Engine Power

Engine power is a critical aspect of marine operations, determining the performance and efficiency of both the main engines that propel ships and the generators that supply essential electrical power. Understanding how engine power is calculated and optimized is vital for marine engineers, as it impacts fuel efficiency, operational costs, and overall ship performance.

The main engine drives the vessel forward, while the generator ensures the smooth operation of onboard systems, from navigation to lighting. Knowing how to balance and monitor power output in both engines is key to maintaining safety and reliability in marine operations, especially in harsh sea conditions. This guide will walk you through the essentials of engine power, including how it’s calculated for both propulsion and electrical generation, and why accurate power management is crucial for efficient marine engine performance in 2024.

What is Engine Power?

Engine power refers to the amount of work an engine can perform within a given time, typically measured in horsepower (HP) or kilowatts (kW). It is a fundamental metric that determines the efficiency, performance, and operational capacity of an engine. In marine applications, engine power plays a critical role in both the propulsion of the vessel and the generation of electrical power.

Types of Engine Power

- Indicated Power (IP):

Indicated power is the theoretical power produced inside the engine’s cylinders before any losses, such as friction, are taken into account. It is calculated based on the pressure exerted on the pistons during the power stroke. - Brake Power (BP):

Brake power is the actual power available at the engine’s output shaft after accounting for mechanical losses, such as friction within the engine. It represents the usable power that can be transmitted for propulsion. - Shaft Power (SP):

Shaft power is the power delivered to the propeller shaft. It is critical for the propulsion system in marine engines, as it directly influences the vessel’s movement.

Relevance to Marine Engines

In marine engines, understanding these types of power is essential for optimizing engine performance. Indicated power helps gauge internal engine efficiency, brake power provides insight into how much usable power the engine generates, and shaft power directly influences the vessel’s propulsion. Efficient management of these power types ensures optimal fuel consumption, reduced operational costs, and reliable performance at sea.

Typical Power Ranges for Various Marine Engines

- Main Engines:

Main engines on large vessels typically range from 10,000 kW to 80,000 kW, depending on the size of the ship and its propulsion needs. These engines are built for continuous operation and long voyages, delivering high torque and power to the propeller shaft. - Auxiliary Engines (Generators):

The power output of auxiliary engines can vary significantly based on the ship’s size and electrical demands:- Small to medium-sized vessels (e.g., fishing boats, tugs): Auxiliary engines generally range from 100 kW to 1,000 kW.

- Large vessels (e.g., container ships, cruise ships, tankers): Auxiliary engines typically range from 500 kW to 10,000 kW or more, depending on the onboard electrical load, such as lighting, navigation systems, HVAC, and other essential services.

These power ranges ensure that both the propulsion and the electrical systems of the vessel are adequately supported for efficient marine operations.

How is Engine Power Calculated?

Main Engine Power Calculation

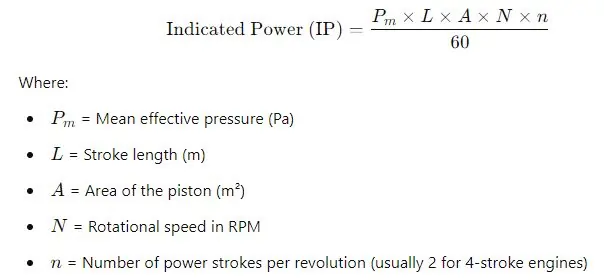

Indicated Power (IP):

Indicated power is the theoretical power generated within the engine’s cylinders before accounting for any mechanical losses such as friction. It is calculated using the following formula:

This calculation gives the total power theoretically generated by the engine before considering frictional or mechanical losses.

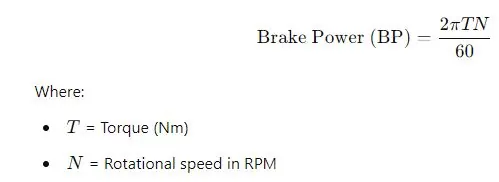

Brake Power (BP):

Brake power represents the actual usable power at the engine’s output shaft, after accounting for mechanical losses such as friction. The formula for brake power is:

Brake power is the real-world power available for driving the ship’s propeller, with losses due to friction already deducted.

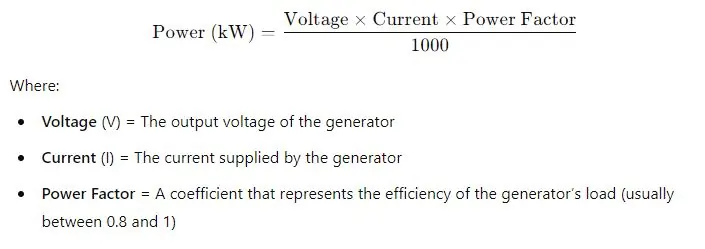

Generator Engine Power Calculation

For generator engines, which produce electrical power rather than mechanical propulsion, the power output is calculated using the following formula:

Shaft Power (SP):

Shaft power is the power transmitted to the propeller shaft for propulsion. It is often calculated using brake power minus mechanical losses in the shaft or coupling system. The formula is:

Factors Affecting Engine Power Output

Several factors influence the power output of marine engines, and understanding these is critical for ensuring optimal performance and fuel efficiency. Below are the key factors that affect engine power output:

Impact of Fuel Quality

The quality of fuel used in marine engines plays a crucial role in determining power output. Low-quality fuel can cause incomplete combustion, leading to reduced engine efficiency, lower power output, and higher fuel consumption. Contaminants or impurities in fuel may also cause carbon buildup, increasing wear on engine components and further reducing power efficiency. Using high-grade fuel improves combustion, allowing the engine to operate at peak power while minimizing maintenance issues.

Efficiency of Turbochargers, Aftercoolers, and Other Auxiliary Systems

- Turbochargers:

Turbochargers are vital for increasing the air intake into the engine’s cylinders, allowing for more fuel to be burned and increasing power output. A well-functioning turbocharger boosts engine efficiency by improving air-fuel combustion. However, a malfunctioning or inefficient turbocharger can significantly reduce engine power. - Aftercoolers:

Aftercoolers cool the compressed air before it enters the combustion chamber, improving air density and allowing the engine to burn more fuel efficiently. If the aftercooler is not functioning properly, it can lead to reduced air density, lowering the engine’s overall power output. - Other Auxiliary Systems:

Other auxiliary systems, such as fuel injection systems, cooling systems, and lubrication systems, also contribute to the overall efficiency of the engine. Inefficiencies or malfunctions in these systems can lead to reduced engine power and increased fuel consumption.

Impact of Weather and Sea Conditions on Marine Engine Performance

Marine engines are heavily impacted by external environmental conditions:

- Weather:

High temperatures can reduce engine power by decreasing air density, which affects combustion efficiency. Conversely, cold weather can enhance engine performance by increasing air density, leading to better combustion. - Sea Conditions:

Rough seas increase the load on the engine as the vessel encounters more resistance from waves. This results in higher power demands from the engine to maintain speed, which can strain the engine and reduce its efficiency over time.

Understanding and managing these factors can significantly enhance the performance and lifespan of marine engines, ensuring reliable power output during operations.

Monitoring and Optimizing Engine Power

Efficient monitoring and optimization of engine power are crucial for the smooth operation of marine engines. By ensuring real-time data and system checks, marine engineers can maximize engine performance, reduce fuel consumption, and prevent potential failures. Here’s a detailed look at how monitoring and optimization are achieved.

Importance of Real-Time Monitoring of Engine Power

Real-time monitoring of engine power is essential for maintaining optimal engine performance and ensuring the vessel operates efficiently. Continuous monitoring allows engineers to detect fluctuations in power output, identify issues such as fuel inefficiencies or mechanical wear, and take corrective action before problems escalate. Real-time data helps in managing fuel consumption, reducing emissions, and extending the lifespan of critical engine components, ensuring that the ship runs smoothly and safely.

Tools and Systems for Monitoring Power Output on Ships

- Engine Control Systems (ECS):

Modern marine engines are equipped with sophisticated ECS that provide real-time data on engine performance. These systems monitor parameters such as power output, fuel consumption, exhaust temperatures, and oil pressure, enabling engineers to make informed decisions. - Power Management Systems (PMS):

PMS is designed to ensure the optimal distribution of power across the vessel, especially in multi-engine configurations. It automatically adjusts load sharing between engines and generators to optimize power efficiency. - Monitoring Sensors:

Sensors placed throughout the engine and auxiliary systems provide real-time data on temperature, pressure, and engine vibrations. This data is crucial for early detection of issues like overheating, excessive wear, or inefficient fuel combustion.

Tips for Optimizing Power Efficiency in Marine Engines

- Regular Maintenance:

Scheduled maintenance, such as cleaning fuel injectors, inspecting turbochargers, and ensuring proper lubrication, can enhance engine efficiency. Well-maintained engines operate more smoothly, reducing power losses due to friction and wear. - Efficient Fuel Management:

Use high-quality fuel and monitor fuel consumption closely. Installing a fuel management system can help optimize fuel use, reducing unnecessary consumption and improving power output. - Optimized Engine Load:

Avoid operating the engine at too low or too high of a load for extended periods. Running the engine within its optimal load range ensures efficient fuel combustion and reduces strain on the engine, improving overall power output. - Use of Auxiliary Systems Efficiently:

Ensure that auxiliary systems like aftercoolers, cooling systems, and air intakes are operating at maximum efficiency to boost overall engine power.

Engine Power and Environmental Regulations

In recent years, environmental regulations have become increasingly stringent, significantly impacting how marine engines are managed. These regulations, particularly those set by the International Maritime Organization (IMO), aim to reduce harmful emissions and improve fuel efficiency without compromising engine power. Understanding these regulations and the strategies for compliance is crucial for marine engineers.

Impact of IMO Regulations on Engine Power Management

The IMO’s MARPOL Annex VI regulations place strict limits on emissions from marine engines, particularly sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. These rules require ship operators to adopt measures that reduce emissions, which can sometimes affect engine power. For example, using low-sulfur fuels or exhaust gas cleaning systems (scrubbers) may change engine performance, requiring adjustments in power management.

Further reading: “IMO 2020 and its Impact on Marine Fuel Management” – a comprehensive guide on fuel management strategies post-IMO regulations.

Strategies for Compliance with Emission Limits While Maintaining Power

- Use of Cleaner Fuels:

Switching to low-sulfur fuels or Liquefied Natural Gas (LNG) can help meet emission regulations while maintaining engine power. These fuels reduce SOx and NOx emissions but may require engine modifications to optimize combustion. - Exhaust Gas Cleaning Systems (Scrubbers):

Installing scrubbers allows ships to continue using high-sulfur fuels while removing pollutants from the exhaust. This strategy helps maintain engine power by avoiding fuel switchovers, but engineers must ensure scrubbers are regularly maintained to prevent power losses. - Engine Tuning and Optimization:

Advanced tuning technologies help adjust fuel injection timing and pressure to maximize combustion efficiency, reducing emissions while ensuring optimal power output. Implementing electronic engine control systems can significantly improve the balance between power and compliance. - Selective Catalytic Reduction (SCR) Systems:

SCR systems reduce NOx emissions by injecting a urea-based reagent into the exhaust, converting NOx into nitrogen and water. This process allows for compliance with stringent NOx regulations without reducing engine power. - Regular Monitoring and Adjustments:

Monitoring exhaust emissions and engine performance in real-time allows for continuous adjustments to keep emissions within permissible limits while maximizing engine efficiency and power. This can be done using modern engine management systems equipped with sensors and data analysis tools.

By implementing these strategies, ship operators can remain compliant with environmental regulations without sacrificing engine power. Marine engineers must stay updated on evolving IMO regulations and emerging technologies to ensure that ships operate efficiently and sustainably. For further learning, consider reading the research paper: “Technological Solutions for Meeting IMO Emission Regulations: Balancing Efficiency and Compliance” which delves into advanced strategies for maintaining power under environmental constraints.

FAQs on Engine Power

Q. What is meant by engine power?

A. Engine power refers to an engine’s work in a specific time, usually measured in horsepower (HP) or kilowatts (kW).

Q. What is the kW of an engine?

A. The kW of an engine is the measure of its power output in kilowatts, where 1 kW equals 1,000 watts of power.

Q. What gives engine power?

A. Engine power is generated by the combustion of fuel, which creates energy that is converted into mechanical power.

Q. What is 1 HP equal to?

A. 1 horsepower (HP) is equal to 746 watts or approximately 0.746 kilowatts (kW).

Conclusion

Understanding engine power is essential for optimizing the performance and efficiency of marine engines. Whether managing the propulsion system with the main engine or generating electrical power with auxiliary engines, accurately calculating and monitoring engine power ensures smooth, cost-effective operations. With factors like fuel quality, auxiliary system efficiency, and environmental conditions impacting power output, marine engineers must stay vigilant in maintaining their engines for peak performance. Additionally, adhering to IMO regulations while maintaining optimal power requires a strategic approach, from using cleaner fuels to integrating advanced emission control technologies. By mastering these principles, marine engineers can ensure safe, efficient, and environmentally compliant operations in today’s maritime industry.