Best Inverter Welder

Inverter welding machines are a type of welding machine. They use motors, inverters, and other electric power sources to quickly heat up and switch between two kinds of welding energy – DC and AC, or DC and AC currents. Such power sources are popular in the market, as they are more reliable and efficient than the older welding machines. Because of their increasing popularity, the market constantly needs new models.

Inverter machines are used for DG maintenance also. This post will cover the use and help them find the right product for their needs.

Key Capacity Formulas for Inverter Welders

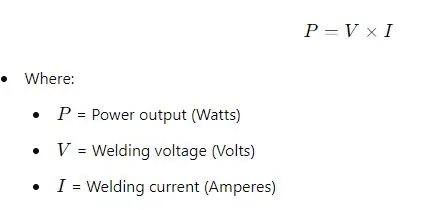

1. Welding Power Output:

This formula calculates the power output of the inverter welder, which is crucial for determining its capacity to handle various welding tasks.

Formula:

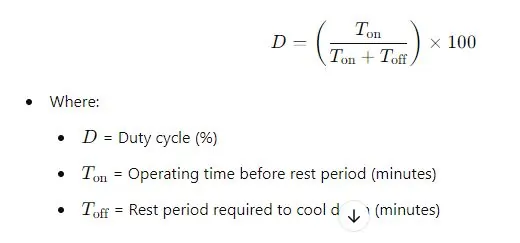

2. Duty Cycle:

The duty cycle indicates how long the inverter welder can operate at a given current without overheating, expressed as a percentage.

Formula:

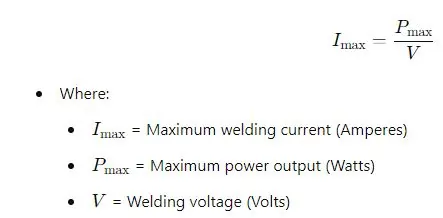

3. Maximum Welding Current Capacity:

This formula determines the maximum welding current the inverter welder can provide, which is essential for understanding its capability for different welding applications.

Formula:

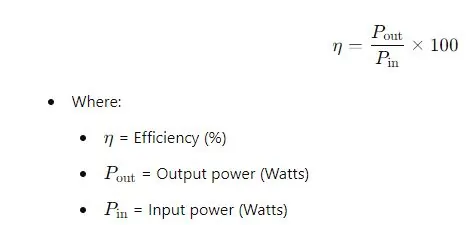

4. Efficiency of the Inverter Welder:

This formula calculates the efficiency of the inverter welder, indicating how effectively it converts input power into welding power.

Formula:

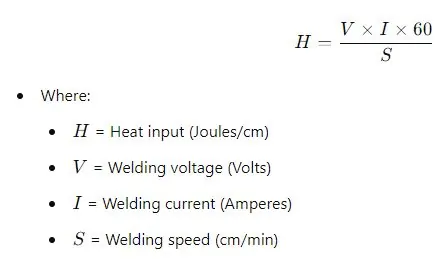

5. Heat Input:

This formula calculates the heat input during welding, which affects the weld quality and penetration.

Formula:

How do Inverter Welders operate?

In its simplest terms, inverter technology constitutes an electronic system designed with voltage regulation to enhance efficiency.

In welding equipment, an inverter welder is precisely engineered to transform the alternating current (AC) it receives into a direct current (DC) with a reduced voltage more suitable for welding purposes.

For example, an inverter welder can reconfigure the system from a 240-volt AC supply to deliver a 20-volt DC output.

The inverter-based welder utilizes a range of electronic components to execute this power and voltage conversion.

These electronic components consist of a sequence of electronic switches that rapidly alternate on and off at rates as high as 1/1,000,000 of a second. This rapid switching enables the welding machine to elevate the frequency of the primary power supply from as low as 50 Hz to as high as 100 GHz (100,000 Hz).

In contrast, transformer welders function by utilizing a large transformer solely for regulating voltage.

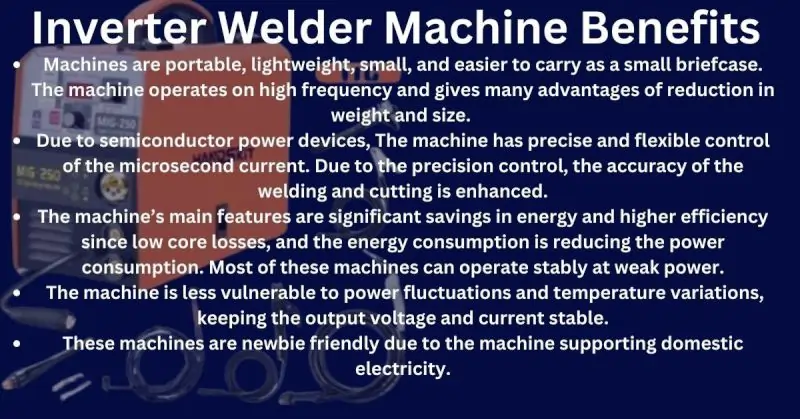

Inverter Welder Machine Benefits

Based on my experience working in Marine, Engineering Industries, Engineering projects, and maintenance jobs, my welders have reported the following good and bad experiences with this type of welders.

- Machines are portable, lightweight, small, and easier to carry as a small briefcase. The machine operates on high frequency and gives many advantages of reduction in weight and size.

- Due to semiconductor power devices, The machine has precise and flexible control of the microsecond current. Due to the precision control, the accuracy of the welding and cutting is enhanced.

- The machine’s main features are significant savings in energy and higher efficiency since low core losses, and the energy consumption is reducing the power consumption. Most of these machines can operate stably at weak power.

- The machine is less vulnerable to power fluctuations and temperature variations, keeping the output voltage and current stable.

- These machines are newbie friendly due to the machine supporting domestic electricity.

Disadvantages of Inverter welder

- The design of the inverter welders is more complicated than the traditional welders and unsuitable for a more extended period.

- Inverter welders don’t provide the solutions to all welding problems.

What is the Duty Cycle?

The duty cycle is the proportion of time that a gadget will correctly perform (or weld) inside a specific period at a given amperage. For instance, the Weldforce WF-205MST multi-feature welder has an obligation cycle of 2 hundred Amps @ 30%. This method will be performed at 200A for three minutes in ten minutes. For the final 7 mins, the gadget will transfer to thermal overload to chill down.

All welding machines are (or ought to be) geared up with thermal overload safety. Because of this, the gadget will reduce important temperatures to save you from damage. The gadget will then re-begin while it returns to a secure temperature. The duty cycle will alternate at exceptional amperages. The gadget will warm up extra rapidly at better amperage output, and the obligation cycle will reduce. At decreased amperages, the obligation cycle will increase.

For instance – if we study the WF-205MST gadget again,

Duty cycle at two hundred amps = 30%

Duty cycle at one hundred forty-five amps = 60%

Duty cycle at one hundred ten amps = 100%

How to use the inverter welding machines?

To use the inverter safely and correctly, you need to prepare it properly. The preparation of property involves a few steps. First, you have to install and connect the inverter, and there are some rules to follow:

- Put the inverter at least 2 meters away from walls or anything else.

- Make sure the inverter is grounded correctly.

- Choose a welding spot that’s far from things that can catch fire.

- It’s a good idea to weld on a free platform or a metal table.

You can connect the inverter to a regular household power outlet (220V), or if you’re using it in a factory or workshop, you can connect it to a 380V power source. If you’re working in a place with no electricity, you can connect the inverter to a generator, whether it runs on diesel or gasoline. This way, you’ll have the power to weld safely and effectively.

Inverter Welder Buying Guide

| Welding condition | Buy good quality tools for welders to achieve the best welding quality |

| Welding Quality | Buy good quality of tools for welders to achieve the best welding quality |

| Thickness of the metal to be welded | Will be decided by the portability factor of the machine |

| Machine type | Will be determined by the basic or complex machine |

| Power source | AC or DC power for the machine |

| Machine mobility | The price of a machine is the main criterion to suit the budget of the buyer |

| Endurance of welding machine | Will decide the maximum period a machine can be operated without getting overheated |

| Price of Machine | Buy good quality tools for welders to achieve the best welding quality |

Top 5 Welding Inverter Options on the Market

TOOLIOM 195A Stick Welder

Features and Specifications

- Amperage: 195A with a welding current of 20 to 195 Amps

- Voltage: 110V/220V

- Overall weight: 17.16 lb

- Rated duty cycle: 60% at 195A – 100% at 150A

- Dimensions: 17.5 x 14.25 x 9.0 inches

- Protection grade: IP21S

- Insulation factor: F

- Power factor: 0.7 at 85% efficiency

- One year warranty

The TOOLIOM 195A Stick Welder is a versatile and powerful welding machine designed for both professionals and beginners. It delivers excellent performance with E6010, 6013, and 7018 electrodes, capable of handling welding rods up to 5/32 inch (4.0mm) with a maximum output of 195A. This welder features an optional Voltage Reduction Device (VRD), allowing you to choose between enhanced safety against electric shocks when “ON,” and easier arcing with superior welding effects when “OFF.”

The intelligent LCD panel provides clear, easy-to-read settings, making it user-friendly, especially for beginners. With adjustable hot start and arc force, striking an arc is effortless, and the welder ensures smoother welding with its automatic anti-stick function, preventing the electrode from sticking in the puddle. The TOOLIOM 195A is a 2-in-1 welder, offering the flexibility to switch between stick welding and lift TIG welding (TIG torch not included; purchase TL-WP-17V-35-50 separately from TOOLIOM).

.

Pros:

- Equipped with an LED display and readout screen for easy monitoring.

- Includes multiple built-in modes like anti-stick, hot start, dig-arc force, and more for versatility.

- Designed with cooling mechanisms to ensure safety during use.

Cons:

- Relatively heavy and may be a bit challenging to transport.

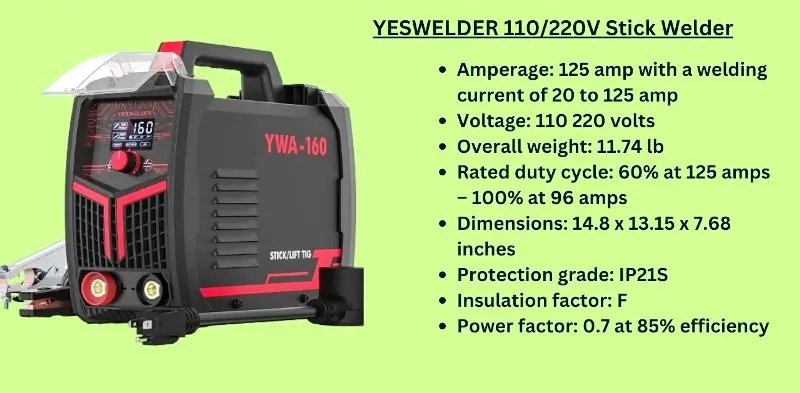

YESWELDER 110/220V Stick Welder: A 125A ARC Welder Machine

Features and Specifications

- Amperage: 125 amp with a welding current of 20 to 125 amp

- Voltage: 110 220 volts

- Overall weight: 11.74 lb

- Rated duty cycle: 60% at 125 amps – 100% at 96 amps

- Dimensions: 14.8 x 13.15 x 7.68 inches

- Protection grade: IP21S

- Insulation factor: F

- Power factor: 0.7 at 85% efficiency

The YESWELDER ARC welder machine is a fantastic choice that won’t strain your budget. It comes in two versions: 125 and 205 amps, making it suitable for various metal welding tasks.

Its duty cycle is impressive – it can work continuously at 125 amps for 60% of the time and at 96 amps for 100%.

Weighing just 11.74 lbs, this welding machine is light and easy to carry. It even has a small LCD screen that shows you the voltage and amperage as you work.

Plus, when you buy this machine, you get all the necessary accessories – the electrode holder, earth clamp, wire brush, and conversion plug. You won’t have to spend extra money on these items separately.

Pros

- Portable and lightweight design

- Affordable price

- Equipped with an LCD

Cons:

- Relatively low amperage

BLUEARC 140 MSI Inverter Welding Machine

Features and Specifications

- Amperage: 140 amp with a welding current of 50 to 140 (MIG) / 10 to 140 (MMA)

- Voltage: 110 volts 220 volts

- Overall weight: 22.0 lbs

- Rated duty cycle: 30% at 140 amps (MIG) – 30% at 120 amps (MMA)

- Dimensions: 24.0 x 12.0 x 16.0 inches inches

- Protection grade: IP21S

- Insulation factor: H

- Power factor: 0.75 at 80% efficiency

- One year warranty

Next up, we have a top-tier choice. This inverter welding machine is unique because it can work as a MIG, stick, or flux-core welding machine. It’s designed to handle standard 2 lbs and 11 lbs spools, and it even comes with built-in clamps and a MIG torch for added convenience.

The MIG and stick welder use advanced single IGBT technology that’s digitally controlled. The user interface is pretty straightforward.

One thing to note is that, unlike many other inverter machines, this one weighs around 22.0 lbs, including the spools. While it’s lighter than traditional welders, it’s a bit heavier than other inverter options.

Pros:

- Versatile operation as a MIG and stick welding machine provides added versatility.

- Capable of welding a wide range of metals, enhancing its usability.

- Offers automatic voltage control for optimized voltage, amperage, and wire feed speed.

Cons:

- Relatively high price point compared to other options on the market.

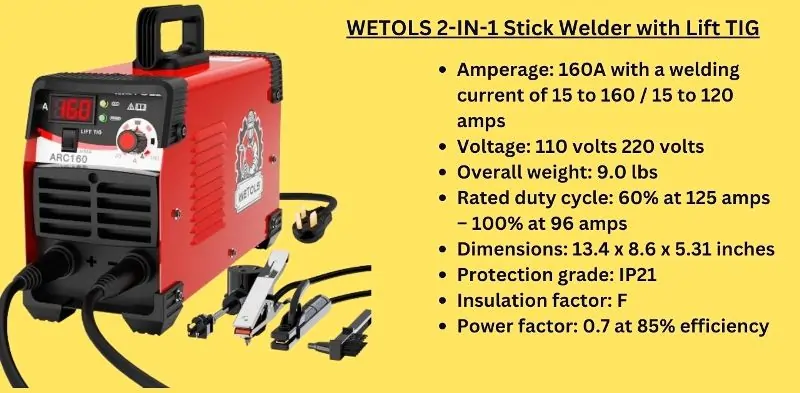

WETOLS 2-IN-1 Stick Welder with Lift TIG

Features and Specifications

- Amperage: 160A with a welding current of 15 to 160 / 15 to 120 amps

- Voltage: 110 volts 220 volts

- Overall weight: 9.0 lbs

- Rated duty cycle: 60% at 125 amps – 100% at 96 amps

- Dimensions: 13.4 x 8.6 x 5.31 inches

- Protection grade: IP21

- Insulation factor: F

- Power factor: 0.7 at 85% efficiency

If you don’t want to spend too much money but still need a good welding machine, check out the WETOLS MMA ARC welder machine.

This powerful welder uses fancy technology to control everything, so your welding is steady and reliable. It’s awesome for new welders and those who know a bit more, and it can weld different kinds of metal like steel and stainless steel.

And guess what? It’s super lightweight, less than 9 pounds! So, you can take it anywhere, whether you’re welding inside or outside.

Pros

- Ideal for budget-conscious buyers

- Highly portable and suitable for indoor and outdoor use

- Offers impressive efficiency for its cost

Cons

- It may produce some splatter while welding.

DEKOPRO 110/220V MMA Welder

Features and Specifications:

- Advanced IGBT Technology:

- Metal Versatility

- Lightweight Design

- Powerful Welding

- Portable

- Versatile

The WETOLS MMA ARC welder machine is a good pick for people new to welding and those with some experience. So whether you’re a beginner or have some welding know-how, you can use this machine confidently.

So whether your project involves various materials or you want to try different welding techniques, this machine can handle it.

The WETOLS MMA ARC welder equipment is dependable and provides high performance.

Pros:

- Budget-Friendly: Perfect for those on a tight budget.

- Portability: Extremely lightweight for easy transport.

- Versatile: Handles various metals.

- Reliable Performance: IGBT technology ensures steady welding.

- Suitable for Beginners: Simple operation for novice welders.

Cons:

- Splatter: May produce minor splatter during welding

FAQ on ” Best Inverter Welde

Q: What is an inverter welder?

A: An inverter welder is a welding machine that converts AC power to DC power for welding.

Q: What are the advantages of inverter welders?

A: Inverter welders are lightweight, energy-efficient, and offer precise control over welding parameters.

Q: Can inverter welders be used for both professional and DIY welding?

A: Inverter welders are suitable for professional and DIY welding projects.

Q: What factors should I consider when choosing the best inverter welder?

A: Consider factors like the welding process, power output, portability, and price when selecting the best inverter welder for your needs.

Blog Post Conclusion

We hope you enjoyed our blog on the inverter welding machines coming into the market. Inverter welding machines are a type of welding machine that uses motors, inverters, and other electric power sources to quickly heat up and switch between two different types of welding energy, DC and AC. These power sources are very popular on the market; they are simple to use, affordable, and reliable. You can use this product daily after reading the information in this blog article.

Don’t hesitate to contact us anytime if you have further questions or concerns by visiting https://marinediesel.co.in/.