making them more sustainable and cost-effective. By integrating renewable energy sources, hybrid systems can significantly lower energy bills while reducing carbon footprints.

FAQ: Air Conditioning System

Q: What is the fundamental of an air conditioning system?

A: It works by using special chemicals that evaporate and condense in a closed system to cool the air.

Q: What is the difference between AC and HVAC?

A: AC cools the air, while HVAC handles heating, cooling, and ventilation for complete climate control.

Q: Which type of AC is best?

A: Ductless units are the most energy-efficient option for air conditioning.

Q: What is an AC unit called?

A: The outdoor part is called a condenser, and the indoor part is known as the furnace, which also helps in cooling.

Conclusion

Maintaining an air conditioning system is essential for ensuring comfort, efficiency, and longevity. From understanding the different types of air conditioning systems to performing regular checks from start to stop, proper care can significantly enhance system performance and reduce costly repairs. Innovations in air conditioning technology, such as energy-efficient designs, smart thermostats, and eco-friendly refrigerants, offer even greater control and sustainability for homeowners and businesses alike. By following best practices in maintenance and staying informed about new technologies, you can keep your air conditioning system running smoothly for years to come.