Fresh Water Generator

Fresh water is a lifeline at sea, crucial not only for human survival but also for maintaining marine ecosystems. Whether you’re sailing for leisure or working on commercial vessels, having a reliable source of fresh water can significantly impact comfort and safety on board. The need for sustainable water solutions has never been greater, as marine adventures often require careful planning to ensure that every drop counts.

In 2024, fresh water generators have seen remarkable advancements that enhance efficiency and reliability, making them indispensable for any maritime journey. This post will delve into the latest technologies, various types of generators, and best practices to optimize their use. By the end, you’ll have all the essential information needed to choose the right fresh water generator for your next adventure on the open water.

Understanding Fresh Water Generators

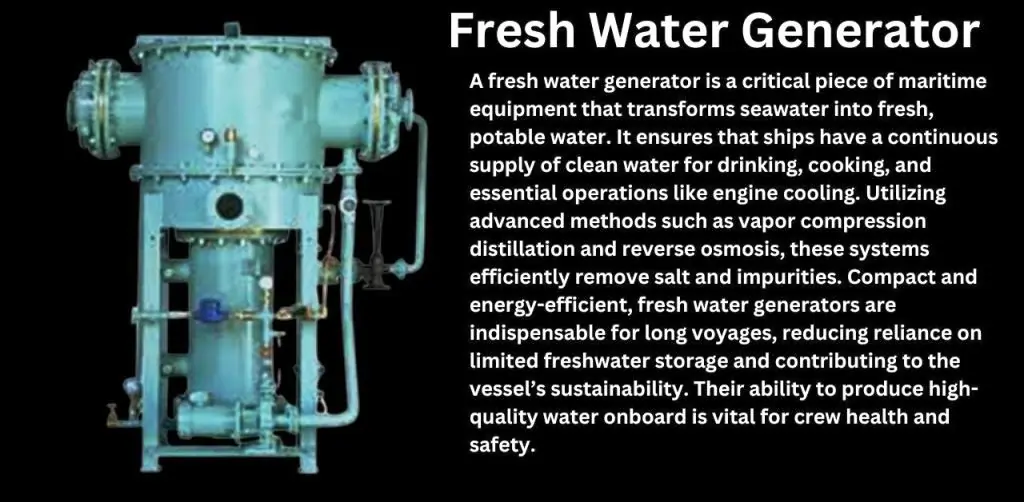

What is a Fresh Water Generator?

A fresh water generator is a device designed to convert seawater or brackish water into potable fresh water, making it essential for marine applications. These generators play a crucial role in ensuring that vessels have a reliable water supply for drinking, cooking, and sanitation, which is vital for the well-being of crew and passengers alike. In marine environments, where access to fresh water is limited, these systems not only enhance comfort but also promote sustainability by reducing the need for water transport.

How They Work

Fresh water generators operate through various processes, primarily reverse osmosis and distillation.

- Reverse Osmosis: This method uses a semipermeable membrane to separate fresh water from salt water. High pressure is applied to push seawater through the membrane, allowing only water molecules to pass while rejecting salts and impurities.

- Distillation: This process involves heating seawater until it evaporates, then cooling the vapor to condense it back into liquid form, leaving salts and contaminants behind.

Essential Uses of Freshwater on Ships

Drinking and Cooking

One of the most critical uses of freshwater on ships is for drinking and cooking. Crew members require a constant supply of clean, potable water to stay hydrated, especially during long voyages. Additionally, freshwater is necessary for preparing meals, which is vital for the crew’s health and well-being. Ensuring the availability of fresh drinking water is a top priority, as water scarcity can severely impact crew performance and morale.

Engine Cooling

Freshwater plays a significant role in the cooling systems of marine engines. It is used to regulate the temperature of engines and other machinery, preventing overheating and ensuring the proper functioning of essential equipment. By circulating through the engine cooling system, freshwater absorbs excess heat and helps maintain optimal operating conditions, thereby extending the lifespan of the equipment and avoiding costly breakdowns.

Steam Production

Many ships rely on steam generation for a variety of functions, including heating, power generation, and propulsion. Freshwater is crucial for producing steam, typically using boilers. The steam is then used to power various ship systems or for direct propulsion in steam turbine-driven vessels. Ensuring an adequate supply of freshwater for steam generation is vital for the ship’s overall operation and energy efficiency.

Firefighting

Freshwater is also a critical resource for firefighting on board ships. In the event of a fire, it is used in fire suppression systems, fire hoses, and other firefighting equipment. Access to freshwater for firefighting is essential for protecting the ship, its crew, and cargo from fire hazards. It ensures that fires can be quickly extinguished before they spread, safeguarding the lives of those on board and minimizing damage to the ship.

Fresh Water Generator Working Principle

Fresh water generation on ships involves converting seawater, which contains high levels of salt and impurities, into potable water for drinking, cooking, engine cooling, and other essential uses. There are two primary working principles for freshwater generation on ships:

1. Desalination

Desalination is the process of removing salt and other contaminants from seawater to produce fresh water. This is typically done using two main techniques:

- Vapor Compression Distillation: This method involves heating seawater to create vapor, which is then condensed into fresh water, leaving behind salt and other impurities. The vapor phase transition separates freshwater from saltwater, utilizing heat to drive the process.

- Reverse Osmosis: This method uses hydraulic pressure to force seawater through a semi-permeable membrane. The membrane allows water molecules to pass while blocking salt ions and other impurities. This process does not involve phase changes but requires high pressure to achieve the separation.

2. Reverse Osmosis

In reverse osmosis, seawater is pumped at high pressure through a semi-permeable membrane, which acts as a filter. The membrane permits only water molecules to pass through while rejecting salt, minerals, and other impurities. This process relies on hydraulic pressure to push water through the membrane, separating freshwater from the concentrated brine.

Both desalination and reverse osmosis require energy input to drive the separation of freshwater from saltwater. Vapor compression distillation uses thermal energy (heat), while reverse osmosis relies on mechanical energy (pressure). Each method has its advantages, with reverse osmosis being particularly energy-efficient and widely used on ships today.

Fresh Water Generator Process

Vapor Compression Distillation

- Boiling Process: Seawater is boiled to produce steam, separating it from salt and other contaminants.

- Condensation: The steam is passed through heat exchangers and a compressor, which raises the steam’s pressure and temperature to facilitate condensation.

- Heat Recovery: The process recycles the heat from condensation to help boil additional seawater, improving energy efficiency.

- Fresh Water Collection: The condensed steam (now freshwater) is collected and processed further to meet drinking water standards.

Reverse Osmosis

- Pressurization: Seawater is compressed and pushed through a semi-permeable membrane.

- Filtration: The membrane allows only water molecules to pass, filtering out salt ions and other impurities.

- Permeate and Brine Separation: Freshwater (permeate) is collected on one side, while the concentrated brine (containing rejected salts) is discharged.

- Additional Treatment: The permeate may undergo remineralization and disinfection to ensure it meets potable water standards.

This organized breakdown highlights the key steps and differences between the vapor compression distillation and reverse osmosis processes in freshwater generation.

Key Features to Consider in 2024

Energy Efficiency

Energy efficiency is a top priority for marine water systems in 2024. Low energy consumption is crucial for reducing operational costs and environmental impact, especially for long voyages. Recent innovations, such as the use of variable speed drives and energy recovery systems, have significantly improved the efficiency of water-making units, allowing them to operate at optimal energy levels while maintaining high output.

Capacity and Output

Selecting the right capacity is essential to meet the fresh water needs of different vessel sizes. Smaller boats may require systems that can generate a few hundred liters per day, while larger ships need systems capable of producing several thousand liters daily. Understanding the daily water consumption for crew, passengers, and operational needs helps in choosing the correct output capacity for your vessel.

Maintenance and Durability

Regular maintenance is key to ensuring the longevity and optimal performance of marine water systems. Essential maintenance tips include routine cleaning, checking for leaks, and replacing filters as necessary. Models designed with corrosion-resistant materials and advanced filtration technologies are particularly durable, offering long-term reliability even in harsh marine environments.

Portability and Size

Portability and size are important considerations depending on the type of vessel. Compact, lightweight models are ideal for smaller boats where space is limited, while larger vessels can accommodate fixed water systems that offer higher capacities and more robust features. The right balance between size and output ensures the system fits seamlessly into the vessel’s layout without sacrificing performance.

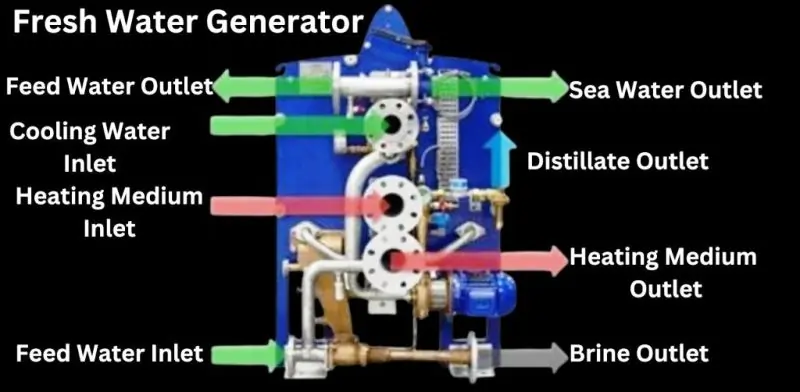

Working of Fresh Water Generator

A freshwater generator onboard ships is designed to produce potable water from seawater. This process involves multiple components and outlets that manage the flow of seawater, brine, and distillate during desalination. Below is a detailed description of the working principle, based on key inlet and outlet points.

1. Sea Water Inlet

- Purpose: This is where seawater enters the freshwater generator.

- Process: The seawater is drawn from the ocean and pumped into the generator, where it is subjected to heating or pressure depending on the desalination process (vapor compression or reverse osmosis).

2. Feed Water Inlet

- Purpose: The feed water inlet supplies seawater to the heating section of the generator.

- Process: This seawater is heated or pressurized as part of the desalination process, which removes salt and impurities.

3. Heating Medium Inlet

- Purpose: This inlet supplies the heating medium, such as steam or engine jacket cooling water, to raise the temperature of the feed water.

- Process: The heating medium transfers heat to the seawater, causing it to evaporate, which is a crucial step in the vapor compression process.

4. Sea Water Outlet

- Purpose: This outlet discharges the remaining seawater that is not used in the evaporation or filtration process.

- Process: After passing through the freshwater generator, the unused seawater is safely discharged back into the ocean.

5. Brine Outlet

- Purpose: The brine outlet is used to discharge the concentrated saltwater, or brine, that remains after the desalination process.

- Process: The brine contains higher concentrations of salt and is typically discharged into the ocean in a controlled manner to minimize environmental impact.

6. Distillate Outlet

- Purpose: This outlet collects the distilled freshwater produced by the generator.

- Process: The freshwater (distillate) is free from salt and impurities and is collected for onboard use, such as drinking, cooking, and engine cooling.

7. Heating Medium Outlet

- Purpose: After the heating medium has transferred its heat to the seawater, it is discharged through this outlet.

- Process: The cooled heating medium, often steam or water, exits the system through this outlet and can be recycled for future use or discharged, depending on the system design.

8. Feed Water Outlet

- Purpose: This outlet removes the treated water that has not been evaporated or processed.

- Process: This excess feed water may either be recycled back into the system or discharged, depending on the needs of the freshwater generator.

Top Fresh Water Generators of 2024

Here are the contact details for some of the top freshwater generator manufacturers mentioned:

- AQUA Blue from Alfa Laval

Website: Alfa Laval AQUA Blue

Contact: You can find detailed contact options for Alfa Laval based on your region on their Contact page. - Wärtsilä Freshwater Generators

Website: Wärtsilä Freshwater Generators

Contact: You can reach Wärtsilä by visiting their global contact page where you can select your region for specific support options. - Genaq Nimbus N5000

Website: Genaq Nimbus

Contact: For inquiries, you can reach Genaq through their contact form on the Contact page. - Tsunami T-500

The Tsunami T-500 is generally sold through distributors specializing in water generation. You may need to contact distributors or dealers for more information. - Genesis Systems Watercube WC-100

Website: Genesis Systems

Contact: For pre-order and inquiries, you can reach Genesis Systems via the contact form on their website or explore other details on their contact page. - Watergen Gen-M Pro

Website: Watergen Gen-M Pro

Contact: Watergen provides a direct contact form on their Contact page for product inquiries. - SOURCE Hydropanel

Website: SOURCE Hydropanel

Contact: For inquiries, you can visit their Contact page.

Installation and Operation Tips

| Section | Description |

|---|---|

| DIY Installation vs. Professional Help | DIY Installation: Cost-saving, but risk of inefficiency or damage if done incorrectly. Professional Help: Ensures correct installation, but is more expensive. Recommended for complex systems or when warranties are involved. |

| Best Practices for Operation | – Regularly clean filters and check for scale buildup. – Operate within recommended temperature and pressure ranges. – Monitor water quality regularly for impurities. – Operate during cooler parts of the day for energy efficiency (for atmospheric systems). |

| Troubleshooting Common Issues | – Low water output: Clean filters and check for scale buildup. – Inconsistent water quality: Inspect for leaks or worn seals. – High energy consumption: Ensure proper temperature and motor efficiency. Consult the manual or a technician for persistent issues. |

Fresh Water Generator Troubleshooting:

| Issue | Troubleshooting Techniques |

|---|---|

| 8.1: Low Freshwater Production | – Check seawater flow: Ensure proper seawater flow to the generator; check input valves, strainers, and pumps for obstructions or failures. – Monitor salinity levels: High salinity may indicate issues such as membrane fouling or low pressure. – Inspect pre-treatment systems: Check sand or cartridge filters for blockage or damage and clean or replace them if necessary. – Inspect seals and gaskets: Examine for leaks or damage in seals/gaskets and replace worn components to prevent seawater bypassing. |

| 8.2: High Energy Consumption | – Clean heat exchangers: Check for mineral deposits or scaling and clean heat exchangers using chemicals or mechanical descaling to restore efficiency. – Check cooling systems: Ensure cooling water systems are functioning properly to maintain the correct temperature for the desalination process. |

| 8.3: Membrane Fouling and Damage | – Monitor pressure differentials: A rise in pressure across membranes may suggest fouling or damage. Clean or replace membranes as needed. – Check for system leaks: Inspect pipelines, valves, and connections for leaks; repair or replace faulty components. – Inspect seals and gaskets: Check for leaks or damage in seals and gaskets around membranes; replace if necessary. |

| 8.4: Control System Malfunctions | – Check control settings: Ensure that feed flow rates, pressure levels, and temperature settings are correctly set. – Calibrate sensors: Regularly calibrate sensors (salinity, temperature, pressure, and flow rate) for accurate readings and system performance. |

Environmental Considerations

Eco-Friendly Options

As environmental sustainability becomes a key focus in marine industries, eco-friendly freshwater generation options are now widely available. Many modern systems prioritize energy efficiency, utilizing waste heat from the engine or renewable energy sources, such as solar power. Technologies like reverse osmosis and advanced distillation processes help reduce the ecological footprint by minimizing energy consumption and ensuring that harmful emissions are kept to a minimum. Additionally, atmospheric water generators that extract moisture from the air without depleting natural water sources provide a sustainable alternative for vessels.

Impact on Marine Ecosystems

While freshwater generators are essential for onboard water supply, their impact on marine ecosystems must be responsibly managed. Improper discharge of brine (the concentrated saltwater byproduct of desalination) can harm marine life due to its high salinity. To mitigate this, many generators are designed with environmentally responsible discharge systems that dilute brine before releasing it into the ocean. Furthermore, regular maintenance to prevent leaks and ensure optimal system efficiency is critical for reducing any inadvertent harm to marine environments. Implementing best practices helps protect marine ecosystems while ensuring a reliable freshwater supply onboard.

Future Trends in Fresh Water Generation

Innovations on the Horizon

The future of freshwater generation is marked by exciting advancements that promise to enhance efficiency and sustainability. Emerging technologies such as membrane distillation and forward osmosis are poised to revolutionize the desalination process by using less energy and producing less brine. These innovations could drastically reduce the environmental impact of freshwater production. Additionally, solar-powered desalination systems are becoming increasingly viable, especially for remote and off-grid locations, offering a green solution for clean water generation. Atmospheric water generation technology is also evolving, with systems designed to extract moisture from the air in a wider range of climates, ensuring reliable access to water even in arid regions.

The Role of AI and Smart Technology

Artificial Intelligence (AI) and smart technology are transforming the operation and management of freshwater generation systems. AI-powered monitoring systems can optimize water output, detect leaks, and predict maintenance needs, ensuring continuous and efficient operation with minimal human intervention. Smart sensors integrated into these systems allow for real-time adjustments, which helps in conserving energy and reducing operational costs. The combination of AI and smart technology also enables automated diagnostics, allowing for proactive troubleshooting and the reduction of downtime. This integration of smart technology is expected to significantly improve the sustainability and cost-effectiveness of freshwater generation systems in the near future.

FAQ on Fresh Water Generator

Q- What is a fresh water generator?

A- It converts seawater into potable water.

Q- What is the use of a water generator?

A- It provides fresh water for onboard use.

Q- What is the principle of FWG?

A- It uses heat or pressure to separate salt from water.

Q- What are water generators called?

A- They are called freshwater generators or desalination units.

Conclusion

In conclusion, freshwater generation is vital to maritime operations, serving as a cornerstone for the health, safety, and efficiency of crew members, as well as environmental stewardship. By ensuring the robust design, regular maintenance, and compliance of freshwater generating systems, ships can consistently provide potable water for critical needs. This not only protects the crew but also minimizes the environmental impact of desalination processes, promoting sustainable practices in marine operations. As the maritime industry continues to advance, prioritizing the efficiency and eco-friendliness of freshwater generators will be key to ensuring long-term operational success and environmental responsibility.