Connecting Rod Bearings

In this blog post, we will explore everything you need to know about connecting rod bearings. We’ll start with an overview of the different types of bearings, followed by a discussion of the materials commonly used to manufacture them. You’ll learn about the causes and symptoms of bearing failure, along with practical insights into avoiding common issues.

We’ll also cover essential topics such as bearing size charts, proper clearance measurements, and the step-by-step process for replacing a connecting rod bearing. Additionally, we’ll introduce key formulas that help in calculating load capacity and oil film thickness, which are critical for maintaining engine performance. Finally, we’ll provide tips to extend the life of your bearings, ensuring your engine runs smoothly and efficiently.

This comprehensive guide is designed to help you make informed decisions and optimize engine reliability in 2024.

Types of Connecting Rod Bearings

Connecting rod bearings come in various types, each suited to different engine requirements. Below is an overview of the most common types of bearings, including their advantages and disadvantages.

1. Plain Bearings

- Overview: Plain bearings are the simplest type, consisting of a smooth surface that supports the connecting rod’s rotation.

- Pros:

- Low cost and simple design.

- Reliable performance under low to moderate load conditions.

- Require minimal lubrication compared to other types.

- Cons:

- Limited ability to handle high loads and extreme temperatures.

- Susceptible to wear over time if not properly maintained.

2. Babbitt Bearings

- Overview: Babbitt bearings are made from a soft metal alloy, typically tin or lead-based, which is applied as a thin lining on a steel or bronze backing.

- Pros:

- Excellent resistance to fatigue and corrosion.

- Soft surface accommodates minor imperfections in the crankshaft.

- Effective in providing a smooth rotation with less friction.

- Cons:

- Relatively soft, so they can wear quickly under high load or pressure.

- More expensive than plain bearings due to material and manufacturing processes.

3. Tri-metal Bearings

- Overview: Tri-metal bearings consist of three layers: a steel backing, a copper-lead intermediate layer, and a thin overlay of softer material such as Babbitt.

- Pros:

- High load-carrying capacity, making them ideal for high-performance engines.

- Better heat dissipation due to their copper-lead structure.

- Strong resistance to wear, even under harsh conditions.

- Cons:

- More expensive than bi-metal and plain bearings.

- Require high-quality oil lubrication to avoid damage.

4. Bi-metal Bearings

- Overview: Bi-metal bearings feature two layers: a steel backing and an aluminum or copper-based lining.

- Pros:

- Cost-effective option for medium-performance engines.

- Good balance between durability and affordability.

- Suitable for a wide range of applications in standard engines.

- Cons:

- Not as strong as tri-metal bearings in handling extreme loads.

- May not dissipate heat as effectively as tri-metal bearings, leading to potential overheating issues.

Connecting Rod Bearing Failure

Connecting rod bearing failure is a common issue in engines, especially under extreme conditions such as high RPMs, excessive loads, or poor lubrication. Understanding the common scenarios in which these failures occur and knowing how to identify the early signs of failure can help prevent serious engine damage.

Common Scenarios of Bearing Failure:

- Oil Starvation: One of the leading causes of bearing failure is a lack of proper lubrication. When oil flow is insufficient, it leads to increased friction between the connecting rod and crankshaft, causing the bearing to wear prematurely.

- Contamination: Foreign particles such as dirt, metal shavings, or carbon deposits can contaminate the engine oil. These particles can cause scoring and damage to the bearing surface, leading to faster deterioration.

- Overheating: High temperatures can cause the bearing material to soften or deform. Overheating can be caused by excessive engine load, poor cooling, or insufficient oil flow.

- Misalignment: If the connecting rod is misaligned, it places uneven pressure on the bearing, leading to uneven wear and eventual failure. This is often caused by improper installation or excessive engine vibrations.

- Excessive Load: Pushing an engine beyond its designed capacity, such as in racing conditions or high-performance applications, can cause excessive stress on the bearing, leading to rapid wear or catastrophic failure.

How to Identify a Failing Bearing:

- Knocking or Tapping Sounds: A common early sign of a failing bearing is a distinct knocking or tapping sound from the engine. This occurs as the worn bearing creates excessive clearance, allowing the connecting rod to make contact with the crankshaft.

- Low Oil Pressure: As the bearing wears, it increases the clearance, causing a drop in oil pressure. A sudden drop in oil pressure, often accompanied by a warning light, can indicate bearing failure.

- Metal Shavings in Oil: During an oil change, the presence of metal shavings in the oil or oil filter is a clear sign of bearing wear. The metal particles are a result of the bearing material breaking down under stress.

- Engine Vibration: A failing bearing can cause an imbalance in the engine’s rotation, leading to noticeable vibrations, especially at higher RPMs.

- Engine Overheating: Excessive friction caused by a worn bearing can lead to increased heat generation in the engine, causing it to overheat.

Causes of Connecting Rod Bearing Failure

Connecting rod bearing failure can be caused by several key factors, many of which are avoidable with proper maintenance and attention. Below are the most common causes:

1. Lubrication Issues

- Oil Starvation: Inadequate lubrication is one of the primary reasons for bearing failure. Without sufficient oil, friction increases between the connecting rod and the crankshaft, causing the bearing to wear out prematurely. Common causes include low oil levels, clogged oil passages, or a faulty oil pump.

- Oil Contamination: Contaminants like dirt, metal debris, or coolant mixing with engine oil create an abrasive environment. These contaminants prevent oil from properly lubricating the bearing, accelerating wear and leading to failure.

2. Overheating

Overheating causes the bearing material to soften or deform, reducing its strength and ability to function. This can be due to insufficient oil flow, inadequate engine cooling, or engine overload. If the bearing overheats, it may melt or warp, causing engine damage.

3. Engine Overload and High RPM Usage

Excessive engine loads or operating at high RPMs place extreme stress on the connecting rod bearings. In performance or racing scenarios, where engines are pushed beyond their design limits, the repeated strain can lead to rapid bearing wear and sudden failure.

4. Improper Installation or Maintenance

Incorrect installation, such as misalignment or improper torque settings, can result in uneven load distribution across the bearing surface, leading to premature failure. Additionally, skipping regular maintenance, such as oil changes and bearing inspections, allows problems like lubrication issues or misalignments to go unnoticed, increasing the risk of failure.

Symptoms of Connecting Rod Bearing Failure

Detecting the early symptoms of connecting rod bearing failure is crucial for preventing further damage to the engine. Below are the most common signs to watch out for:

1. Engine Knocking Sound

A distinct knocking or tapping sound from the engine, particularly during acceleration, is often the first noticeable sign of a failing connecting rod bearing. This sound is caused by increased clearance between the bearing and the crankshaft, allowing the connecting rod to knock against other components.

2. Low Oil Pressure Warning

A sudden drop in oil pressure, usually indicated by a warning light on the dashboard, is another common symptom of bearing failure. As the bearing wears down, the increased clearance disrupts the oil flow, reducing overall pressure. Prolonged low oil pressure can lead to further damage to the engine if not addressed immediately.

3. Excessive Metal Particles in the Oil

During routine oil changes, finding metal shavings or particles in the oil or oil filter is a clear indicator that the bearing is deteriorating. These metal fragments are the result of the bearing material breaking down under stress and friction, which can damage other engine components if left unchecked.

4. Vibration and Rough Idling

A failing connecting rod bearing can cause noticeable engine vibrations, especially at higher RPMs. As the bearing wears, it disrupts the balance and smooth rotation of the engine’s components, leading to rough idling and increased vibration during operation.

Connecting Rod Bearing Size Chart

Selecting the right size of a connecting rod bearing is critical to ensuring the engine operates efficiently and reliably. Bearings come in both standard and oversized options, and knowing when to use each type is key to maintaining proper engine performance.

Standard Size vs. Oversized Bearings

Standard-size bearings are designed to fit the original dimensions of the engine’s connecting rod and crankshaft as specified by the manufacturer. These are typically used when the engine components have not experienced significant wear or damage. In contrast, oversized bearings are used when the crankshaft has been ground down during a rebuild to remove damage or wear. Oversized bearings compensate for the material removed from the crankshaft, ensuring a tight fit and proper clearance.

Reference to OEM Size Charts for Common Engine Types

Each engine has specific size requirements for its connecting rod bearings, which are outlined in the OEM (Original Equipment Manufacturer) size charts. These charts provide detailed measurements for standard and oversized bearings, ensuring the correct fit for each engine model. It’s essential to consult the OEM chart for your engine type to determine the exact bearing dimensions required.

How to Measure and Select the Correct Size

To measure and select the right bearing size:

- Measure the Crankshaft Journal: Use a micrometer to measure the diameter of the crankshaft journal. This will help determine whether the journal is standard or undersized due to wear or grinding.

- Measure the Connecting Rod Bore: The bore of the connecting rod also needs to be measured using an inside micrometer to ensure the right fit for the bearing.

- Check Bearing Thickness: Compare the measurements against the OEM size chart to choose the appropriate bearing size. If the crankshaft has been reground, select an oversized bearing to account for the reduction in journal size.

Connecting Rod Bearing Clearance

Proper connecting rod bearing clearance is crucial for optimal engine performance, preventing premature wear or failure. Bearing clearance refers to the small gap between the bearing surface and the crankshaft journal, which allows for a protective oil film to form. This oil film reduces friction, heat, and wear on engine components.

Importance of Proper Clearance for Optimal Engine Performance

Correct bearing clearance ensures proper lubrication. If the clearance is too tight, there won’t be enough room for oil, leading to metal-on-metal contact and overheating. If the clearance is too wide, the oil won’t maintain adequate pressure, leading to poor lubrication and bearing instability. Maintaining the right clearance allows for smooth engine operation, reduced friction, and extended engine life.

How to Measure Clearance Using Tools like a Plastigauge

Plastigauge is a simple and effective tool for measuring bearing clearance:

- Step 1: Clean the crankshaft journal and the bearing.

- Step 2: Place a strip of plastigauge on the crankshaft journal.

- Step 3: Install the bearing cap and tighten to the specified torque without rotating the crankshaft.

- Step 4: Remove the cap and measure the width of the flattened plastigauge using the scale provided with it. The wider the plastigauge, the tighter the clearance.

Acceptable Clearance Values for Different Engine Types

Typical clearance values vary based on engine type:

- Standard automotive engines: 0.001 to 0.003 inches (0.025 to 0.076 mm).

- High-performance engines: Often require slightly looser clearances to accommodate higher RPM and stress.

It’s important to consult your engine’s service manual or OEM specifications for the recommended clearance values.

How to Calculate Bearing Clearance

You can also calculate bearing clearance manually:

- Bearing Clearance = Bearing Inside Diameter – Crankshaft Journal Diameter

Measure the crankshaft journal with a micrometer and the bearing bore with an inside micrometer. The resulting clearance should match the manufacturer’s specified range.

Thumb Rule for Bearing Clearance

A commonly used thumb rule is 0.001 inch of clearance per inch of crankshaft journal diameter. For example, a 2-inch diameter crankshaft journal would require approximately 0.002 inches of clearance. This rule offers a quick and rough guide but should be verified against OEM specifications for precision.

Connecting Rod Bearing Replacement

Replacing a connecting rod bearing is a critical maintenance task that requires precision and attention to detail. Here is a step-by-step guide to help you through the process, along with the necessary tools and safety precautions.

Step-by-Step Guide to Replacing a Connecting Rod Bearing

- Prepare the Engine

- Disconnect the battery and drain the engine oil to avoid leaks during disassembly.

- Remove the oil pan to gain access to the connecting rod and crankshaft.

- Remove the Connecting Rod Cap

- Locate the connecting rod and crankshaft. Remove the connecting rod cap bolts using a wrench or socket set.

- Carefully remove the connecting rod cap, exposing the bearing underneath.

- Inspect the Crankshaft and Connecting Rod

- Before removing the old bearing, inspect the crankshaft journal and the connecting rod for any signs of wear or damage. Ensure they are clean and free from debris.

- Remove the Old Bearing

- Carefully slide the old bearing out from the connecting rod and cap. Note the orientation for proper installation of the new bearing.

- Install the New Bearing

- Lubricate the new bearing with clean engine oil. Place the bearing into the connecting rod and cap, ensuring proper alignment.

- Reinstall the Connecting Rod Cap

- Align the connecting rod cap with the connecting rod and crankshaft. Install the cap bolts and tighten them to the manufacturer’s torque specifications.

- Reassemble the Engine

- Reinstall the oil pan and fill the engine with fresh oil.

- Reconnect the battery and start the engine, checking for any abnormal noises or vibrations.

Tools Required for the Replacement Process

- Wrench or socket set (for removing and tightening connecting rod cap bolts)

- Torque wrench (for proper tightening of cap bolts)

- Micrometer (for measuring crankshaft journal size)

- Plastigauge (for checking bearing clearance)

- Engine oil (for lubricating the new bearing and refilling the engine)

- Oil drain pan (for draining the engine oil)

- Cleaning supplies (to ensure all components are free of debris)

Safety Precautions to Take During Replacement

- Disconnect the Battery: Always disconnect the battery before starting any engine work to prevent accidental starts or electrical shocks.

- Use Proper Torque Specifications: Ensure that the connecting rod cap bolts are tightened to the exact torque specified by the manufacturer. Over-tightening or under-tightening can lead to engine damage.

- Work in a Clean Environment: Ensure that the area where you’re working is free from dust and contaminants. Dirt or debris entering the engine can cause premature bearing failure.

- Wear Protective Gear: Always wear gloves, safety glasses, and appropriate clothing to protect yourself from engine oil and sharp components.

- Check for Clearance Issues: After installation, always check that the connecting rod moves freely with no binding before reassembling the engine.

Safety Precautions to Take During Replacement (Pneumatic Start Engines)

- Isolate the Air Start System: Ensure the pneumatic start system is isolated by closing the air supply valve and draining any residual compressed air from the system. This will prevent the engine from accidentally turning over due to air pressure in the start system.

- Lock Out/Tag Out Procedures: For additional safety, use lockout/tagout procedures to prevent accidental operation of the air start valve or other systems while performing maintenance. Clearly label the isolated air supply to alert others.

- Release Engine Cylinder Pressure: Before working on the engine, ensure that the engine cylinders are depressurized. This can be done by opening indicator cocks or decompressing valves to ensure no trapped pressure remains that could rotate the crankshaft unexpectedly.

- Secure Engine Rotation: If necessary, manually lock the engine’s crankshaft in place using the engine’s turning gear to prevent unintended movement during bearing replacement.

- Work in a Clean Environment: As with any engine work, maintain a clean workspace to avoid contamination of the engine components. Dust or debris in the engine can cause damage to the bearings or other components.

- Use Proper Torque Specifications: Ensure that all bolts, particularly the connecting rod cap bolts, are tightened to the manufacturer’s recommended torque specification. This prevents improper bearing installation, which could lead to engine failure.

- Wear Protective Gear: Always wear appropriate protective gear such as gloves, safety goggles, and durable clothing to avoid injury from sharp engine parts, hot components, or lubricants.

Important Formulas on Connecting Rod Bearings

Understanding the critical formulas related to connecting rod bearings is essential for engineers and technicians working with high-performance engines. These formulas help in calculating bearing load capacity, oil film thickness, and heat dissipation, ensuring optimal engine performance and longevity.

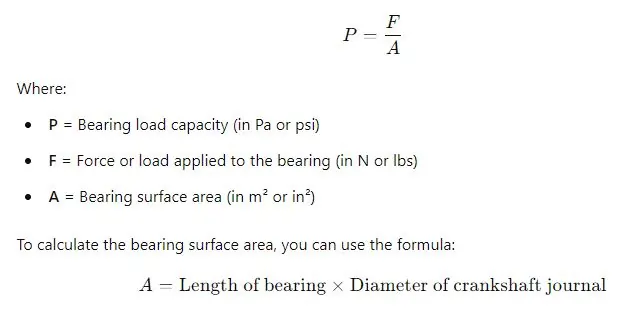

1. Calculation of Bearing Load Capacity

The bearing load capacity refers to the maximum load that the connecting rod bearing can handle without failure. This is an important factor in engine design, particularly in high-performance applications. The formula for calculating bearing load capacity is:

Ensuring that the load remains within the bearing’s capacity helps prevent premature wear, deformation, and potential failure under extreme operating conditions.

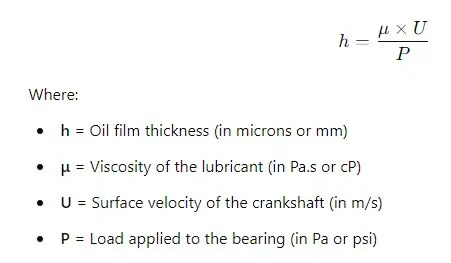

2. Oil Film Thickness Formula

The oil film thickness between the crankshaft journal and the bearing is critical for reducing friction and preventing metal-to-metal contact. Adequate oil film thickness ensures smooth engine operation and protects the bearing surfaces. The oil film thickness can be estimated using the following simplified formula:

Maintaining an optimal oil film thickness prevents excessive friction and overheating, ensuring longer bearing life and efficient engine performance.

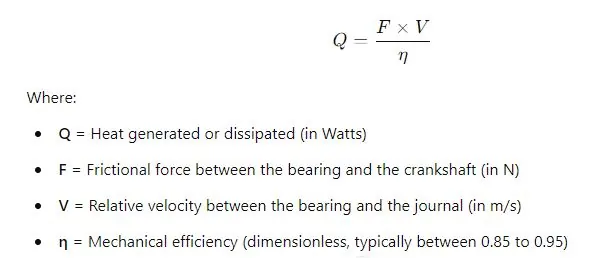

3. Heat Dissipation Formula for High-Performance Engines

In high-performance engines, the connecting rod bearing must dissipate heat generated due to friction and the extreme loads placed on it. Heat dissipation ensures that the bearing does not overheat and maintains its structural integrity during operation. The heat dissipation can be calculated using:

High-performance engines generate more heat due to higher frictional forces, so proper cooling and lubrication are critical to avoid bearing damage.

How to Extend the Life of Connecting Rod Bearings

Extending the life of connecting rod bearings is crucial for ensuring long-term engine reliability and performance. By following key maintenance practices, choosing the right oil, and monitoring engine performance, you can significantly reduce wear and prevent bearing failure.

1. Regular Maintenance Tips

Regular maintenance is vital to prevent the buildup of wear and damage over time. Some important steps include:

- Frequent Oil Changes: Replace engine oil at regular intervals as recommended by the manufacturer. Fresh oil reduces friction and prevents contamination from wearing down the bearing surfaces.

- Inspect Bearings During Overhauls: Whenever the engine is disassembled for an overhaul, inspect the connecting rod bearings for signs of wear, scoring, or uneven contact patterns. Replacing worn bearings during scheduled maintenance can prevent catastrophic failure later.

- Clean Oil Filters: Ensure oil filters are replaced regularly to prevent dirt, metal shavings, and contaminants from circulating through the engine and damaging the bearings.

2. Choosing the Right Oil and Maintaining Proper Lubrication

Selecting the right oil is essential for ensuring proper lubrication and prolonging the life of connecting rod bearings:

- Use Manufacturer-Recommended Oil: Always use the oil grade specified by the engine manufacturer. High-performance or heavy-duty engines may require specialized oil with higher viscosity and better high-temperature properties.

- Maintain Correct Oil Pressure: Ensure the engine maintains adequate oil pressure at all times. Low oil pressure can lead to insufficient lubrication, causing excessive wear on the bearings.

- Monitor Oil Levels Regularly: Consistently check and top up engine oil levels. Running the engine with low oil levels leads to oil starvation, which can cause bearing failure.

- Consider Oil Additives for High-Performance Engines: In high-performance or heavily loaded engines, oil additives can enhance lubrication, improve viscosity, and provide additional protection against wear.

3. Monitoring Engine Performance to Prevent Premature Wear

- Check for Unusual Noises: Engine knocking or tapping sounds can indicate bearing wear. Early detection of these symptoms allows for timely maintenance before major damage occurs.

- Watch Oil Pressure Gauges: A sudden drop in oil pressure can signal potential bearing issues. Monitoring oil pressure helps detect lubrication problems early, preventing extensive bearing wear.

- Inspect for Metal Shavings: During oil changes, check for metal particles in the oil or oil filter, which can be an early sign of bearing deterioration. This can help catch the issue before it becomes severe.

- Temperature Monitoring: In high-performance engines, consistently high operating temperatures can stress the bearings. Monitoring engine temperature helps ensure the engine is not overheating, which could damage the bearings.

FAQ on “Connecting Rod Bearing”

Q- What is the function of a connecting rod bearing?

A- It reduces friction between the connecting rod and crankshaft for smooth engine operation.

Q- What causes connecting rod bearing failure?

A- Common causes include oil starvation, contamination, overheating, and engine overload.

Q- How do you know if a connecting rod bearing is failing?

A- Symptoms include engine knocking, low oil pressure, and metal particles in the oil.

Q- How often should connecting rod bearings be replaced?

A- They should be inspected during engine overhauls and replaced if signs of wear are found.

Conclusion

Proper maintenance and understanding of connecting rod bearings are crucial for ensuring engine reliability and performance. By selecting the right bearing type, monitoring engine conditions, and adhering to regular maintenance practices, you can extend the life of your bearings and prevent costly repairs. Paying attention to key signs like oil pressure, unusual noises, and oil contamination will help detect problems early, keeping your engine running smoothly for years to come.