Capacitor

Capacitors play a critical role in the power generation industry and marine applications, ensuring systems operate efficiently and reliably. Their ability to store and release energy rapidly makes them indispensable for maintaining power quality, voltage regulation, and energy storage. This blog post delves into the top 10 most transformative uses of capacitors in these demanding environments, highlighting their crucial impact on advancing energy systems.

Understanding these uses is not just about appreciating a component’s versatility; it’s crucial for driving innovation in Electricity generation and marine applications. As we strive for more sustainable and efficient energy solutions, capacitors are at the forefront, enabling breakthroughs in renewable energy integration, power factor correction, and industrial automation. By exploring these transformative uses, engineers can better grasp how capacitors contribute to a more robust and efficient energy infrastructure, making this knowledge essential for those involved in cutting-edge power generation and marine engineering.

Capacitor Working and Power Consumption

A capacitor is an electrical component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material (dielectric). When voltage is applied, an electric field is created between the plates, allowing the capacitor to store energy.

How Does a Capacitor Work?

- Charging: When a capacitor is connected to a power source, electrons accumulate on one plate, while the other plate loses electrons, creating an electric field. This process is known as charging.

- Discharging: Once the power source is removed, the stored energy can be released back into the circuit, known as discharging.

Does a Capacitor Consume Power?

A capacitor does not consume power in the traditional sense. It stores energy during charging and releases it when discharging. During steady-state AC operation, a capacitor only draws reactive power (measured in VARs), which is related to energy storage and release, not actual power consumption like resistive loads (measured in watts). Therefore, it does not consume real power, but it plays a key role in improving power factor and stabilizing voltage in electrical systems.

Capacitors in Renewable Energy Systems

Energy Storage Solutions

Capacitors play a crucial role in renewable energy systems, particularly in storing and discharging energy generated from solar and wind power. In these systems, energy is often produced intermittently, depending on weather conditions and time of day. Capacitors help manage this variability by storing excess energy generated during peak production times and discharging it when production is low, ensuring a consistent and reliable power supply. This capability is essential for maintaining the stability and efficiency of renewable energy systems, allowing them to meet the continuous energy demands of industrial and marine applications.

Benefits

The use of capacitors in renewable energy storage brings several significant benefits:

- Improved Efficiency: Capacitors can quickly store and release energy, which minimizes energy losses compared to other storage methods. This rapid response helps in balancing supply and demand, ensuring that energy is available when needed without significant loss.

- Enhanced Reliability: By smoothing out the fluctuations in energy supply, capacitors contribute to the stability and reliability of renewable energy systems. This is particularly important in industrial and marine applications where consistent power is critical for operations.

- Extended Lifespan of Energy Systems: Capacitors help reduce the strain on other components of the energy storage system, such as batteries, by handling rapid charge and discharge cycles. This reduces wear and tear on these components, extending their operational lifespan and reducing maintenance costs.

- Scalability: Capacitor-based energy storage systems can be easily scaled to meet varying energy demands. Whether it’s a small-scale solar installation or a large wind farm, capacitors can be configured to match the specific storage needs, making them versatile for different applications.

- Environmental Benefits: By improving the efficiency and reliability of renewable energy systems, capacitors contribute to reducing reliance on fossil fuels. This helps lower greenhouse gas emissions and supports the transition to cleaner energy sources, benefiting the environment.

Types of Capacitors

Electrolytic Capacitors

Uses and Benefits in Industrial and Marine Applications Electrolytic capacitors are widely used in various industrial and marine applications due to their high capacitance and ability to handle large voltage loads. These capacitors are essential in power supply circuits, motor drives, and industrial automation systems. In marine applications, they are often found in power conditioning and energy storage systems.

Benefits:

- High Capacitance: Electrolytic capacitors can store large amounts of energy, making them ideal for applications requiring significant power support.

- Cost-Effective: They offer a high capacitance-to-cost ratio, providing an economical solution for energy storage and power management.

- Voltage Handling: Capable of handling high voltage loads, electrolytic capacitors are suitable for industrial environments where robust power support is needed.

Ceramic Capacitors

Importance in Robust Electronic Systems Used in Marine Environments Ceramic capacitors are known for their stability, reliability, and high-frequency performance, making them indispensable in robust electronic systems used in marine environments. They are used in filtering, bypassing, and coupling applications, ensuring the smooth operation of electronic circuits in harsh conditions.

Benefits:

- Stability and Reliability: Ceramic capacitors maintain consistent performance over a wide range of temperatures and environmental conditions, crucial for marine applications.

- High-Frequency Performance: They excel in high-frequency applications, making them ideal for RF circuits and signal processing in marine electronics.

- Durability: Ceramic capacitors are highly resistant to environmental stresses such as humidity and temperature fluctuations, ensuring long-term reliability in marine settings.

Tantalum Capacitors

Role in High-Performance, High-Reliability Applications Tantalum capacitors are prized for their reliability, stability, and high performance, particularly in applications requiring precise and dependable operation. They are commonly used in aerospace, military, and high-end industrial applications where failure is not an option.

Benefits:

- High Reliability: Tantalum capacitors offer exceptional reliability, with low failure rates, making them suitable for critical applications where dependability is paramount.

- Stable Performance: They provide stable capacitance values over a wide range of temperatures and operating conditions, ensuring consistent performance.

- Compact Size: Tantalum capacitors offer high capacitance in a compact form factor, making them ideal for applications where space is limited but high performance is required.

Improving Power Factors in Power Systems

Power Factor Correction

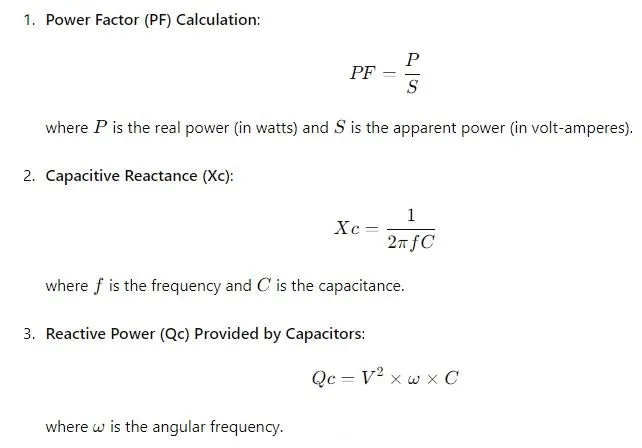

Capacitors play a crucial role in improving the power factor in power generation and distribution systems by providing reactive power compensation. The power factor is the ratio of real power (used to do work) to apparent power (total power in the system). A low power factor indicates inefficiency as more apparent power is required to perform a given amount of real work. Capacitors supply reactive power locally, which compensates for the inductive loads that cause a lagging power factor. This compensation improves the power factor, leading to more efficient power usage.

Reduction of Power Losses

Improving the power factor through the use of capacitors reduces the current flow in the system. Lower current flow decreases the I²R losses (where I is the current and R is the resistance) in the electrical distribution network. This reduction in power losses enhances the overall efficiency of the system, resulting in energy savings and reduced operational costs.

Voltage Regulation

Capacitors help maintain proper voltage levels within power systems. By providing reactive power support, they counteract the voltage drops caused by inductive loads. This regulation ensures stability and reliability in power systems, preventing issues such as voltage sags and surges, which can negatively impact equipment performance and lifespan.

Increased System Capacity

By improving the power factor, capacitors enable power systems to handle a greater load without the need for additional generation capacity. This is because less apparent power is required for the same amount of real power, effectively increasing the system’s capacity to deliver power to additional loads. This capacity increase is crucial for growing industrial and commercial operations without incurring significant infrastructure costs.

Related Formulas

Important Formulas for Capacitor Calculations

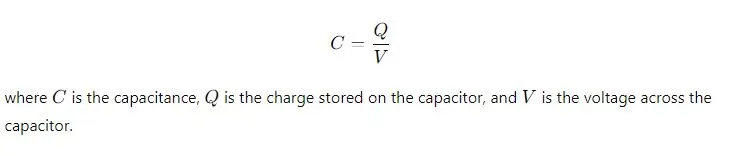

Capacitance Formula

Description: The capacitance formula defines the ability of a capacitor to store an electric charge per unit of voltage applied. It is a fundamental property that quantifies how much charge a capacitor can hold at a given voltage.

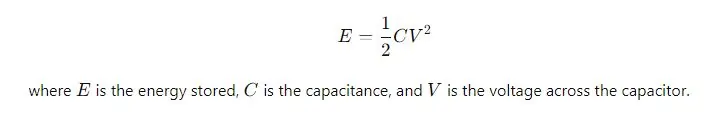

Energy Stored in a Capacitor

Description: This formula calculates the energy stored in a capacitor. The energy is directly proportional to the capacitance and the square of the voltage. It is crucial for understanding the energy handling capabilities of capacitors in various applications.

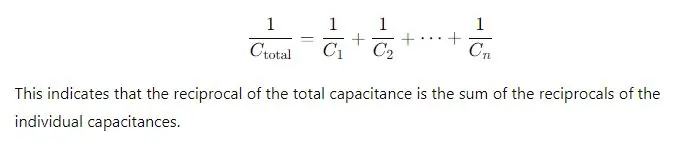

Series Capacitance

Description: When capacitors are connected in series, the total or equivalent capacitance is less than the smallest individual capacitor. This formula helps in determining the overall capacitance of multiple capacitors arranged in series.

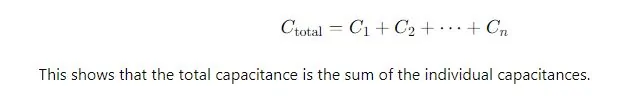

Parallel Capacitance

Description: For capacitors connected in parallel, the total or equivalent capacitance is the sum of the individual capacitances. This configuration results in a greater capacitance than any single capacitor in the group, suitable for increasing storage capacity.

Design Considerations

Description: When selecting and using capacitors, several key design aspects and considerations should be taken into account to ensure optimal performance. These considerations include voltage rating, temperature stability, tolerance, physical size, ESR (Equivalent Series Resistance), ESL (Equivalent Series Inductance), lifetime, reliability, and application specifics. Properly addressing these factors ensures capacitors meet the specific requirements of their applications, leading to optimal performance and longevity.

Electric Vehicles (EVs) in Marine Applications

Power Management

Capacitors play a pivotal role in the power management systems of electric and hybrid marine vehicles. These vessels, which include electric boats, ferries, and hybrid ships, rely on capacitors for efficient energy storage and distribution. Capacitors are essential for smoothing out power fluctuations, ensuring that the electric motors receive a stable power supply. This stability is crucial for maintaining optimal performance and extending the lifespan of the electrical components.

In marine environments, where power demands can vary widely due to changing loads and operational conditions, capacitors help to buffer the power supply, absorbing and releasing energy as needed. This buffering capability ensures that the power management system can respond quickly to changes, providing the necessary power for propulsion, navigation, and onboard systems without causing excessive strain on the batteries. Additionally, capacitors help in reducing the load on batteries, thereby enhancing their efficiency and longevity, which is vital for the reliability and sustainability of marine EVs.

Regenerative Braking

Regenerative braking is a key technology in electric and hybrid marine vehicles, and capacitors significantly enhance its efficiency. In regenerative braking systems, the kinetic energy that would otherwise be lost as heat during braking is captured and converted back into electrical energy. This energy is then stored in capacitors, which can quickly absorb and release large amounts of power.

Capacitors are particularly well-suited for this application because of their ability to handle rapid charge and discharge cycles. When the marine vehicle slows down or stops, the regenerative braking system captures the energy and transfers it to the capacitors. This stored energy can then be reused for propulsion or other onboard systems, reducing the overall energy consumption and increasing the efficiency of the marine EV.

In marine environments, regenerative braking systems with capacitors offer several advantages:

- Enhanced Energy Efficiency: By capturing and reusing energy, capacitors help reduce the overall energy demand, leading to more efficient operation and lower fuel consumption in hybrid systems.

- Extended Battery Life: Reducing the reliance on batteries for frequent charge and discharge cycles minimizes wear and tear, extending the operational life of the battery systems.

- Improved Performance: Capacitors provide a quick and reliable energy source, ensuring that the regenerative braking system operates smoothly and effectively, which enhances the overall performance and responsiveness of the marine vehicle.

Top Capacitor Manufacturers

Brand Overview

Several leading manufacturers dominate the capacitor market, known for their innovation, quality, and reliability. Here are some of the top capacitor manufacturers:

- Murata Manufacturing Co., Ltd.

- TDK Corporation

- KEMET Corporation

- Vishay Intertechnology, Inc.

- Panasonic Corporation

- Nichicon Corporation

- AVX Corporation

- Samsung Electro-Mechanics

- EPCOS (a TDK Group Company)

- Rubycon Corporation

Key Products and Innovations

Murata Manufacturing Co., Ltd.

- Products: Ceramic capacitors, polymer capacitors, and supercapacitors.

- Innovations: Murata is known for its advancements in miniaturization and high-reliability ceramic capacitors, which are essential for compact electronic devices and high-frequency applications.

- Contact:

- Website: Murata Manufacturing Co., Ltd.

- Headquarters: 10-1 Higashikotari 1-chome, Nagaokakyo, Kyoto 617-8555, Japan

- Phone: +81-75-951-9111

TDK Corporation

- Products: Multilayer ceramic capacitors (MLCC), aluminum electrolytic capacitors, and film capacitors.

- Innovations: TDK has pioneered in developing MLCCs with high capacitance and low ESL, critical for modern electronics requiring high performance and stability.

- Contact:

- Website: TDK Corporation

- Headquarters: 1-13-1 Nihonbashi, Chuo-ku, Tokyo 103-8272, Japan

- Phone: +81-3-6778-1055

KEMET Corporation

- Products: Tantalum, ceramic, film, aluminum, and electrolytic capacitors.

- Innovations: KEMET’s focus on high-reliability tantalum capacitors has led to significant improvements in energy density and performance, especially in aerospace and military applications.

- Contact:

- Website: KEMET Corporation

- Headquarters: One East Broward Boulevard, Fort Lauderdale, FL 33301, USA

- Phone: +1-954-766-2800

Vishay Intertechnology, Inc.

- Products: Aluminum electrolytic capacitors, tantalum capacitors, and ceramic capacitors.

- Innovations: Vishay is recognized for its high-reliability capacitors used in industrial and automotive applications, enhancing performance and longevity under harsh conditions.

- Contact:

- Website: Vishay Intertechnology, Inc.

- Headquarters: 63 Lancaster Avenue, Malvern, PA 19355, USA

- Phone: +1-610-644-1300

Panasonic Corporation

- Products: Aluminum electrolytic capacitors, film capacitors, and polymer capacitors.

- Innovations: Panasonic’s polymer capacitors are notable for their low ESR and high ripple current capability, making them ideal for power supply applications in various industries.

- Contact:

- Website: Panasonic Corporation

- Headquarters: 1006, Oaza Kadoma, Kadoma-shi, Osaka 571-8501, Japan

- Phone: +81-6-6908-1121

Nichicon Corporation

- Products: Aluminum electrolytic capacitors, tantalum capacitors, and film capacitors.

- Innovations: Nichicon is a leader in producing high-capacitance aluminum electrolytic capacitors, which are crucial for energy storage and power conditioning applications.

- Contact:

- Website: Nichicon Corporation

- Headquarters: Karasuma Oike, Nakagyo-ku, Kyoto 604-0845, Japan

- Phone: +81-75-231-8461

AVX Corporation

- Products: Tantalum, ceramic, film, and electrolytic capacitors.

- Innovations: AVX’s development of high-voltage and high-capacitance ceramic capacitors has been instrumental in the advancement of medical and industrial electronics.

- Contact:

- Website: AVX Corporation

- Headquarters: One AVX Boulevard, Fountain Inn, SC 29644, USA

- Phone: +1-864-967-2150

Samsung Electro-Mechanics

- Products: Multilayer ceramic capacitors (MLCC), tantalum capacitors.

- Innovations: Samsung’s MLCCs are known for their high volumetric efficiency, supporting the miniaturization of electronic devices while maintaining high performance.

- Contact:

- Website: Samsung Electro-Mechanics

- Headquarters: 314, Maetan 3-dong, Yeongtong-gu, Suwon-si, Gyeonggi-do 16674, Korea

- Phone: +82-31-210-5114

EPCOS (a TDK Group Company)

- Products: Film capacitors, aluminum electrolytic capacitors, and ceramic capacitors.

- Innovations: EPCOS is renowned for its robust film capacitors used in renewable energy systems and industrial power electronics, providing high reliability and efficiency.

- Contact:

- Website: EPCOS

- Headquarters: St.-Martin-Strasse 53, 81669 Munich, Germany

- Phone: +49-89-54020-0

Rubycon Corporation

- Products: Aluminum electrolytic capacitors, polymer capacitors.

- Innovations: Rubycon’s high-temperature and long-life electrolytic capacitors are critical for automotive and renewable energy applications, offering stability and durability.

- Contact:

- Website: Rubycon Corporation

- Headquarters: 1-1-3 Hatsunae, Ina, Nagano 396-0025, Japan

- Phone: +81-265-72-1151

Market Influence

These leading capacitor manufacturers significantly impact the capacitor market and drive technological advancements:

- Innovation and R&D: Through continuous research and development, these brands introduce new capacitor technologies that enhance performance, reliability, and efficiency. Innovations such as high-capacitance MLCCs, high-reliability tantalum capacitors, and low ESR polymer capacitors are pivotal in advancing electronic applications.

- Market Leadership: Their market leadership ensures widespread adoption of advanced capacitor technologies across various industries, including automotive, aerospace, consumer electronics, renewable energy, and industrial automation.

- Standard Setting: These manufacturers set industry standards for quality, performance, and reliability, influencing other market players and ensuring that high benchmarks are maintained across the industry.

- Global Reach: With extensive global distribution networks, these brands ensure that cutting-edge capacitor technologies are accessible worldwide, fostering technological growth and development across regions.

FAQ on “Capacitor”

Q: What is the primary function of a capacitor?

A:A capacitor stores and releases electrical energy in a circuit.

Q: How does a capacitor improve power factor?

A: Capacitors provide reactive power compensation, reducing the phase difference between voltage and current.

Q: Why are capacitors used in renewable energy systems?

A: Capacitors store excess energy from solar and wind power, ensuring a stable power supply.

Q: What types of capacitors are commonly used in industrial applications?

A: Common types include electrolytic, ceramic, and tantalum capacitors, each suited for specific uses and performance needs.

Conclusion

Capacitors are indispensable components in modern technology, playing critical roles in various applications from renewable energy systems to electric and hybrid marine vehicles. Their ability to store and release energy efficiently enhances power management, improves power factor, and supports advanced technologies like regenerative braking. By understanding the different types of capacitors and their specific uses, engineers can optimize system performance and reliability. As innovations continue to drive capacitor technology forward, their impact on energy systems and electronic applications will only grow, making capacitors a cornerstone of sustainable and efficient technological advancements.