Electrical Faults

Electrical faults can cause significant disruptions in power systems, especially in marine applications. These faults, including open, short, and earth faults, occur when there is an unintended interruption or flow of electrical current, potentially leading to equipment damage, system failures, or safety hazards. Understanding electrical faults is crucial for maintaining the safety and efficiency of any electrical system. Accurate diagnosis of these faults ensures that they can be addressed promptly, minimizing risks and downtime. In marine environments, where reliability is critical, identifying and resolving electrical faults quickly can prevent costly repairs and enhance operational stability.

What Are Electrical Faults?

Definition of Electrical Faults

Electrical faults are abnormal conditions that occur when the flow of current deviates from the intended path due to interruptions, short circuits, or insulation failures. These faults can result in unwanted changes in current flow, causing potential damage to equipment and posing safety risks.

Common Causes of Electrical Faults

- Insulation Breakdown: Worn or damaged insulation can lead to exposed conductors, causing short circuits or earth faults.

- Mechanical Damage: Physical damage to cables or equipment can disrupt current flow, leading to open or short circuits.

- Moisture and Corrosion: In marine environments, moisture and saltwater exposure can corrode electrical components, leading to faults.

- Overloading: Excessive current flow can cause overheating, leading to insulation failure and electrical faults.

Types of Electrical Faults in Industrial and Marine Applications

- Open Circuit Faults: Occur when there is a break in the electrical path, leading to a complete loss of current flow.

- Short Circuit Faults: Happen when current flows along an unintended path due to a direct connection between conductors.

- Earth Faults: Occur when current leaks from a conductor to the ground, posing a risk of electric shock and equipment damage.

These faults are especially critical in industrial and marine applications, where electrical reliability and safety are paramount.

Open Circuit Faults

Explanation of Open Circuit Faults

An open circuit fault occurs when there is a break or discontinuity in an electrical circuit, preventing current from flowing through the intended path. This interruption can be caused by broken wires, loose connections, or faulty components, resulting in the complete loss of current flow in the affected section of the circuit.

How to Identify an Open Circuit Fault

- Visual Inspection: Look for any visible signs of breaks in wiring or loose connections in the circuit.

- Continuity Testing: Using a multimeter, check for continuity in the suspected area. A lack of continuity indicates an open circuit.

- Voltage Drops: Measure the voltage across different points in the circuit. An unexpected voltage drop or zero voltage may indicate an open circuit fault.

Examples of Open Circuit Faults in Marine Systems

- Faulty Navigation Lights: A break in the wiring of navigation lights can cause them to stop working entirely.

- Disconnected Sensor Wires: An open circuit in the wiring of pressure or temperature sensors can lead to false readings or alarms.

- Broken Windings in Motors: If a winding in a marine motor breaks, it creates an open circuit, causing the motor to stop functioning.

Effects of Open Circuit Faults on Electrical Equipment

- Equipment Malfunction: Open circuits prevent electrical equipment from receiving power, leading to their failure to operate.

- System Shutdowns: Essential systems, like pumps or control panels, may shut down entirely if the power supply is interrupted due to an open circuit.

- Inaccurate Readings: Open circuits in sensor connections can cause inaccurate or missing data, affecting the monitoring and control of marine systems.

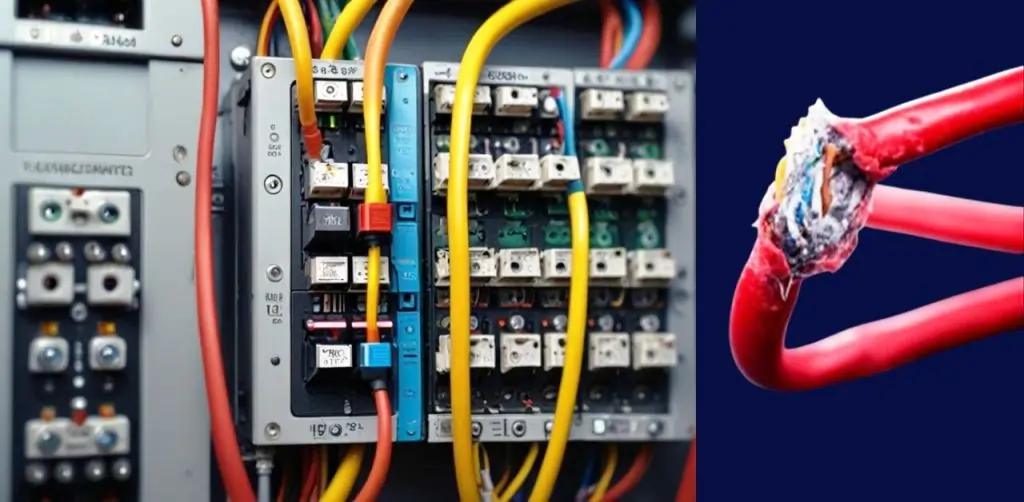

Short Circuit Faults

Definition of Short Circuit Faults

A short circuit fault occurs when an unintended low-resistance path is created in an electrical circuit, causing a large amount of current to flow through the path. This abnormal flow bypasses the regular load and can lead to severe damage, overheating, or even fires.

Causes of Short Circuits in Electrical Systems

- Insulation Failure: Deterioration or damage to insulation can expose conductors, allowing them to come into contact and create a short circuit.

- Loose Connections: Poorly secured wires can shift and make contact with other components, leading to short circuits.

- Moisture Ingress: In marine environments, moisture can penetrate equipment, causing condensation that bridges conductors.

- Mechanical Damage: Physical impacts or wear on cables can cause conductors to touch each other, resulting in a short circuit.

Examples of Short Circuit Faults in Marine Applications

- Damaged Control Panel Wiring: Water ingress in control panels can lead to short circuits, causing critical systems to malfunction.

- Faulty Electrical Motors: Internal short circuits in motor windings can result in excessive current flow, causing the motor to overheat and shut down.

- Power Distribution Issues: Short circuits in power distribution boards can lead to tripped breakers and loss of power to essential systems on board.

Impact of Short Circuits on Equipment and Safety

- Equipment Damage: The high current generated by a short circuit can cause severe overheating, leading to permanent damage to components like motors, transformers, and circuit boards.

- Fire Hazards: Short circuits can generate sparks or excessive heat, increasing the risk of fire, especially in enclosed spaces.

- Power Interruptions: Critical systems may lose power due to circuit breakers tripping, impacting operations on ships or industrial facilities.

- Safety Risks: Short circuits can pose a risk of electric shock to personnel if not properly isolated and contained.

How to Detect and Respond to a Short Circuit Fault

- Use of Circuit Breakers: Circuit breakers or fuses are designed to trip when a short circuit occurs, immediately cutting off power to prevent damage.

- Thermal Imaging: A thermal camera can help detect hot spots in electrical panels, which may indicate a short circuit.

- Visual Inspections: Look for signs of burnt or damaged wires that could indicate a short circuit.

- Immediate Response: When a short circuit is detected, power should be shut off immediately to prevent further damage or hazards. Inspect the affected area, repair damaged insulation, and ensure connections are secure before restoring power.

Difference Between Continuity Check and Earth Check

A continuity check and an earth check are two different electrical tests used to ensure the proper functioning and safety of electrical systems.

1. Continuity Check

A continuity check is performed to verify whether there is an unbroken electrical path between two points in a circuit. It ensures that current can flow through the circuit without any interruptions. This test is typically done using a multimeter set to the continuity mode, which produces an audible beep if the circuit is continuous. Continuity checks are crucial for detecting broken wires, poor connections, or faulty components.

Purpose: To ensure that the circuit is complete and capable of carrying current.

2. Earth Check

An earth check, on the other hand, is used to verify the connection between the electrical system and the earth (ground). This test ensures that the equipment or circuit has a proper grounding connection, which is essential for safety. Proper grounding prevents electrical shock hazards and helps dissipate stray electrical currents safely into the ground. An earth check is commonly performed with an earth tester or a multimeter to measure resistance between the system and the ground.

Purpose: To ensure a safe and secure grounding connection, preventing potential shock or hazards.

Earth Faults

Explanation of Earth Faults and Their Significance

An earth fault, also known as a ground fault, occurs when an unintended connection is made between a live conductor and the earth or the metal frame of an electrical device. This can lead to a leakage of current into the ground, which can pose serious safety risks and disrupt the functioning of electrical systems. The significance of earth faults lies in their potential to cause electric shocks, equipment damage, and unplanned power outages, making early detection and proper grounding essential.

Common Causes of Earth Faults in Electrical Systems

- Insulation Degradation: Over time, insulation around conductors can wear out, leading to current leakage into grounded parts.

- Moisture Penetration: Water ingress, especially in marine environments, can cause leakage currents through conductive paths.

- Mechanical Damage: Physical impacts to cables or enclosures can break insulation and create contact with grounded surfaces.

- Improper Grounding: Poorly executed grounding systems can contribute to unintended pathways for current flow during faults.

Detection and Troubleshooting of Earth Faults

- Earth Leakage Circuit Breaker (ELCB): An ELCB can detect small currents leaking to the ground and automatically trip to prevent hazards.

- Insulation Resistance Testing: Use a megger to test the insulation resistance between conductors and earth. A low reading can indicate an earth fault.

- Visual Inspections: Regular inspections for signs of moisture, damage, or wear in cables and equipment can help identify potential earth faults.

- Troubleshooting: After identifying an earth fault, isolate the affected section, repair any damaged insulation, ensure proper sealing against moisture, and verify grounding integrity before restoring power.

Earth Faults in Marine Environments and Their Risks

- Risk of Corrosion: Continuous exposure to saltwater can accelerate corrosion in electrical systems, increasing the likelihood of earth faults.

- Safety Hazards: Earth faults pose a significant risk of electric shocks to personnel working in marine environments due to the conductive nature of wet surfaces.

- Equipment Damage: Leakage currents from earth faults can cause overheating, tripping of protective devices, and damage to sensitive equipment like navigation and communication systems.

- Operational Disruptions: Earth faults can lead to unexpected shutdowns of critical systems, affecting the safety and operation of vessels or offshore installations.

Comparison: Open vs. Short vs. Earth Faults

Key Differences Between Open, Short, and Earth Faults

Understanding the differences between open, short, and earth faults is crucial for diagnosing issues in electrical systems. Here’s a breakdown of each:

Open Circuit Faults:

- Occur when there is a break or discontinuity in an electrical circuit, stopping current flow.

- Characterized by a complete loss of current through the affected circuit.

- Commonly caused by broken wires, loose connections, or damaged components.

- Equipment stops functioning entirely, as it receives no power.

Short Circuit Faults:

- Arise when an unintended low-resistance path is created, causing excessive current flow.

- Often result from insulation failure, exposed conductors, or moisture ingress.

- Can lead to overheating, sparks, or fire hazards due to the sudden surge in current.

- Circuit breakers or fuses typically trip to prevent damage.

Earth Faults:

- Occur when a live conductor comes into contact with the ground or a grounded surface.

- Characterized by leakage of current into the earth, creating safety risks.

- Often caused by insulation breakdown, moisture, or improper grounding.

- May lead to electric shocks, equipment damage, and unplanned shutdowns..

Tools for Diagnosing Electrical Faults

| Section | Details |

|---|---|

| Overview of Tools | Multimeter: Measures voltage, current, and resistance. Useful for detecting open circuits and identifying short circuits through resistance measurements. |

| Megger: Tests insulation resistance between conductors and ground, essential for detecting earth faults by simulating operating conditions. | |

| Insulation Tester: Measures insulation quality, ideal for detecting leakage currents and ensuring proper insulation in marine systems. | |

| Step-by-Step Guide | Using a Multimeter for Continuity and Voltage Testing: |

| 1. Set to continuity mode and place probes on either end of the circuit. | |

| 2. A beep indicates no open circuit; silence suggests a break. | |

| 3. For voltage testing, set the range and place probes across terminals to measure voltage. | |

| Using a Megger for Insulation Resistance Testing: | |

| 1. De-energize the circuit before testing. | |

| 2. Connect leads to the conductor and earth point. | |

| 3. Select voltage setting and press the test button; low readings indicate possible earth faults. | |

| Using an Insulation Tester for Leakage Detection: | |

| 1. Disconnect equipment from power supply. | |

| 2. Connect tester probes to wire or equipment terminals. | |

| 3. Press the test button and compare insulation resistance with standards. | |

| Best Practices for Accurate Diagnosis | Always De-energize the Circuit: Turn off power before using tools like the megger or insulation tester to ensure safety. |

| Use Correct Settings: Select the appropriate range or voltage for precise measurements. | |

| Calibrate Tools Regularly: Calibration ensures accurate readings and tool reliability over time. | |

| Check for Environmental Factors: Perform tests in controlled conditions to avoid variations due to moisture or temperature. | |

| Document Readings: Maintain records of test results to track changes and identify recurring issues. |

Key Practices for Preventing Electrical Faults

| Section | Details |

|---|---|

| Routine Maintenance Tips | – Regular Inspection: Inspect cables, connections, and insulation for signs of wear, corrosion, or damage. |

| – Tighten Connections: Ensure all electrical connections are tight to avoid loose wires that can lead to open or short circuits. | |

| – Moisture Control: Keep electrical equipment in dry conditions to prevent insulation breakdown and corrosion, especially in marine environments. | |

| – Replace Damaged Components: Immediately replace any damaged wires, connectors, or insulation to prevent faults from developing. | |

| Safety Protocols | – De-energize Before Maintenance: Always turn off power before inspecting or repairing electrical equipment to avoid electric shock. |

| – Use Insulated Tools: Use tools with proper insulation to minimize the risk of accidental contact with live components. | |

| – Wear Personal Protective Equipment (PPE): Use gloves, safety glasses, and insulated footwear when working with electrical systems. | |

| – Follow Lockout/Tagout Procedures: Secure and label circuits undergoing maintenance to ensure they are not accidentally powered on. | |

| Importance of Proper Grounding | – Grounding Prevents Earth Faults: Proper grounding directs leakage currents safely into the earth, reducing the risk of electric shock and equipment damage. |

| – Enhanced Safety: Effective grounding minimizes voltage surges during faults, protecting both equipment and personnel. | |

| Importance of Proper Insulation | – Prevents Short Circuits: Good insulation prevents direct contact between conductors, reducing the risk of short circuits. |

| – Maintains System Integrity: Proper insulation ensures consistent current flow, avoiding unexpected breakdowns and power losses due to open circuits. | |

| – Prolongs Equipment Life: Regular checks and maintenance of insulation materials help prolong the life of cables and other electrical components. |

Why Reverse Power Trip?

A reverse power trip is a crucial protection mechanism designed to prevent damage to generators, particularly in parallel operation or during emergency conditions. It activates when power flows in the opposite direction—from the load back to the generator—indicating a fault or malfunction. This reverse power flow can occur due to issues like loss of prime mover power (such as engine failure in a generator set), causing the generator to act as a motor and absorb power from the system instead of generating it. This can result in mechanical stress, overheating, and severe damage to the generator and other connected equipment.

The reverse power trip ensures the system’s safety by disconnecting the faulty generator to avoid damage and prevent energy losses.

How Reverse Power Trip Works

The reverse power trip operates through a protective relay that monitors the direction of power flow in the electrical system. Here’s how it works step by step:

- Power Flow Monitoring: The reverse power relay continuously measures the active power being supplied by the generator. Normally, the power flows from the generator to the load, but if something goes wrong, the direction can reverse.

- Detection of Reverse Power Flow: When the generator starts to receive power instead of supplying it (reverse power flow), the relay detects this abnormal condition. The power threshold for reverse flow is usually set very low to prevent any significant damage.

- Time Delay: To avoid nuisance tripping due to transient conditions, the reverse power trip relay incorporates a time delay. This ensures that the relay only trips when reverse power persists beyond a safe limit.

- Trip Signal: After the time delay, if the reverse power condition remains, the relay sends a trip signal to the generator breaker, disconnecting the generator from the system. This prevents the generator from drawing power and becoming a motor, protecting it from mechanical damage.

- Restoration: Once the fault is rectified, the generator can be reconnected to the system after ensuring the conditions are back to normal, restoring normal power flow.

The reverse power trip is essential in preventing potential catastrophic failures in generators, ensuring safe and reliable operation in power systems.

FAQs on Electrical Faults

Q: What is an electrical fault?

A: An electrical fault is an abnormal condition that disrupts the normal flow of current in a circuit.

Q: How can you detect a short circuit fault?

A: A short circuit can be detected using a multimeter to measure low resistance between conductors.

Q: What causes open circuit faults?

A: Open circuit faults are often caused by broken wires, loose connections, or damaged components.

Q: Why is grounding important in preventing earth faults?

A: Proper grounding safely directs leakage currents, reducing the risk of shocks and equipment damage.

Conclusion

Understanding electrical faults is crucial for maintaining the safety and efficiency of any electrical system, especially in marine applications where reliability is essential. By recognizing the differences between open, short, and earth faults, and using the right tools for diagnosis, you can ensure timely identification and resolution of issues. Preventive measures like regular maintenance, proper grounding, and adhering to safety protocols further enhance the longevity and safety of your equipment. Staying informed about these aspects not only minimizes risks but also helps in maintaining a smooth and safe operational environment throughout 2024 and beyond.