How To Connect Two Generators Together

In today’s interconnected power systems, parallel operation of alternators plays a vital role in maintaining a stable, economical, and reliable electricity supply. By connecting multiple 3-phase alternators across various power stations, the national grid achieves a level of flexibility and resilience essential for modern energy demands.

The parallel operation allows for seamless transitions during maintenance, efficiently meets peak loads, and prevents service disruptions by redistributing power when one alternator is taken offline. This method isn’t just about backup; it ensures each alternator operates near its optimal load, reducing fuel consumption and overall operational costs. Furthermore, as energy demands grow, adding new alternators in parallel without overhauling existing systems makes scaling the grid simpler and cost-effective. From ensuring power stability to supporting load growth, the parallel operation of alternators is a foundational technique that enhances grid efficiency and reliability, making it indispensable in today’s energy infrastructure.

Why Operate Alternators in Parallel?

Continuity of Service

Operating alternators in parallel ensures an uninterrupted power supply even during maintenance or repairs. If one alternator requires downtime, others in the system seamlessly continue supplying power, preventing service disruptions.

Enhanced Efficiency

Parallel operation enhances efficiency by allowing some alternators to be shut down during low-demand periods, letting the remaining units operate closer to full load, thus reducing fuel and operating costs.

Capacity for Greater Loads

Multiple alternators in parallel can supply larger loads than a single unit, meeting high demand more effectively and providing flexibility for variable loads.

Reliability and Safety

The reliability of the power supply is reinforced, as a breakdown in one alternator does not affect the overall operation, ensuring safety and consistency.

Adaptation to Load Growth

As demand increases, additional alternators can be added in parallel without disrupting the system, making it easier to scale up power generation.

Economic Benefits

Parallel operation reduces operating and generation costs by optimizing alternator load distribution, minimizing inefficiencies, and achieving cost-effective power generation.

What Is Generator Paralleling?

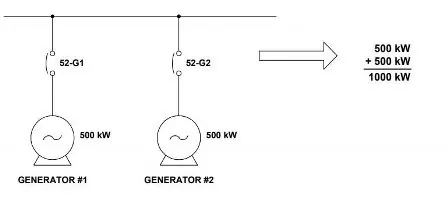

Generator paralleling is the process of connecting two or more generators to operate simultaneously and supply a combined electrical load. By synchronizing their voltage, frequency, and phase, multiple generators can function as a unified system, efficiently sharing power demands across the connected units. Paralleling generators is common in applications where a stable, flexible, and resilient power supply is essential, such as in industrial plants, hospitals, data centers, and marine vessels.

Paralleling provides numerous advantages, including increased reliability, as the system can continue operating if one generator fails. It also enables flexibility, allowing generators to be taken offline for maintenance without interrupting the power supply. Additionally, paralleling generators can improve fuel efficiency by optimizing each unit’s load, allowing them to operate within their most efficient range. As energy needs grow, extra generators can be added in parallel to meet rising demand without extensive infrastructure changes.

Requirements for Running Generators in Parallel

- The voltage from the incoming generator and the bus bar should match instantly.

- The frequency of the incoming generator and the bus bar must be the same.

- The phase of the incoming generator should line up with the bus bar voltage.

- The phase sequence must also be the same.

These conditions must be met for a successful parallel operation.

How To Parallel Generators

Synchronizing Generators Manually

Manual Synchronization Steps:

- Start the incoming machine and let it warm up. Adjust the speed to reach the desired frequency.

- Check the incoming machine’s voltage to match the bus bar voltage.

- Make sure both machines have the same phase sequence.

- Make necessary adjustments for identical voltage, frequency, and phase sequences.

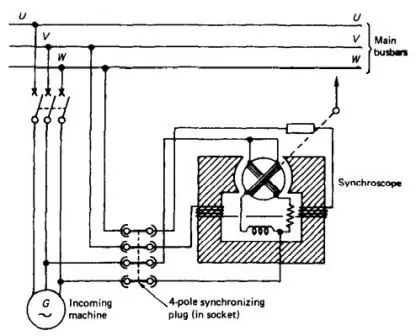

- Turn on the synchronoscope and observe the pointer’s movement.

- Stabilize the speed of the machine to the desired level.

- Keep the incoming machine’s speed slightly higher than the loaded machine to move the pointer slowly and clockwise.

- Engage the breaker before the pointer reaches 12 o’clock, indicating phase alignment.

- Decide whether to stop one machine or run them in parallel.

- Adjust speeds accordingly, decreasing the running machine’s speed while increasing the incoming machine’s speed.

- Turn off the synchroscope.

- Trip the breaker of the running machine when done.

Using a Parallel Cable Kit

How to Connect Two Generators for More Power

If you’ve got two inverter generators and want to make them work together for extra power, here’s what you need to know.

- Choose the Right Pair: Get two generators from the same brand and with the same ratings. This makes it easier to connect them.

- Check for Compatibility: Look on the front panel of the generators. You should see something like “Parallel Ready” if they can be connected.

- Get a Parallel Kit: Buy a Generator Parallel Kit from the same manufacturer as your generators. This kit has special connectors to link the generators.

- Connect with Care: Follow the instructions in your user manuals. Usually, you’ll connect the green ground connector first, then the red and black wires in that order for both generators.

- Start ‘Em Up: Once they’re connected, start both generators. Now you’ll have double the power (if they’re the same).

These steps might vary for different generators, so always check the manuals. Some models even have a specific order for turning them on, so read those user guides for precise info.

Note: This info is for India, not America.

Paralleling Three-Phase Machines Using the Lamp Method

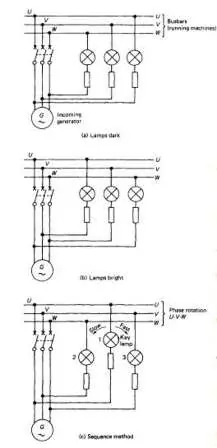

Dark Lamp Method for Paralleling Generators:

Unlike the expensive synchroscope method, the dark lamp method is cost-effective for parallel generators. Here’s how it works:

Lamp Connection: In this method, three lamps are connected to the same phase. Using a voltmeter, two phases are linked across the bus bar and the incoming machine.

One Dark, Two Bright: In the one dark and two bright lamp system, one lamp is connected to a phase, while the other two bright lamps are connected out of phase to the bus bar.

Working Principle: When two generators are in parallel, their combined frequency is zero. Initially, when there’s a frequency difference, all three lights will stay dark. As the frequencies align, the lamps flicker together.

Incorrect Phase Sequence: If the lamps don’t flicker simultaneously, it indicates an incorrect phase sequence. In this case, stop the incoming machine and adjust the terminal connections.

Breaker Engagement: The breaker should be closed when the lamps are in the dark phase, and the net frequency is close to one. This signifies that the generators are in parallel.

Synchronization with Two Brights and One Dark Lamp Method

Here’s the procedure for synchronizing machines using the Two Brights and One Dark Lamp Method:

- Start the machine and increase its speed to the rated value.

- Connect all three lamps and a voltmeter to the terminals as shown in the image, following the Two Brights and One Dark Lamp Method.

- Compare the voltage of the incoming machine with that of the bus bar. If they are not the same, adjust the voltage of the incoming machine until it matches the terminal voltage.

- Observe the flickering of the bulbs to determine their clockwise or anticlockwise movement.

- If the bulbs move anticlockwise, the speed is slow compared to the bus bar or the running machine. If they move clockwise, it means the speed is fast.

- Adjust the speed to minimize the flickering of the bulbs until it approaches zero.

- Engage the breaker when the bulb connected to the phase is dark and the other two bright bulbs.

- Decide whether to stop one machine or run them in parallel based on your requirements and take the necessary action.

- You can achieve this by decreasing the running machine’s speed while increasing the incoming machine’s speed.

- Disconnect the power supply to the bulbs and step-down transformer.

- Trip the breaker of the running machine to complete the process.

How to Parallel Single-Phase Generators

Synchronizing a Single-Phase Generator for Parallel Operation

Synchronizing a single-phase generator for parallel operation can be achieved using dark or bright lamp synchronization. In this case, you will only need two lamps throughout the synchronization process. Here’s how it works:

- Dark Lamp Method: Connect both lamps in phase to the generator’s terminals and the bus bar.

- Bright Lamp Method: Connect the lamps out of phase with each other.

The bright lamp will flicker with alternating bright and dark phases, depending on the net frequency of the generators. When the voltage and frequency of the incoming generator match those of the operating generator, the bulb will turn black.

For synchronization, engage the breaker of the three-phase machine during the dark phase period. At this point, the two outputs are in opposition phase sequence. If the synchronization process is not executed correctly, the machines won’t synchronize, potentially leading to a reverse power trip.

Benefits of Operating Generators in Parallel

Advantages of Paralleling Generators

When you connect two generators in parallel, several advantages come your way:

- Increased Power: Paralleling two identical generators doubles your power output, allowing you to run more appliances and equipment simultaneously.

- Cost-Effective: Buying a second small generator of the same type is more economical than investing in a larger, more expensive one. Plus, you avoid the hassle of selling your old generator at a loss.

- Compact Size: Even two small generators are physically smaller and lighter than a single large generator. This benefit is especially valuable for RV owners and campers.

- Redundancy: If one generator fails, the other can keep running, providing backup power during repairs or maintenance.

- Reliability: Parallel generators share the load, reducing stress on individual units and increasing overall reliability.

- Efficiency: Smaller generators maintain high efficiency even at light loads, ensuring more efficient power usage than a large generator.

What is a Synchroscope?

A synchroscope is an instrument used to display the frequency difference and phase angle between two alternating current (AC) power sources. It is crucial for synchronizing or paralleling generators to ensure that they operate in unison. For two AC power systems to be interconnected (paralleled), they must be synchronized, meaning they must match in voltage, frequency, and phase angle. Only when all three parameters align is it safe to connect the systems. Paralleling unsynchronized systems can lead to sudden current surges and mechanical stress on rotating equipment, potentially damaging one or both systems.

How Does a Synchroscope Work?

- Frequency and Phase Angle Display: A synchroscope shows the frequency difference and phase angle between the two AC power sources. It is commonly used to match an auxiliary generator to a main power system, connect one generator to another, or synchronize a facility’s power plant with a utility grid.

- Voltage Matching: In addition to frequency and phase angle, the voltages of both systems must match for successful synchronization. This often requires separate indicators for monitoring voltage, while the synchroscope focuses on frequency and phase alignment.

- Phase Sequence in Polyphase Systems: For polyphase systems, maintaining the same phase sequence is critical. Since most synchroscopes are connected to a single phase, additional indicator lights or instruments are used to verify the correct phase sequence before connecting.

Types of Synchroscopes

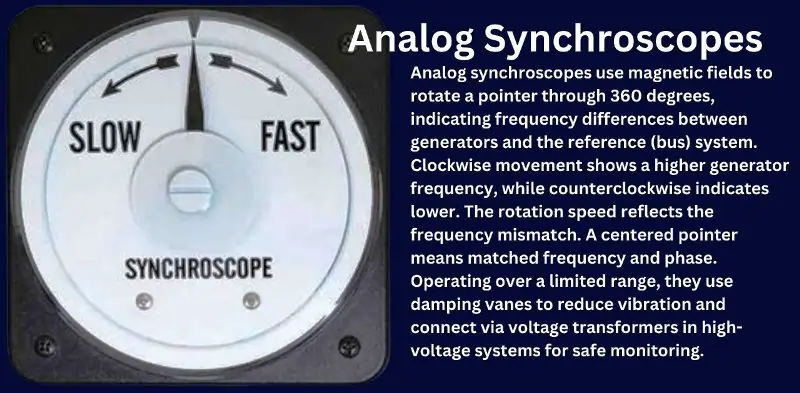

Analog Synchroscopes

- Mechanism: Analog synchroscopes operate as electrodynamic meters, using the interaction of magnetic fields to rotate a pointer continuously through 360 degrees.

- Pointer Movement: A clockwise-moving pointer indicates that the generator frequency is higher than the reference frequency (bus frequency), while counterclockwise movement shows a lower frequency. The speed of rotation reflects the degree of frequency mismatch.

- Frequency Range: These devices operate over a limited frequency range, typically a few percent above or below the nominal system frequency. A damping vane inside the meter smooths out vibrations to ensure a steady reading.

- Application Example: In high-voltage systems, analog synchroscopes are often connected through voltage transformers, reducing input voltage to 120 volts for safety.

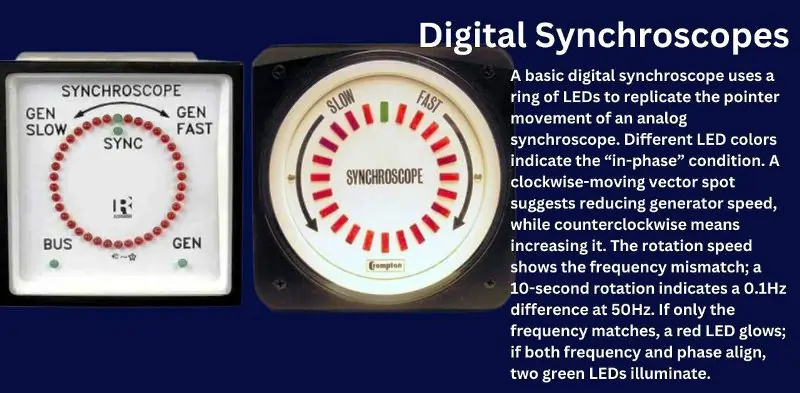

Digital Synchroscopes

- LED Display: Digital synchroscopes use a ring of LEDs to mimic the pointer movement seen in analog models. Different colors are used to indicate the “in-phase” condition, making it easier for operators to identify the right time for synchronization.

- Phase and Frequency Indication: If the LEDs rotate clockwise, it indicates that the generator speed needs to be reduced. A counterclockwise rotation suggests that the generator speed should be increased. The rotation speed represents the frequency mismatch, where a slower rotation indicates a closer match.

- Precision in Readings: For example, a rotation time of 10 seconds suggests a frequency difference of 0.1 Hz at 50 Hz. When both frequency and phase align, two green LEDs light up at the top center, indicating the right moment for connecting the generators.

Use of a Synchroscope in Paralleling Generators

A synchroscope is indispensable in the process of paralleling generators, ensuring a smooth and safe connection between power sources. Here’s how it aids in the synchronization process:

- Frequency Matching: The synchroscope helps adjust the speed of the incoming generator so that its frequency aligns with the frequency of the existing system, a critical step before paralleling.

- Phase Synchronization: It allows operators to monitor the phase angle, ensuring that the generator and the power grid are in phase. When the synchroscope shows a phase match, the circuit breaker can be closed safely.

- Voltage Adjustment: While the synchroscope focuses on frequency and phase, voltage indicators ensure that the voltages of both systems are matched, preventing potential voltage imbalances.

- Safe Interconnection: By using a synchroscope, operators ensure that the generators are synchronized properly, preventing surges and mechanical stress that could otherwise disrupt or damage the power systems.

Using a synchroscope enables seamless integration of generators, ensuring that they work together efficiently to share the load while maintaining stability in the power system. It is especially crucial in settings like marine power systems, industrial facilities, and power plants where reliable parallel operation of generators is essential.

FAQ on ” How to Parallel Generators

Q: What is the parallel operation of generators?

A: It’s when multiple generators work together to provide more power.

Q: Can I connect different generator brands in parallel?

A: It’s best to use identical generators for safe parallel operation.

Q: What are the benefits of paralleling generators?

A: You get more power, cost savings, and increased reliability.

Q: How do I synchronize generators for parallel operation?

A: You can use lamps or synchronization devices to align voltage and frequency.

Blog Post Conclusion

You might have carefully selected a portable generator to meet your initial power needs, but those needs can grow over time.

When you find your current generator stretched to its limit, the solution isn’t necessarily to purchase a new and larger one. There’s a cost-effective alternative – paralleling two generators. We discussed the value of connecting generators in parallel as well as their operation in this tutorial.

Imagine you got a good generator, and it worked just fine. But as time passed, you needed more power, and your old generator couldn’t keep up.

Well, you’re not alone. Many people buy slightly smaller generators, and then their power needs grow.

So, what can you do? Do you have to toss your old generator and buy a bigger, more expensive one? Not necessarily!

There’s a clever solution. You can keep using your current generator and buy a new one. Then, you run them together to get more power without breaking the bank.

It’s like having two heroes working as one team. If this idea is new to you, don’t worry; we’ll explain how to do it. Let’s dive into how to parallel generators and get that extra power you need.