Engine Spare Parts

In the world of diesel engines and generators, particularly with leading brands like MAN and Hyundai, the reliability and performance of your machinery hinge on the quality and availability of engine spare parts. These components are the lifeblood of your engines, ensuring that they run smoothly and efficiently under demanding conditions. Whether it’s the wearing parts that require regular replacement or the critical spares needed in emergencies, having the right parts on hand is crucial.

In this post we will explore the best and most critical insights of 2024, offering a comprehensive guide to maintaining and managing engine spare parts effectively. By focusing on the specific needs of MAN and Hyundai engines, we aim to equip you with the knowledge necessary to optimize your spare parts inventory, minimize downtime, and enhance the overall performance of your diesel engines and generators

What is a Spare Part?

A spare part, also known as a replacement part, service part, or repair part, is an interchangeable component that is kept in inventory and used for the repair or replacement of failed, worn-out, or damaged parts in machinery, equipment, or vehicles. Spare parts are essential to ensuring the continued operation and reliability of mechanical systems, especially in industries where equipment downtime can lead to significant financial losses, safety hazards, or operational disruptions.

Key Characteristics of Spare Parts:

- Interchangeability: Spare parts are designed to be identical or compatible with the original parts they are intended to replace. This interchangeability allows them to be easily swapped in when the original part fails or needs maintenance.

- Durability and Quality: Spare parts are typically manufactured to meet or exceed the quality and durability standards of the original equipment manufacturer (OEM). This ensures that the replacement part will perform reliably and contribute to the overall longevity of the system.

- Availability: The timely availability of spare parts is critical. Spare parts are often kept in stock or can be quickly sourced to minimize downtime and keep machinery or equipment operational. The importance of availability is particularly pronounced in industries like manufacturing, shipping, and power generation, where even short periods of downtime can have significant consequences.

- Classification: Spare parts can be categorized based on their function and importance:

- Wearing Parts: These are parts that are subject to regular wear and tear and are expected to be replaced periodically (e.g., gaskets, bearings, seals).

- Critical Parts: Essential components whose failure would lead to a significant loss of function or safety risk, necessitating their availability at all times (e.g., fuel pumps, electronic control modules).

- Consumables: Items that are consumed during the normal operation of machinery and need regular replacement (e.g., filters, lubricants).

- Emergency Spares: Parts that are rarely needed but are critical in the event of an unexpected failure (e.g., backup batteries, pressure relief valves).

- Importance in Maintenance: Spare parts play a vital role in preventive and corrective maintenance. By having the right spare parts on hand, maintenance teams can quickly restore equipment to working order, thus minimizing downtime and extending the life of the machinery.

Example in Industry:

In the context of diesel engines, such as those manufactured by MAN and Hyundai, spare parts are crucial for maintaining engine reliability and performance. For example, components like fuel injectors, turbochargers, and oil filters are critical spare parts that must be readily available to prevent engine failure and ensure continuous operation in demanding environments like marine vessels and power plants.

Wearing Spare Parts: Definition and Examples

Wearing spare parts are the components of an engine that are subject to continuous wear and tear during operation. These parts require regular monitoring and replacement to ensure the engine operates efficiently and reliably. In MAN and Hyundai engines, these wearing parts are critical to maintaining optimal performance and preventing unexpected breakdowns.

List of Wearing Spare Parts for MAN and Hyundai Engines:

- Piston Rings: Essential for sealing combustion gases and controlling oil consumption.

- Cylinder Liners: Protect the cylinder walls and provide a smooth surface for the piston movement.

- Bearings: Includes Main Bearings and Connecting Rod Bearings, which support the crankshaft and connecting rods.

- Gaskets: Such as Cylinder Head Gaskets and Exhaust Gaskets, ensuring a tight seal between engine components.

- Seals: Includes Oil Seals, O-Rings, and Crankshaft Seals, preventing leaks of fluids and gases.

- Valve Seats and Guides: Critical for ensuring proper sealing and guiding of the engine’s valves.

- Timing Belts/Chains: Coordinate the timing of the engine’s camshaft and crankshaft.

- Water Pumps: Circulate coolant throughout the engine to maintain proper operating temperatures.

- Camshafts and Rocker Arms: Control the opening and closing of engine valves.

MAN Wearing Parts

Hyundai Wearing Parts

Importance of Regular Inspection

Regular inspection of these wearing parts is crucial to avoid unexpected downtime and costly repairs. By monitoring the condition of these components, potential issues can be identified early, allowing for timely replacements and maintenance.

Replacement Schedule

Best practices for replacing wearing parts are based on engine hours and the specific operating conditions of MAN and Hyundai engines. For example, piston rings and cylinder liners typically require replacement every 10,000 to 15,000 engine hours, depending on the engine’s load and operating conditions. Bearings, such as main and connecting rod bearings, may need replacement during major overhauls, often around the same interval.

Gaskets and seals should be inspected regularly and replaced if any signs of wear, leaks, or degradation are detected. Valve seats and guides are usually serviced during cylinder head overhauls, depending on wear patterns. Water pumps should be checked for proper function and replaced if any signs of leakage or reduced efficiency are observed. Adhering to these schedules, with guidance from manufacturer-specific recommendations, ensures optimal engine performance and longevity.

Mandatory Spare Parts: Definition and Regulatory Requirements

Mandatory spare parts are critical components that must be kept in stock to ensure the continuous operation of engines, especially in mission-critical applications such as ships and industrial settings. For MAN and Hyundai engines, these spares are essential to meet regulatory requirements and industry standards. These parts are required to be on hand to address potential failures promptly, ensuring the reliability and safety of the engine’s operation.

Critical Components

Each of these components plays a vital role in the reliability and performance of MAN and Hyundai engines:

- Fuel, Oil, and Air Filters: Prevent contaminants from entering critical systems, thus safeguarding engine performance and longevity.

- Starter Motors and Alternators: Key electrical components that ensure the engine starts reliably and that electrical systems remain functional.

- Emergency Backup Batteries: Vital for ensuring that essential systems remain operational during power interruptions.

- Pressure Relief Valves: Act as a safety mechanism to prevent excessive pressure build-up, thus protecting engine integrity.

- Cooling System Components: Maintain the engine’s operating temperature, preventing overheating and associated damage.

- Fuel Pumps and Lubrication System Components: Ensure the engine receives the fuel and lubrication it needs to run efficiently and avoid wear.

Compliance

Maintaining a stock of these mandatory spare parts ensures compliance with classification societies and industry standards, particularly for maritime operations where downtime can result in significant operational and financial impacts. Adhering to these regulations is not only a legal requirement but also a best practice to ensure the safety and reliability of MAN and Hyundai engines in critical applications.

List of Mandatory Spare Parts for MAN and Hyundai Engines:

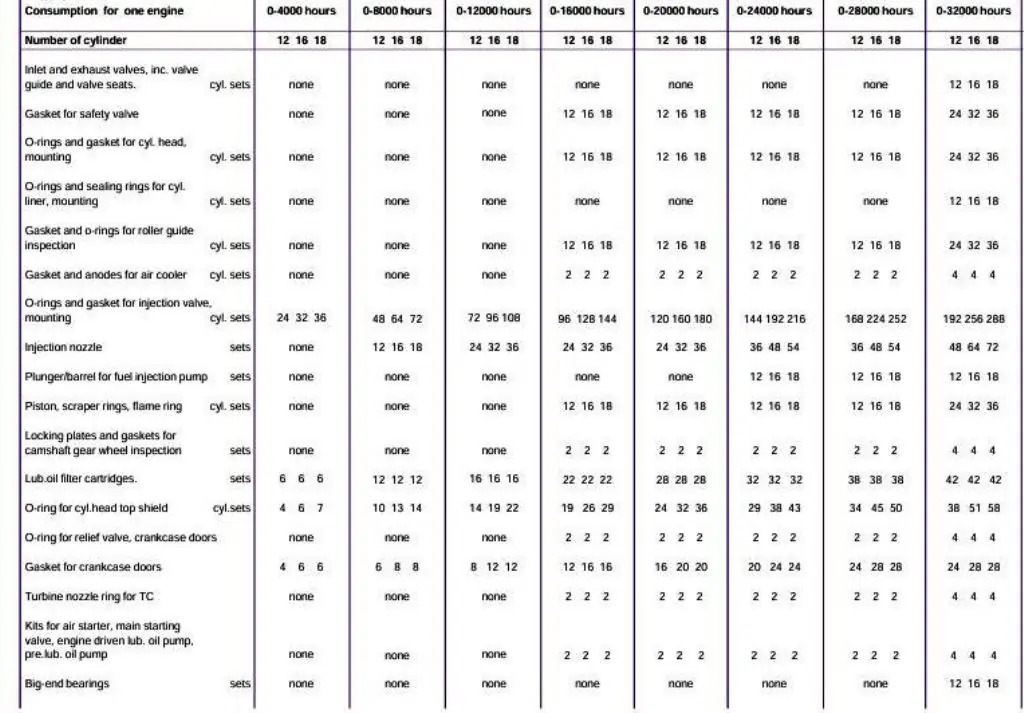

MAN Mandatory Spare Parts

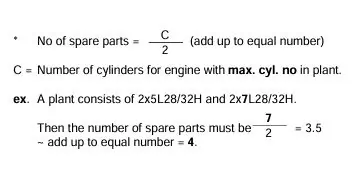

Mandatory Spare parts stocking Formula

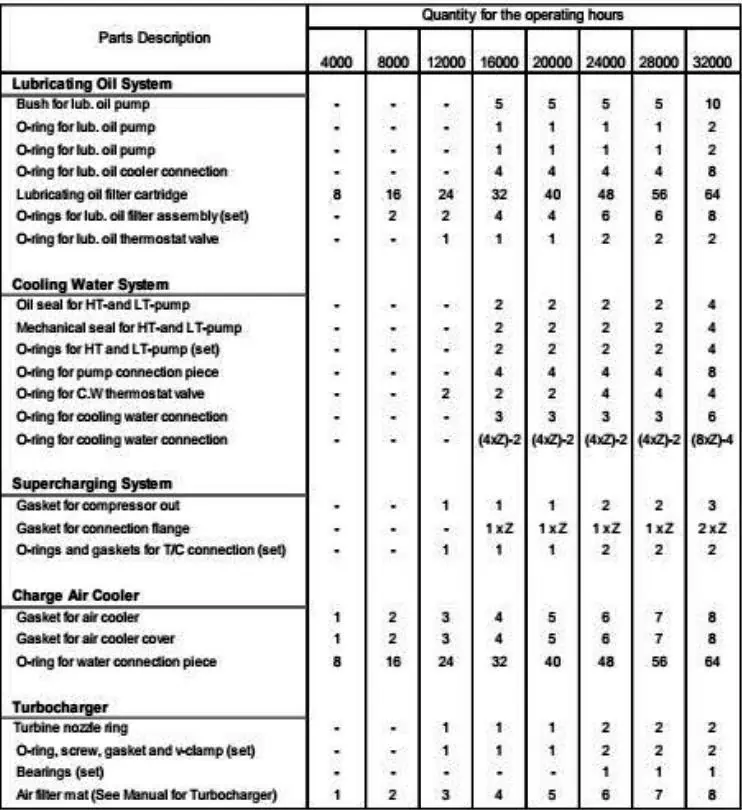

Hyundai Mandatory Spare parts

Experienced-Based Spare Parts

Understanding Experienced-Based Parts

Experienced-based spare parts are components that tend to fail more frequently due to specific operational conditions, particularly in engines from manufacturers like MAN and Hyundai. These parts may experience higher wear and tear because of the unique stresses placed on them during regular engine operation, such as variations in load, environmental conditions, and maintenance practices. Recognizing these parts and having them readily available in inventory is crucial for minimizing downtime and maintaining engine reliability.

List of Experienced-Based Spare Parts for MAN and Hyundai Engines:

- Turbochargers: Vital for boosting engine power by forcing more air into the combustion chamber, but prone to wear due to high-speed operation and exposure to extreme temperatures.

- Fuel Injectors: Essential for precise fuel delivery, but can become clogged or wear out due to impurities in the fuel or high-pressure operation.

- Alternators: Critical for generating electricity to power the engine’s systems, yet susceptible to failure due to continuous operation and exposure to heat.

- Electronic Control Modules (ECMs): Control the engine’s electronic functions; vulnerable to failures from electrical surges or software issues.

- High-Pressure Fuel Pumps: Responsible for delivering fuel at high pressures; these can wear out or fail due to constant high-pressure operation.

- Exhaust Manifolds: Channel exhaust gases from the engine cylinders; prone to cracking or warping due to extreme temperature fluctuations.

- Heat Exchangers: Maintain optimal engine temperature by transferring heat; can become less efficient or fail due to scale build-up or corrosion.

- Engine Mounts: Secure the engine to the chassis, absorbing vibrations; can degrade over time, leading to increased vibration and noise.

- Pistons: Key components in the combustion process; can wear out or suffer from thermal fatigue.

- Connecting Rods: Transfer motion from the piston to the crankshaft; can fail under high-stress conditions, particularly in high-performance applications.

Data-Driven Decisions

Making informed decisions about stocking experienced-based spare parts requires analyzing historical failure data specific to MAN and Hyundai engines. By examining patterns in part failures—such as the frequency of turbocharger or fuel injector replacements—operators can identify which components are more likely to fail under certain operational conditions. This data-driven approach allows for smarter inventory management, ensuring that the right parts are available when needed, thus reducing downtime and avoiding costly last-minute purchases.

Case Studies

In both the marine and industrial sectors, the proactive stocking of experienced-based spares has proven to be a cost-effective strategy. For instance, in a marine application using MAN engines, early identification of frequent turbocharger failures led to the decision to keep additional units in stock. This preparation significantly reduced the vessel’s downtime during an unexpected turbocharger failure, saving the operator considerable time and money. Similarly, in an industrial setting with Hyundai engines, the regular failure of electronic control modules (ECMs) prompted the facility to increase their stock levels. As a result, the plant was able to quickly replace failed modules, maintaining continuous operation and avoiding production losses.

Spare Parts Stocking & Formula

Importance of Proper Stocking

Effective spare parts stocking is crucial for the uninterrupted operation of MAN and Hyundai engines, especially in industries and maritime operations where downtime can have significant financial and operational consequences. Proper stocking ensures that essential parts are available when needed, avoiding the costly delays associated with understocking. Conversely, overstocking can lead to unnecessary capital being tied up in inventory, increased storage costs, and the risk of parts becoming obsolete. Striking the right balance is key to maintaining operational efficiency and cost-effectiveness.

The Spare Parts Stocking Formula

To achieve optimal stocking levels, a systematic approach is necessary. The following formula helps in determining the ideal quantity of spare parts to keep in stock for MAN and Hyundai engines:

This formula allows for a tailored approach to stocking, ensuring that the inventory is aligned with the specific needs of MAN and Hyundai engines. For example, a critical component like a fuel pump with a high failure rate and long lead time would have a higher stocking level compared to less critical or more readily available parts.

Optimizing Inventory

In 2024, the focus on optimizing spare parts inventory is more critical than ever due to increased cost pressures and the need for efficient operations. For MAN and Hyundai engines, inventory optimization involves several key strategies:

- Data-Driven Decisions: Utilize historical data on part failures, usage patterns, and supplier lead times to make informed stocking decisions.

- Just-in-Time (JIT) Inventory: Implement JIT practices where feasible, particularly for non-critical components with predictable usage.

- Vendor Managed Inventory (VMI): Collaborate with suppliers to manage inventory levels, reducing the burden on internal resources and ensuring parts availability.

- Regular Inventory Audits: Conduct periodic reviews of inventory levels and adjust based on operational changes, such as new maintenance schedules or engine upgrades.

- Use of Technology: Leverage advanced inventory management software to track stock levels, predict future needs, and automate reordering processes.

By applying these strategies, you can maintain a lean yet effective spare parts inventory for MAN and Hyundai engines, ensuring readiness for any operational challenge while controlling costs.

FAQ on “Engine Spare Parts”

Q: What are engine spare parts?

A: Engine spare parts are components kept in stock for replacing worn or damaged parts in engines.

Q: Why are engine spare parts important?

A: They ensure continuous engine operation by preventing downtime due to part failures.

Q: What are mandatory engine spare parts?

A: Mandatory spares are essential parts required for compliance and reliable engine function.

Q: How should engine spare parts be stocked?

A: Stocking should be based on failure rates, lead times, and engine criticality factors.

Conclusion

In summary, maintaining and managing engine spare parts effectively is crucial for the reliability and performance of MAN and Hyundai engines. Each category of spare parts—from wearing parts to critical spares, consumables, and safety components—plays a vital role in ensuring that your engines operate smoothly and efficiently. Regularly monitoring and replacing wearing parts like piston rings and bearings, keeping critical spares such as fuel pumps and alternators readily available, and adhering to best practices in inventory management are all essential steps to avoid unexpected downtime and costly repairs.

As we move into 2024, the emphasis on optimized inventory management is more important than ever. Leveraging data-driven decisions, implementing just-in-time practices, and conducting regular inventory audits are best practices that can help you maintain a balanced and cost-effective spare parts inventory.

We encourage you to review your current spare parts inventory, particularly for MAN and Hyundai engines, and make adjustments based on the latest insights provided in this post. By doing so, you can ensure that your engines are always ready to perform at their best, minimizing downtime and maximizing operational efficiency.