Emergency Generator On Ships

Emergency generators on ships are crucial for providing power when the main power source fails, such as when shore power is unavailable. These generators are designed to ensure critical safety services, especially those on the bridge, continue to function during power outages. They supply power even when the ship is upright or inclined at specific angles, ensuring reliability in various conditions.

Located above the uppermost continuous deck, emergency generators are easily accessible and positioned away from critical areas like the forward collision bulkhead. Their main function is to supply power to the emergency switchboard, which distributes electricity to essential systems on the bridge, such as navigation and communication. Additionally, large ships often have diesel-powered generators to serve as backup, providing a dependable power source in emergencies, safeguarding both crew and vessel operations.

Types of Emergency Generators Used on Ships

Diesel-Driven Emergency Generators

Diesel-driven emergency generators are the most common type used on ships. These generators operate using diesel fuel, which is stored onboard, providing a reliable and consistent power source during emergencies. They are designed to start automatically when the main power fails, supplying power to essential systems, such as lighting, communication, and firefighting equipment.

Battery Backup Emergency Power Systems

Battery backup systems are used as an additional or supplementary source of emergency power. They are typically utilized for short durations and can immediately provide power while diesel generators start up. These systems are often used to maintain critical operations that require an uninterrupted power supply, like communication systems and emergency lighting.

Differences Between Shipboard Emergency Generators and Shore-Based Systems

Shipboard emergency generators provide power for critical systems such as emergency lighting, communication, and restarting the ship’s plant during main power failures. These generators are designed to function under maritime conditions and are typically rated at 750 kW with the ability to handle a 25% overload for two hours.

In contrast, shore-based systems, also known as shore power or cold-ironing, supply electrical power to docked ships, allowing auxiliary engines to be turned off and reducing fuel consumption. Shore power typically supports vessels with lower power requirements (less than 50 to 100 kW), and the use of such systems can decrease fuel consumption by up to 2.1%. Additionally, shore-based systems can remotely monitor and control a ship’s power system, offering enhanced control capabilities not available with onboard generators.

Emergency Generator Location and Installation

When installing an emergency generator on a ship, several key factors must be considered to ensure safety, compliance, and ease of maintenance.

Location

The emergency generator should be installed in an open, accessible area on the ship, ideally above the uppermost continuous deck, away from critical machinery. It must be positioned at least 5 feet away from any exterior doors or windows, and should not be located forward of the collision bulkhead. Sufficient space must be allowed around the generator for maintenance, inspections, and ventilation.

Exhaust and Ventilation

The generator’s exhaust system should be directed away from living areas and workspaces to prevent the buildup of harmful fumes, such as carbon monoxide. Additionally, the installation should provide adequate ventilation for the generator to dissipate heat and exhaust gases efficiently.

Security and Noise

The generator should be securely installed to withstand the ship’s motion, vibrations, and environmental conditions. It must also comply with noise level regulations to avoid disturbances in the surrounding areas or crew quarters.

Maintenance Access

Sufficient clearance should be provided for easy access to the generator for routine maintenance, fueling, and repairs. This includes ensuring proper ceiling height and enough headroom to accommodate exhaust piping and other essential components.

Following the manufacturer’s manual and maritime safety guidelines during installation is crucial to ensure the emergency generator functions optimally and safely during power outages.

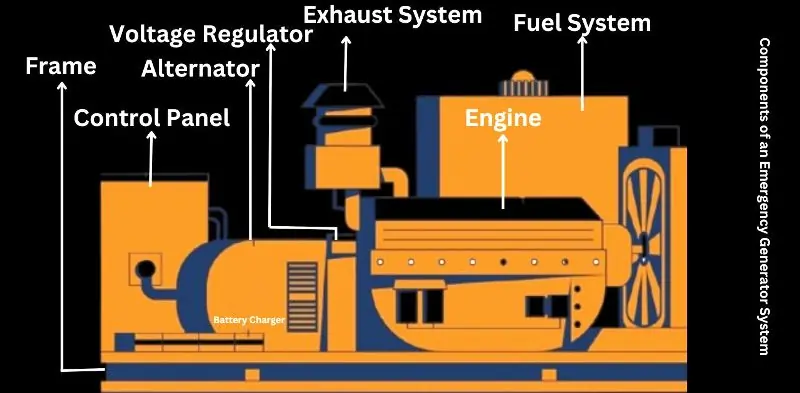

Components of an Emergency Generator System

An emergency generator system consists of several critical components that ensure reliable operation during power outages:

Fuel System

The fuel system stores and supplies the correct type of fuel, such as diesel, in sufficient quantity to keep the generator running during an emergency.

Battery

The battery provides power to start the generator’s engine and control panels, ensuring the system can activate when needed. It plays a crucial role in initiating the operation during a power failure.

Engine

The engine converts fuel into mechanical energy, which drives the generator. In cogeneration systems, this mechanical energy is transformed into electrical power through the alternator.

Alternator

The alternator is responsible for converting the mechanical energy from the engine into electrical energy. It consists of key components like the stator, rotor, and brushes, which work together to generate electricity.

Control Panel

The control panel serves as the user interface for managing and monitoring the generator. It allows operators to control the system’s functions, including starting and stopping the generator.

Cooling and Exhaust Systems

The cooling system prevents the generator from overheating by regulating its temperature, while the exhaust system safely vents harmful gases produced during operation.

Voltage Regulator

The automatic voltage regulator (AVR) maintains a steady output voltage, ensuring the generator produces stable electricity that is safe for the ship’s electrical systems.

Lubrication System

The lubrication system ensures the engine operates smoothly by reducing friction between moving parts. Regular oil checks are necessary to maintain optimal performance and longevity of the engine.

Exhaust

The exhaust system efficiently removes gases produced during combustion, ensuring they are safely vented away from the generator and crew areas to prevent hazardous buildup.

Working Principle of Emergency Generators

Automatic Start During Power Failure

Emergency generators are designed to start automatically when the main power source fails. This is achieved through sensors that continuously monitor the electrical supply. Once a power failure is detected, the generator’s control system signals the engine to start. The battery provides the initial power needed to crank the engine, and within seconds, the generator begins producing electricity to power essential systems on the ship.

The Role of the Automatic Transfer Switch (ATS)

The automatic transfer switch (ATS) plays a crucial role in the functioning of an emergency generator system. The ATS constantly monitors the main power supply and, when a failure occurs, it automatically disconnects the main power and connects the generator to the ship’s electrical system. This ensures a seamless transition, allowing the generator to provide power without manual intervention.

Transition Back to Main Power

Once the main power supply is restored, the ATS again takes control, disconnecting the generator and reconnecting the ship’s electrical system to the main power source. The generator then shuts down after a brief cooldown period, ready for the next power failure. This automatic transition ensures that the ship’s critical systems remain powered with minimal downtime, maintaining safety and operations.

Emergency Generator Maintenance Procedures

Regular maintenance of emergency generators is essential to ensure they function reliably when needed. Proper upkeep helps prevent failures and extends the life of the generator. Below are key maintenance procedures:

Routine Maintenance Tasks

Routine maintenance includes tasks such as cleaning, lubricating, and testing the generator. The oil and filters should be changed regularly to keep the engine running smoothly. The generator should also be started periodically to verify that it operates correctly and that the automatic start system is functional.

Inspection of Fuel System, Cooling System, and Battery

The fuel system must be inspected for leaks and to ensure that fuel levels are adequate. Fuel filters should be checked and replaced if necessary. The cooling system requires regular inspections to make sure it can properly regulate the generator’s temperature. This includes checking coolant levels and ensuring the radiator and hoses are free of blockages. The battery should also be inspected for corrosion, and its charge levels tested to confirm it can reliably start the generator.

Periodic Checks for Mechanical and Electrical Components

Mechanical and electrical components, including the alternator, control panel, and automatic transfer switch (ATS), must be regularly checked for wear, damage, or malfunction. Ensuring proper operation of these systems is vital for the generator’s performance. Connections, cables, and circuit breakers should also be tested and cleaned to avoid electrical faults. These periodic inspections help detect potential issues before they lead to generator failure.

Autostarting of the Emergency Generator

The autostarting of an emergency generator is a critical safety feature on ships, ensuring that the generator automatically starts during a main power failure. The key component in this system is the sensing relay, which monitors the voltage from the main switchboard.

What is the Power Source for the Sensing Relay?

The power source for the sensing relay typically comes from the main power supply. Under normal conditions, the sensing relay receives voltage from the main switchboard. When the main power supply fails or drops below a certain threshold, the relay senses this loss and triggers the start of the emergency generator. This ensures that the emergency generator can take over and supply power to critical systems without manual intervention.

Emergency Generator Load and Offload Testing Methods

Importance of Load Testing for Emergency Generators

Load testing is critical for ensuring that emergency generators are capable of handling the power demands required during actual use. It verifies the generator’s ability to provide continuous power under load, identifying potential issues that could compromise its performance during an emergency. Regular load testing helps prevent unexpected failures and ensures the generator is ready when needed.

Types of Load Tests

There are several types of load tests used to assess the performance of emergency generators:

- Manual Load Testing: In this test, loads are manually applied to the generator to simulate real operating conditions. This helps verify the generator’s performance under controlled circumstances.

- Automatic Load Testing: This test is conducted automatically by the generator’s control system. The system starts the generator and applies a predefined load to simulate emergency conditions, ensuring the generator can handle the required load without manual intervention.

- Real Load Testing: This method involves connecting the generator to actual loads, such as shipboard systems, to test its performance under real operational conditions. It provides the most accurate assessment of the generator’s ability to function during an emergency.

Offload Testing Procedures

Offload testing checks the generator’s reliability and responsiveness without applying a full load. This involves running the generator under no-load or partial-load conditions to verify that it starts, runs smoothly, and transitions between load levels efficiently. While not as comprehensive as load testing, offload testing is useful for detecting issues with the generator’s starting and basic operation.

Documentation and Interpretation of Test Results

All test results must be documented to track the generator’s performance over time. Detailed records of load and offload tests should include data on operating conditions, load levels, and any anomalies observed during the test. This documentation helps in identifying trends or potential problems and is crucial for compliance with maritime regulations. Proper interpretation of these results ensures that necessary adjustments or repairs are made to keep the generator in optimal working condition.

Emergency Generator Safety Measures

Ensuring the safe operation of emergency generators on ships is vital for both personnel and equipment. Adhering to strict safety protocols helps prevent accidents, fires, and equipment failure. Below are important safety measures for operating emergency generators:

Key Safety Protocols During Operation

Operators must follow standard safety protocols during generator operation, such as wearing appropriate personal protective equipment (PPE) and conducting pre-operational checks. The generator area should be kept clear of flammable materials, and adequate ventilation must be ensured to avoid the buildup of hazardous fumes. Regular inspections of electrical connections, fuel lines, and mechanical components should be performed to detect potential safety risks. Proper signage and safety barriers should be placed around the generator area to prevent unauthorized access.

Emergency Shutdown Procedures

In case of malfunction or safety hazards, an emergency shutdown procedure must be in place. This typically involves activating an emergency stop button located near the generator or on the control panel. The system will immediately shut down to prevent damage or unsafe conditions. All crew members should be trained on the location and use of these shutdown mechanisms. A controlled cooldown period may follow to prevent engine damage, even during an emergency stop.

Fire Suppression Systems for Generator Rooms

Generator rooms should be equipped with fire suppression systems, such as CO2 or water mist systems, to quickly extinguish any fire that may break out due to electrical faults or fuel leaks. These systems should be regularly inspected and tested to ensure they function properly in an emergency. Additionally, fire alarms and smoke detectors must be installed to provide early warnings, and fire extinguishers should be readily accessible in the area surrounding the generator.

Common Issues and Troubleshooting for Emergency Generators

| Problem | Description | Troubleshooting Technique |

|---|---|---|

| Failure to Start | The generator does not start automatically during a power failure. | – Check battery charge and connections. – Inspect the fuel system for blockages. |

| Low Fuel Pressure | The generator runs but loses power due to low fuel pressure. | – Verify fuel levels and inspect fuel lines for leaks or blockages. |

| Overheating | The generator overheats during operation. | – Check coolant levels and inspect the cooling system for leaks or blockages. – Ensure proper ventilation. |

| Low Voltage Output | The generator produces lower-than-expected voltage. | – Test the alternator and voltage regulator. – Check for loose or damaged wiring. |

| Frequent Shutdowns | The generator shuts down unexpectedly. | – Check oil levels and pressure. – Inspect sensors and control panel settings. |

| Excessive Noise or Vibration | The generator makes unusual noise or vibrates excessively. | – Check for loose components or misalignment. – Inspect engine mounts. |

| Fuel Leaks | Fuel is leaking from the generator system. | – Inspect fuel lines, filters, and connections for damage or corrosion. |

| Battery Failure | The battery is unable to start the generator. | – Test the battery for charge and replace if necessary. – Check for corroded terminals. |

| Exhaust Smoke | Excessive smoke is emitted from the exhaust. | – Check fuel quality and filters. – Inspect air filters and adjust fuel-air mixture. |

| Electrical Faults (Short Circuits) | The generator experiences electrical short circuits or grounding issues. | – Inspect wiring for damage or fraying. – Check circuit breakers and replace fuses. |

FAQs on Emergency Generator On Ships

Q. What is an emergency generator on a ship?

A. It provides electrical power when the main generator fails or is not operational.

Q. How does an emergency generator work?

A. It automatically starts during power failure, supplying backup power to essential systems.

Q. What type of generator is used for emergencies on ships?

A. Diesel-driven generators are commonly used for emergency power on ships.

Q. How long can an emergency generator run on a ship?

A. It can run for hours or days but requires regular maintenance and fuel replenishment.

Conclusion

Emergency generators on ships are vital components that ensure the safety and functionality of essential systems during power outages. Understanding the different types of generators, their components, and the principles behind their operation is crucial for maintaining reliable emergency power. Regular maintenance, load testing, and adherence to safety protocols are key to ensuring these generators are always ready to perform when needed. By following the proper guidelines for installation, testing, and troubleshooting, marine professionals can safeguard their vessels and crews, ensuring smooth operations even in the most challenging conditions. Reliable emergency power is not just a regulatory requirement—it’s a lifeline at sea.