“Readers can easily navigate this blog post by scrolling through the table of contents to find the topic of their choice. Each section is clearly marked for quick reference, allowing you to jump directly to the information you need.”

Exhaust Stack Height Requirement

In both industrial and residential settings, the height of an exhaust stack is a critical factor that impacts air quality, safety, and regulatory compliance. Whether you’re managing emissions from a large manufacturing plant or a residential chimney, understanding the correct stack height is essential for ensuring optimal performance and minimizing harmful pollutants.

This guide aims to provide you with a comprehensive understanding of exhaust stack height requirements. You’ll learn about the key factors that influence stack height, methods for accurate calculation, and the importance of choosing the right materials and installation techniques. By the end of this guide, you’ll be equipped with the knowledge to make informed decisions and ensure your exhaust stack meets all necessary standards.

Adhering to exhaust stack height requirements is not just about following regulations—it’s about protecting public health and the environment. Proper stack height helps disperse emissions effectively, reducing the concentration of pollutants at ground level. Compliance with these requirements is crucial for avoiding legal penalties and contributing to a safer, cleaner environment.

Understanding Exhaust Stack Height

Definition and Function

Exhaust stack height refers to the vertical measurement of a chimney or exhaust pipe from its base to its top. This height is a critical component in the design and operation of exhaust systems, whether in industrial plants, commercial buildings, or residential homes. The primary function of exhaust stack height is to ensure the effective dispersion of emissions, such as smoke, gases, and particulate matter, into the atmosphere. By elevating the point of discharge, exhaust stacks help minimize the concentration of pollutants at ground level, thus reducing their impact on the immediate environment and human health.

Key Factors Affecting Stack Height

- Building Height: The height of the building or structure where the exhaust stack is installed plays a significant role. The stack height must be sufficient to ensure that emissions are released above the building’s roofline, promoting better dispersion and minimizing the risk of re-entry into the building through windows or ventilation systems.

- Local Topography: The surrounding landscape, including hills, valleys, and other natural features, can influence how emissions disperse. Higher elevations or nearby obstacles can alter wind patterns and affect the dilution and transport of pollutants. Therefore, exhaust stack height may need adjustment to account for these geographical factors.

- Prevailing Winds: Wind speed and direction are crucial in determining the effective dispersion of emissions. In areas with strong and consistent winds, a lower stack height might suffice, as the wind can help spread pollutants over a wider area. Conversely, in regions with low or variable wind speeds, a taller stack may be necessary to achieve adequate dispersion.

Health and Environmental Impacts

Improper exhaust stack height can lead to a variety of adverse health and environmental effects. When emissions are not adequately dispersed, pollutants such as sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter (PM) can accumulate at ground level. This can result in increased exposure to harmful substances, leading to respiratory problems, cardiovascular diseases, and other health issues for nearby residents and workers.

From an environmental perspective, insufficient stack height can contribute to localized air quality degradation, harming ecosystems and wildlife. Pollutants can settle on vegetation, water bodies, and soil, leading to acidification, eutrophication, and the contamination of natural resources.

Regulatory Requirements

Global Standards

Exhaust stack height requirements are governed by a variety of international regulations aimed at minimizing environmental impact and protecting public health. Prominent among these are:

- Environmental Protection Agency (EPA): In the United States, the EPA sets stringent guidelines on emissions through the Clean Air Act. This includes specifying minimum stack heights to ensure effective dispersion of pollutants.

- World Health Organization (WHO): WHO provides guidelines on air quality, recommending stack height standards that reduce the concentration of harmful pollutants at ground level.

- European Union (EU) Directives: The EU has established several directives, such as the Industrial Emissions Directive (IED), which mandates appropriate stack heights to limit emissions of hazardous substances.

- International Maritime Organization (IMO): For marine applications, the IMO’s MARPOL Annex VI regulates air pollution from ships, including requirements for exhaust stack heights to control emissions of sulfur oxides (SOx) and nitrogen oxides (NOx).

Regional Differences

While global standards provide a framework, specific requirements for exhaust stack height can vary significantly across different countries and even within regions of the same country. These variations account for local environmental conditions, industrial practices, and public health priorities.

- United States: The EPA’s guidelines are complemented by state-specific regulations. For instance, California’s Air Resources Board (CARB) enforces more stringent standards due to the state’s unique air quality challenges.

- European Union: Member states implement the EU directives with additional national regulations. Germany, for example, imposes stricter requirements on industries near densely populated areas to protect public health.

- Asia:

- China: The Ministry of Ecology and Environment (MEE) sets localized standards to address severe air pollution issues.

- India: The Ministry of Environment, Forest and Climate Change (MoEFCC) and the Central Pollution Control Board (CPCB) are responsible for setting and enforcing air quality and emission standards, including those related to exhaust stack height.

- Australia: The National Environment Protection Council (NEPC) sets national standards, but individual states like New South Wales have additional requirements reflecting local environmental conditions.

Case Study: Application of Specific Regulation in Germany

In Germany, the Federal Immission Control Act (BImSchG) provides a comprehensive framework for controlling emissions from industrial sources. One notable example of its application is in the Rhine-Ruhr industrial region, known for its high population density and concentration of industrial activities.

Scenario: A new chemical manufacturing plant is being established in the Rhine-Ruhr area, which is subject to the stringent requirements of the BImSchG.

- Initial Assessment: The plant undergoes a detailed environmental impact assessment, focusing on potential air quality impacts.

- Stack Height Calculation: Using modeling software, the required stack height is determined to ensure pollutants are dispersed effectively, minimizing ground-level concentrations.

- Approval and Monitoring: The proposed stack height is reviewed and approved by the local environmental authority, which also mandates continuous monitoring of emissions to ensure compliance.

- Ongoing Compliance: The plant must submit regular reports and undergo periodic inspections to verify that the stack height and emission levels remain within the permissible limits.

Calculation Methods

Basic Calculation Principles

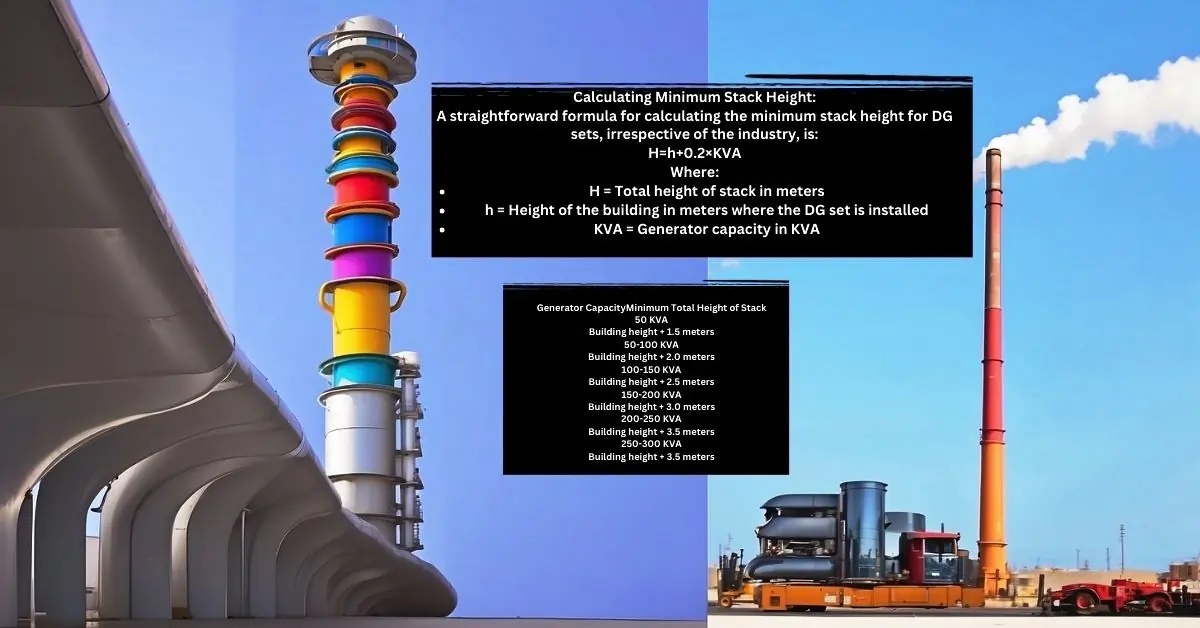

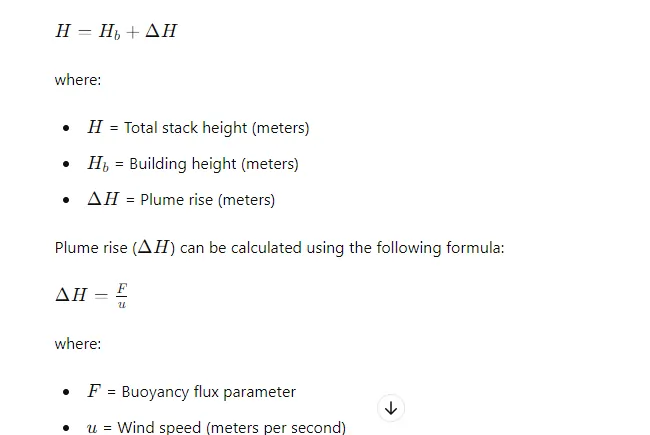

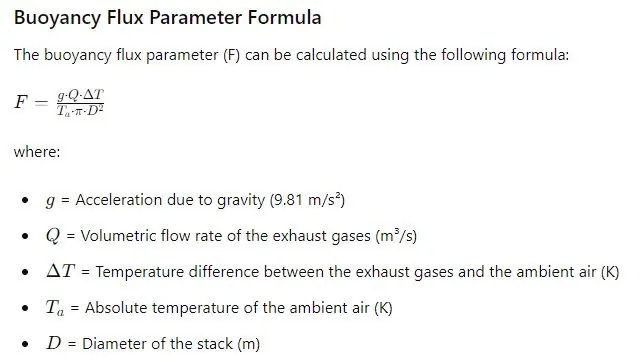

Determining the optimal height for an exhaust stack involves several key factors to ensure effective dispersion of emissions. The basic formula used for calculating stack height is derived from the Gaussian dispersion model, which considers factors such as emission rate, wind speed, and atmospheric stability.

A simplified version of the stack height formula is:

Components Explained

- Acceleration Due to Gravity (g): A constant value representing the force of gravity acting on the plume.

- Volumetric Flow Rate (Q): The volume of exhaust gases emitted per unit time, which influences the initial velocity of the plume.

- Temperature Difference (ΔT\Delta TΔT): The difference in temperature between the exhaust gases and the surrounding air. Hotter exhaust gases are less dense, causing them to rise more quickly.

- Ambient Air Temperature (T_a): The absolute temperature of the air surrounding the stack, which affects the buoyancy of the plume.

- Stack Diameter (D): The diameter of the stack, which influences the initial area through which the gases are emitted.

Advanced Calculation Techniques

For more precise and tailored calculations, advanced techniques involving modeling software and simulations are employed. These methods consider a broader range of variables and complex interactions between emissions and environmental conditions. Some advanced methods include:

- Computational Fluid Dynamics (CFD) Models: CFD models simulate the flow of air and pollutants around buildings and other structures. They provide detailed insights into how emissions disperse under various conditions, allowing for optimized stack height design.

- AERMOD: Developed by the EPA, AERMOD is an advanced air dispersion model that incorporates atmospheric turbulence and terrain features. It is widely used for regulatory purposes and can predict the impact of stack height on pollutant concentrations over large areas.

- CALPUFF: This modeling system is capable of simulating the dispersion of pollutants over complex terrains and long distances. It accounts for the effects of time-varying meteorological conditions and is suitable for assessing regional air quality impacts.

- Wind Tunnel Testing: Physical models of proposed stacks and surrounding structures can be tested in wind tunnels to observe the dispersion patterns of emissions under controlled conditions. This method provides empirical data that can validate and refine computational models.

Tools and Resources

Several tools and software programs are available to assist in the calculation of exhaust stack height, ranging from simple online calculators to sophisticated modeling platforms. Some recommended resources include:

- EPA’s SCREEN3: A screening tool that provides a quick estimate of pollutant dispersion and stack height requirements based on basic input parameters.

- BREEZE AERMOD: A user-friendly interface for the AERMOD model, offering comprehensive support for regulatory air dispersion modeling.

- WindSim: A CFD-based software that helps in simulating wind flow and pollutant dispersion, useful for optimizing stack height in complex environments.

- STACK-HEIGHT.com: An online tool that offers basic stack height calculations and guidelines based on input data such as building height and emission rates.

Incorporating these tools and advanced techniques into the stack height calculation process ensures a thorough and accurate assessment, leading to better compliance with regulatory standards and improved environmental outcomes.

By understanding both the basic principles and advanced methods for calculating exhaust stack height, you can ensure that your stack designs are effective, compliant, and environmentally responsible. Utilizing the recommended tools and resources will further enhance your ability to achieve optimal results.

Design and Installation Considerations

Material Selection

Choosing the right materials for constructing exhaust stacks is crucial for ensuring durability, efficiency, and compliance with environmental standards. The best materials for exhaust stacks should possess high resistance to corrosion, heat, and mechanical stress. Commonly used materials include:

- Stainless Steel: Known for its excellent corrosion resistance and high-temperature strength, stainless steel is ideal for environments with acidic or high-moisture emissions.

- Carbon Steel: Often used in less corrosive environments, carbon steel offers good strength and durability at a lower cost compared to stainless steel. It may require protective coatings to prevent corrosion.

- Fiberglass Reinforced Plastic (FRP): FRP is lightweight and highly resistant to corrosion, making it suitable for applications involving corrosive gases. It also provides good thermal insulation.

- Brick and Concrete: Traditional materials for large industrial stacks, brick and concrete offer excellent structural integrity and thermal mass but can be more expensive and complex to construct.

Structural Integrity

Ensuring the structural integrity of an exhaust stack involves several key considerations to withstand environmental and operational stresses:

- Foundation Design: A strong and stable foundation is essential to support the stack’s weight and prevent settlement or tilting. The foundation design should account for soil conditions, load-bearing capacity, and environmental factors like seismic activity.

- Wind and Seismic Load: The stack must be designed to withstand wind forces and seismic loads. Engineers use codes and standards, such as ASCE 7, to determine the appropriate load factors and design criteria.

- Thermal Expansion: Exhaust stacks experience thermal expansion and contraction due to temperature variations. Expansion joints and flexible connections can accommodate these movements, preventing structural damage.

- Corrosion Protection: Applying protective coatings, using corrosion-resistant materials, and incorporating cathodic protection systems can extend the life of the stack by preventing corrosion.

Installation Best Practices

Proper installation of exhaust stacks is vital for meeting height requirements and ensuring long-term performance. Here are some best practices:

- Site Preparation: Conduct thorough site surveys and prepare the site by clearing obstacles, leveling the ground, and ensuring adequate access for construction equipment.

- Assembly Techniques: Use precise assembly techniques, such as welding or bolting, to connect stack sections securely. Ensure all joints are airtight to prevent leaks.

- Alignment and Plumb: Use laser levels and plumb bobs to ensure the stack is perfectly vertical. Misalignment can lead to structural instability and uneven stress distribution.

- Anchoring and Guying: For tall stacks, use anchors and guy wires to provide additional stability. These supports help the stack resist wind and seismic forces.

- Inspection and Testing: Conduct thorough inspections and testing during and after installation. Check for weld quality, alignment, structural integrity, and compliance with design specifications.

- Compliance with Regulations: Ensure that the installation meets all local and international regulations regarding exhaust stack height, emissions, and safety standards.

Common Challenges and Solutions

Challenges in Urban Areas

In densely populated urban areas, installing and maintaining exhaust stacks presents unique challenges due to space constraints, regulatory requirements, and potential impacts on residents. Some specific issues include:

- Space Constraints: Limited space can make it difficult to find suitable locations for exhaust stacks without encroaching on neighboring properties or violating building codes.

- Air Quality Regulations: Urban areas often have stricter air quality standards, requiring higher stack heights and advanced emission control technologies to minimize ground-level pollution.

- Noise and Vibration: The operation of exhaust systems can generate noise and vibration, which can disturb nearby residents and businesses. Effective noise control measures are necessary.

- Aesthetic Concerns: Tall stacks can impact the skyline and aesthetics of urban areas, leading to opposition from local communities and authorities.

Solutions:

- Compact Designs: Use compact, modular stack designs that can be easily integrated into limited spaces.

- Advanced Filtration Systems: Implement high-efficiency particulate air (HEPA) filters and catalytic converters to reduce emissions and meet stringent air quality standards.

- Noise Reduction Measures: Install silencers, vibration dampers, and noise barriers to mitigate the impact of noise and vibration.

- Community Engagement: Engage with local communities and authorities early in the planning process to address aesthetic concerns and gain support.

Maintenance and Inspection

Regular maintenance and inspection are critical to ensuring the longevity and performance of exhaust stacks. Common practices and routines include:

- Visual Inspections: Conduct routine visual inspections to check for signs of wear, corrosion, and structural damage.

- Non-Destructive Testing (NDT): Use NDT methods such as ultrasonic testing, radiography, and magnetic particle testing to detect internal defects without damaging the stack.

- Cleaning and Debris Removal: Regularly clean the interior of the stack to remove soot, ash, and other deposits that can obstruct airflow and reduce efficiency.

- Corrosion Control: Apply protective coatings and cathodic protection systems to prevent corrosion and extend the stack’s lifespan.

- Monitoring Systems: Install continuous monitoring systems to track emissions, temperature, and pressure, enabling proactive maintenance and early detection of issues.

Solutions:

- Scheduled Maintenance: Develop a comprehensive maintenance schedule based on manufacturer recommendations and industry best practices.

- Training Programs: Provide training for maintenance personnel to ensure they are equipped with the skills and knowledge to perform thorough inspections and maintenance.

- Maintenance Records: Keep detailed records of all inspections, maintenance activities, and repairs to track the stack’s condition over time and plan future maintenance.

Problem-Solving

Exhaust stacks can encounter several common problems, such as corrosion, blockages, and the need for height adjustments. Addressing these issues promptly is essential for maintaining optimal performance.

- Corrosion: Exposure to harsh environmental conditions and acidic emissions can lead to corrosion, compromising the stack’s structural integrity.

- Solution: Apply high-performance coatings, use corrosion-resistant materials, and implement cathodic protection systems to prevent and mitigate corrosion.

- Blockages: Accumulation of soot, ash, and other debris can obstruct airflow, reducing the efficiency of the exhaust system.

- Solution: Schedule regular cleaning and use automated cleaning systems like soot blowers to keep the stack interior clear of obstructions.

- Height Adjustments: Changes in regulatory requirements or operational needs may necessitate adjustments to the stack height.

- Solution: Design stacks with modular sections that can be easily added or removed to adjust the height. Conduct structural assessments to ensure the stack can safely support height modifications.

FAQ on “Exhaust Stack Height Requirement”

Q: Why is the height of an exhaust stack important?

A: It ensures effective dispersion of pollutants, reducing ground-level concentrations and protecting air quality.

Q: What factors determine the required height of an exhaust stack?

A: Factors include building height, local topography, wind patterns, and regulatory standards.

Q: How often should exhaust stacks be inspected and maintained?

A: Regular inspections should be conducted annually, with maintenance as needed based on the stack’s condition and usage.

Q: What materials are best for constructing exhaust stacks?

A: Stainless steel, carbon steel, and fiberglass reinforced plastic (FRP) are commonly used for their durability and resistance to corrosion.

Conclusion

Ensuring the proper height of exhaust stacks is vital for effective emission control, environmental protection, and regulatory compliance. By understanding the key factors that influence stack height, adhering to global and regional regulations, and employing advanced calculation methods and materials, you can design and maintain exhaust stacks that meet stringent standards. Regular maintenance and proactive problem-solving are essential to keep your system running efficiently and safely. By prioritizing these elements, you contribute to a cleaner, healthier environment and ensure the longevity and reliability of your exhaust stack system.