AC Capacitor

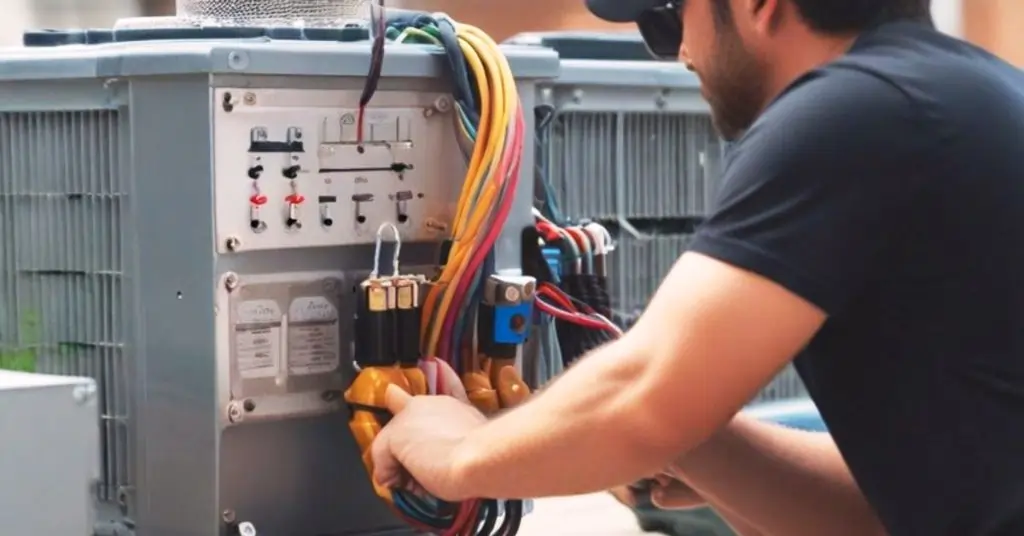

In marine environments, air conditioning units face unique challenges due to constant exposure to saltwater, humidity, and varying temperatures. A key component that ensures the efficient operation of these systems is the AC capacitor. This small but crucial device stores and releases electrical energy, helping to start and run the motors that power your air conditioner. Without a properly functioning capacitor, your marine AC unit can suffer from reduced performance, increased energy consumption, and potential system failures.

In this article, you will learn the most ultimate 7 tips for selecting, installing, maintaining, and troubleshooting AC capacitors specifically for marine use. Whether you’re a homeowner, an HVAC technician, or a DIY enthusiast, these insights will help you enhance the efficiency, longevity, and overall performance of your marine air conditioning system. Dive in to discover practical advice and expert recommendations that will keep your AC unit running smoothly even in the harshest marine conditions.

Understanding AC Capacitors in Marine Applications

Definition and Function of AC Capacitors

AC capacitors are electrical components that store and release energy to help start and run the motors in air conditioning systems. They work by accumulating electrical charge and then discharging it as needed to provide the necessary boost for the motors. In essence, capacitors ensure that the motors receive a steady and reliable flow of power, enabling them to operate efficiently and effectively.

Importance in Marine Air Conditioning Systems

In marine environments, air conditioning systems are subjected to harsher conditions than those on land. Saltwater exposure, high humidity, and fluctuating temperatures can significantly impact the performance and longevity of these systems. AC capacitors play a crucial role in maintaining the functionality and efficiency of marine air conditioning units. They help:

- Start the Motors: By providing an initial surge of power, capacitors ensure that the compressor, fan, and blower motors start smoothly.

- Maintain Continuous Operation: Run capacitors provide a consistent flow of energy to keep the motors running efficiently, reducing wear and tear.

- Enhance Energy Efficiency: Efficient capacitors contribute to lower energy consumption, which is particularly important in a marine setting where power resources can be limited.

- Protect Against Power Fluctuations: Capacitors help stabilize voltage levels, protecting the air conditioning system from damage caused by power surges and drops.

Differences Between Marine and Standard Applications

While the fundamental function of AC capacitors remains the same in both marine and standard applications, there are notable differences due to the challenging marine environment:

- Durability and Construction: Marine AC capacitors are often designed with more robust materials to withstand corrosion from saltwater and high humidity levels. They may also have additional protective coatings or enclosures to shield them from the harsh elements.

- Maintenance Requirements: Regular maintenance is more critical for marine capacitors due to the increased risk of corrosion and damage. This includes frequent inspections, cleaning, and timely replacements to ensure optimal performance.

- Energy Efficiency Considerations: In marine settings, where power availability can be unpredictable, energy-efficient capacitors are essential. They help conserve energy and reduce the load on the system, ensuring reliable operation even with limited power resources.

Types of AC Capacitors

Start Capacitors

Start capacitors are crucial components in air conditioning systems, designed to provide a substantial initial boost of power to start the motor. When an AC unit begins operation, it requires a significant amount of torque to get the compressor and other motors up to speed. The start capacitor delivers this surge of power, enabling the motor to overcome initial inertia and start rotating. Once the motor reaches a certain speed, the start capacitor disengages from the circuit, as its function is solely to assist with startup.

- Usage: Typically used in motors that require a high starting torque, such as those in air conditioners, refrigerators, and other heavy-duty appliances.

- Specifications: Start capacitors generally have a higher capacitance (measured in microfarads, µF) compared to run capacitors, and they are only in the circuit for a short duration.

- Formula: The energy stored in a start capacitor can be calculated using:

Run Capacitors

Run capacitors are designed to provide continuous power to keep the motor running efficiently once it has started. Unlike start capacitors, run capacitors remain in the circuit for the entire operation of the motor. They help to smooth out the power supply, maintain a stable voltage level, and improve the motor’s efficiency by ensuring a consistent phase angle between the current and voltage.

- Usage: Found in a wide range of appliances, including air conditioners, ceiling fans, and pumps, where they enhance performance and efficiency.

- Specifications: Run capacitors have a lower capacitance than start capacitors and are designed for continuous duty. They are rated for both the capacitance and the voltage they can handle.

- Formula: The capacitive reactance (Xc) of a run capacitor, which affects the phase angle, can be calculated using:

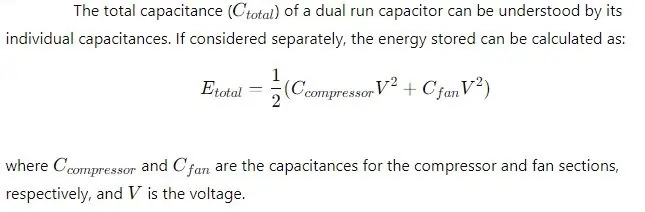

Dual Run Capacitors

Dual run capacitors combine the functions of two separate capacitors into a single unit. They have three terminals instead of the usual two, with one terminal connected to the common wire, one to the compressor, and the other to the fan motor. This design simplifies the wiring and reduces the number of components required in the AC system.

- Usage: Commonly used in HVAC systems to simultaneously power both the compressor and the fan motor, making them highly efficient and space-saving.

- Specifications: Dual run capacitors are rated with two capacitance values, one for the compressor and one for the fan motor, along with a shared voltage rating. For example, a dual run capacitor might be labeled as 40/5 µF with a voltage rating of 370V or 440V.

- Formula:

Tip 1: Selecting the Right Capacitor for Marine Use

Selecting the right capacitor for marine use is crucial to ensure the reliability and efficiency of your air conditioning system in the harsh marine environment. Here are key factors to consider and some recommended brands and types specifically designed for marine applications.

Factors to Consider

- Voltage Rating

- Importance: The voltage rating of a capacitor indicates the maximum voltage it can handle. In marine environments, where power fluctuations can be common, it is essential to choose a capacitor with a sufficient voltage rating to prevent breakdown and ensure longevity.

- Guideline: Always select a capacitor with a voltage rating higher than the operating voltage of your AC system. For instance, if your system operates at 220V, a capacitor rated at 370V or 440V is advisable.

- Capacitance Value

- Importance: Capacitance, measured in microfarads (µF), determines the amount of electrical charge the capacitor can store. The correct capacitance value is crucial for the efficient starting and running of the motor.

- Guideline: Follow the manufacturer’s specifications for capacitance. Using a capacitor with a different capacitance value can lead to improper motor operation and potential damage.

- Size and Form Factor

- Importance: The physical size of the capacitor must fit within the designated space in your AC unit. Additionally, the form factor (cylindrical, oval) should match the mounting design.

- Guideline: Measure the available space and ensure the new capacitor fits properly. Check the dimensions and mounting type before purchasing.

- Durability and Environmental Resistance

- Importance: Marine environments are harsh, with high humidity, saltwater exposure, and temperature fluctuations. Capacitors need to be robust enough to withstand these conditions.

- Guideline: Look for capacitors that are specifically rated for marine use or have protective coatings and enclosures to resist corrosion and moisture.

Recommended Brands and Types for Marine Environments

- Titan Pro

- Features: Known for high durability and reliable performance, Titan Pro capacitors are often used in demanding environments. They offer a wide range of voltage and capacitance ratings suitable for marine applications.

- Recommended Models: Titan Pro 440V Round Dual Run Capacitors

- Packard

- Features: Packard capacitors are designed to meet rigorous standards, ensuring longevity and stable performance. They are available in various sizes and configurations.

- Recommended Models: Packard Oval Run Capacitor 370V/440V

- Genteq

- Features: Genteq, formerly GE capacitors, are renowned for their high-quality construction and reliability. They are widely used in HVAC systems and are suitable for marine environments due to their robust design.

- Recommended Models: Genteq 97F Dual Run Capacitor

- SUPCO

- Features: SUPCO offers capacitors with enhanced environmental protection, making them ideal for marine use. They provide consistent performance under extreme conditions.

- Recommended Models: SUPCO Round Dual Run Capacitor

- Mars

- Features: Mars capacitors are engineered for high performance and durability. They are available in various configurations to fit different marine AC systems.

- Recommended Models: Mars 440V Round Run Capacitors

Tip 2: Proper Installation Techniques

Step-by-Step Guide to Installing an AC Capacitor in a Marine Setting

| Step | Description | Note |

|---|---|---|

| Turn Off the Power | Ensure that the power to the air conditioning unit is completely turned off. Disconnect the unit from the power source to prevent any accidental electrical shocks. | Use a voltage tester to confirm that there is no residual electrical charge in the unit. |

| Locate the Capacitor | Open the access panel of the air conditioning unit to locate the capacitor. The capacitor is typically found near the compressor or the fan motor. | Refer to the unit’s manual for the exact location and type of capacitor used. |

| Discharge the Capacitor | Use a capacitor discharge tool or an insulated screwdriver to discharge any stored electrical energy in the capacitor. Place the tool across the terminals to safely release the charge. | Always wear insulated gloves and use insulated tools to avoid electric shock. |

| Remove the Old Capacitor | Carefully disconnect the wires from the terminals of the old capacitor. Note the wire connections to ensure correct reinstallation. | Take a photo or label the wires to remember their original positions. |

| Install the New Capacitor | Position the new capacitor in place and reconnect the wires to the corresponding terminals. Ensure the connections are tight and secure. | Double-check the capacitance and voltage ratings of the new capacitor to ensure they match the specifications of the old one. |

| Secure the Capacitor | Secure the capacitor in its mounting bracket or holder. Ensure it is firmly in place to withstand vibrations and movement in the marine environment. | Use corrosion-resistant fasteners to prevent rusting. |

| Close the Access Panel | Replace the access panel and secure it with screws or clips. Make sure the panel is properly sealed to protect the internal components from moisture and salt air. | Inspect the sealing gasket for wear and replace if necessary. |

| Restore Power and Test | Turn the power back on and test the air conditioning unit. Observe the startup and running operation to ensure the capacitor is functioning correctly. | Listen for any unusual noises or signs of malfunction. |

Common Mistakes to Avoid

| Mistake | Description | Solution |

|---|---|---|

| Using the Wrong Capacitor | Installing a capacitor with incorrect voltage or capacitance ratings. | Always verify the specifications of the replacement capacitor to match the original. |

| Improper Discharge | Failing to discharge the old capacitor properly, leading to electric shock. | Use proper discharge tools and techniques to safely release stored energy. |

| Incorrect Wiring | Misconnecting the wires to the wrong terminals. | Label wires or take a photo before disconnecting to ensure correct reinstallation. |

| Loose Connections | Leaving wire connections loose, causing poor electrical contact. | Ensure all wire connections are tight and secure. |

| Neglecting Environmental Protection | Failing to use corrosion-resistant materials in a marine setting. | Use appropriate materials and secure the access panel to protect against moisture and salt. |

Safety Precautions Specific to Marine Installations

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always wear insulated gloves and safety goggles to protect against electrical shocks and debris. |

| Use Insulated Tools | Use tools with insulated handles to prevent electric shock when working with electrical components. |

| Work in Dry Conditions | Ensure the work area is dry and free from water to reduce the risk of electrical hazards. |

| Check for Corrosion | Inspect for any signs of corrosion on electrical connections and components. Replace any corroded parts to maintain electrical integrity. |

| Follow Manufacturer Guidelines | Adhere to the manufacturer’s installation instructions and safety recommendations for the specific air conditioning unit. |

Tip 3: Regular Maintenance and Inspection

| Section | Details |

|---|---|

| Importance of Routine Checks | Prevention of Malfunctions: Routine checks can identify issues before they cause system malfunctions, ensuring continuous comfort. Enhanced Efficiency: Regular maintenance helps keep the AC system running efficiently, reducing energy consumption and operational costs. Extended Lifespan: Consistent care and timely replacements of worn-out parts can significantly extend the lifespan of your AC system. |

| How to Perform Visual Inspections | 1. Turn Off the Power: Ensure the air conditioning unit is powered off completely to avoid electrical hazards. Disconnect the unit from the power source as an additional safety measure. 2. Access the Capacitor: Open the access panel of the AC unit to reach the capacitor. Refer to the unit’s manual if necessary to locate the capacitor. 3. Inspect the Capacitor: Look for any signs of physical damage such as bulging, cracks, or leaks. A bulging capacitor indicates that it is failing and needs to be replaced. Check for corrosion on the terminals and connections. Corrosion can lead to poor electrical contact and should be cleaned or the component replaced. <br> – Ensure all connections are secure and there are no loose wires. 4. Examine the Surrounding Area: Inspect the mounting bracket or holder for any signs of rust or damage. Ensure that the area around the capacitor is clean and free of debris, which can affect its operation. |

| Tools Needed for Maintenance | Voltage Tester: To ensure the power is completely off before starting the inspection. Insulated Screwdrivers: To safely open the access panel and handle electrical components. Multimeter: To test the capacitance and voltage of the capacitor. Capacitor Discharge Tool: To safely discharge any stored electrical energy in the capacitor before handling. Cleaning Supplies: Such as a brush and corrosion-resistant spray to clean terminals and connections. Protective Gear: Insulated gloves and safety goggles to protect against electrical shocks and debris. |

| Signs of Wear and When to Replace | Bulging or Swelling: If the capacitor appears swollen or bulged, it is a clear sign that it is failing and needs to be replaced immediately. Leaking Fluid: Any signs of fluid leakage from the capacitor indicate it is compromised and should be replaced. Corrosion: Severe corrosion on the terminals or casing can affect the capacitor’s performance. If cleaning does not restore proper function, replacement is necessary. Burn Marks or Smell: Any burn marks on the capacitor or a burnt smell are indicators of overheating and potential failure. Replace the capacitor to prevent further damage to the system. Decreased Performance: If the air conditioning unit is not operating efficiently or takes longer to start, it may be due to a failing capacitor. Testing with a multimeter can confirm if the capacitance is within the specified range. If not, replacement is needed. |

Tip 4: Troubleshooting Common Issues

| Section | Details |

|---|---|

| Identifying Symptoms of a Failing Capacitor | Unusual Noises: Humming or buzzing sounds from the AC unit can indicate a failing capacitor. Difficulty Starting: The AC unit struggles to start or fails to start altogether. Intermittent Operation: The AC unit starts and stops frequently or runs inconsistently. Decreased Cooling Efficiency: The AC system is not cooling as effectively as it should. Physical Damage: Visible signs of damage such as bulging, leaks, or corrosion on the capacitor. |

| Diagnostic Procedures | 1. Visual Inspection: Turn off the power and inspect the capacitor for any visible signs of damage, such as bulging, leaks, or corrosion. 2. Capacitance Testing: Use a multimeter to measure the capacitance. Set the multimeter to the capacitance setting, connect the probes to the capacitor terminals, and compare the reading to the capacitor’s rated capacitance. 3. Voltage Testing: Measure the voltage across the capacitor terminals with a multimeter while the unit is running. Ensure the voltage matches the capacitor’s specifications. 4. Discharge Test: Discharge the capacitor using a resistor or capacitor discharge tool before handling it to avoid electric shock. |

| Solutions for Common Problems | Failed Start Capacitor: Replace the start capacitor if it fails to provide the necessary boost for starting the motor. Failed Run Capacitor: Replace the run capacitor if the motor runs inconsistently or fails to maintain proper operation. <br> – Corrosion and Rust: Clean corrosion from the terminals and connections using a corrosion-resistant spray. Replace the capacitor if corrosion is severe. Incorrect Capacitance: Ensure the replacement capacitor has the correct capacitance and voltage ratings as specified by the manufacturer. Loose Connections: Tighten any loose connections to ensure proper electrical contact. Check all wire connections and secure them firmly. |

Important Formulas and Calculations

When working with AC capacitors, understanding the key formulas and calculations is essential for selecting, testing, and maintaining these components. Here are some important formulas related to capacitance, energy storage, and reactance.

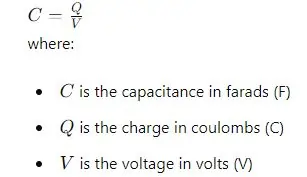

1. Capacitance (C) Calculation

This formula indicates that capacitance is directly proportional to the charge stored and inversely proportional to the voltage across the capacitor.

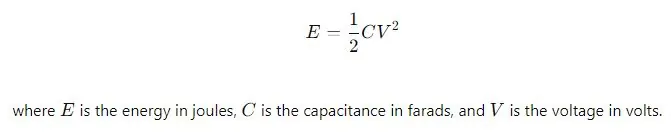

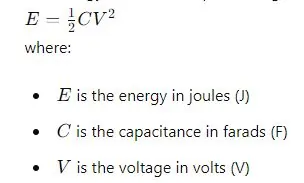

2. Energy Stored (E) in a Capacitor

This formula shows that the energy stored in a capacitor increases with the square of the voltage and is directly proportional to the capacitance.

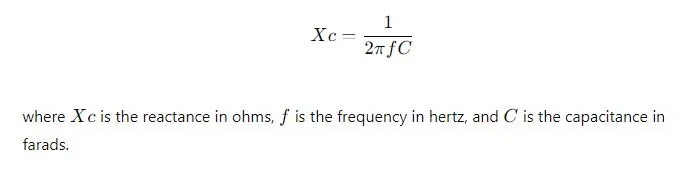

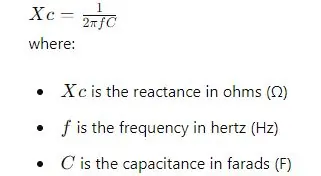

3. Reactance (Xc) of a Capacitor

This formula indicates that the reactance decreases with increasing frequency and capacitance. Capacitive reactance is inversely proportional to both frequency and capacitance, meaning higher frequencies or larger capacitances result in lower reactance.

FAQs on AC Capacitor

Q: What does an AC capacitor do?

A: It stores and releases energy to start and run the compressor and fan motors.

Q: How can I tell if my AC capacitor is failing?

A: Look for unusual noises, difficulty starting, intermittent operation, or decreased cooling.

Q: How often should I inspect my AC capacitor?

A: Inspect it at least once a year, especially before peak cooling season.

Q: Can I replace an AC capacitor myself?

A: Yes, but turn off the power and discharge the capacitor first.

Conclusion

Maintaining and understanding your AC capacitor is essential for the optimal performance and longevity of your air conditioning system, especially in marine environments. By selecting the right capacitor, following proper installation techniques, performing regular maintenance, and troubleshooting common issues, you can ensure your AC unit runs efficiently and reliably. Regular care and timely replacements not only prevent unexpected failures but also enhance the overall efficiency of your system, providing comfort and peace of mind in the demanding marine setting.