Air Compressor

Introduction

In this post on Best Tutorial on Marine Air Compressor,We will discuss the following topics

- What is a compressor,

- Uses of main Air Compressor on Board a ship,

- Compressor working principles,

- The general problem in compressors,

- How does a compressor work?

What is Air Compressor?

An Air compressor is a machine to increase the pressure. by compressing from low pressure to higher pressure by utilizing. some external source of energy.Electric motor or Diesel Engine drives the compressor

Classification of compressed air

- Main Air

- Instrument Air

Main Air: – (11 to 30 bar)

- Use of main air is for starting the main and auxiliary engines onboard a ship

- For supercharging purpose the engines

- For the operation of Lambda controller to boos the air at the change of loads in the engine.

Instrument Air; – (7 bars)

Use of Instrument air

1. Control system for several controls and automation.

2. Service air and control air application

3. Paint and spray instruments

4.Pneumatic hand tools

5. For machine cleaning

6. For Hydrophore ( A system to maintain the water pressure)

Important terminology used for compressor

Compression Ratio; – Ratio of volume pre- compression to the volume of air. post- compression is compression ratio.

Compressor Capacity; – Absolute volume of air delivered by a compressor in M3 / minute. is compressor capacity.

Free Air Delivery; – Quantity of air in M3 / minute produced by. existing temperature and pressure. at the suction of compressor is free air delivered.

Swept Volume; – The swept volume is the volume of air displaced by the diameter of the piston in one full stroke. from BDC to TDC

Bumping Clearance

Importance of Bumping Clearance:

- Prevents Mechanical Damage:

- Bumping clearance ensures that the piston does not physically touch the cylinder head or valves at TDC. Without sufficient clearance, contact could cause severe mechanical damage to the piston, cylinder head, and valves.

- Affects Compression Ratio:

- Bumping clearance influences the compression ratio in an engine or compressor. A smaller clearance increases the compression ratio, while a larger clearance decreases it. The compression ratio affects the efficiency and performance of the system.

- Ensures Safe Operation:

- In compressors, adequate bumping clearance allows for the thermal expansion of the piston and connecting rods during operation, ensuring smooth movement without risk of collision or seizure.

- Reduces Risk of Overheating:

- Sufficient clearance helps in avoiding excessive heat build-up in the cylinder head area, which can occur if the piston is too close to the head, especially in high-temperature environments like marine diesel engines.

- Improves Efficiency:

- Proper bumping clearance allows for optimal air or gas compression, improving the volumetric efficiency of compressors and maintaining the power output of engines. Incorrect clearance can lead to inefficient operation or failure to achieve the desired pressure levels.

- Ensures Smooth Operation:

- Bumping clearance helps maintain smooth operation by allowing for oil film formation between moving parts, reducing friction and wear on the piston and cylinder components.

Classes of Compressors

Positive displacement compressor

Compresses the volume of air and forces it to a smaller volume

- Rotary compressor

- Reciprocating

Centrifugal type of compressor

This type of compressor accelerates the air and. converts the energy into kinetic energy

- Centrifugal

- Axial

Reciprocating Compressor

In reciprocating type, compressor

- compressor sucks the air in the cylinder

- The piston compresses the air and expels to the discharge line.

- The valves fitted in the cylinder regulate the flow of air from the cylinder.

Types of reciprocating compressor

- Single-acting

- Double acting

Single acting

Single-acting compressor is with one discharge stroke in each revolution of the crankshaft.

Double acting

Double acting compressor is with two discharge strokes in every revolution of crankshaft.

1) Screw type

2) Reciprocating Type

3) Centrifugal Type

4) Rotary Type

5) Diaphragm Type

Use of Reciprocating Compressors.

1) Marine Engines

2) Industrial Diesel Engines

Air Compressor working principle

- A spring-loaded Non- return delivery valve operates.

- The compressed air flows through at constant pressure.

- The cycle completes the stroke.

- The differential pressure across the valve shuts the discharge valve.

- This process traps a small quantity of high-pressure air in the. clearance area between the piston and the cylinder head.

- On the induction stroke, the air in the clearance space expands.

How does a Marine compressor work?

A single crank single-acting Marine Air Compressor is the connection of- Low-pressure and high-pressure piston is tandem to a single crankpin low-pressure stage.

The external power of an Electric motor or a Diesel Engine rotates the crankshaft. Crankshaft gives drive to the piston.

In single-acting crank compressors.

The low-pressure and high-pressure pistons connects to two separate cranks. As the low-pressure piston moves down, the air sucks in through the air filter. And delivers the compressed air to the second stage through the intercooler.

During this cycle piston compresses the air in the second stage. Delievers high-pressure air to the aftercooler.

The compression process takes place during the upward and downward strokes.

As per the Arrangement, The low-pressure first-stage piston is at the top, and the high-pressure piston is at the bottom. Thus, as the piston moves up in the first stage, it compresses the air. Compressed air enters in the second stage.

The compressed air is once again pressurized in the second stage in the down stroke of the piston.

In the meantime the low-pressure side sucks. The fresh charge from the atmosphere through the filter. This process completes the cycle.

In the three-stage compressor type, the First stage sucks the air. Compresses the air and after the compression. Sends the air to intercooler for the cooling. From the IntercoolerIntercooler, the air eneters the second stage.

After compressing the air, compressed air gets in to 3rd stage

In the upward stroke of the piston, the piston compresses the air in the first and third stages. The air from the first stage enters into the second stage.

Working Principle of Multi-Stage Air Compressors

Multi-stage air compressors are designed to compress air through multiple stages, increasing efficiency and reducing the overall workload on each compression phase. The process involves compressing the air progressively in stages, with cooling between each stage to improve performance and reduce the risk of overheating.

Working Principle

- First Stage Compression:

- The air is drawn into the compressor through an inlet valve and is compressed in the first cylinder (low-pressure stage). At this stage, the air is compressed to an intermediate pressure, but its temperature increases significantly due to compression.

- Intercooling:

- After the first stage compression, the air passes through an intercooler. The intercooler cools the air to reduce its temperature, making it denser and preparing it for the next compression stage. Cooling the air increases efficiency by lowering the amount of work needed for further compression.

- Second Stage Compression:

- The cooled air is then directed to the second cylinder (high-pressure stage), where it is compressed further to a higher pressure. The reduced temperature from intercooling allows for better performance and more efficient compression in this stage.

- Aftercooling:

- After the final compression stage, the air passes through an aftercooler to reduce its temperature once again. This is necessary to ensure that the compressed air can be safely used or stored, as cooler air is less likely to cause damage to the equipment.

Advantage of Multistage compressors

- Power reduction in driving the compressor

- Enhanced mechanical balancing of the complete unit with uniform torque.

- Improved volumetric Efficiency

- Minimized losses due to leakages.

- Low working temperatures enable easy lubrication.

- Reduction in-cylinder weights.

- Due to low working temperature, could use low-cost material.

Compressor Efficiencies

- Volumetric Efficiency. Volumetric efficiency is the ratio of air discharged to the volume a displaced by piston.

- Isothermal Efficiency;- Is the ratio of isothermal power to the indicated power.

- Mechanical Efficiency- indicated power to the brake power ratio is the definition of Mechanical efficiency

Non-Return Valve on the Compressor Discharge Side

A non-return valve (also known as a check valve) is installed on the discharge side of a compressor to ensure that the compressed air or gas flows only in one direction — from the compressor to the system — and to prevent backflow into the compressor. Here’s why it’s important:

1. Prevents Backflow of Compressed Air/Gas

- The non-return valve prevents the compressed air or gas from flowing back into the compressor when it is shut down or during off-cycles. Without it, the high-pressure gas from the system could flow back into the low-pressure side of the compressor, potentially damaging the compressor.

2. Protects the Compressor

- When a compressor is not running, the discharge line is still pressurized. If a non-return valve is not present, the pressurized air could backflow into the compressor cylinders or other internal parts, which can cause mechanical damage, overheating, or even force the compressor to rotate in reverse.

3. Maintains System Pressure

- The non-return valve ensures that system pressure is maintained by preventing the escape of pressurized air or gas from the system back into the compressor when it’s not in operation.

4. Improves Energy Efficiency

- By preventing backflow, the non-return valve helps maintain the compressor’s efficiency. If backflow occurs, the compressor would have to work harder and longer to repressurize the system, leading to increased energy consumption.

5. Ensures Safe Operation

- Non-return valves play a key role in ensuring the safe operation of the compressor and the overall system. Backflow of high-pressure air or gas could create safety hazards, including overheating or causing system components to fail under pressure.

6. Protects Other Components

- Other downstream components, such as air receivers, dryers, or filters, can be damaged by reverse flow. The non-return valve prevents backflow from damaging these components by isolating the compressor from the pressurized system when it’s off.

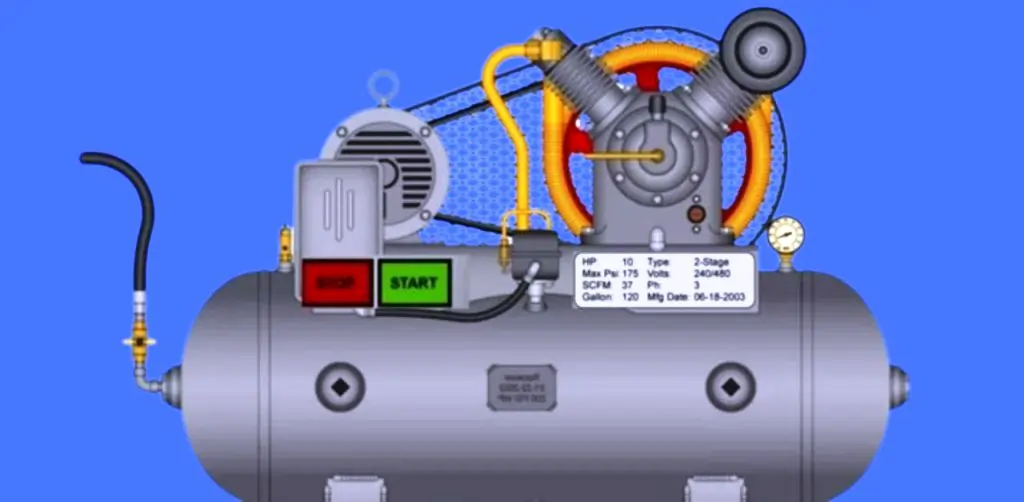

Components of Marine Air Compressor

Safety devices on Air Compressor

Relief valve on HP and LP stage.

Intercooler bursting disc( water side)

After cooler fusing plug

Auto Moisture drain valve

Cooling water supply failure alarm

Low lubricating pressure alarm

Crankcase lube oil pump relief valve

Discharge air high temperature cut out alarm.

Starting procedure of a Marine Air Compressor

- Always keep the Marine Air Compressor unloading system in on position.

- Turn the supply of cooling water on and check the flow and inlet pressure of cooling water.

- Rotate the wheel drive belt by few turns for the freeness. This action is mandatory for the compressor starting after a prolonged period.

- Check the oil level and operate the force-feed lubricator for around 8 to 10 turns.

- Ensure the availability of lube oil to cylinders.

- Check the oil level in the sump and top up if needed.

- Position of the safety shut down switches in normal working condition.

- Drain the condensate from the intercooler and aftercooler.

- Ensure the V belt is tight as per norms.

- Open the stop valve for the air to flow to the air bottle/receiver.

- Press on the button from the control panel to start the compressor.

- Watch the oil pressure with the pressure gauge. stop the compressor immediately If the indicator is not showing the proper pressure.

- Check the lubricating oil flow from the lubrication pump.

- Put the compressor load after 5 minutes of satisfactory operation.

- Check the water flow to the cylinder and coolers.

- The inter-stage pressure should be within range.

- Check and rectify leakages in the system.

- The voltage at each terminal must be as per the specified levels.

- Check the discharge air temperature. The greatest permitted air outlet temperature is 75Deg C.

- Check and tighten the fasteners at regular intervals of operation.

- Listen to the abnormal noises and take immediate action. if any obnoxious noise is present.

Stopping procedure of a Marine Air Compressor

- Unload the compressor with the help of the installed control/ device

- Run the compressor at idle for 5minutes.

- Stop the compressor

- Close the cooling water supply

- Drain the condensate from the points.

- Isolate the power supply to the starter.

How to make a Marine Air Compressor more efficient?

- Supply the cool air to comressor for better efficiency.

- Clean the air filters at correct interval.

- Maitain the Compressor valves.

- The manometer instrument across the filter should be in good condition.

- Reduce the compressor low load operations.

- clean the inter coolers as per schedule or is the air temperature increases..

- Conduct the free air delivery test and compare with the compressor design data.

- Keep Option of Multistage compressor as far as possible.

- Regulate the delivery pressure.

- Maitain the closer range between load and unload.

The key points of the Marine Air Compressor efficiency

- Regulate the drain frequency.

- Check and take the action on logbook abnormal records.

- Carry out periodic leakage test.

- Install the solenoid valve to interlock and cutoff the machine if not in use.

- Maintain all the pneumatic tools with proper lubrication.

- Discourage the improper use of compressed air for cleaning the body and floor.

- Maintain the correct operating pressure of instruments to prevent waste of air.

- Replace the tools with tools operating on electricity.

- Try to use welded connections.

- Always use ball or gate valves.

Why Reduce the Temperature of Air After the First Stage?

After the first stage of compression, the air temperature rises significantly. Reducing the temperature of the air before it enters the second stage of compression is crucial because cooler air is denser, making it easier to compress. By cooling the air, less work is required during the subsequent stage, improving the overall efficiency of the compression process.

Advantages of Intercooling in the Second Stage

Intercooling between the stages of a compressor provides several advantages:

- Increased Efficiency: Cooling the air before the second stage reduces the work required for compression, leading to energy savings.

- Lower Discharge Temperature: Intercooling prevents excessive temperature buildup, protecting components from thermal stress.

- Improved Performance: Cooler air allows for more effective compression in the second stage, contributing to better overall compressor performance.

Requirement for an Aftercooler in a Compressor

An aftercooler is essential in compressors to lower the temperature of the compressed air before it is used or stored. The aftercooler reduces the risk of moisture condensation in the air distribution system, which can lead to corrosion or damage to pneumatic tools and machinery. Additionally, lowering the air temperature ensures safer operation and increases the lifespan of the compressor and downstream equipment.

How to Test Low Lube Oil Pressure and High Air Temperature Trips in a Compressor

Procedure to Check Low Lube Oil Pressure Trip:

- Ensure Safety and Preparation:

- Ensure the compressor is isolated from the system.

- Inform relevant personnel about the testing procedure.

- Wear appropriate personal protective equipment (PPE) and follow standard safety procedures.

- Simulate Low Oil Pressure:

- To simulate low oil pressure, you can either manually reduce the oil pressure by throttling the oil supply or drain oil from the system temporarily (only for testing).

- Some compressors are equipped with test buttons or systems to artificially lower the oil pressure without affecting the system. Use this method if available.

- Observe the Alarm and Trip:

- Monitor the pressure gauge as the pressure drops.

- The low lube oil pressure alarm should activate when the oil pressure reaches the preset trip value.

- The compressor should automatically shut down once the oil pressure falls below the safe operating threshold.

- Check the Trip Reset:

- Once the compressor has tripped, reset the trip system by restoring oil pressure and resetting the control panel.

- Ensure the system is operating normally before restarting the compressor.

- Inspect and Test Sensors:

- Check the pressure sensors or switches for proper calibration. Ensure the trip is triggered at the correct set point as recommended by the manufacturer.

- If necessary, recalibrate or replace faulty sensors.

Procedure to Check High Air Temperature Trip:

- Ensure Safety and Preparation:

- Confirm that the compressor is isolated from the system and all safety protocols are followed.

- Ensure adequate ventilation and protection in case the compressor overheats.

- Simulate High Temperature:

- Manually simulate high air temperature by gradually restricting airflow or increasing the load to cause a temperature rise. If the compressor has a test switch for high temperature, use it to simulate the fault without causing actual overheating.

- Alternatively, some systems allow for sensor manipulation by applying external heat to the temperature sensor (e.g., using a heat gun) to simulate a rise in air temperature.

- Monitor the Temperature and Alarm:

- Observe the air temperature gauge and wait for the temperature to reach the pre-set trip level.

- The high air temperature alarm should activate as the temperature approaches the dangerous limit.

- Once the temperature exceeds the safe limit, the compressor should trip automatically to prevent damage.

- Inspect and Test Temperature Sensors:

- After tripping, inspect the temperature sensors or thermocouples to ensure they are functioning correctly.

- Verify that the trip is occurring at the correct temperature as per the manufacturer’s settings.

- Reset the Trip:

- Allow the compressor to cool down if it was heated manually.

- Reset the high-temperature trip system by adjusting the temperature back to normal operating levels and resetting the trip on the control panel.

- Restart the Compressor:

- Once all parameters are back to normal, restart the compressor and ensure smooth operation.

Important Points:

- Always follow the manufacturer’s guidelines for trip set points and test procedures.

- Periodically check and calibrate all pressure and temperature sensors to ensure reliable operation.

- Document the test results and ensure that all safety mechanisms are functioning as intended.

General Problem of Marine Air Compressor on Ship

Pressure Test of Air Compressor

Carry out the hydraulic test on Cylinders, cylinder cover, Inter & After coolers

- Air Side: 1.5 x max. Working Pressure.

- Water Side: 4 bar or 1.5 x max. WP (whichever is greater)

Blog Conclusion

In conclusion, a marine air compressor is a crucial tool for anyone who owns a boat or yacht. It allows for the inflation of life jackets, fenders, and other important safety equipment, as well as powering air tools and other devices on board.

When choosing a marine air compressor, it’s important to consider factors such as power output, tank size, and noise level. A compressor with a high CFM rating and large tank size will provide ample power and allow for longer periods of use, while a quieter compressor will minimize noise pollution on board.

Additionally, it’s important to consider the type of power source required for the compressor, such as AC or DC power, and whether it comes with features such as an automatic shut-off or moisture trap to ensure safe and efficient operation.

Overall, investing in a quality marine air compressor is a wise choice for any boat or yacht owner, as it will ensure the safety and comfort of all on board, while also providing the power necessary to complete a wide range of tasks and projects.