Engine Oil Failure

Lubricating oil is the lifeblood of marine diesel engines, reducing friction and wear between moving engine parts and carrying away heat. Engine components can quickly suffer from excessive wear and tear without proper lubrication, leading to catastrophic engine failure.

In this blog post, we’ll explore the dangers of Engine Oil Failure in marine diesel engines and how it can lead to engine failure. We’ll discuss the common causes of lube oil starvation, such as leaks, clogged oil filters, insufficient oil levels, and their effects on engine components.

We’ll also cover the signs of lube oil starvation and how to detect them early, such as increased engine noise, elevated temperatures, and reduced oil pressure. We’ll provide tips on preventing lube oil starvation, such as regular oil analysis, filter replacement, and proper oil level maintenance.

Whether you’re a marine engineer or a vessel owner, this post will provide valuable insights into the dangers of lube oil starvation, how to detect it, and how to prevent it for optimal engine performance and longevity.

Engine failure by Lube oil starvation

What is Lube oil starvation?

- What happens during engine oil starvation?

- Causes for engine oil starvation?

- Period to run an engine without oil before damage?

During my working period onboard ships and industries, I have encountered several engine failures due to Engine Failure Lube Oil Starvation. Negligence in operation and engine maintenance was the reason for such failure.

The other reason is the use of spurious spares and non-grade lubrication oil. We can compare the function of lubricating oil in the engine with the role of blood in the human body. No engine can ever experience failure due to lube oil starvation, provided all the recommended parameters are within limits. Like any deficiency in the blood will indicate a problem in human body parts, Lubricating oil test parameters will also display the situation in particular engine components. In the preceding topics, I will explain the issues regarding lube oils to the best of my experience.

Lubricating Failure: Impact on Essential Functions

- Wear control

- Friction control

- Temperature control

- Pollution control

- Corrosion control

- Hydraulics control

Failure of Wear, friction, and temperature controls will lead to the catastrophic failure of the major components of the Diesel engines.

A good oil supply will always make the hydrodynamic film between the moving components. The hydrodynamic lubrication will turn into boundary lubrication as the oil supply goes to poor condition. If the oil supply starts starving completely, the welding and galling effect will occur in the metallic components.

What is Engine Failure by Lube Oil Starvation?

In running machinery, if, for some reason, the oil film keeping the moving parts apart depletes, then the condition of Engine Failure by Lube Oil Starvation will occur.

Hydrodynamic lubrication will come down to boundary lubrication as soon as the oil film breaks. If it continues, the moving parts will contact each other, and a seizure will occur due to heat development by friction.

Lube Oil Starvation symptoms

- Abnormal or burning smell

- Low oil pressure warning signal

- Obnoxious noise from the engine

- Poor performance of the engine

- The engine is getting overheated.

What happens during Engine Failure by Lube Oil Starvation?

The design of a lube oil pump is to supply an ample quantity of lubricating oil to the engine. The oil pressure develops due to the resistance provided by the engine. During the engine’s operation, clearance between the moving parts increases, and the oil loses its viscosity at temperature. The increase in clearance and viscosity loss reduces resistance to the oil flow, and subsequently, oil pressure decreases. To maintain the required pressure, the demand for oil supply increases.

If the pressure of the oil decreases, oil quantity will also drop, and oil starvation will occur. During the oil starvation, moving components will have metal-to-metal contact. Due to the friction, the temperature of the components will increase, and the parts will start melting. This phenomenon will lead to the components’ seizure.

Causes for Engine Failure by Lube Oil Starvation

In light of experience, Engine Failure by Lube Oil Starvation will occur for the following reasons.

- Lubricating oil pump failure

- Starting the engine without proper priming.

- The low oil level of the sump/lube oil tank (in the dry-sump system).

- Oil is contaminated with carbon and other combustion products.

- Choked lube oil filters

- Damage of oil supply pressure pipe

- Lube oil emulsification due to the water from the water pump seal, leakage from liners, Cracks in cylinder heads, etc.

- A cleaning rag or other foreign material blocks lube oil suction in the sump or tank.

- Decrease of viscosity due the lube oil dilution with fuel oil.

- Engine with high temperature due to the failure of cooling water.

- Reverse power causing the Engine Motoring.

- Ignoring the lube oil priming schedule during the shaft training in the propulsion engine.

- Excessive blow-by causes hot spots in the crankcase.

- Use of lube oil not meeting the engine manufacturer’s recommendations.

- Thermostatic valve Malfunctioning.

- Lube oil paper filter element deteriorated due to the ingress of water.

A safety and alarm system in modern Engines will save the Engine Failure by Lube Oil Starvation

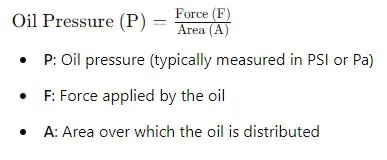

Key Formulas for Monitoring and Preventing Engine Oil Failure

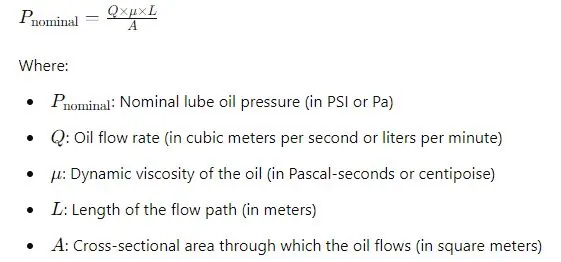

1. Oil Pressure Formula:

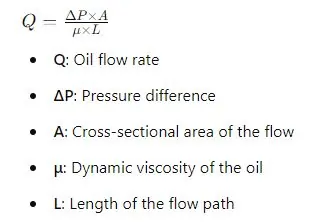

2. Flow Rate of Oil:

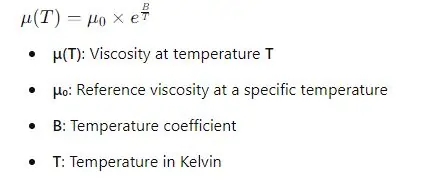

3. Viscosity-Temperature Relationship:

The viscosity of engine oil changes with temperature, which can impact oil pressure:

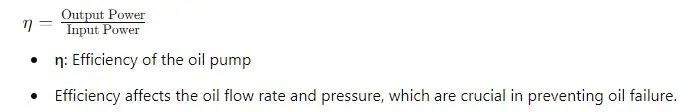

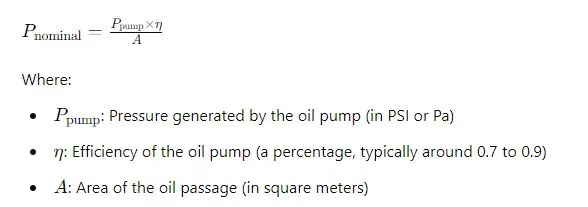

4. Oil Pump Efficiency:

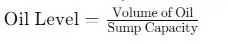

5. Oil Level Check Formula:

While more of a practical method, the formula for oil level would be based on:

- Ensuring the oil level is within the recommended range is essential to prevent oil starvation or overpressure.

Nominal Engine Lube Oil Pressure Calculation

The nominal engine lube oil pressure is typically calculated based on the oil pump’s characteristics, engine design, and operational conditions. Here’s a basic formula for estimating the nominal lube oil pressure:

Lube Oil Pressure Formula:

Simplified Formula for Common Engines:

In many engines, a more simplified approach can be used:

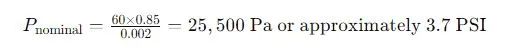

Example Calculation:

For an engine with an oil pump that generates 60 PSI and an efficiency of 85% with a passage area of 0.002 square meters:

Period to run an engine without oil before Engine Failure by Lube Oil Starvation

The design of the bearings of the modern engine is to prevent friction between the shaft and bearing to a greater extent compared to the older designs of machines. Current bearings are tri-metal and have enough capacity to withstand high temperatures before the melting of the metals reaches the base of bearing steel backing. As per the designers, an engine can run up to 30 minutes, but in these thirty minutes, extensive component damage would have occurred. Hence, 5 minutes is the maximum period for an engine to operate without lubrication.

Maintenance Types

The Maintenance Department looks after types of Maintenance.

1. Maintenance to take the corrective action

2. Planned Preventive Maintenance

Maintenance to take the corrective action Engine Oil Failure

Corrective Maintenance is encompassed during any failure or damage in a machine. This policy is generally adopted in smaller industries where production flow is not affected due to such damages.

Planned Preventive Maintenance

Planned preventive Maintenance for Lubrication Oil is crucial Planned Preventive Maintenance. Planned Preventive maintenance aims to yieldthe maximum machinery output without any breakdown, interrupting the production target.

Prevention of Engine Oil Failure

We could prevent the Lube oil starvation with the following crucial lubricating oil and the engine.

- Use the correct grade of lubricating oil as per the OEM’s recommendations.

- Carry out the lube oil testing and the action on the negative findings.

- To procure the lubricating oil from the authorized source.

- Clean the Lube oil filter at correct intervals.

- Carry out the changeover of the filters immediately at the high-pressure difference across the filters.

- Change of lubricating oil schedules as per the OEM’s recommendations/ test results predictions.

- Immediately take the necessary action in the event of high crankcase pressure.

- Immediately prepare the engine to stop in the event of a low lube oil pressure alarm.

- Carry out the engine maintenance as per the schedule. During Maintenance, take special care of the lube oil pump since this is the most crucial component of the engine.

- Always maintain the correct level in the sump/ lube oil tank.

- Take immediate action to investigate the increased lube oil level in the sump.

- Test all the warning and tripping devices as per the schedule. Carry out the function test of safety devices.

- Rectify the abnormalities observed in the Engine performance data report (EPD).

- Maintain the proper TBN and TAN values. Especially for the engines operating on heavy fuel with high sulfur contents.

- Check the sump and other critical liberating points for any leftover rags or blockage in the lube oil system.

- Check all the lubricating oil points by circulating the lube oil with the help of a priming pump before starting the engine after overhaul or a long standstill period. All the checkpoints are published in the engine manual pre-commissioning schedule after overhaul and engine beginning after a long standstill.

Turbo parts failure prevention due to Poor lubrication

- Constantly monitor the oil pressure for the turbocharger

- Carry out the priming of the turbocharger before starting the engine

- Never use the rubber or silicone gaskets in the oil system

- Carry out the proper inspection and cleaning of the oil supply pipelines and system before re-installing.

- Always use the fresh oil after the replacement of TC or the TC parts before re-starting.

- The warming up the engine before putting on load and cooling down the machine before stopping will enhance the life of components.

Lubrication problems and the remedies

I had the opportunity to visit various industries during my consultancy period as a consultant for the audit of the power plants. During my visit to the industries for the consultancy, I have identified various lubricating issues that had been the cause of machinery failures. I am listing below the common problems with their remedies.

Missing standard Operating Procedures

There has been a big problem due to personnel retirement. Retired personnel have taken a great deal of experience and working knowledge with them. In many plants, only a single person was deployed to carry out the particular job.

These people had a rich understanding of machinery behavior, every type of sound and smell. Unfortunately, the knowledge was not passed down to their successors and resulted in smooth plant operations. The experience-based Procedure did not document. In the absence of such experienced-based standard procedures, there have been significant problems in the new operators’ smooth operation of the machinery.

Corrective action; – prepare the SOP (Standard Operating Procedure) for reference. The following points need to be defined in the policy.

· Oil change schedule

· Re-greasing schedule

· Lube oil storage and handling procedures

· Procedure for the sampling of fresh oil.

· Decontamination of fresh oil upon arrival

· Disposal procedure for the used oil

Incorrect sampling and use of Hardware

Oil analysis is an essential tool for monitoring oil and machine health. Oil report analysis can avoid many failures before they turn into catastrophic failures. To get the best analysis reports will be possible only if the sampling has been done correctly from the appropriate sampling point. The Hardware used for the sample must be correct.

Samples taken from the drain points or the bottom of the sump may lead to wrong analysis since the sampled oil will contain many contaminants filled with scale, debris, and rust particles settled at the bottom.

Corrective action;- Following instructions will illustrate the correct sampling procedures.

· Use the proper Hardware for the sampling

· Install a sampling valve with a pilot extension tube for the components with splash lubrication, like gearbox and bearings.

· Install several sampling points for the circulating systems.

· Always take the sample from the main return line before the filter.

· A trained technician should take the sample.

· Flush the sampling tube at least ten times.

· Reduce the quantity of contamination during the complete process.

Over-greasing ( Engine Failure by Lube Oil Starvation )

In most industries, I have observed that technicians don’t consider grease a precision instrument. Improper use of grease guns can be the cause of many serious problems. Technicians attach the grease gun to the greasing point and keep pumping the grease until it comes out of some opening.

Over-greasing is a common problem in industries and can cause high bearing temperatures, premature failures of bearings with heavy ingress of contaminants. For the proper lubrication, every bearing requires a set volume of grease.

Corrective action;- Take the following corrective action to overcome the over-greasing problem of bearings.

- Standardize the grease guns with a single type.

- Check the grease guns annually for the use of grease guns in a single type of grease.

- Provide a grease purge fitting on bearings for the expulsion of extra grease without compromising seal integrity.

- Greasing should only be carried out by the trained and experienced operator.

Formulae for the amount of grease for a bearing

G = 3.2319x d x w

Where G = the amount of grease in grams

d = the OD of the bearing in inches

w= the bearing width in inches

Missing labels on Lubricants

Missing labels on lubricants will misguide the technicians. Technicians will use the wrong oil for different applications. In a plant, there are various types of machines using other kinds of oils and greases. The inappropriate use of oil will lead to premature or catastrophic failure of the machine. Hence anything that touches a lubricant should be labeled with a dedication to the single lubricant.

Corrective action;-

- Use the correct labels for the lubricants with the information of, grade of oil/ grease, and lubrication intervals

- Use the labels with different color codes.

- Labels should indicate the essential lubricant properties like viscosity, type of application, etc.

Improper Breathers and dust caps ( Engine Failure by Lube Oil Starvation )

Most OEMs provide the breathers and duct caps to prevent the ingress of bigger particles in the sump and crankcase. These types of fittings are generally filled with steel wool or mesh screen. Such fittings don’t protect the ingress of finer particles in the lube oils. These fine particles may travel with the lube oil and can cause severe damage to the bearings. Lube oil being hygroscopic will absorb the moisture. High moisture contents in the lube oil will cause rust on the parts and an increased oxidation rate.

Corrective action;- The OEMs breathers should be replaced with highly protective breathers and dust caps to prevent the ingress of moisture and particulates. Always use the breather and dust caps as per the working environment.

Procedures and inspections during re-lubrication

Follow the following basic steps.

- Filling and re-filling fitting areas must be neat and clean

- Relief valve should have free movement and should remove the drain plug.

- There should be no obstruction to the relief passage with hardened grease or any other material.

- Always use the correct quantity of grease by slowly adding in each shot to avoid excessive excess pressure build-up.

- Run the motor before and after greasing with an opened relief valve and plug to expel any extra grease.

Over-greasing control tips

- Immediately stop greasing if the abnormal backpressure is felt

- Clear the exhaust port from any debris or dry grease and hard crust to ensure the free passage for exiting extra grease.

- Grease guns should have the pressure gauge, quick shut off grease fittings, or relief vent plug.

- Pumping of grease must be slow. Fast greasing could be the cause of damage to the seal.

The Best Book On Engine Failure Analysis

Engine failures result from a complex set of conditions, effects, and situations. To understand why engines fail and remedy those failures, one must understand how engine components are designed and manufactured, how they function, and how they interact with other engine components. To this end, this book examines how engine components are designed and how they function, along with their physical and technical properties.

FAQs on Engine Oil Failure

Q- What causes engine oil failure?

A- Low oil pressure, inadequate lubrication, or using the wrong type of oil can lead to engine oil failure.

Q- How can I prevent engine oil failure?

A- Regularly check oil levels, change oil as recommended, and use the correct oil grade for your engine.

Q- What are the signs of engine oil failure?

A- Low oil pressure warning light, unusual engine noise, and overheating are common signs.

Q- What should I do if my engine experiences oil failure?

A- Stop the engine immediately and check the oil level. Refill or seek professional assistance if needed.

Conclusion;- I hope the post on Engine Failure by Lube Oil Starvation has been helpful to my valued readers. I would welcome the comments on this post for improvement.

Good Luck!!!