Crosshead Bearing

Crosshead bearings play a crucial role in marine engines, ensuring smooth and efficient operation under heavy loads. These bearings are essential components that reduce friction between moving parts, particularly where the piston rod connects to the crankshaft. By absorbing lateral forces and keeping the piston rod in proper alignment, crosshead bearings prevent excessive wear and tear on engine components, extending the engine’s life and enhancing performance. Without the support of crosshead bearings, the piston rod would experience undue strain, leading to potential misalignment, increased vibrations, and even component failure.

Their importance in marine engines cannot be overstated, as they provide the critical function of distributing loads while maintaining optimal engine efficiency. Regular maintenance and monitoring of crosshead bearings are vital to ensure the engine operates reliably and safely, making these components a key focus in any marine engine’s care regimen.

Crosshead Bearing Warning Signs & Quick Fixes

| Symptom | Possible Cause | Quick Fix / Action | Additional Tips |

|---|---|---|---|

| Abnormal vibration | Excessive clearance | Inspect bearing, measure clearance | Compare with maker’s specs; if out of limits, adjust or replace bearing |

| Rattling noise | Misalignment or wear | Realign, check/replace components | Inspect piston rod alignment and crosshead shoe; check for uneven wear |

| High oil temperature | Poor lubrication | Check oil flow, replace dirty oil | Inspect lubrication system for blockages and ensure oil grade is correct |

| Oil leakage | Excessive clearance/wear | Inspect seal, correct clearance | Ensure all sealing surfaces are clean and undamaged; renew seals if needed |

| Metallic knocking | Excessive bearing wear | Stop engine, inspect immediately | Check for visible scoring or damage; don’t restart until cause is found |

| Sudden oil pressure drop | Bearing failure or blockage | Stop engine, inspect bearings and oil lines | Change oil filters if debris is found; confirm main oil galleries are clear |

| Increased metal particles in oil | Advanced bearing wear | Analyze oil sample and plan urgent inspection | Schedule bearing overhaul; perform regular oil analysis for early warning signs |

What is a Crosshead Bearing?

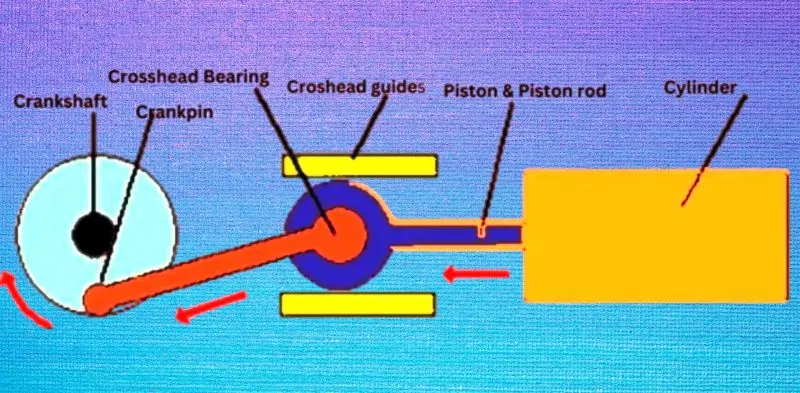

A crosshead bearing is a critical component in large marine engines, specifically designed to handle the reciprocating motion of the piston and convert it into rotary motion. This bearing is positioned between the piston rod and the connecting rod, enabling smooth movement by supporting the piston rod’s linear motion while allowing the connecting rod to rotate with the crankshaft.

Function of the Crosshead Bearing in Marine Engines

The primary function of a crosshead bearing is to reduce friction and absorb lateral forces that occur during engine operation. It supports the piston rod’s movement while preventing undue wear on the connecting rod and crankshaft. By maintaining alignment and reducing wear, the crosshead bearing ensures smooth operation and extends the life of the engine components.

Key Components of a Crosshead Bearing

- Piston rod: Transmits motion to the crosshead bearing.

- Connecting rod: Rotates with the crankshaft while attached to the crosshead bearing.

- Sliding surfaces: Reduce friction between moving parts.

- Lubrication system: Ensures smooth operation and minimizes wear.

Types of Crosshead Bearings

Crosshead bearings are designed to manage the heavy loads and dynamic forces in marine engines. There are two main types of crosshead bearings used in these engines, each with unique characteristics suited for specific applications: full-floating crosshead bearings and semi-floating crosshead bearings.

Full-Floating Crosshead Bearings

A full-floating crosshead bearing is designed to move freely between the piston rod and connecting rod. It is not fixed to either part, allowing it to rotate and reduce wear on both surfaces. This type of bearing distributes load more evenly and reduces the impact of friction, making it ideal for high-performance engines. The bearing is fully surrounded by lubricating oil, which helps maintain smooth operation.

Semi-Floating Crosshead Bearings

In a semi-floating crosshead bearing, the bearing is fixed to one component, typically the connecting rod, and only moves relative to the piston rod. This design allows for less rotational freedom compared to full-floating bearings, but it still provides adequate load distribution and friction reduction.

Key Differences

- Rotational Movement: Full-floating bearings rotate freely between both components, while semi-floating bearings are fixed to one part.

- Wear Distribution: Full-floating bearings offer better wear distribution due to their ability to move freely, while semi-floating bearings may concentrate wear on one surface.

- Application: Full-floating bearings are preferred for engines requiring higher performance and durability, while semi-floating bearings are used in applications with moderate demands.

Material Used in Crosshead Bearings

Crosshead bearings in marine engines must endure high pressures, heavy loads, and extreme conditions, so the choice of materials is critical. The materials used in manufacturing crosshead bearings are selected for their strength, durability, and ability to handle the tough demands of marine environments.

Common Materials Used in Crosshead Bearings

- White Metal (Babbitt Alloy): A soft, wear-resistant material often used for the lining of crosshead bearings. It provides excellent conformity and embeddability, allowing it to accommodate minor misalignments and absorb small particles without causing damage.

- Bronze Alloys: Known for their strength and durability, bronze alloys are often used in the backing of crosshead bearings. They offer high load-bearing capacity and resistance to wear, making them ideal for heavy-duty applications.

- Steel: Steel is used as the main structural material for the outer shell of crosshead bearings. Its high strength and toughness provide the necessary support to withstand high pressures.

Why These Materials Are Chosen

- Wear Resistance: Materials like white metal and bronze alloys are selected for their ability to resist wear, ensuring the longevity of the bearing and reducing the frequency of replacements.

- High Load-Bearing Capacity: Crosshead bearings must support the heavy loads generated by the engine’s reciprocating motion. Bronze alloys and steel offer the strength required to handle these forces without deforming.

- Friction Reduction: White metal provides a low-friction surface, reducing the heat generated by the constant movement within the engine, which helps improve efficiency and prevent premature failure.

Crosshead Bearing Clearance: What It Means

Crosshead bearing clearance refers to the small gap between the bearing surface and the components it supports, such as the piston rod and connecting rod. This clearance is critical in marine engines, as it ensures that the bearing functions smoothly, reducing friction and allowing proper lubrication to reach all surfaces.

Explanation of Crosshead Bearing Clearance

Crosshead bearing clearance is essential for the smooth operation of an engine. It allows a thin film of lubricating oil to form between the bearing surfaces, reducing metal-to-metal contact and minimizing wear. If the clearance is too tight, there may not be enough room for oil to circulate, leading to excessive friction and heat. On the other hand, if the clearance is too large, the bearing may not adequately support the moving parts, causing misalignment and increased vibration.

The Significance of Maintaining the Correct Clearance

Maintaining the correct crosshead bearing clearance is crucial for several reasons:

- Prevents Excessive Wear: Proper clearance helps ensure that the bearing doesn’t wear down prematurely, extending its lifespan.

- Reduces Friction: Optimal clearance allows for efficient lubrication, reducing friction between moving parts and improving engine performance.

- Prevents Misalignment: Maintaining the correct clearance ensures that the piston rod and connecting rod remain properly aligned, preventing issues like vibration and uneven load distribution.

- Enhances Engine Efficiency: When clearance is within the recommended range, the engine operates more efficiently, reducing fuel consumption and wear on other engine components.

What Will Happen if Crosshead Bearing Clearance Increases?

An increase in crosshead bearing clearance can have serious consequences for the performance and longevity of a marine engine. When the clearance grows beyond the specified limits, the engine’s components are no longer properly supported, leading to a cascade of mechanical issues.

Effects of Increased Crosshead Bearing Clearance

- Increased Wear and Tear on Engine Components

- With excessive clearance, the bearing’s ability to reduce friction diminishes, causing more metal-to-metal contact. This leads to accelerated wear of the piston rod, connecting rod, and other associated components, potentially shortening their lifespan and requiring more frequent maintenance.

- Potential Misalignment Between Piston and Crankshaft

- A larger clearance can cause the piston rod to shift slightly out of alignment, creating uneven loading on the crankshaft. This misalignment can lead to inefficient engine operation and uneven wear, increasing the likelihood of mechanical failure over time.

- Increased Engine Vibration

- As the bearing clearance increases, the engine components may move erratically, causing abnormal vibrations. These vibrations can be felt throughout the engine and can exacerbate wear, loosen fasteners, and create additional stresses on the engine structure.

- Risk of Overheating Due to Improper Lubrication

- Proper lubrication depends on maintaining a precise clearance. When the gap becomes too large, the oil film cannot effectively fill the space, resulting in improper lubrication. This can lead to increased friction, causing overheating in the bearing and surrounding components, which may eventually lead to damage.

- Possibility of Crosshead Bearing Failure

- If the clearance issue is not addressed, the crosshead bearing itself may fail. Bearing failure can cause severe damage to the engine, leading to costly repairs or even a complete engine overhaul. In extreme cases, bearing failure may result in engine shutdown, jeopardizing the operation of the vessel.

How to Measure Crosshead Bearing Clearance

Measuring the clearance of a crosshead bearing is an essential maintenance task in marine engines. Proper clearance ensures smooth operation and prevents premature wear. Below is a step-by-step guide on how to accurately measure crosshead bearing clearance and the tools required for the job.

Step-by-Step Guide

- Preparation

- Ensure the engine is stopped, locked out, and has cooled down to a safe temperature.

- Drain the lubricating oil from the system, if necessary, to avoid contamination during the process.

- Access the Crosshead Bearing

- Open the necessary inspection covers or access panels to expose the crosshead bearing assembly.

- Clean the area thoroughly to remove any dirt, debris, or oil that could affect the measurement process.

- Position the Piston

- Turn the crankshaft manually to bring the piston to the correct position, typically at the bottom dead center (BDC), where the bearing is most accessible.

- Insert Measuring Tool

- Use a feeler gauge or a dial gauge to measure the clearance. Feeler gauges are commonly used to measure the gap between the bearing surface and the crankpin.

- Insert the feeler gauge between the bearing surface and the crankpin or rod end, checking for the correct fit.

- Record the Clearance

- Gently move the gauge in and out, taking note of the resistance. The gauge should fit snugly without force.

- Record the clearance value at several points around the bearing to ensure consistent measurement and detect any uneven wear.

- Compare with Manufacturer Specifications

- Compare the recorded measurements with the manufacturer’s recommended clearance range for your engine model. If the clearance exceeds the specified limits, corrective action may be required.

- Reassemble the Engine

- Once the measurements are complete, reassemble the engine, ensuring all components are clean and securely in place.

- Restore the lubricating oil, if necessary, and ensure that all inspection panels are closed and sealed properly.

Tools and Instruments Required

- Feeler Gauge: A precision tool used to measure small gaps between components.

- Dial Gauge: A more advanced tool that can measure the exact clearance with high precision.

- Crankshaft Turning Tool: Used to manually rotate the crankshaft to the desired position.

- Torque Wrench: For tightening bolts and securing components after measurement.

- Inspection Light: To improve visibility inside the engine compartment during measurement.

What to Do if Crosshead Bearing Clearance Increases?

If crosshead bearing clearance increases beyond the manufacturer’s specified limits, immediate action is necessary to prevent serious engine damage. While the clearance is typically measured when the engine is at a standstill, certain symptoms during engine operation can indicate the issue. Here’s a complete guide on what to do if excessive clearance is detected, including steps for managing the engine while running, actions to take once the engine is stopped, and the importance of regular inspections and maintenance.

Indications of Excessive Crosshead Bearing Clearance in a Running Engine

- Abnormal Vibration

Excessive clearance can lead to misalignment, causing the piston rod and crosshead to move erratically. This misalignment results in noticeable vibrations, which may become more severe as the engine continues to operate. - Increased Engine Noise

A metallic knocking or rattling noise during engine operation may suggest excessive clearance. This sound results from improper movement and contact between the engine’s moving parts, particularly in the crosshead and piston rod areas. - High Lubrication Oil Temperature

Improper lubrication is often caused by excessive clearance, leading to increased friction between the bearing surfaces. This results in a rise in lubrication oil temperature, which can be an early warning sign. - Abnormal Oil Consumption or Oil Leaks

Excessive clearance can cause improper sealing, leading to higher oil consumption or oil leaks around the crosshead area. These issues can indicate that the bearing is wearing down or that lubrication is insufficient. - Increased Wear Particle Count in Oil Analysis

Regular oil analysis can reveal elevated levels of metal particles, indicating bearing wear. This is a strong indicator of excessive clearance and should prompt immediate investigation. - Engine Performance Decrease

Increased friction and misalignment due to excessive clearance can reduce the engine’s performance. You might notice a drop in power output or fuel efficiency, which could suggest crosshead bearing issues.

Immediate Actions to Take During Operation

If excessive clearance is suspected while the engine is running, immediate actions can help mitigate damage until a full inspection can be carried out:

- Reduce Engine Load

Lowering the engine load minimizes stress on the crosshead bearing, reducing the risk of severe damage. This allows the engine to operate at a safer level while monitoring the situation. - Monitor Temperature and Vibration

Continuously monitor the engine’s temperature and vibration levels. Significant increases in temperature or abnormal vibrations indicate the need to stop the engine as soon as safely possible. - Notify the Engine Room Team

Inform the engine room crew about the situation so they can prepare for potential shutdown and maintenance. Early coordination ensures readiness for prompt action. - Plan for Immediate Maintenance

Schedule the engine to be stopped at the earliest opportunity for inspection. This should be treated as urgent maintenance to prevent further damage.

Actions After Stopping the Engine

Once the engine is safely shut down, follow these steps to address the issue:

- Inspect for Signs of Wear

Conduct a thorough inspection of the crosshead bearing, piston rod, and connecting rod for any signs of excessive wear, misalignment, or damage. Additionally, check the lubrication system for proper oil flow and any signs of leakage. - Measure the Crosshead Bearing Clearance

Use a feeler gauge or dial gauge to measure the clearance. Compare the results with the manufacturer’s specifications to determine if adjustments or replacements are necessary.

Procedures for Adjusting or Replacing the Crosshead Bearing

- Adjustment of Clearance

If the increased clearance is within adjustable limits, fine adjustments can be made by tightening the bearing caps or adjusting shims. Careful measurements should be taken to ensure the clearance returns to specification. Always verify clearance after making adjustments. - Replacement of Crosshead Bearing

If the clearance is beyond the adjustment range or if the bearing shows significant wear, replacement is required:- Remove the bearing caps and disassemble the crosshead bearing carefully.

- Inspect the crankpin and other related components for damage.

- Install a new crosshead bearing, ensuring proper fit and alignment.

- Recheck the clearance after the installation to ensure it meets the recommended values.

- Lubrication System Check

After adjustments or replacement, check the lubrication system to ensure it is functioning correctly. Proper oil flow is critical for the long-term performance of the new or adjusted bearing.

Importance of Regular Inspections and Maintenance

Maintaining the correct crosshead bearing clearance is critical for the safe and efficient operation of marine engines. Regular inspections help detect wear early, allowing for timely adjustments or replacements before serious damage occurs. Routine monitoring of engine performance, oil analysis, and vibration levels can provide early warning signs of clearance issues, helping to prevent costly repairs or unscheduled downtime.

By staying proactive with crosshead bearing inspections and maintenance, engine operators can extend the lifespan of these essential components, ensuring reliable engine operation and reducing the risk of catastrophic failure.

Common Causes of Increased Crosshead Bearing Clearance

Excessive crosshead bearing clearance can arise from a variety of factors, all of which can negatively affect the performance and longevity of a marine engine. Understanding the common causes is essential for preventing premature wear and ensuring the engine operates smoothly.

Normal Wear and Tear Over Time

As with any mechanical component, crosshead bearings are subject to normal wear and tear due to the continuous movement and heavy loads they endure. Over time, the surfaces of the bearing and related components may experience gradual degradation, leading to increased clearance. Regular maintenance and timely replacement are necessary to address this inevitable wear and keep the engine in optimal condition.

Poor Lubrication or Contamination in the Bearing

Poor lubrication is one of the most common causes of increased clearance. When the bearing does not receive sufficient oil or the oil is contaminated with dirt, debris, or metal particles, friction between the bearing surfaces increases. This leads to faster wear of the bearing and other components. Contamination can also cause pitting and scoring on the bearing surface, further exacerbating clearance issues. Ensuring proper lubrication and clean oil is crucial for preventing this problem.

Misalignment in the Engine

Engine misalignment can occur due to improper assembly, shifting of components during operation, or gradual wear in other parts of the engine. When the piston rod or crankshaft becomes misaligned, uneven forces are applied to the crosshead bearing. This uneven load distribution can cause localized wear, leading to increased clearance. Correcting misalignment and regularly checking the engine’s alignment during maintenance can help avoid this issue.

Incorrect Installation or Use of Substandard Materials

Improper installation of the crosshead bearing, such as incorrect torque on bearing caps or failure to follow the manufacturer’s guidelines, can cause premature clearance increases. Additionally, using substandard materials for the bearing or associated components may lead to faster wear and inadequate performance under load. Ensuring proper installation procedures and using high-quality materials are critical for maintaining the correct bearing clearance over time.

By understanding these common causes of increased crosshead bearing clearance, operators can take proactive steps to address potential issues, minimize wear, and extend the life of the engine’s critical components. Regular inspections and maintenance are key to preventing these problems from becoming major failures.

Crosshead Bearing Maintenance and Inspection

Regular maintenance and inspection of crosshead bearings are essential for ensuring the long-term reliability and efficiency of marine engines. Proper care can prevent unexpected failures, reduce wear, and extend the lifespan of these critical components. Here’s a guide to the importance of regular inspections, maintenance tips, and warning signs to watch for.

Importance of Regular Inspection Intervals

Crosshead bearings operate under extreme loads and high-stress conditions, making them susceptible to wear over time. Regular inspection intervals are crucial to detecting early signs of wear, misalignment, or lubrication issues before they cause serious damage. Scheduled inspections allow for preventive measures such as adjustments, lubrication checks, and, if necessary, bearing replacement. These intervals should be based on the manufacturer’s recommendations and the operating conditions of the engine.

Timely inspections ensure that minor issues are addressed early, preventing costly repairs and downtime. Inspections also help in optimizing engine performance, as crosshead bearings play a critical role in the engine’s smooth operation.

Tips for Maintaining Optimal Crosshead Bearing Performance

- Ensure Proper Lubrication

Regularly check the lubrication system to confirm that the bearings are receiving the right amount of oil. Proper lubrication reduces friction, minimizes wear, and keeps the bearing cool during operation. Ensure that the oil used is clean and free from contaminants, as dirty oil can accelerate bearing wear. - Monitor Engine Alignment

Misalignment can cause uneven loading on the crosshead bearings, leading to increased wear and clearance issues. Regularly check the engine’s alignment to ensure that all components, including the piston rod and crankshaft, are correctly positioned. - Follow Manufacturer’s Maintenance Guidelines

Adhere to the manufacturer’s specifications for bearing installation, clearance measurements, and torque settings. Using the right procedures and tools during maintenance ensures that the bearing is installed and adjusted properly, which helps maintain optimal performance. - Use Quality Materials

When replacing bearings, always use high-quality, manufacturer-approved materials. Substandard bearings may not withstand the heavy loads and harsh operating conditions, leading to premature failure.

Warning Signs to Watch For

Detecting early warning signs of crosshead bearing issues can prevent major failures and reduce costly repairs. Here are some key indicators to watch for:

- Unusual Sounds: A knocking or rattling sound coming from the engine may indicate excessive bearing clearance or misalignment. This sound results from components moving more freely than they should due to increased clearance.

- Engine Vibration: Excessive vibrations during operation can signal that the crosshead bearing is misaligned or worn. These vibrations may worsen over time and can affect the entire engine system if not addressed promptly.

- Oil Leakage: Leaking oil from the crosshead bearing area can indicate improper sealing due to excessive clearance or wear. Oil leaks should be addressed immediately, as they can lead to lubrication failure and overheating of the bearing.

- Abnormal Oil Consumption: A sudden increase in oil consumption may be a sign of poor lubrication within the bearing or wear that is causing oil to escape.

FAQ: Crosshead Bearing

Q: What is a crosshead bearing?

A: A crosshead bearing is part of an engine, typically used in long-stroke engines like ship engines.

Q: What is the purpose of the crosshead?

A: The crosshead helps reduce sideways pressure on the piston.

Q: Where is the crosshead located?

A: The crosshead is positioned between the piston and the connecting rod in an engine.

Q: What material is used for the crosshead?

A: The crosshead is made of forged steel, with guide shoes lined with white metal for durability.

Conclusion

Crosshead bearings are vital components in marine engines, playing a key role in reducing friction and ensuring smooth operation under heavy loads. Proper maintenance and regular inspections are essential for preventing excessive wear, misalignment, and other issues that can lead to costly repairs or engine failure. By understanding the causes of increased clearance, taking proactive measures, and following recommended guidelines, operators can extend the life of crosshead bearings and maintain optimal engine performance. Investing in regular care and monitoring of these critical components ensures the reliability and efficiency of marine engines, making crosshead bearing maintenance a top priority for marine engineers.