Air Circuit Breakers

Air circuit breakers are essential components in modern electrical systems, designed to protect circuits from damage caused by overloads or short circuits. Unlike other types of breakers, air circuit breakers use air as the medium to extinguish the arc that forms when interrupting the current flow. This makes them particularly effective and reliable for high-current applications.

The importance of air circuit breakers extends across various industries, notably in marine and electrical systems, where their ability to handle large currents safely is critical. In marine applications, they protect vital systems from electrical faults, ensuring the safety and efficiency of operations. Switchgear used in marine applications relies heavily on air circuit breakers to maintain robust and reliable performance. In electrical systems, they provide robust protection and maintain the stability of power distribution networks.

This article will cover key aspects of air circuit breakers, starting with a fundamental understanding of their principles, components, and working mechanisms. We will explore their different types and applications, advantages, installation and maintenance practices, troubleshooting tips, technological advancements, and best practices and standards.

Understanding Air Circuit Breakers

Definition and Basic Concept

Air circuit breakers (ACBs) are a type of electrical protection device that interrupts the flow of current in an electrical circuit when a fault is detected, such as an overload or short circuit. Unlike other circuit breakers that use oil or vacuum to quench the arc, ACBs use air as the medium to extinguish the arc formed during the interruption process. This makes them particularly suitable for high-current and high-voltage applications, ensuring the safety and reliability of electrical systems.

Working Principles Explained

The primary function of an air circuit breaker is to detect fault conditions and interrupt the current flow to prevent damage to the circuit. When the breaker detects an overcurrent or fault, its contacts open, creating an arc between them. The arc is a discharge of electricity through the air, which can cause significant damage if not properly managed. Air circuit breakers use a combination of air and mechanical components to effectively extinguish this arc.

How Air is Used to Extinguish Arcs

In an air circuit breaker, when the contacts separate, an electric arc forms between them. To extinguish this arc, ACBs utilize several mechanisms:

- Arc Chute: This is a set of splitters or metal plates that divide the arc into smaller segments, increasing its length and cooling it down more rapidly.

- Blowout Coils: These generate a magnetic field that drives the arc into the arc chute, aiding in the quenching process.

- Air Blasts: High-speed air blasts can be directed at the arc to cool and elongate it, helping to extinguish it faster.

These mechanisms ensure that the arc is quickly and efficiently extinguished, preventing damage to the breaker and the electrical system.

Key Components

- Arc Chute: A series of metal plates that divide and cool the arc.

- Contacts: Main and arcing contacts that separate to create the arc.

- Main Contacts: Carry the load current under normal conditions.

- Arc Contacts: Engage first and disengage last to handle the initial and final arcing.

- Blowout Coils: Create a magnetic field to drive the arc into the arc chute.

- Air Blasts: Direct high-speed air at the arc for rapid cooling and elongation.

- Trip Unit: Detects fault conditions and triggers the opening of the contacts.

Historical Background and Evolution

The concept of air circuit breakers has evolved significantly since their inception. Early circuit breakers were rudimentary, relying on simple mechanical means to interrupt current flow. As electrical systems became more complex and the demand for higher safety and reliability increased, the technology of ACBs advanced. The introduction of arc chutes and blowout coils marked significant milestones in their development, allowing for more effective arc quenching and higher current handling capabilities.

Understanding the Air Circuit Diagram

Introduction to Air Circuit Diagrams

Air circuit diagrams are essential tools for understanding the operation and functionality of air circuit breakers. These diagrams provide a visual representation of the electrical and mechanical components within the breaker, illustrating how they interact during normal operation and fault conditions. By studying these diagrams, engineers and technicians can gain insights into the breaker’s design, troubleshoot issues, and ensure proper maintenance and operation.

Importance of Air Circuit Diagrams in Understanding Breaker Operation

Air circuit diagrams are crucial for several reasons:

- Operational Clarity: They help in understanding the sequence of operations within the breaker, from the closing of contacts to the extinguishing of arcs.

- Troubleshooting: By referencing the diagram, technicians can identify potential points of failure and understand the path of electrical flow, aiding in diagnostics and repair.

- Maintenance: Diagrams provide a clear layout of components, which is invaluable for routine inspections and maintenance tasks.

- Safety: Understanding the layout and operation of the breaker through diagrams ensures that technicians can safely work on or around the equipment.

Overview of Symbols and Components Commonly Used

Air circuit diagrams use standardized symbols to represent various components and their interactions. Common symbols include:

- Contacts: Represented by pairs of parallel lines that open or close.

- Arc Chutes: Depicted as segmented blocks where the arc is extinguished.

- Coils and Magnetic Elements: Shown as loops or spirals to indicate magnetic fields and blowout coils.

- Current Paths: Lines that illustrate the flow of current through the breaker.

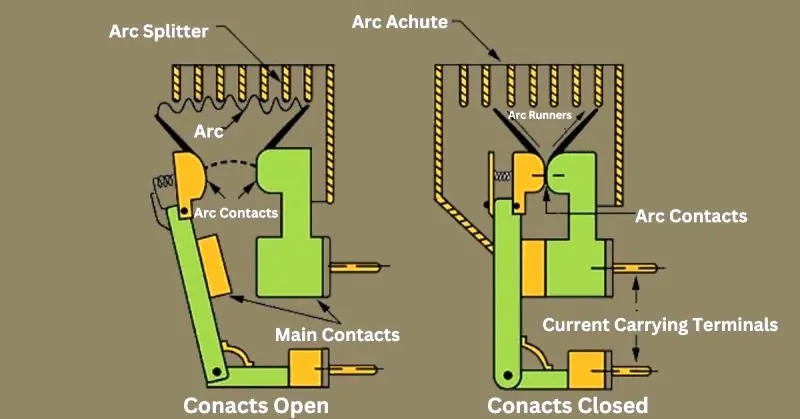

Key Components in the Diagram

Contact Open: The position where the circuit is interrupted, and no current flows. This is depicted by separated lines in the diagram.

Main Contacts: These are the primary contacts responsible for carrying the main load current during normal operation. They are shown as pairs of parallel lines that make or break the circuit.

Arc Contacts: Specialized contacts designed to handle the arc created during the interruption of high current. They engage first and disengage last to manage the arcing process.

Arc: Represented as a zigzag or lightning bolt symbol, the arc is the plasma discharge that occurs when the current is interrupted.

Arc Splitter: A device that divides the arc into smaller sections to help extinguish it. In diagrams, it appears as a series of parallel lines or plates that split the arc.

Contact Closed: The position where the circuit is completed, and current flows uninterrupted. This is depicted by connected lines in the diagram.

Current Carrying Terminals: Points where the current enters and exits the circuit breaker. These are usually marked with terminal symbols indicating connection points.

Arc Runners: Paths designed to direct the arc away from the contacts, shown as guided lines leading towards the arc chute.

Arc Chute: The structure designed to cool and extinguish the arc, often illustrated as a segmented or boxed area where the arc is directed and dissipated.

Reading the Diagram

Step-by-Step Guide on How to Interpret Air Circuit Diagrams

- Identify the Power Source: Locate the terminals where the power enters and exits the breaker.

- Follow the Current Path: Trace the lines from the power source through the main and arc contacts.

- Understand the Contact States: Differentiate between open and closed positions of the contacts.

- Locate the Arc Handling Components: Identify the arc contacts, arc runners, and arc chute, understanding their roles in arc extinguishment.

- Examine the Trip Mechanism: Understand how the trip unit operates to open the contacts during a fault condition.

Example Diagrams with Explanations

Provide a simple diagram showing the main components:

- Label each part: Main Contacts, Arc Contacts, Arc Chute, etc.

- Explain the sequence: Describe how current flows in normal operation and how the arc is managed during a fault.

Practical Tips for Engineers and Technicians

- Regular Review: Frequently review and familiarize yourself with the diagram to quickly identify components and their functions.

- Use During Maintenance: Always have the diagram on hand during maintenance to reference component locations and interactions.

- Update Diagrams: Ensure that diagrams are updated to reflect any modifications or upgrades to the breaker.

Types and Applications of Air Circuit Breakers

| Type | Definition and Features | Advantages | Applications |

|---|---|---|---|

| Plain Break Type | 1. Simplest form of air circuit breaker 2. Operates by separating contacts in the air without any additional arc control mechanisms | 1. Cost-effective and straightforward design 2. Suitable for low to medium voltage applications | 1. Residential or small commercial settings 2. Limited industrial applications where fault currents are low |

| Magnetic Blowout Type | 1. Incorporates magnetic blowout coils to enhance arc control 2. Magnetic field generated by coils drives the arc into an arc chute or other extinguishing mechanism | 1. Better arc control compared to plain break types 2. Suitable for higher current and voltage applications | 1. Industrial settings with higher currents 2. Electrical power distribution systems to manage fault currents |

| Air Chute Type | 1. Uses an arc chute with splitters to divide and cool the arc 2. Arc is directed into the chute, splitting into smaller, easier-to-extinguish arcs | 1. Superior arc extinguishing capabilities 2. Effective for high-current and high-voltage applications | 1. Power plants, large industrial complexes, and critical infrastructure 2. Marine industry switchgear |

Specific Applications in Different Industries

| Industry | Requirements | Applications | Advantages |

|---|---|---|---|

| Marine Industry | 1. Robust and reliable circuit protection 2. Handles harsh conditions and critical systems | 1. Extensively used in marine switchgear 2. Protects systems like navigation, communication, and propulsion | 1. High reliability and safety 2. Capable of withstanding harsh marine environments |

| Electrical Power Systems | 1. Handles high currents and voltages 2. Provides reliable fault protection | Used in substations, power plants, and large-scale power distribution networks | 1. Effective arc extinguishing ensures minimal downtime 2. High reliability and durability |

| Industrial Applications | Robust circuit protection for heavy machinery and high-power equipment | 1. Used in manufacturing plants, refineries, and large industrial complexes 2. Protects equipment and ensures safety | 1. Superior arc control and fault management 2. Ensures uninterrupted operation and safety |

Advantages of Each Type in Specific Applications

| Type | Specific Applications | Advantages |

|---|---|---|

| Plain Break Type | 1. Residential and small commercial settings 2. Low-demand industrial applications | 1. Cost-effective for low-demand applications 2. Suitable for low to medium voltage applications |

| Magnetic Blowout Type | 1. Industrial and electrical power systems 2. Medium to high current applications | 1. Enhanced arc control 2. Ideal for managing fault currents in industrial and power systems |

| Air Chute Type | 1. Critical infrastructure 2. High-demand environments<br>- Marine industry | 1. Superior arc extinguishing 2. Optimal for high-current and high-voltage applications 3. High reliability and safety in marine environments |

Troubleshooting Common Issues with Air Circuit Breakers

| Issue | Description | Troubleshooting Steps | Preventive Measures |

|---|---|---|---|

| Tripping Issues | Air circuit breakers may trip frequently due to various reasons, such as overcurrent, short circuits, or faulty trip units. | Identifying the Problem: 1. Inspect the breaker for visible signs of damage. 2. Check for loose connections. 3. Analyze recent load changes. Diagnostic Tools and Methods: 1. Use a multimeter to check for overcurrent or short circuits. 2. Employ a thermal imaging camera to detect hotspots. 3. Test the trip unit with a secondary injection test set. Repair and Replacement Solutions: 1. Tighten or replace loose connections. 2. Replace damaged trip units. 3. Adjust or replace the breaker if necessary. | Preventive Measures: 1. Regularly inspect and maintain the breaker. 2. Ensure proper load management. 3. Periodically test the trip unit to ensure proper functioning. |

| Contact Wear and Tear | Contacts can degrade over time due to repeated arc formation, leading to poor conductivity and increased resistance. | Identifying the Problem: 1. Visual inspection for pitting or burning on contacts. 2. Measure contact resistance. Diagnostic Tools and Methods: 1. Use a contact resistance tester. 2. Perform a visual inspection using a magnifying glass. 3. Check for abnormal heating or discoloration. Repair and Replacement Solutions: 1. Clean minor pitting and oxidation. 2. Replace heavily damaged contacts. 3. Ensure proper alignment of contacts during replacement. | Preventive Measures: 1. Regularly clean and inspect contacts. 2. Use protective coatings to reduce oxidation. 3. Monitor and manage load conditions to minimize contact wear. |

| Arc Chute Degradation | The arc chute can degrade due to prolonged exposure to high temperatures and repeated arcing, leading to ineffective arc quenching. | Identifying the Problem: 1. Inspect for signs of wear, cracks, or damage. 2. Check for buildup of debris or deposits. Diagnostic Tools and Methods: 1. Visual inspection of the arc chute. 2. Use an endoscope for hard-to-reach areas. 3. Check for changes in breaker performance. Repair and Replacement Solutions: 1. Clean or replace damaged arc chutes. 2. Remove any debris or deposits. 3. Ensure proper installation and alignment of replacement parts. | Preventive Measures: 1. Conduct regular inspections of the arc chute. 2. Maintain a clean environment to prevent debris buildup. 3. Schedule periodic replacements of arc chutes as per manufacturer recommendations. |

Step-by-Step Troubleshooting Guide

- Identifying the Problem

- Begin with a visual inspection for any obvious signs of damage or wear.

- Note any recent changes in load conditions or unusual breaker behavior.

- Use diagnostic tools to gather data on current, temperature, and resistance.

- Diagnostic Tools and Methods

- Multimeter: Check for overcurrent, short circuits, and proper voltage levels.

- Thermal Imaging Camera: Detect hotspots that indicate overheating or loose connections.

- Contact Resistance Tester: Measure resistance across contacts to identify wear or poor conductivity.

- Secondary Injection Test Set: Test the trip unit’s functionality and settings.

- Endoscope: Inspect hard-to-reach areas within the breaker for wear or damage.

- Repair and Replacement Solutions

- Loose Connections: Tighten or replace as necessary to ensure good electrical contact.

- Damaged Trip Units: Replace faulty trip units to restore proper breaker operation.

- Worn Contacts: Clean or replace contacts showing significant wear or damage.

- Arc Chute: Clean or replace the arc chute if degradation is evident.

- Preventive Measures to Avoid Common Issues

- Conduct regular inspections and maintenance of the breaker and its components.

- Manage loads to avoid overcurrent conditions and excessive wear on contacts.

- Schedule periodic testing of trip units and other critical components.

- Keep the breaker and its environment clean to prevent debris buildup and ensure optimal performance.

Best Practices and Standards for Air Circuit Breakers

Industry Best Practices for Using Air Circuit Breakers

Implementing industry best practices ensures the reliable and efficient operation of air circuit breakers (ACBs). These practices encompass installation, maintenance, and adherence to safety standards.

Installation Guidelines

- Site Assessment

- Conduct a thorough site assessment to determine the suitability of the location for installing the ACB.

- Ensure the environment is free from excessive dust, moisture, and corrosive substances.

- Proper Handling

- Use appropriate handling equipment to avoid physical damage.

- Follow the manufacturer’s guidelines for unpacking and transporting the breaker.

- Installation Steps

- Secure the ACB on a stable, vibration-free surface.

- Connect the breaker to the electrical system using appropriate cables and connectors.

- Verify that all connections are tight and secure to prevent loose connections.

- Testing

- Perform initial tests to ensure the breaker operates correctly.

- Test for continuity, insulation resistance, and functionality of the trip unit.

Maintenance Protocols

- Regular Inspections

- Conduct visual inspections at regular intervals to check for signs of wear, corrosion, or damage.

- Inspect arc chutes, contacts, and connections.

- Cleaning

- Clean the breaker and its components to remove dust and debris.

- Use appropriate cleaning agents that do not harm the breaker’s materials.

- Lubrication

- Lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

- Functional Testing

- Perform regular functional tests to verify the breaker’s performance.

- Test the trip unit and protective features to ensure they operate within specified parameters.

Safety Standards

- Personal Protective Equipment (PPE)

- Ensure all personnel involved in installation and maintenance wear appropriate PPE, including gloves, safety glasses, and insulated tools.

- Lockout/Tagout Procedures

- Implement lockout/tagout procedures to prevent accidental energization during maintenance.

- Arc Flash Protection

- Follow arc flash protection guidelines to protect against arc flash incidents.

Compliance with Regulations and Standards

- National and International Standards

- Adhere to relevant national and international standards such as IEC 60947-2 and IEEE C37.13.

- Ensure compliance with local electrical codes and regulations.

- Certification Requirements

- Verify that ACBs meet certification requirements from recognized bodies such as UL, CSA, and CE.

- Maintain records of certifications for auditing and compliance purposes.

FAQ on “Air Circuit Breakers”

Q: What is an air circuit breaker?

A: It uses air to extinguish electrical arcs and protect circuits.

Q: How do air circuit breakers extinguish arcs?

A: They use air chutes and arc runners to split and cool the arc.

Q: What are common issues with air circuit breakers?

A: Tripping, contact wear, and arc chute degradation.

Q: Why is regular maintenance of air circuit breakers important?

A: It ensures reliability, safety, and longevity.

Conclusion

In this article, we explored the fundamental aspects of air circuit breakers, including their types, working principles, key components, and applications across various industries. We also delved into common issues, troubleshooting methods, and preventive measures to ensure their optimal performance. Understanding and properly maintaining air circuit breakers is crucial for the safety and efficiency of electrical systems, particularly in demanding environments like marine and industrial settings.

Proper maintenance and timely troubleshooting can significantly extend the lifespan of these critical devices, ensuring reliable protection against electrical faults. Looking ahead, advancements in technology will continue to enhance the capabilities of air circuit breakers, integrating smart features and improving efficiency. Adopting best practices and staying updated with the latest innovations will be essential for maintaining robust and effective electrical systems.