Bearing Puller

Choosing the right bearing puller is crucial for any maintenance or repair task involving bearings. The wrong tool can lead to damaged components, increased downtime, and even safety hazards. Whether you’re a seasoned professional or a DIY enthusiast, understanding how to select the best bearing puller can make all the difference in the efficiency and success of your work.

In this post, we’ll walk you through five powerful tips that will help you identify the perfect bearing puller for your needs. From understanding different puller types to considering essential factors like durability and compatibility, these tips are designed to ensure that you make an informed choice every time. By the end of this post, you’ll be equipped with the knowledge to confidently choose a bearing puller that enhances your workflow and safeguards your equipment.

Tip 1: Understand the Types of Bearing Pullers

When it comes to selecting the right bearing puller, understanding the various types available and their specific applications is crucial. Each type of bearing puller is designed to handle different scenarios, and knowing these distinctions can save you time, effort, and potential damage to your equipment.

Overview of Different Bearing Pullers

- Two-Jaw Pullers: Versatile tools with two arms that grip the bearing from opposite sides. Ideal for smaller bearings and limited access situations.

- Three-Jaw Pullers: These provide a more secure grip with three arms, distributing force evenly. Perfect for larger or tightly-fitted bearings where extra leverage is needed.

- Slide Hammer Pullers: Designed for use in tight or recessed areas, these pullers use a slide hammer to apply strong, outward force, making them ideal for bearings that can’t be accessed with traditional pullers.

Importance of Knowing the Types

Knowing the different types of bearing pullers allows you to select the most effective tool for your specific job, preventing inefficient work and avoiding potential damage. For example, choosing the correct puller type ensures that you apply the right amount of force in the right manner, which minimizes the risk of slippage, equipment damage, or even personal injury. This knowledge equips you to make the right choice, ensuring that your maintenance tasks are carried out smoothly and safely, ultimately protecting both your tools and your machinery.

Tip 2: Consider the Bearing Size and Fit

Selecting the correct bearing puller isn’t just about the type; it’s also crucial to match the puller size to the bearing size. A mismatch can lead to inefficient work, potential damage, or even the failure to remove the bearing altogether. Understanding how to properly assess and match the puller to the bearing size ensures that the removal process is both safe and effective.

How to Match the Puller Size to the Bearing Size

The size of the bearing puller should be directly proportional to the size of the bearing you need to remove. The arms of the puller must be long enough to reach around the bearing without slipping, and the pulling mechanism should generate sufficient force to dislodge the bearing without excessive strain on the tool or the bearing itself.

To determine the appropriate puller size, you can use the following simple formula:

Puller Size Selection Formula

Puller Jaw Length≥Bearing Radius+Clearance

Where:

- Puller Jaw Length: The length of the puller’s arms or jaws, which should be long enough to reach around the bearing and apply force effectively.

- Bearing Radius: Half of the outer diameter of the bearing, representing the distance from the center to the outer edge.

- Clearance: An additional margin to account for any obstructions or recessed positions, ensuring that the puller can grip the bearing securely.

Practical Advice on Measuring and Selecting Based on Bearing Dimensions

- Measure the Bearing’s Outer Diameter: Start by measuring the outer diameter of the bearing. This measurement will help you determine the jaw size required for the puller. The jaws should be able to grip the bearing securely without slipping off during the pulling process.

- Calculate the Bearing Radius: Divide the bearing’s outer diameter by 2 to find the bearing radius.

- Estimate the Required Clearance: Assess any space constraints around the bearing, such as obstructions or recesses, and add a margin (typically a few millimeters to centimeters, depending on the application).

- Select the Puller Based on the Formula: Choose a puller with jaw length equal to or greater than the sum of the bearing radius and the clearance. For example, if a bearing has an outer diameter of 100 mm, the bearing radius is 50 mm. If there’s an obstruction or recess requiring an additional 10 mm of clearance, then the puller jaw length should be at least 60 mm.

Tip 3: Prioritize Durability and Build Quality

When selecting a bearing puller, durability and build quality should be top priorities. A well-constructed puller made from high-quality materials not only ensures a longer lifespan but also provides the strength and reliability needed to perform demanding tasks without the risk of failure. Investing in a durable bearing puller is crucial to avoid costly repairs, downtime, and potential safety hazards.

Importance of Material and Construction in a Bearing Puller

The material and construction of a bearing puller are critical factors that determine its strength, durability, and overall performance. Bearing pullers are subjected to significant force during operation, and the quality of the materials used directly impacts the tool’s ability to withstand this force without bending, breaking, or wearing out prematurely.

A bearing puller made from substandard materials may fail under pressure, leading to damage to both the tool and the bearing, and potentially causing injury. In contrast, a puller made from high-grade materials and constructed with precision will maintain its integrity over time, providing consistent performance and ensuring safe and efficient bearing removal.

Guidance: What to Look for in Terms of Materials and Design

- Material Quality:

- Forged Steel: Look for pullers made from forged steel, as this material is known for its exceptional strength and durability. Forged steel can withstand the high levels of stress and force applied during the bearing removal process without deforming or breaking.

- Hardened Alloy Steel: Another excellent option is hardened alloy steel, which offers a perfect balance of strength, toughness, and resistance to wear and tear. This material is particularly suitable for heavy-duty applications where the puller is subjected to frequent use.

- Construction:

- Precision Machining: Ensure that the puller components are precisely machined to fit together seamlessly. Precision machining enhances the puller’s performance by reducing the risk of slippage and ensuring even distribution of force during operation.

- Reinforced Jaws: The jaws of the puller should be reinforced and designed to grip the bearing securely. Look for pullers with thick, sturdy jaws that can withstand high pressure without bending or slipping.

- Robust Central Screw or Hydraulic Mechanism: The central screw or hydraulic mechanism, which is responsible for applying the pulling force, should be robust and made from high-strength materials. This component must be able to generate and withstand significant force without stripping or failing.

- Coating and Finish:

- Corrosion Resistance: Choose a puller with a corrosion-resistant coating or finish, such as black oxide or chrome plating. This coating protects the tool from rust and corrosion, especially in environments where it may be exposed to moisture or chemicals.

- Smooth Finish: A smooth finish on the puller’s surfaces reduces friction and wear, enhancing the tool’s longevity and making it easier to clean and maintain.

Tip 4: Ensure Compatibility with Your Equipment

Selecting the right bearing puller is not just about choosing a tool with the correct size and durability; it’s also essential to ensure that the puller is compatible with the specific equipment or machinery you’re working on. A puller that isn’t designed for your particular application can lead to inefficiencies, damage to both the tool and the machine, and potential safety hazards. Ensuring compatibility is key to performing maintenance tasks smoothly and effectively.

The Need to Match the Puller with Specific Equipment or Machine

Different types of machinery and equipment come with varying designs, bearing sizes, and configurations. This diversity means that a bearing puller suitable for one machine might not be effective or safe for another. For instance, industrial machinery might require heavy-duty pullers with enhanced force capacity, while automotive applications might need more compact pullers designed for tighter spaces. Matching the puller to the equipment ensures that the tool can perform the task without causing damage to the machinery or compromising safety.

Using an incompatible puller can result in improper alignment, inadequate force application, and even damage to the bearing housing or surrounding components. Moreover, it can lead to inefficient work, increased downtime, and added costs for repairs or replacements. Therefore, compatibility is not just a matter of convenience but a crucial factor in ensuring the success and safety of your maintenance operations.

Tips: How to Check for Compatibility with Different Machinery

- Review Equipment Specifications:

- Start by checking the manufacturer’s specifications for the machinery you’re working on. These specifications often include details about the bearing sizes and the recommended tools for maintenance tasks. Cross-reference these details with the puller’s specifications to ensure a proper match.

- Assess the Bearing Type and Location:

- Identify the type of bearing and its location within the equipment. Some bearings are situated in tight, hard-to-reach areas, while others may require special pullers, such as hydraulic or slide hammer types. Make sure the puller you choose can access and engage the bearing without obstruction.

- Consider the Machine’s Structural Design:

- Examine the machine’s structure, including any surrounding components that might interfere with the puller’s operation. For example, if the bearing is located in a confined space, you might need a puller with a more compact design or adjustable arms that can fit within the available space.

- Check the Puller’s Force Capacity:

- Ensure that the puller’s force capacity matches the requirements of the bearing removal task. Heavy-duty industrial machinery might need pullers that can generate higher pulling forces, while smaller equipment might only require a standard puller. Using a puller with insufficient force can lead to incomplete bearing removal, while excessive force might damage the equipment.

- Test Fit Before Use:

- Before fully committing to the bearing removal, do a test fit of the puller on the equipment. Ensure that the jaws align properly with the bearing and that the tool can be securely fastened. This step helps confirm that the puller will operate effectively without slipping or misaligning during use.

- Consult Equipment Manuals or Experts:

- If you’re unsure about compatibility, consult the equipment’s manual or speak with an expert who is familiar with the specific machinery. They can provide guidance on the appropriate tools and any potential issues to watch out for.

Tip 5: Apply the Puller Selection Formula

Selecting the right bearing puller involves more than just picking a tool off the shelf. To make an informed choice, you can apply a simple formula that takes into account key factors such as bearing size, accessibility, tool compatibility, and the required force for the task. This formula helps you identify the most suitable puller for your specific needs, ensuring efficiency and safety in your maintenance work.

Puller Selection Formula

This formula provides a straightforward way to determine the appropriate puller by balancing the physical size of the bearing and the working environment (accessibility) against the tool’s compatibility with the equipment and the force needed to remove the bearing.

Explanation: Breaking Down the Formula

- Bearing Size: The size of the bearing, specifically its diameter, is the first consideration. Larger bearings require pullers with longer arms and stronger mechanisms to apply the necessary force effectively.

- Accessibility: This refers to the space around the bearing. If the bearing is in a tight or recessed area, you’ll need a puller that can fit and operate within those constraints. Accessibility often dictates the type of puller you choose (e.g., slide hammer for tight spaces).

- Tool Compatibility: This factor ensures that the puller is suitable for the specific type of bearing and machine you’re working on. Not all pullers are designed to work with all types of bearings or machinery, so compatibility is crucial to avoid damage and ensure effective operation.

- Required Force: The amount of force needed to remove the bearing is another critical consideration. Heavier, tightly fitted bearings require pullers that can generate sufficient force without breaking or damaging the tool or the bearing.

Subsection: Applying the Formula

- Bearing Size:

- Measure the outer diameter of the bearing. For instance, if the bearing has a diameter of 150 mm, this is your baseline for choosing a puller with arms that can securely grip the bearing.

- Accessibility:

- Assess the space around the bearing. If the bearing is located in a confined space with only 30 mm of clearance, you’ll need a puller with a compact design or adjustable arms that can fit within this space.

- Tool Compatibility:

- Ensure the puller is designed for the specific type of bearing and machine. If you’re working on a large industrial machine, a heavy-duty puller designed for industrial applications is necessary.

- Required Force:

- Estimate the force needed to remove the bearing. If the bearing is tightly fitted, requiring significant force, you’ll need a puller with a high force capacity, such as a hydraulic puller.

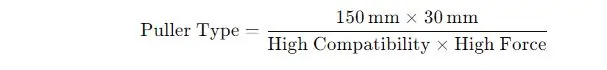

Practical Example: Applying the Formula

Let’s say you need to remove a bearing with a 150 mm diameter that is located in a tight space with 30 mm of clearance. The bearing is on an industrial machine, so you need a heavy-duty puller. The bearing is tightly fitted, requiring a significant amount of force.

Applying the formula:

In this scenario, you would select a heavy-duty, compact hydraulic puller with adjustable arms that can fit into the tight space, securely grip the 150 mm bearing, and apply the necessary force to remove it safely.

FAQ on “Bearing Puller”

Q: What is a bearing puller used for?

A: A bearing puller is used to remove bearings from a shaft or housing safely.

Q: How do I choose the right bearing puller?

A: Match the puller to the bearing size, accessibility, and force required.

Q: Can a bearing puller damage the bearing?

A: Yes, if not used correctly or if the puller is incompatible with the bearing.

Q: What materials should a durable bearing puller be made from?

A: Look for pullers made from forged or hardened steel for durability.

Conclusion

Choosing the right bearing puller is crucial to the success and safety of your maintenance tasks. By following the five powerful tips outlined in this post, you can ensure that you select the best tool for the job. First, understand the different types of bearing pullers and their applications to make an informed choice. Next, consider the bearing size and fit, using the puller selection formula to match the tool to your specific needs. Prioritize durability and build quality to invest in a tool that will last, and ensure compatibility with your equipment to avoid inefficiencies and damage. Finally, apply the puller selection formula to balance all these factors and confidently choose the right puller every time.

Now that you’ve learned these essential tips, take a moment to evaluate your current tools. Are they up to the task, or is it time for an upgrade? By considering the insights and formula provided, you can make informed decisions that enhance your work efficiency and protect your valuable equipment. Don’t wait—assess your toolkit today and invest in the right bearing puller to ensure smooth and successful maintenance operations.