Diesel Engine Breakdown and Remedies

Diesel Engine Breakdowns are something that happens to a lot of people. When their engines start to fail, they often have to go out and buy a new engine. In some cases, this can be a very expensive endeavor. In this blog post, we will help the readers to understand Diesel Engine Breakdowns and how to avoid them. We will also cover the different types of Diesel Engine Breakdowns and what you can do to prevent them. The author has put in all their best efforts to explain the topic of the Breakdown Of Marine Diesel Engines with his 43 years of experience in various make leading Diesel Engines installed onboard ships and land industries.

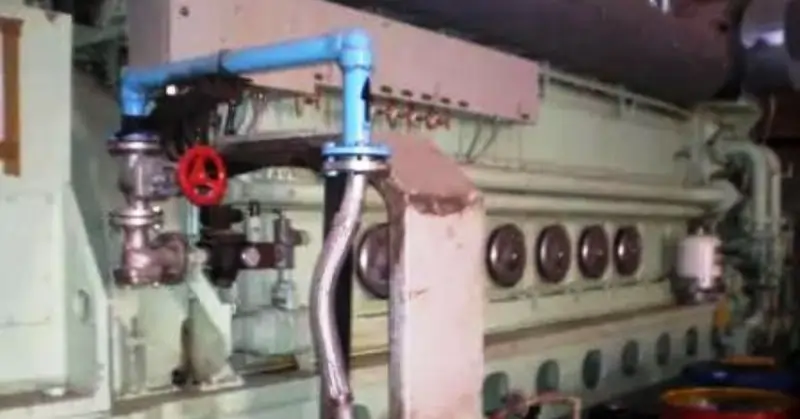

Engine Monitoring concept

Introduction

There are rare intermittent and catastrophic failure chances if a machine is maintained with genuine spare parts as per the manufacturer’s guidelines. Every machine has its shortcomings. A shortcoming will only appear after the engine has been put on its absolute life service—almost one-quarter of the Breakdown Marine Diesel Engine Breakdown and accidents onboard a ship occur only due to machinery failure.

In the light of experience, one will realize that any Engine before a failure will give the warning signals. Warning signals in the form of some abnormal sound, any operating parameters beyond the specified limits, or any visual vibrations are the potential indications of any Major or catastrophic failure. If the warning signals are not taken care of, then there will be a breakdown.

Maintenance minimizes the severity of the failure and Breakdown Of Marine Diesel Engines. Preventive maintenance cost is much less than the occurred damage.

Due to the following general reasons, machinery fails apart from the reasons discussed further in the post.

- Unfit equipment for the Marine.

- Ingress of water into Machinery systems

- Not maintained properly

- Operator’s mistake

- Almost a great % of accidents take place after maintenance

Diving Deep: Diesel Engine Breakdown Causes & Prevention

Never continue a machine operation in case of the following abnormalities.

(Abnormal )Running Conditions of an Engine

Obnoxious Sound. – In case of any obnoxious sound, the Engine Engineer should be stopped immediately. However, there are other sounds of associated parts on the machine as well as in the Engine room. Not to take The abnormal sound is from other oscillating and running features like Turbochargers, the oscillating sound of pistons, pumps, etc. If overlooked then it will cause Diesel Engine Breakdown.

- Abnormal parameters/lubricating oil. If the Lube oil Pressure has gone down below the prescribed minimum limit and the temperature is rising higher than the limit, the Engineer should stop immediately. Carry out RCA (Root cause analysis) and rectify the abnormality before restarting.

- Smoke: – if you observe smoke from any part, Stop the Engine immediately without giving a second thought to it as there are many serious reasons for fire apart from leakage of exhaust from some loose joint. Any ignoring of smoke could lead to a crankcase explosion and major seizure of components.

- Observation of parameters.- During the Engine parameters monitoring, it is good practice to report the abnormal parameters. In Lube Oil’s uncommon pressure difference (Differential pressure), the Engineer should immediately stop the Engine. Else could be a significant seizure as a typical practice Lube oil filter is to be primed immediately during assembly after cleaning. In this case of changing over during the Engine in operation, the changeover will be successful.

- Sudden choking of Lube Oil Filters is a clear warning signal of the Ingress of water in Lube oil or the Bearing failure. After changing over the filter, carry out a thorough inspection to look for the water particles or any bearing material on the filter cartridge.

- Overspeeding: – In most cases, speeding takes place due to the malfunctioning of the Governor. Governor overhauling is not done due to the non-availability of proper facilities like unique test benches and tools. It is also impossible for the Chief Engineer/ Engineer to send the Governor to external agencies for the overhaul due to the short stay at port. It is a good practice to stock a standby Governor. Another reason for overspeed is stuck/ jammed fuel racks.

- Cooling Water Failure.- In case of Cooling water supply to the Engine fails. The Engine will get overheated, and Engine moving parts like pistons and Crankshaft will seize due to the overheating. A Piston seizure in the liner took place in many such cases and led to a significant Piston breaking and connecting rod damaging the cylinder block. In case an engineer observes the cooling water supply failure, he must stop the Engine immediately and continue turning the Engine by shaft barring arrangement. If the Engine is small, then continue turning the Engine manually till the coolant temperature is average.

- Vibration:- Vibration is the most critical and complex problem of a Diesel Engine and Diesel Engine Breakdown. The vibration will take place due to the following three main reasons.

- Engine running at a critical speed. Critical speed is the speed at which natural frequency coincides with the forced frequency.

- Loose part in a machine.

- Due to the Engine running unturned. The Engineer should check and balance the power by adjusting the fuel racks and controlling the peak pressures to balance it in all the cylinders.

However, In the case of vibration Engineer should stop the Engine immediately. The Engineer should never attempt to start without finding out the reason for the vibration.

- Leakages from Engine System: – Stop the Engine immediately if there is heavy leakage of Lube oil, Cooling water, and fuel. Many Engineers try to arrest the leakage while the engine is running. This practice can lead to leakage getting exaggerated and may lead to significant leakage. Hence never attempt to rectify the leakage while the Engine is in running condition.

Malfunctioning of Main Engine Safety Devices-Alarms and tripling instruments: Alarm and tripping system failure continues the Engine running with the malfunctioning /non-functional Alarm and Trip system of the Engine. The malfunctioning Alarm/trip system instrument should be changed or re-adjust the setting, whichever the case might be, before re-starting the Engine. otherwise, it will cause a Diesel Engine Breakdown.

- Lube oil Contamination with water/Fuel Oil:- There are two types of contamination of Lubrication oil.

- Water Contamination: This type of contamination is due to the leaky seals of pumps or Cylinder Liner sealing rings’ failure. In this process, Oil gets emulsified and chokes the Lubricating oil filters creating an abnormal differential pressure across the filters. Emulsification also reduces the lubricating qualities of Oil.

- Fuel Dilution:- In this case, Lube oil will get diluted with the fuel. Fuel dilution will reduce the viscosity of Lube oil and will affect the load-carrying capacity of Oil. If the Engine continues to run with this Oil condition, a significant failure of components like bearing seizure and Piston seizure will occur.

Reason for High Lubricating Oil Temperature

- Mal-functioning of Lube oil Thermostat

- Failure of Lubricating Oil cooling system

- Dilution with fuel oil

- Development of any hot spot inside the crankcase. ( Failure of Crankshaft Bearing, Con-rod Bearing, Piston seizure, Excessive Blow by In Crankcase.)

- Low Lube oil Level in Engine Sump

- Wrong reading by Instrument ( Temperature gauge, Temperature sensor)

In the event of a drop in Lube oil pressure, the Engine must be stopped immediately and rectify the fault.

Essential Tips to avoid Diesel Engine Breakdown on board ship for

- Carry out the Overhauling /Maintenance of the Engine as per the OEM ( Original Equipment Manufacturer) Recommendations

- Carry out all the laid-down maintenance routines

- Always use genuine spares. Superior quality spares are the most common reason for the Engine Breakdown.

- Take the services of an OEM (Original Equipment Manufacturer) service Specialist.

- Calibrate all the maintenance Tools before the maintenance.

- Maintain the stock of all the spares as per OEM (Original Equipment Manufacturer) and experienced base.

- Include all the points observed during the Engine Operation.

- Read the instruction book before assisting the service specialist.

- Most of the time Checking the tightest of the foundation bolts is neglected. Always check the tightness of the foundation bolts else it may lead to cracks due to vibrations

Solenoid Checks

A solenoid is a cylindrical coil of wire which becomes a magnet when the current passes through it. A movable core will be drawn into this coil and act like a switch or control the mechanical device. During the action it either pushes a knob or actuates a pneumatic valve to operate the system. Solenoid is used on board a ship mainly for the following

- Engine Starting Motor for Engine Starting and stopping the Engine as stop solenoid on the Engine Governor.

- Windlasses for the Ships anchor lowering and hoisting.

Each Solenoid has its own pattern of working. The following method is applicable for troubleshooting. In this case, if we attempt to start some equipment like an engine or windlass. Nothing happens after giving the command.

Causes of problem for Diesel Engine Breakdown

- Is the power is available on the solenoid from the main source? If there is no power then the problem might be due to a breaker trip, blown fuse or broken connection, or off battery position. If no power on the line side then it indicates that the solenoid is malfunctioning.

- Check whether the solenoid is working. Now it’s time to investigate the control circuit, which is the smaller terminals. If the voltage is not shown while the switch is kept on, the problem is somewhere else, somewhere in the keys and controls. Or in the power supply to that particular switch. Hence the problem is not in a solenoid. The problem may be in the circuit leading to the solenoid. If there is no time for you to follow the problem, then bypass the control circuit and operate the solenoid manually.

Governor oil selection chart (Diesel Engine Breakdown)

Always use the correct grade of oil for Governor per the following chart. An incorrect grade of oil may result in the malfunctioning of the Governor and consequently, the engine will overspend.

For the smooth voyage maintain the following emergency spares.

Engine Block and Covers

| Sr N. | Part | Qty |

| 1 | Main Bearing | 2 |

| 2 | Main Bearing Stud | 2 |

| 3 | Nut for Stud | 2 |

| 4 | Thrust Washer | 2 |

| 5 | Oil Sealing Ring for Cover | 1 |

Cylinder head and Cylinder Liner

| Sr. No. | Part | Qty |

| 1 | Valve Spindle Inlet | 2 |

| 2 | Valve Spindle Exhaust | 4 |

| 3 | Conical Piece | 6 |

| 4 | Valve Spring | 4 |

| 5 | Valve Seat Inlet | 2 |

| 6 | Valve Seat Exhaust | 4 |

| 7 | Valve Rotator | 4 |

| 8 | O ring For Cylinder Head | 4 |

| 9 | Sealing Ring for Cylinder Liner | 2 |

Piston and Connecting Rod

| Sr. No. | Part | Qty |

| 1 | Piston Pin | 1 |

| 2 | Piston Ring Top | 2 |

| 3 | Piston Ring 2nd | 2 |

| 4 | Piston Ring Scraper | 2 |

| 5 | Connecting Rod Bearing | 2 |

| 6 | Bush for Connecting Rod | 2 |

Fuel Injection Equipment

| Sr No. | Part | Qty |

| 1 | Fuel Injection Pump | 2 |

| 2 | Fuel Injection Valve | 2 |

| 3 | Atomizer | half of Cylinder Nos |

Piping System

| Sr.No | Part | Qty |

| 1 | Flexible Connection Pipe | 1 set |

| 2 | Lube Oil Filter Cartridge | 2 Set |

| 3 | Shaft Seal For Pre-Lube Oil Pump | 1 |

| 4 | Shaft Seal For Freshwater Pump | 2 |

Best Books on Diesel Engines

Fundamentals of Medium/Heavy-Duty Diesel Engines

Based on the 2014 National Automotive Technicians Education Foundation (NATEF) Medium/Heavy Truck Tasks Lists and ASE Certification Test Series for truck and bus specialists, Fundamentals of Medium/Heavy Duty Diesel Engines is designed to address these and other international training standards. The text offers comprehensive coverage of every NATEF task with clarity and precision in a concise format that ensures student comprehension and encourages critical thinking. Fundamentals of Medium/Heavy Duty Diesel Engines describes safe and effective diagnostic, repair, and maintenance procedures for today’s medium and heavy vehicle diesel engines, including the most current, relevant, and practical coverage of • HD-OBD emission diagnostics • Common rail injection systems

Pounder’s Marine Diesel Engines and Gas Turbines

Pounder’s Marine Diesel Engines has served seagoing engineers, students of the Certificates of Competency examinations, and the marine engineering industry throughout the world.

Now in its ninth edition, Pounder’s retains the directness of approach and attention to essential detail that characterized its predecessors. There are new chapters on monitoring control and HiMSEN engines as well as information on developments in electronic-controlled fuel injection. It is fully updated to cover new legislation including that on emissions and provides details on enhancing overall efficiency and cutting CO2 emissions.

After experience as a seagoing engineer with the British India Steam Navigation Company, Doug Woodyard held editorial positions with the Institution of Mechanical Engineers and the Institute of Marine Engineer

- Helps engineers to understand the latest changes to marine diesel engineers

- Careful organization of the new edition enables readers to access the information they require

- Brand new chapters focus on monitoring control systems and HiMSEN engines.

- Over 270 high-quality, clearly labeled illustrations and figures to aid understanding and help engineers quickly identify what they need to know.

Lamb’s Questions and Answers on the Marine Diesel Engine

Nearly every aspect of marine diesel engines is covered in the book.

Additionally, it describes air tanks, compressors, balancing, instruments, controls, and safety in addition to engine parts.

The book is called “Lamb’s Questions and Answers on the Marine Diesel Engine.” It was published in 1990 by Butterworth-Heinemann. The latest edition is the eighth, and it comes in hardcover.

A Pocket Book of Marine Engineering: Questions and Answers

Engine air filters are covered in depth in the book “A Pocket Book of Marine Engineering: Questions and Answers”. The person who wrote this book is an expert in Marine Engineering. He explains in detail the workings of engines and how to pick filters. Basics like steering, safety, engines, and many more marine engineering topics are in the scope of this book.

Diesel Generator Handbook

Diesel Generator Handbook meets the need for an authoritative reference work covering the range of mechanical and electrical topics embodied in the practical design and application of diesel-generating plants. It will be particularly welcomed in many parts of the developing world where the diesel generator is basic to the electricity supply system.

The discussion covers, in fifteen chapters, the prime mover, power ratings, synchronous generators, load assessment, control principles and systems, switchgear and control gear, standby power, fuels and lubricating oils, installation and commissioning, noise reduction, plant operation and maintenance.

The book thus caters to all who are concerned with the selection, specification, testing, commissioning, operation, and maintenance of diesel-based generator systems: not only the practicing plant or services engineers but also non-specialist engineers and users. The young technician or trainee engineer who is embarking on a career in the supply industry will find this handbook an invaluable investment.

L L J Mahon, FIEE, FBIM, after an engineering apprenticeship with BTH in Rugby, gained over 30 years of experience in the design, development, manufacture, installation, and commissioning of both stationary and highly specialized mobile diesel generator plants for a range of applications.

Blog Conclusion

We hope you enjoyed our article on Diesel Engine Breakdown. Diesel Engine Breakdown is a very large topic and there are a lot of different things to learn about it. However, we tried to break it down as much as possible for the readers. If you have any further questions about Diesel Engine Breakdown, please reach out to us at ttps://sh057.global.temp.domains/~arinedie/contact-us/. Thank you for reading and please leave a comment so we can hear from you.

FAQ

What is the major problem in diesel engine?

Over heating

Do diesel engines break down more?

Yes, due to the higher working pressure than the petrol engines

What is the life of a diesel engine?

More than 2lacs running hours

Which is the best diesel engine in India?

Hyundai