Electrical Transformers

Electrical transformers are crucial components in the electrical power industry, facilitating the transfer of electrical energy between circuits through electromagnetic induction. These devices are essential for adjusting voltage levels to meet the requirements of various applications, ensuring safe and efficient power distribution from generation sources to end users. Whether in power plants, industrial settings, or residential areas, transformers play a vital role in maintaining electrical stability and performance.

In this blog post, we will delve into the world of electrical transformers, focusing on the 11 best types known for their efficiency. From power transformers that handle high voltage transmission to toroidal transformers designed for minimal electromagnetic interference, we’ll explore each type’s unique features and applications. By understanding these top-rated transformers, you can make informed decisions to enhance your electrical systems’ efficiency and reliability.

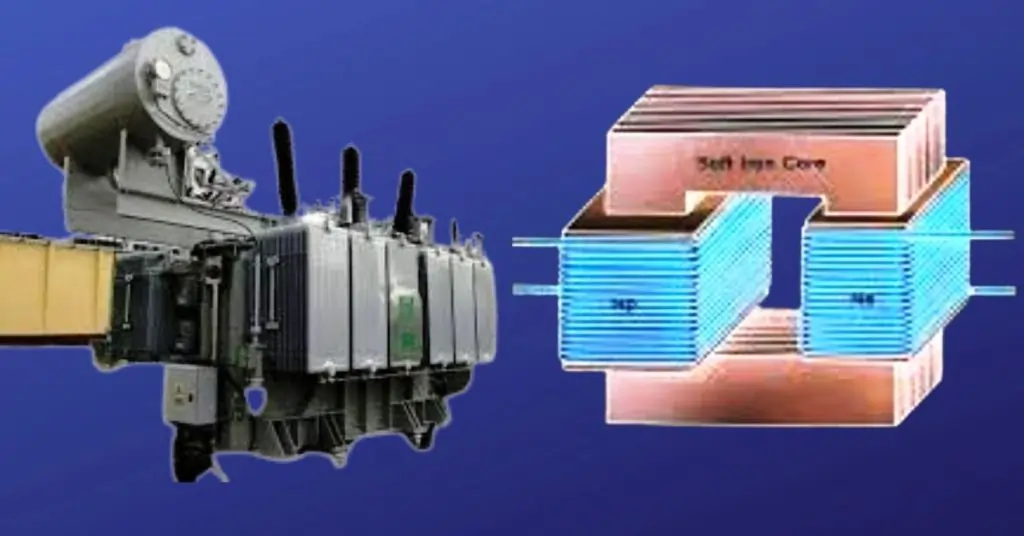

Working of a Transformer

A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. It works on the principle of Faraday’s Law of Electromagnetic Induction, which states that a change in magnetic flux in a coil induces a voltage across the coil.

Key Components of a Transformer:

- Primary Winding: The winding connected to the input voltage source.

- Secondary Winding: The winding connected to the load, delivering the transformed voltage.

- Core: A magnetic core that provides a path for the magnetic flux between the primary and secondary windings.

Working Principle:

- Magnetic Induction: When an alternating current (AC) flows through the primary winding, it creates a magnetic field. This magnetic field generates a time-varying magnetic flux in the transformer’s core.

- Induced Voltage: The changing magnetic flux passes through the secondary winding, where it induces a voltage due to electromagnetic induction. The voltage induced in the secondary winding depends on the ratio of the number of turns between the primary and secondary windings.

- Voltage Transformation:

- Step-up Transformer: If the secondary winding has more turns than the primary winding, the output voltage is higher than the input voltage.

- Step-down Transformer: If the secondary winding has fewer turns than the primary winding, the output voltage is lower than the input voltage.

Energy Transfer:

The transformer transfers electrical energy without direct electrical connection between the primary and secondary circuits. Instead, energy is transferred through the magnetic flux in the core, ensuring electrical isolation.

Example:

If a transformer has a primary winding with 100 turns and a secondary winding with 50 turns, it is a step-down transformer. If the input voltage is 240V, the output voltage would be halved to 120V.

Transformers efficiently transfer electrical power over long distances, reducing losses and allowing for safe voltage levels at various stages in power distribution.

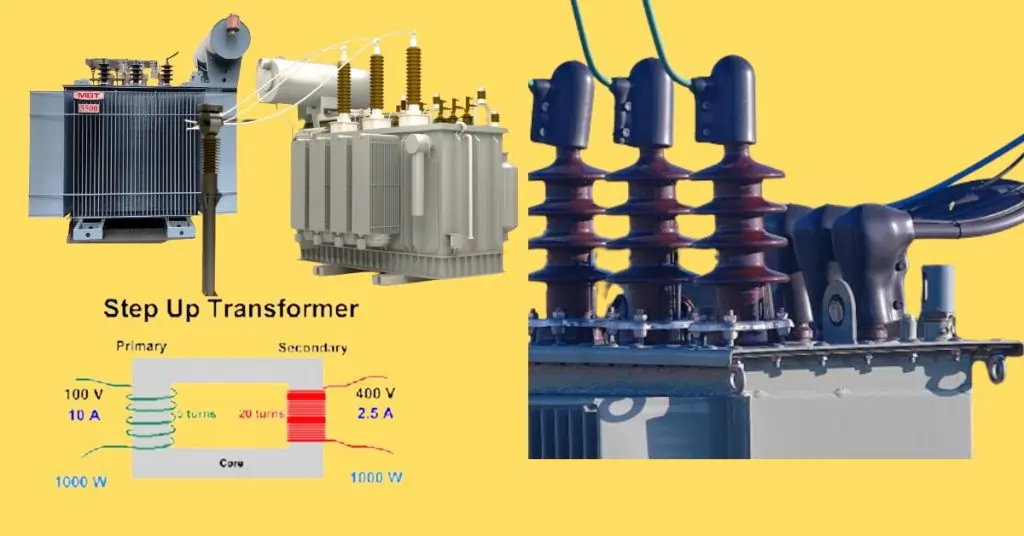

Difference Between Step-Up and Step-Down Transformers

Step-up and step-down transformers are essential for voltage regulation in electrical systems, but they serve opposite purposes. Here’s a breakdown of the key differences:

1. Function

- Step-Up Transformer: Increases the voltage from the primary winding to the secondary winding. It is commonly used in power transmission systems to raise the voltage and reduce current, minimizing energy loss over long distances.

- Step-Down Transformer: Decreases the voltage from the primary winding to the secondary winding. It is used in power distribution systems to lower the voltage to safe, usable levels for household or industrial applications.

2. Winding Turns

- Step-Up Transformer: The secondary winding has more turns than the primary winding, which results in a higher output voltage.

- Step-Down Transformer: The secondary winding has fewer turns than the primary winding, leading to a lower output voltage.

3. Applications

- Step-Up Transformer: Used in power plants and high-voltage transmission lines to transmit electricity efficiently over long distances.

- Step-Down Transformer: Found in residential areas, industrial plants, and commercial buildings to provide lower, safer voltage levels for use in electrical appliances and equipment.

4. Voltage Transformation

- Step-Up Transformer: Converts low voltage to high voltage (e.g., 11kV to 220kV).

- Step-Down Transformer: Converts high voltage to low voltage (e.g., 220kV to 110V or 240V).

11 The Best Types Most Efficient

Power Transformers

Power transformers are integral to electrical transmission networks, designed to step up (increase) or step down (decrease) voltage levels. They are essential for efficiently transmitting electrical energy over long distances, minimizing energy losses. Typically used in power generation stations and large distribution networks, power transformers ensure that electricity reaches consumers safely and reliably.

Benefits and Applications:

- High Efficiency: Power transformers are designed to operate at maximum efficiency, reducing energy losses and improving overall system performance.

- Voltage Regulation: They help maintain stable voltage levels, ensuring consistent power supply to various applications.

- Versatility: Suitable for a wide range of applications, from industrial facilities to residential areas, ensuring adaptable power distribution.

Current Transformers

Current transformers (CTs) are devices used to measure and monitor alternating current (AC) in electrical power systems. By reducing high voltage currents to a lower, more manageable value, CTs enable safe and accurate measurement and protection of electrical circuits.

Definition and Purpose:

- Measurement: Current transformers are used to accurately measure high currents by scaling them down to a lower, standardized value that can be safely read by meters and instruments.

- Protection: They provide essential data for protective relays, which can detect faults and prevent damage to electrical equipment by isolating affected sections of the network.

Potential Transformers

Potential transformers (PTs), also known as voltage transformers, are specialized devices used to step down high voltage levels to a lower, safer value for measurement and monitoring purposes. They play a crucial role in ensuring accurate voltage measurements in electrical power systems.

Overview and Function:

- Function: Potential transformers reduce high voltage to a standardized, lower voltage that can be accurately measured by meters and instrumentation.

- Purpose: They ensure the safe and precise monitoring of high-voltage circuits, protecting equipment and personnel.

Step-Up Transformers

Step-up transformers are essential devices in electrical power systems, designed to increase (step up) the voltage from a lower level to a higher level. This transformation is crucial for efficient power generation and transmission over long distances.

Explanation and Usage:

- Function: Step-up transformers increase the voltage output from power generators, enabling the efficient transmission of electricity over long distances.

- Usage: Commonly found in power plants, they boost the voltage generated by turbines and other power sources before it enters the transmission network.

Importance in Power Generation and Transmission:

- Reduced Energy Loss: By increasing voltage and reducing current, step-up transformers minimize energy losses during transmission, making the process more efficient.

- Long-Distance Transmission: Higher voltage levels enable the transmission of electricity over vast distances with minimal loss, ensuring that power reaches distant consumers reliably.

- System Stability: They help maintain stable voltage levels across the transmission network, supporting the overall stability and reliability of the power grid.

Step-Down Transformers

Step-down transformers are critical components in electrical power distribution systems, designed to reduce (step down) high voltage levels to lower, usable levels suitable for consumers.

Description:

- Function: Step-down transformers decrease the voltage from high transmission levels to lower distribution levels, making it safe and suitable for residential, commercial, and industrial use.

- Structure: They consist of primary and secondary windings, where the primary winding is connected to the high voltage input, and the secondary winding provides the lower voltage output.

Role in Power Distribution to Consumers:

- Voltage Reduction: By lowering high transmission voltages, step-down transformers make electricity safe for use in homes, businesses, and factories.

- Safety and Accessibility: They ensure that the power delivered to consumers is at a safe voltage level, preventing damage to electrical appliances and ensuring user safety.

- Network Integration: Step-down transformers integrate seamlessly into the distribution network, connecting high voltage transmission lines to lower voltage distribution lines.

Factors that Enhance Their Efficiency:

- Core Material: Using high-quality core materials, such as silicon steel, reduces energy losses and improves efficiency.

- Winding Quality: Precision in winding construction and insulation minimizes electrical losses and enhances performance.

- Cooling Mechanisms: Effective cooling systems, such as oil cooling or air cooling, maintain optimal operating temperatures and prevent overheating.

- Load Matching: Selecting a transformer that matches the load requirements ensures optimal performance and avoids efficiency losses due to underloading or overloading.

Auto Transformers

Auto transformers are a type of electrical transformer that uses a single winding to serve both the primary and secondary sides, unlike traditional transformers that have separate windings for each.

What are Auto Transformers and How They Differ:

- Single Winding: Auto transformers have a single, continuous winding with taps at different points to provide the primary and secondary voltage.

- Construction: This design contrasts with traditional transformers, which have separate primary and secondary windings, leading to a more compact and cost-effective solution.

Advantages in Terms of Efficiency:

- Reduced Material Use: The single winding design uses less copper and iron, resulting in lower costs and reduced losses.

- Higher Efficiency: With fewer winding losses and less leakage inductance, auto transformers are typically more efficient than traditional transformers.

- Compact Size: The smaller size and reduced weight make auto transformers easier to install and maintain.

Common Scenarios for Their Use:

- Voltage Regulation: Auto transformers are often used in applications requiring slight voltage adjustments, such as in voltage regulators and stabilizers.

- Motor Starting: They are commonly used in motor starting applications, where they provide a gradual increase in voltage, reducing inrush current and mechanical stress on the motor.

- Power Distribution: In power distribution systems, auto transformers can efficiently step down or step up voltage levels over short distances, making them ideal for interconnecting different parts of a power grid.

Instrument Transformers

Instrument transformers are specialized transformers designed to provide accurate measurements and isolation for metering and protection systems in electrical power networks.

Overview:

- Function: Instrument transformers, which include both current transformers (CTs) and potential transformers (PTs), scale down high currents and voltages to safer, measurable levels.

- Types: Current transformers measure high current levels, while potential transformers measure high voltage levels, both ensuring safe and accurate data for monitoring and control.

Importance in Metering and Protection:

- Accurate Measurement: They provide precise data for metering equipment, essential for billing, monitoring, and analyzing electrical consumption and performance.

- Protective Relaying: Instrument transformers supply crucial information to protective relays, enabling quick detection and isolation of faults, preventing equipment damage and enhancing system reliability.

- Safety: By stepping down high voltages and currents, they ensure the safety of measurement and protection devices, as well as the personnel handling them.

Efficiency Considerations:

- Precision: High accuracy in measurement is vital for reliable data, affecting billing accuracy and system performance analysis.

- Minimal Losses: Efficient instrument transformers have low energy losses, maintaining overall system efficiency and reducing operational costs.

- Durability: Quality construction and materials ensure long-term reliability and consistent performance, minimizing maintenance and replacement costs.

Three-Phase Transformers

Three-phase transformers are vital components in electrical power systems, designed to convert three-phase electrical power to the desired voltage levels. They are commonly used in industrial, commercial, and large-scale power distribution applications.

Explanation and Applications:

- Function: Three-phase transformers efficiently transform voltage levels in three-phase power systems, which are the standard for high-power applications due to their balance and efficiency.

- Applications: They are widely used in power generation plants, substations, and large industrial facilities to distribute and manage electrical power.

Efficiency Benefits in Large Power Systems:

- Improved Power Quality: Three-phase transformers provide a balanced load, reducing power losses and improving overall power quality.

- Higher Efficiency: By converting power in three phases, these transformers achieve higher efficiency and lower energy losses compared to single-phase transformers.

- Reduced Infrastructure Costs: They allow for more compact and cost-effective infrastructure, as they can handle higher power loads with fewer components.

Key Features to Look For:

- Core Material: High-quality core materials, such as silicon steel, enhance magnetic efficiency and reduce energy losses.

- Cooling Systems: Effective cooling mechanisms, like oil or air cooling, ensure the transformer operates within safe temperature limits, maintaining performance and longevity.

- Insulation Quality: Superior insulation materials protect against electrical faults and extend the transformer’s lifespan.

- Voltage Regulation: Look for transformers with reliable voltage regulation capabilities to ensure consistent and stable output under varying load conditions.

- Durability: Robust construction and weather-resistant features ensure reliable performance in diverse environmental conditions.

Single-Phase Transformers

Single-phase transformers are fundamental electrical devices used to step up or step down voltage levels in single-phase power systems. They are crucial for delivering consistent and reliable power to various applications.

Description:

- Function: Single-phase transformers operate with a single-phase AC supply, converting voltage levels to meet specific requirements of residential and light commercial loads.

- Construction: They typically consist of two windings, primary and secondary, wound around a magnetic core to transfer energy through electromagnetic induction.

Common Applications:

- Residential Use: Widely used in homes to power everyday appliances, lighting, and HVAC systems.

- Light Commercial Settings: Found in small businesses, shops, and offices to supply power to equipment, lighting, and other electrical needs.

- Rural Electrification: Employed in rural areas to provide electrical power where three-phase power is not available.

Tips for Achieving Maximum Efficiency:

- Proper Sizing: Select a transformer that matches the load requirements to avoid underloading or overloading, which can lead to inefficiency and increased energy losses.

- High-Quality Materials: Choose transformers made from high-quality core and winding materials to reduce hysteresis and eddy current losses.

- Cooling Mechanisms: Ensure adequate cooling, such as natural air cooling or oil-filled designs, to maintain optimal operating temperatures and prevent overheating.

- Regular Maintenance: Perform regular inspections and maintenance to keep the transformer in good working condition, ensuring longevity and consistent performance.

- Load Management: Distribute loads evenly and avoid sudden large loads that can strain the transformer and reduce its efficiency.

Voltage Transformers

Voltage transformers, also known as potential transformers, play a critical role in regulating voltage levels within electrical power systems. They ensure that voltage levels are accurately measured and maintained, providing stability and efficiency throughout the network.

Role in Regulating Voltage Levels:

- Function: Voltage transformers step down high voltage levels to a lower, standardized value suitable for measurement and control.

- Stability: By providing precise voltage readings, they help maintain consistent voltage levels across the power system, ensuring safe and reliable operation.

Contribution to System Efficiency:

- Accurate Monitoring: Accurate voltage measurements are crucial for the efficient operation of protective relays and metering devices, which monitor and control the electrical system.

- Energy Savings: By maintaining optimal voltage levels, voltage transformers help reduce energy losses, contributing to the overall efficiency of the power network.

- Enhanced Protection: They enable quick detection of voltage anomalies, allowing for immediate corrective actions that prevent equipment damage and reduce downtime.

Selection Criteria for Optimal Performance:

- Accuracy Class: Choose a voltage transformer with a high accuracy class to ensure precise voltage measurements, which are essential for effective monitoring and control.

- Rated Burden: Select a transformer with an appropriate rated burden to match the load requirements of your system, ensuring optimal performance without overloading.

- Insulation Quality: Opt for transformers with high-quality insulation materials to withstand high voltages and prevent breakdowns, enhancing reliability and safety.

- Durability: Look for robust construction and weather-resistant features to ensure long-term performance, especially in harsh environmental conditions.

- Frequency Rating: Ensure the transformer’s frequency rating matches the operating frequency of your power system to maintain accuracy and efficiency.

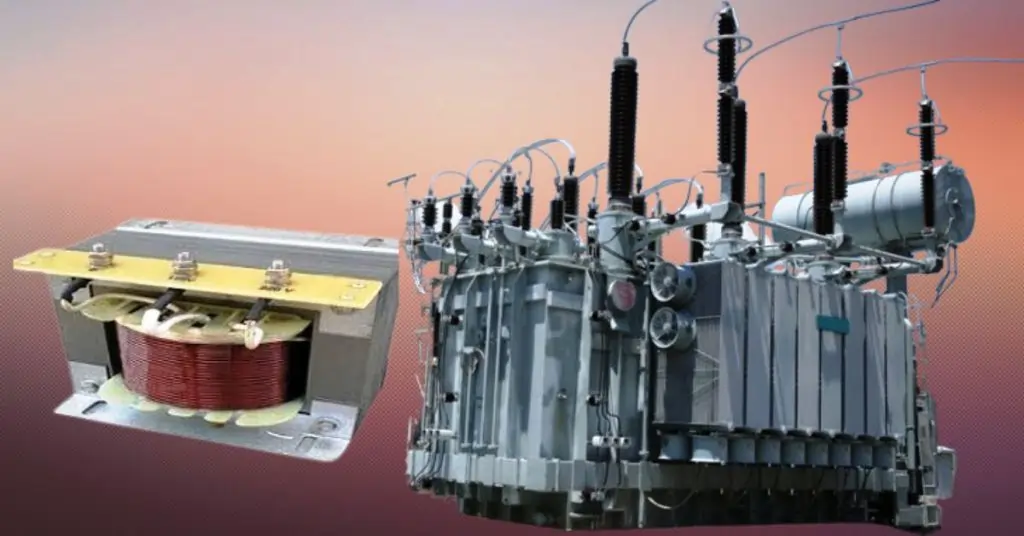

Toroidal Transformers

Toroidal transformers are a specialized type of transformer characterized by their unique doughnut-shaped core, which offers distinct advantages in performance and efficiency.

Overview and Unique Design:

- Structure: Toroidal transformers feature a circular, ring-shaped core, typically made of ferrite or laminated iron, with windings uniformly distributed around the core.

- Design Benefits: This design minimizes the length of wire required, reducing resistance and energy losses. The closed-loop shape also helps contain the magnetic field within the core, reducing leakage.

Efficiency Advantages:

- Reduced Electromagnetic Interference (EMI): The toroidal shape significantly reduces EMI, making these transformers ideal for sensitive electronic equipment where noise reduction is critical.

- High Efficiency: With lower core losses and better magnetic coupling, toroidal transformers achieve higher efficiency compared to traditional transformers.

- Compact Size: The design allows for a more compact and lightweight transformer, which can be beneficial in space-constrained applications.

Best Use Cases:

- Audio Equipment: Due to their low noise and minimal interference, toroidal transformers are commonly used in high-fidelity audio amplifiers and other audio equipment.

- Medical Devices: The low EMI is particularly advantageous in medical equipment, where accurate readings and minimal interference are essential.

- Telecommunications: They are used in telecom systems to ensure clear signal transmission and reduce noise.

- Industrial Control Systems: Their efficiency and reliability make them suitable for various industrial applications requiring precise voltage control and minimal energy loss.

Tips for Selection:

- Load Requirements: Ensure the transformer’s power rating matches your application’s load requirements to avoid underloading or overloading.

- Quality Core Material: Opt for high-quality core materials to maximize efficiency and minimize losses.

- Proper Shielding: For applications sensitive to EMI, select transformers with additional shielding to further reduce interference.

- Thermal Management: Consider the operating environment and ensure adequate cooling solutions are in place to maintain performance and longevity.

- Size and Mounting: Choose a transformer that fits the available space and mounting configuration in your application.

Transformer Losses: Types and Their Impact

Transformers, essential for transferring electrical energy between circuits, experience losses during operation. These losses reduce the efficiency of the transformer and are generally divided into two main categories: core losses and copper losses.

1. Core Losses (Iron Losses)

Core losses occur in the transformer’s core and are mainly due to the alternating magnetic field that induces voltage. These losses are further divided into:

- Hysteresis Loss: Caused by the repeated magnetization and demagnetization of the core material as the magnetic field changes direction. The energy lost during each cycle results in heat, contributing to the overall losses.

- Eddy Current Loss: Caused by circulating currents (eddy currents) induced in the core due to the changing magnetic field. These currents produce heat and are minimized by using laminated cores, which reduce the path for current flow.

2. Copper Losses (Winding Losses)

Copper losses occur in the transformer’s windings due to the resistance of the copper (or aluminum) conductors. As current flows through the windings, resistive heating occurs, leading to energy loss. Copper losses are proportional to the square of the current and increase with higher load conditions.

3. Stray Losses

These losses are caused by leakage flux, which induces eddy currents in other components of the transformer, such as the tank or structural parts. Though relatively small, stray losses contribute to the overall energy loss in the transformer.

4. Dielectric Losses

Dielectric losses occur due to the insulation materials used in the transformer. Over time, these materials can degrade, leading to small energy losses due to leakage currents in the insulation.

Impact of Transformer Losses

Transformer losses reduce the overall efficiency of the system, leading to wasted energy in the form of heat. Minimizing these losses through proper design, material selection, and cooling methods is essential to enhance transformer performance and efficiency.

FAQ on “Electrical Transformers”

Q: What is the primary function of an electrical transformer?

A: They convert voltage levels for efficient power transmission.

Q: How do step-up and step-down transformers differ?

A: Step-up increases voltage; step-down decreases voltage.

Q: Why are toroidal transformers preferred in audio equipment?

A: Due to low electromagnetic interference and high efficiency.

Q: What role do instrument transformers play in power systems?

A: They provide accurate measurements and protection.

Conclusion

Electrical transformers are the backbone of modern power systems, ensuring efficient voltage conversion and reliable power distribution. Understanding the various types of transformers—such as power, current, potential, step-up, step-down, auto, instrument, three-phase, single-phase, voltage, and toroidal—allows you to select the best one for your specific needs. Each type offers unique benefits and applications, from industrial power plants to residential homes.

By focusing on efficiency, accuracy, and durability, you can optimize your electrical systems for better performance and lower operational costs. Whether you’re looking to enhance power generation, ensure accurate metering, or reduce electromagnetic interference, there’s a transformer that fits your requirements.

Stay informed about the latest advancements in transformer technology and make well-informed decisions to keep your power systems running smoothly and efficiently. Share this knowledge, explore further, and feel free to engage with us through comments and questions. Your journey to mastering electrical transformers starts here!