Diesel Generator Parts

Diesel generators are known for their efficiency and reliability as a primary power source and emergency backup. To keep these generators running smoothly, spare parts play a crucial role. These spare parts are necessary for emergency replacements in case of breakdowns and routine maintenance as recommended by the original equipment manufacturer (OEM) when certain components wear out.

Maintaining an inventory of emergency spare parts is essential, and it’s vital to create a list of critical spares that should be procured in advance to handle unexpected situations. On the other hand, spare parts for regular maintenance do not need to be stocked and can be obtained as part of planned maintenance activities, a task best carried out by experienced engineers.

From my own experience, I’ve encountered challenges when dealing with emergency breakdowns. Inadequate spare procurement planning for preventive maintenance can delay getting the engine back into operation after maintenance. It can also incur additional costs when procuring parts in a hurry.

I strongly emphasize using genuine spare parts, as using substandard alternatives can lead to catastrophic failures, causing significant damage to the equipment. Unfortunately, some individuals prioritize cost savings over quality. In such cases, engineering staff may acquire parts from unauthorized sources in the grey market, potentially jeopardizing the machine’s integrity and reliability. It’s crucial to prioritize the machine’s health and longevity over short-term financial gains.

What are spare parts?

Diesel generator parts are essential components that should be kept in inventory for various situations, including:

End of Part Life: When a part reaches the end of its operational life, it should be replaced with a new one to ensure the generator’s efficiency and reliability.

Rejection During Preventive Maintenance: Certain parts may be deemed unfit for further use during routine preventive maintenance checks. These rejected parts should be replaced promptly.

Damage During Equipment Breakdown or Accidents: Accidents or equipment breakdowns can damage generator parts. In such cases, immediate replacement is necessary to restore functionality.

The maintenance of spare parts inventory, as mentioned in points 1 and 2, should align with the equipment manufacturer’s guidelines. These guidelines typically list “wearing parts” that need regular replacement.

However, maintaining spare parts beyond these manufacturer guidelines is often based on practical experience and the insights of experienced engineers. Such decisions consider the unique history and performance of similar machines.

In some instances, certain high-value parts may have a low usage rate throughout the machine’s lifetime. Nonetheless, not having these critical parts readily available could result in significant costs for the plant or ship in case of unexpected failures.

Furthermore, given the extended delivery times for specific parts from suppliers, keeping these parts in stock for emergency use is advisable, ensuring minimal downtime during critical situations.

Critical Issues In Generator Maintenance

Based on my experience as the Head of Services and Spares, I have encountered several issues in the field:

- Owners often acquire generators and engines from ships, which are generally well-maintained. However, these machines can fail shortly after installation at new industrial sites. The primary reasons for these failures include:

- Procurement of Parts from Unreliable Sources: Owners sometimes opt for cheaper parts from the grey market, compromising the quality and reliability of the components.

- Short-Term Savings, Long-Term Costs: To save money in the short term, some owners make decisions that cost them more in the long run—a classic case of being “pound foolish, penny-wise.”

- Inexperienced Technicians: Machines are sometimes handled by technicians lacking the necessary experience, leading to improper maintenance and operation.

- Neglecting Pre-Commissioning Maintenance: Failure to conduct essential maintenance before re-commissioning at a new site can result in unexpected breakdowns.

- Ignoring OEM Maintenance Guidelines: Failure to follow the manufacturer’s recommended preventive maintenance routines can lead to equipment issues.

- Improper Engineering Design: Incomplete installation or inadequate engineering design of the power plant can cause operational problems.

- Incorrect Erection and Commissioning: Adopting improper procedures for the erection and commissioning machinery can lead to operational inefficiencies.

- Lack of Experienced Operators: Operating the plant without experienced operators can result in suboptimal performance and maintenance practices.

- Absence of Standby Equipment: Not having a standby machine for maintenance while another operates can lead to delays in essential servicing.

These challenges highlight the importance of adhering to industry best practices, using genuine parts, and ensuring proper training and maintenance to prevent costly breakdowns and ensure reliable operation.

The Significance of Authentic Spare Parts

Genuine spares from OEM are used to maintain the efficient operation of the Diesel Generator in addition to the repairs and replacement of the damaged and worn parts. Original spare parts will help protect the generator from any catastrophic failure due to the use of duplicate parts procured from the grey market.

Hence, original equipment manufacturer (OEM) spare parts are essential for diesel engine electric generators. It will cause irritation and expensive replacement several times during the problems. In all the circumstances

Genuine spare parts are the only option for maintaining your device’s original performance and keeping it running for as long as possible. Genuine spare parts are manufactured to be compatible with the original equipment from the manufacturer. Spares are manufactured for easy interchanging and use in the same manner as their equipment counterparts.

It is necessary to keep the inventory of OEM spares because they can be required at any time, thus creating a significant financial burden to the owner if they are not readily available and in sufficient condition to be installed.

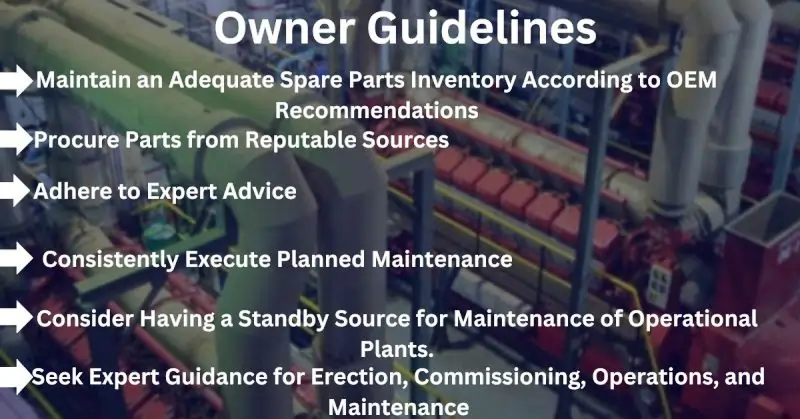

Owner Guidelines

- Maintain an Adequate Spare Parts Inventory According to OEM Recommendations.

- Procure Parts from Reputable Sources.

- Seek Expert Guidance for Erection, Commissioning, Operations, and Maintenance.

- Adhere to Expert Advice.

- Consistently Execute Planned Maintenance.

- Consider Having a Standby Source for Maintenance of Operational Plants.

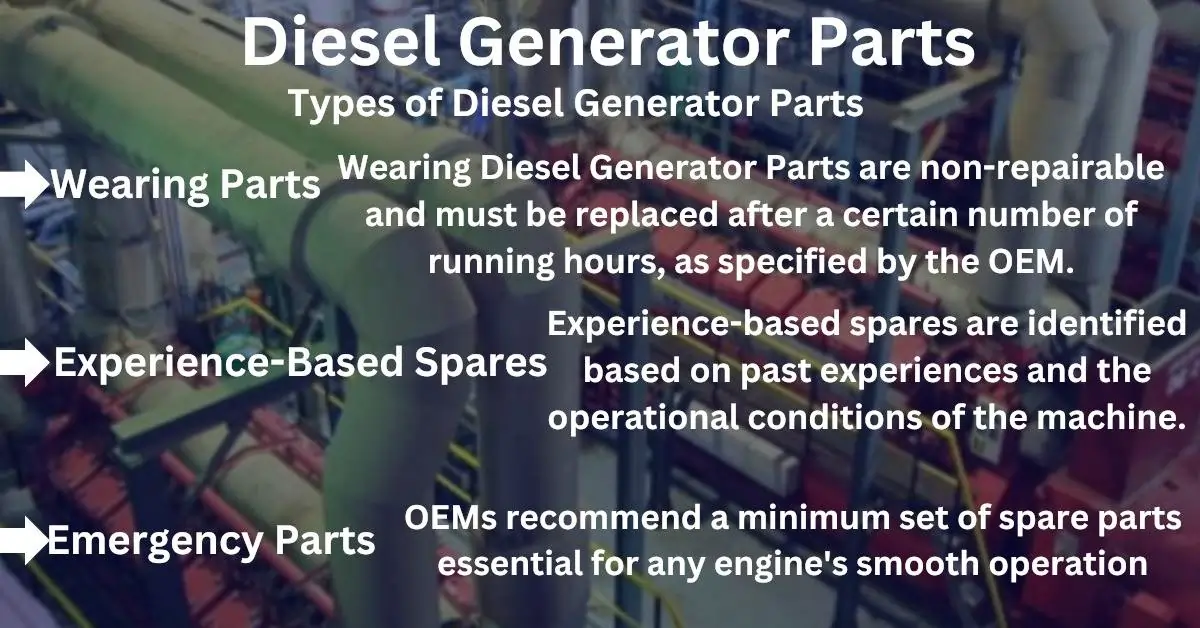

Types of Diesel Generator Parts

Wearing Parts

Wearing Diesel Generator Parts are non-repairable and must be replaced after a certain number of running hours, as specified by the OEM. Planning for the replacement of worn parts should be done well in advance. The overhaul maintenance schedule can be predicted based on the monthly or yearly running hours. OEMs provide a list of these wearing parts in their operational manuals.

Experience-Based Spares

Experience-based spares are identified based on past experiences and the operational conditions of the machine. Maintaining an inventory of these spares is critical. Failure to prepare and maintain such a list of experience-based spares has led to delays in overhaul schedules.

Emergency Parts

OEMs recommend a minimum set of spare parts essential for any engine’s smooth operation. This list should be an integral part of the inventory and updated regularly. Based on my experience, I have found these spare parts invaluable at sea on board ships and as a chief engineer of a captive diesel power plant. Even today, I always recommend customers keep an inventory of these critical spares.

How can I increase the efficiency of my diesel generator

Emergency Spare Parts Inventory List

| r. No. | Part Description | Quantity |

| 1 | Main Bearing Set | 02 set |

| 2 | Thrust Washer ( bearing) | 01 set |

| 3 | Main Bearing Stud | 02 |

| 4 | Nut for main Bearing | 02 |

| 5 | Oil Sealing ring for crankcase door | 01 |

| 6 | Inlet valve Spindle | 02 |

| 7 | Exhaust Valve Spindle | 02 |

| 8 | Conical Piece ( Valve Locks) | 06 |

| 9 | Valve Spring | 06 |

| 10 | Valve Seals | 02 |

| 11 | Valve seat exhaust | 04 |

| 12 | Valve Rotator | 04 |

| 13 | O ring for Cylinder head | 04 |

| 14 | O ring for Cylinder head Cover | 02 |

| 15 | Complete set of O rings for Cylinder Head | 02 |

| 16 | Cylinder Liner sealing ring | 02 |

| 17 | Piston Pin | 01 |

| 18 | Piston Ring Set compete | 02 |

| 19 | Connecting rod bearing | 02 |

| 20 | Bush for connecting rod | 02 |

| 21 | Connecting rod big end stud | 02 |

| 22 | Connecting rod shaft stud | 02 |

| 23 | Nut for connecting rod big end | 02 |

| 24 | Nut for connecting rod shaft stud | 02 |

| 25 | Cylindrical pin | 04 |

| 26 | Fuel Injection pump | 02 |

| 27 | Fuel injection valve complete | 02 |

| 28 | Nozzle ( Atomizer) | No. of cylinder/2 |

| 29 | Fuel Injection High-pressure pipe | 02 |

| 30 | Flexible connecting pipe | 01 set |

| 31 | Nut for the main Bearing | 01 each |

We hope you enjoyed the blog about Diesel generator parts. We are always happy when we can help our readers understand a topic like this. We hope this helps you learn more about Diesel generator parts and makes sharing your knowledge with others easy. If you’ve enjoyed our post, please share it on social media, and if you want to learn more, visit our website at https://marinediesel.co.in/. Thank you for reading; we are always excited when one of our posts can provide useful information on a topic like this!

FAQ on ” Diesel Generator Parts

Q: What are the main components of a diesel generator?

A: Diesel engine, alternator, fuel system, cooling system, and control panel.

Q: What are the most common parts that need to be replaced during maintenance?

A: Oil filter, fuel filter, coolant, belts, and hoses.

Q: How often should I change the oil in my diesel generator?

A: Every 250-500 hours of operation, or as the manufacturer recommends.

Q: What is the lifespan of a diesel generator?

A: A diesel generator can last 20-30 years with proper maintenance.