An Automatic Voltage Regulator (AVR) is a crucial device that regulates and stabilizes voltage in an electrical system. By automatically adjusting voltage levels, it ensures a consistent power supply to connected devices, safeguarding them from fluctuations and promoting efficient operation.

Understanding Automatic Voltage Regulators (AVRs)

Definition: What is an Automatic Voltage Regulator?

An Automatic Voltage Regulator (AVR) is a device designed to maintain a constant voltage level to electrical equipment. It ensures that the voltage output remains within a desired range, protecting sensitive devices from voltage fluctuations that can cause damage or affect performance. AVRs are essential in various applications, from industrial machinery and medical equipment to household appliances and computer systems, where stable power supply is critical.

The Working Principle of a Voltage Regulator

Many electrical appliances contain coil components that generate eddy currents during the initial stage of energization. These eddy currents hinder the flow of current, weakening the instantaneous voltage at startup, resulting in a slow start. Additionally, they can strengthen the instantaneous voltage after a circuit break, potentially causing sparks that may damage the circuit. To ensure the normal operation of the circuit and protect it from such issues, a voltage regulator is essential.

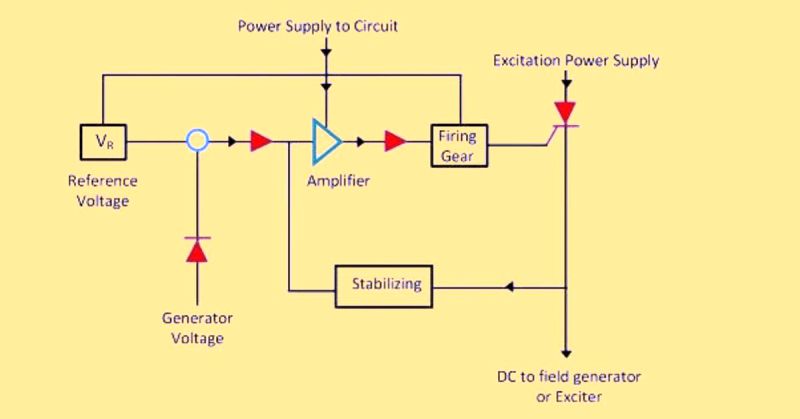

A voltage stabilizer consists of three main components: a voltage regulating circuit, a control circuit, and a servo motor. When there are changes in the input voltage or load, the control circuit performs sampling, comparison, and amplification. It then drives the servo motor to adjust the position of the carbon brush on the voltage regulator. This adjustment changes the coil turns ratio, thereby maintaining a stable output voltage. For larger capacity voltage regulators, the principle of voltage compensation is also employed to ensure consistent voltage levels.

By automatically adjusting the voltage to the desired level, voltage regulators protect electrical appliances from the adverse effects of voltage fluctuations, ensuring efficient and safe operation.

Components: Key Components of an AVR and Their Roles

- Sensing Circuit: The sensing circuit monitors the input voltage and detects any deviations from the desired voltage range. It sends this information to the control circuit, enabling real-time adjustments.

- Control Circuit: The control circuit processes the data from the sensing circuit and determines the necessary corrective action. It sends signals to the regulating components to either increase or decrease the voltage.

- Voltage Regulator: The voltage regulator is the core component that adjusts the voltage. It can include components such as transformers, relays, and electronic switches that work together to maintain the output voltage within the desired range.

- Feedback Mechanism: The feedback mechanism provides continuous monitoring and adjustment. It ensures that the AVR responds accurately to any changes in input voltage, maintaining consistent power stability.

- Protective Components: These include fuses, surge protectors, and circuit breakers that protect the AVR and connected devices from potential damage due to extreme voltage variations or electrical faults.

Achieving 23% Power Stability with AVRs

Technical Explanation: How AVRs Maintain Voltage Within a 23% Range

Automatic Voltage Regulators (AVRs) are designed to ensure that the voltage supplied to electrical equipment remains stable within a 23% range. They achieve this by continuously monitoring the input voltage and making real-time adjustments. When fluctuations occur, the AVR’s control circuit samples and compares the input voltage against the desired output voltage. The circuit then amplifies any discrepancies and drives the servo motor to adjust the position of the carbon brush on the voltage regulator. This adjustment alters the coil turns ratio, thereby stabilizing the output voltage. The precision of this process allows AVRs to maintain voltage within the critical 23% range, protecting sensitive equipment from damage due to over-voltage or under-voltage conditions.

Case Studies: Real-World Examples of AVRs Achieving 23% Stability in Various Applications

- Medical Equipment in Hospitals: In hospitals, maintaining stable power supply is crucial for the operation of sensitive medical equipment such as MRI machines and life-support systems. An AVR installed in a hospital’s power system successfully maintained voltage stability within 23%, ensuring the uninterrupted operation of critical medical devices and enhancing patient safety.

- Data Centers: Data centers require a stable power supply to prevent data loss and hardware damage. An AVR system implemented in a major data center provided consistent voltage regulation, maintaining stability within the 23% range. This not only protected the servers and storage devices but also improved the overall efficiency and reliability of the data center operations.

- Industrial Machinery: In manufacturing plants, stable power is essential for the smooth operation of machinery. An AVR installed in an automotive manufacturing plant maintained voltage stability within 23%, preventing production downtimes and reducing maintenance costs due to voltage-related equipment failures.

Comparison: Comparing the Performance of AVRs with Other Voltage Regulation Solutions

Compared to other voltage regulation solutions, AVRs offer superior performance in maintaining precise voltage stability. Traditional voltage stabilizers, while effective, often lack the real-time adjustment capability that AVRs provide. This can result in slower response times to voltage fluctuations and less precise control over the output voltage. Static voltage regulators (SVRs), another alternative, can maintain voltage stability but are typically less effective in handling sudden and significant changes in load conditions.

AVRs, with their advanced control circuits and servo motors, offer a more dynamic and responsive solution. They continuously monitor and adjust the voltage, ensuring that even minor fluctuations are corrected promptly. This results in a higher level of protection for sensitive equipment, making AVRs the preferred choice for applications requiring stringent voltage stability within a 23% range.

Benefits of Using AVRs

Increased Lifespan of Equipment

Automatic Voltage Regulators (AVRs) play a crucial role in protecting and extending the life of electrical devices. By maintaining a stable voltage level, AVRs prevent the harmful effects of voltage fluctuations, such as over-voltage and under-voltage conditions, which can cause significant wear and tear on electronic components. This protection ensures that sensitive equipment, from industrial machinery to household appliances, operates within safe voltage ranges, thereby reducing the risk of damage. Consequently, the lifespan of these devices is significantly increased, as they are shielded from the stress and strain caused by unstable power supply.

Cost Savings

One of the most compelling benefits of using AVRs is the potential for cost savings. Stable voltage provided by AVRs minimizes the need for frequent repairs and replacements of electrical devices, leading to reduced maintenance costs. Additionally, by ensuring optimal performance of electrical equipment, AVRs contribute to energy efficiency. Devices operating under stable voltage conditions consume power more efficiently, reducing overall energy costs. These savings can be substantial, especially in settings with numerous high-value electrical assets, such as industrial plants or large commercial buildings.

Enhanced Performance

AVRs not only protect equipment but also enhance the overall performance and reliability of electrical systems. Stable voltage ensures that devices operate at their intended efficiency levels, without the disruptions caused by power fluctuations. This consistent performance is particularly important in environments where precision and reliability are critical, such as in medical facilities, data centers, and manufacturing plants. By providing a steady and reliable power supply, AVRs help maintain optimal operational conditions, thereby boosting productivity and ensuring that processes run smoothly without unexpected interruptions.

Choosing the Right AVR for Your Needs

Factors to Consider

When selecting an Automatic Voltage Regulator (AVR), several key factors should be considered to ensure you choose the right one for your needs:

- Voltage Range: Determine the input voltage range that the AVR needs to handle. Ensure the AVR can accommodate fluctuations in your power supply.

- Load Capacity: Consider the total load the AVR will support. Ensure the AVR’s capacity matches or exceeds the combined power requirements of all connected devices.

- Response Time: Evaluate the AVR’s response time to voltage fluctuations. Faster response times provide better protection for sensitive equipment.

- Regulation Accuracy: Look for AVRs with high regulation accuracy to maintain voltage within a narrow range, ensuring stable power supply.

- Features and Functionality: Consider additional features such as surge protection, noise filtering, and user-friendly interfaces for monitoring and control.

- Reliability and Durability: Choose an AVR from a reputable brand known for reliability and long-term performance.

Top Brands and Models

Here are some top AVR brands and models renowned for their stability and performance:

- APC by Schneider Electric: Known for reliable AVRs with advanced features, APC models like the APC Line-R series offer excellent voltage regulation and surge protection.

- Tripp Lite: Offers a range of AVRs, such as the Tripp Lite LC2400, known for robust performance, multiple outlets, and comprehensive surge protection.

- Eaton: Eaton’s AVR models are celebrated for their industrial-grade reliability, making them suitable for both commercial and residential applications.

- CyberPower: Known for affordable and efficient AVRs, CyberPower models like the CyberPower AVR Series provide dependable voltage regulation and user-friendly interfaces.

- Emerson: Emerson AVRs are highly regarded for their precision and reliability, often used in critical applications requiring stringent voltage control.

Installation and Maintenance Tips

Proper installation and maintenance of your AVR are crucial to ensure its optimal performance and longevity:

- Location: Install the AVR in a well-ventilated, dry, and dust-free environment to prevent overheating and contamination.

- Correct Sizing: Ensure the AVR is appropriately sized for your load. Overloading an AVR can lead to failure and inadequate voltage regulation.

- Wiring and Connections: Use high-quality wiring and secure connections to prevent electrical faults and ensure stable operation.

- Regular Inspection: Periodically inspect the AVR for any signs of wear, damage, or loose connections. Regular checks help identify and address potential issues before they escalate.

- Cleaning: Keep the AVR clean and free from dust and debris. Regularly clean the unit using appropriate methods to prevent overheating and maintain efficient operation.

- Professional Servicing: For complex maintenance or repairs, engage professional technicians to ensure the AVR continues to operate effectively and safely.

Modern Innovations in AVR Technology

Smart AVRs: Introduction to Smart AVRs with Advanced Features

The evolution of Automatic Voltage Regulators (AVRs) has led to the development of smart AVRs, which incorporate advanced features for enhanced performance and user convenience. Smart AVRs are equipped with digital controls and microprocessors that offer precise voltage regulation and real-time monitoring capabilities. These advanced devices can automatically adjust voltage levels with greater accuracy and speed, ensuring optimal power stability. Smart AVRs often come with features such as remote monitoring, data logging, and automatic diagnostics, which provide users with comprehensive insights into their power systems. This level of sophistication makes smart AVRs ideal for applications where reliability and precision are paramount, such as in critical infrastructure and high-tech industries.

Integration with IoT: How AVRs Are Integrating with IoT for Better Monitoring and Control

The integration of AVRs with the Internet of Things (IoT) is revolutionizing voltage regulation by providing enhanced monitoring and control capabilities. IoT-enabled AVRs can communicate with other connected devices and systems, allowing for seamless data exchange and centralized management. This connectivity enables users to monitor voltage levels, track performance metrics, and receive alerts about potential issues from anywhere, using smartphones or other internet-enabled devices. IoT integration also allows for predictive maintenance, where data analytics can identify patterns and predict failures before they occur, minimizing downtime and improving efficiency. By leveraging IoT technology, AVRs become part of a smart grid, contributing to more efficient and resilient power management.

Future Trends: Emerging Trends and Technologies in Voltage Regulation

As technology continues to advance, several emerging trends are shaping the future of voltage regulation:

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms are being incorporated into AVRs to enhance their ability to predict and respond to voltage fluctuations. These intelligent systems can learn from historical data and optimize voltage regulation strategies for improved performance.

- Energy Efficiency and Sustainability: There is a growing emphasis on developing AVRs that are more energy-efficient and environmentally friendly. Innovations in materials and design are leading to AVRs that consume less power and have a smaller environmental footprint.

- Wireless Communication: Future AVRs are likely to incorporate more advanced wireless communication technologies, enabling even greater flexibility and ease of installation. Wireless AVRs can be easily integrated into existing power systems without the need for extensive wiring.

- Enhanced Cybersecurity: As AVRs become more connected through IoT, ensuring the security of these devices is crucial. Future developments will focus on enhancing the cybersecurity features of AVRs to protect against potential cyber threats and ensure the integrity of power systems.

- Scalability and Modularity: The next generation of AVRs will be designed to be more scalable and modular, allowing users to easily upgrade and expand their voltage regulation capabilities as their needs evolve.

Troubleshooting Common AVR Issues

| Aspect | Details |

|---|---|

| Identifying Problems | Common issues faced with AVRs and how to identify them |

| Issue: Voltage Fluctuations | |

| Identification: Equipment experiencing erratic behavior or performance drops | |

| Issue: Overheating | |

| Identification: AVR unit feels excessively hot to the touch, or shuts down intermittently | |

| Issue: Unusual Noises | |

| Identification: Hearing humming, buzzing, or clicking sounds from the AVR unit | |

| Issue: Burnt Smell or Visible Damage | |

| Identification: Detecting a burnt odor or seeing scorch marks on the AVR | |

| Issue: Inconsistent Output Voltage | |

| Identification: Measuring output voltage reveals significant deviations from the expected range | |

| Solutions and Repairs | Practical solutions and repair tips for common AVR problems |

| Solution for Voltage Fluctuations | |

| Steps: Check input voltage stability, ensure proper grounding, inspect for loose connections | |

| Solution for Overheating | |

| Steps: Improve ventilation around the AVR, clean dust from vents and fans, check for overloading | |

| Solution for Unusual Noises | |

| Steps: Tighten loose components, inspect internal parts for wear, lubricate moving parts if needed | |

| Solution for Burnt Smell or Visible Damage | |

| Steps: Disconnect the AVR immediately, inspect for burnt components, replace damaged parts | |

| Solution for Inconsistent Output Voltage | |

| Steps: Calibrate the AVR, check and replace worn-out brushes, ensure proper load balancing | |

| When to Replace | Signs that it’s time to replace your AVR |

| Sign: Frequent Failures | |

| Explanation: If the AVR fails frequently despite repairs, it may be time for a replacement | |

| Sign: Inability to Maintain Voltage Stability | |

| Explanation: If the AVR cannot maintain stable voltage within the required range, consider replacing | |

| Sign: Obsolete Technology | |

| Explanation: If the AVR uses outdated technology and lacks modern features, upgrading is advisable | |

| Sign: Excessive Repair Costs | |

| Explanation: If repair costs exceed the cost of a new AVR, replacement is more economical | |

| Sign: Physical Deterioration | |

| Explanation: Visible wear and tear, corrosion, or damage to the AVR casing indicate replacement need |

Conclusion

In conclusion, Automatic Voltage Regulators (AVRs) are indispensable for maintaining a stable power supply, protecting sensitive equipment, and enhancing operational efficiency. By understanding their working principles, benefits, and modern innovations, you can make informed decisions about selecting and maintaining the right AVR for your needs. Whether you’re safeguarding medical devices, ensuring the reliability of data centers, or optimizing industrial machinery, AVRs provide the stability and protection essential for smooth operations. Embrace the advancements in AVR technology to future-proof your electrical systems and achieve unparalleled power stability.

FAQ on Automatic Voltage Regulator

Q: What is the main function of an Automatic Voltage Regulator (AVR)?

A: It maintains a constant voltage level.

Q: How does an AVR enhance the lifespan of electrical devices?

A: It prevents damage from voltage fluctuations.

Q: Can AVRs be integrated with modern technologies like IoT?

A: Yes, for advanced monitoring and control.

Q: What are the signs that an AVR needs to be replaced?

A: Frequent failures, unstable voltage, outdated tech, high repair costs, and physical wear.