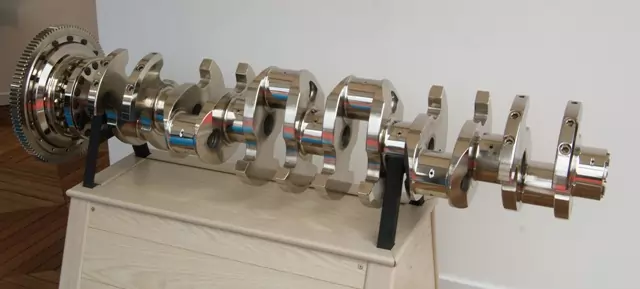

Crankshaft In Engine

The crankshaft is an internal combustion engine’s most mysterious, complicated, and crucial component. A crankshaft is the heart of an engine. The crankshaft converts the reciprocating motion into rotary motion developed due to the combustion of fuel and air inside the combustion chamber. This rotary motion is further transmitted for various applications. In the case of Propulsion engines, it is used for rotating the Propeller, and for Generators, it is used for turning the Alternator.

Crankshaft Function

Other components’ function depends upon the correct revolution of Crankshafts, such as the Camshaft for the firing order and fuel timing. The Engine will stand a standstill if a single part of the Crankshaft fails.

Due to the operation’s nature, the Diesel engine crankshaft is subjected to several forces like bending and twisting action upon the Crankshafts depending upon the applications’ nature. These forces are due to various factors not limited to the piston’s weight, combustion loads, axial load from propellers, compression loads of webs on journals, and generators’ heavy torque loads.

It is also used in many other types of machines, such as diesel engines, lawn mowers, and farm machines. In this article, we will be discussing the basics of crankshaft theory and how to choose the best one for your need.

We will also be discussing the different types of crankshafts and how to choose the right one for your engine. There are different types of the crankshaft, and it’s important to know which one you are using in order to properly operate your engine.

What is the best crankshaft material?

The SAE-4340 (AMS-6414) is a high-performance alloy that is a favorite choice in forged and billet applications. With its excellent strength and fatigue properties, this alloy is ideal for high-performance crankshaft applications. It is also very ductile and impact-resistant, making it a great choice for engines and motors.

What are the main parts of the crankshaft?

A crankshaft comprises the following components:

- Main journals.

- Crank pins.

- Crank webs.

- Counterweights.

Types of the Diesel engine crankshaft

Solid Single Piece crankshaft

A solid Single Piece crankshaft is a single piece of material. These types of crankshafts are usually used in the multi-cylinder engine and are compatible with engines working on both moderate speed and high speed.

Semi Built crankshaft

Semi-Built crankshafts are designed to offer high performance and durability. The crankshafts are cast from a single piece of forged steel and have a shrink-fit main shaft. The pins and crank throws are cast separately and then installed. This design offers high strength and eliminates the need for connecting rods.

The advantage of this method is the crankpins and webs are single forgings and the web can be reduced in thickness reducing the weight without affecting the strength. But there is a disadvantage that due to the shrink fit developed hoop stresses can lead to cracks. This can be prevented by balancing the unit.

Fully Built designed Crankshaft

Fully Built Crankshaft is a brand of crankshafts that are designed for ease of assembly and replacement of damaged parts. The crankshaft is assembled by shrink fitting. There is no welding or brazing required. Very simple construction and design make the replacement of damaged parts very easy.

Welded Crankshaft

The welded crankshaft was developed in the 1980s. It was made up of a series of forgings each comprising of half a main journal, web, crankpin, second web, and half a main journal. These forgings were then welded together using a submerged arc welding process to form the crankshaft.

Reasons for engine crankshaft Failure

- Over speeding of Engine on Load.

- Eddy currents/ stray currents being passed from Faulty Alternator

- Fatigue failure originated from the lip of a bored oil hole in the crankpin.

- Heavy vibration created due to torsion may lead to a crack in the crankpin and main journals.

- Starvation of lubrication has been found the most common cause of bearing failures resulting in the significant loss of crankshafts.

- The cylinder was over-pressurized due to the hydraulic lock due to water leakage in the cylinders.

- Crack developed on the fillets.

- Misaligned Crankshaft

Reason for the engine crankshaft misalignment

- Damaged main Bearing

- Disturbed line bore of bedplate in Over slung type of Crankshaft holding arrangement

- Disturbed line bore of the cylinder block in the underslung type of crankshaft holding arrangements.

- Incorrect tightness of the foundation bolts

- Crack in bearing saddle

- Loose Main bearing bolts

- Excessive forces from piston assembly are causing bending moments.

- Crankcase fire/explosion

- Cracked bearing housing

- Broken tie bolts

- Structure weakening due to erosion and corrosion

How to prevent engine crankshaft failure

- Take immediate action to eliminate the vibration. Don’t run the engine for a prolonged period with heavy vibration.

- Check the foundation bolts of the Engine regularly.

- Keep the Engine Tuned

- Check the Deflection of the Crankshaft regularly.

- Keep the Engine and Alternator aligned and should maintain the alignment reading within the prescribed limits.

- Always look for any metal particle on the lube oil filter disc while cleaning.

- Get the Lube oil sample checked periodically.

- Many times Governor Malfunctioning has been the reason for Engine over speeding. Hence carry out the Governor maintenance periodically as per the schedule.

- Avoid Overloading of Engine

- Avoid Over speeding of Engine.

- Carry out the function test of the following instruments

- a) Over-speed trip

- b) Low lube oil pressure alarm.

- c) High lube oil temperature alarm

- d) Crankcase pressure alarm

Primary Symptoms of engine crankshaft Misalignment

- Increased Vibration

- High body casting temperature

- Frequent loosening/breaking of foundation bolts

- Shims and dowels are getting loosened up.

- Excessive leakage at seals

- High rate of coupling failure

- Premature & frequent failure of Bearings

Our top picks on Crankshaft In Engine

Eagle Cast Steel Crankshaft for Small Block Chevy

The Eagle Specialty Products 103523480 3.48″ Cast Steel Crankshaft for Small Block Chevy is designed to fit a small block, Chevy. It is made from high-quality steel and has a fit type that is specific to the Chevrolet small block. The package dimensions are 71.12 L x 22.098 H x 20.828 W (centimeters) and the package weight is 52.8 pounds. The Eagle Specialty Products 103523480 3.48″ Cast Steel Crankshaft for Small Block Chevy is a great choice for a small block Chevy.

Eagle Specialty Products Crankshaft

The Eagle Specialty Products 103503480 3.48″ Cast Steel Crankshaft for Small Block Chevy is a high-quality crankSHAFT for your small-block Chevy engine. This crankSHAFT is designed to fit most small block Chevy engines and is made of high-quality, Cast Steel. This crankSHAFT is a great option for those who are looking to improve their engine performance. The Eagle Specialty Products 103503480 3.48″ Cast Steel Crankshaft for Small Block Chevy is a reliable and affordable option that will help you achieve better performance and fuel economy.

Scat Cast Steel Crankshaft

Scat’s hi-tech, fatigue-resistant 9000 material cast steel cranks have near forged steel endurance at a value price! A perfect way to increase cubic inches on mild to the moderate street or race engines. For 2-piece rear main blocks. Aero-wing counterweights increase horsepower by reducing windage. Straight shot oil holes. Lightening holes in all rod throws. Precision ground and micro-polished. Externally balanced.

Eagle Specialty Products 103404000

Eagle Specialty Products 103404000 4″ Stroke Cast Steel Crankshaft for Small Block Mopar is a high-quality cast iron crankSHAFT for your small-block car. This crankSHAFT is designed for superior performance and durable use. It is a great addition to your small block car and is perfect for those who want to improve the performance of their small-block car. With a dimension of 9.24 inches by 24.79 inches by 11.02 inches, this crankSHAFT is perfect for your small-block car. This cast iron crankSHAFT is also a weight of 54.0 pounds.

Eagle Specialty Products 103503750

Eagle Specialty Products 103503750 3.75″ Cast Steel Crankshaft for Small Block Chevy is a cast iron crankSHAFT that is specifically designed for small block Chevy engines. This crankSHAFT is a great replacement for your failing or worn-out crankSHAFT and is a direct replacement for your OEM part. This crankSHAFT is a high-quality product and is designed to fit your small-block Chevy engine.

What is a Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert reciprocating motion into rotary motion. A crankshaft is a rotating shaft containing one or more crankpins driven by pistons through connecting rods.

What are the factors to be considered for the selection of material for crankshaft?

Crankshaft materials must have sufficient strength, toughness, hardness and high fatigue strength. The main competitors for crankshaft materials in the industry are forged steel and cast iron. Performance comparisons of these materials refer to CES analysis.

What is the best type of crankshaft?

Forged steel crankshafts are ideal for heavily modified engines and most race applications. During the forging process, a single piece of molten steel is compressed and pressed into a virtually final state using heavy-duty presses and dies

FAQ on Crankshaft In Engine

Blog Conclusion

We hope you enjoyed our article on what a crankshaft is. This article will help you find the correct crankshaft product that will meet your needs. It’s all about finding the right product for the job. Please contact us if you have any questions or comments. You can find us at http://sh057.global.temp.domains/~arinedie/contact-us/. Thank you for reading, you can find a lot more information about crankshafts on our website.