Fuel Injector Guide

Have you ever wondered what makes a marine diesel engine run smoothly and efficiently? The answer lies in a crucial component: the fuel injector. Whether you’re a seasoned marine engineer or a maritime enthusiast, understanding how fuel injectors work can save you time, money, and frustration.

In this comprehensive guide, we’ll delve into the seven powerful facts about fuel injectors that every marine engineer must know. From their basic function and common issues to maintenance tips and the latest technological advancements, this article will provide you with the knowledge to keep your marine diesel engine performing at its best. So, get ready to explore the fascinating world of fuel injectors and discover how they can significantly impact your vessel’s performance and longevity.

What is a Fuel Injector?

Definition

A fuel injector is a vital component in a marine diesel engine, responsible for delivering fuel into the combustion chamber at precise intervals. It ensures that the right amount of fuel is sprayed into the engine’s cylinders, allowing for optimal combustion and engine performance.

Function

The primary role of a fuel injector is to atomize the fuel, breaking it into tiny droplets for efficient mixing with air. This process is crucial because it ensures complete combustion, which leads to maximum power output and fuel efficiency. Proper fuel injection helps reduce emissions, improve fuel economy, and maintain consistent engine performance. By delivering the exact amount of fuel needed at the right moment, fuel injectors play a key role in preventing engine knock and reducing the risk of overheating or underperformance.

Types of Fuel Injectors

Fuel injectors come in various types, each suited to different engine designs and performance requirements:

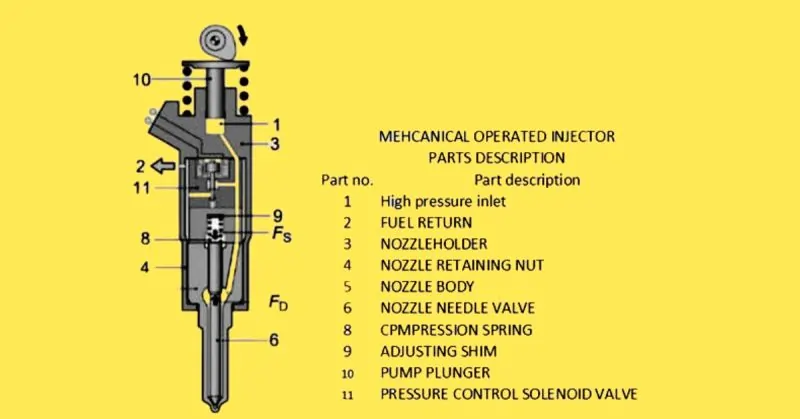

Mechanical Fuel Injectors

- Description: These injectors operate using mechanical means, typically involving a spring-loaded needle valve. They rely on the engine’s mechanical components to create the necessary pressure for fuel injection.

- Application: Commonly used in older or simpler engine designs, mechanical injectors are known for their durability and simplicity but may lack the precision of more advanced systems.

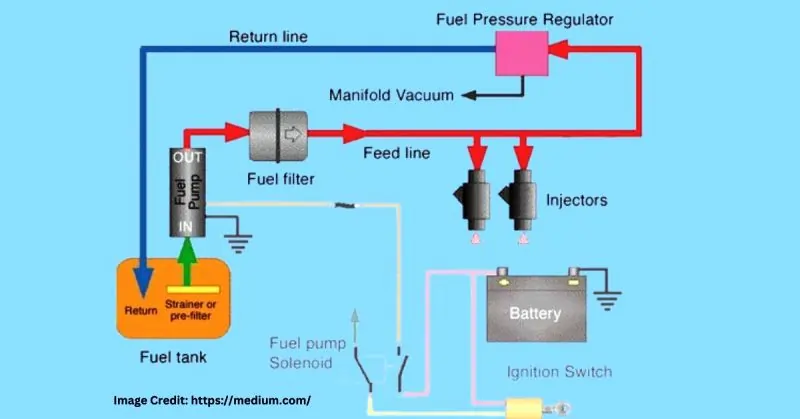

Electronic Fuel Injectors

- Description: These injectors are controlled electronically by the engine control unit (ECU). They use electrical signals to precisely control the timing and amount of fuel injected into the combustion chamber.

- Application: Widely used in modern marine diesel engines, electronic injectors offer superior accuracy and efficiency. They allow for advanced features like multi-point injection and variable injection timing, enhancing overall engine performance and fuel efficiency.

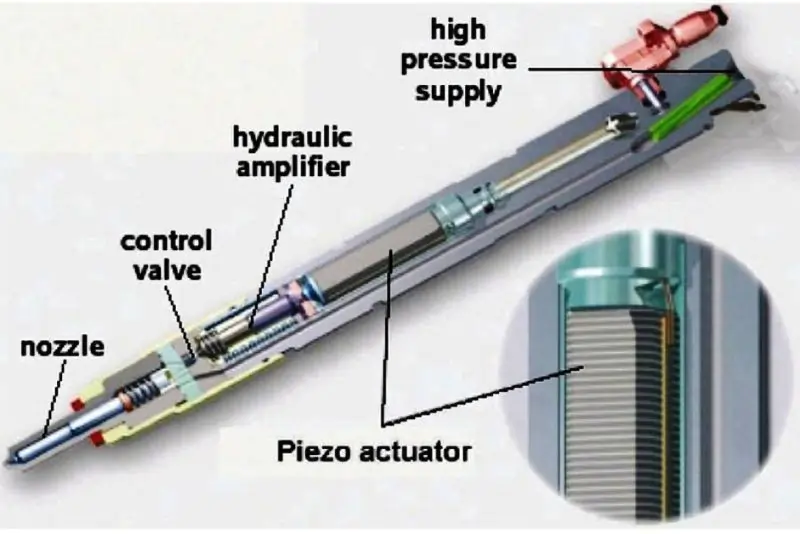

Piezoelectric Fuel Injectors

Description: These advanced injectors use piezoelectric materials that change shape when an electrical current is applied. This rapid movement controls the injector needle with exceptional precision and speed.

Application: Found in high-performance marine engines, piezoelectric injectors provide ultra-fine control over fuel delivery, resulting in better combustion efficiency, lower emissions, and improved engine responsiveness.

How Fuel Injectors Work

Basic Mechanism

Fuel injectors operate on a fundamental principle: they atomize fuel and deliver it into the combustion chamber of an engine at precise intervals. The goal is to mix the fuel with air in the optimal ratio for efficient combustion. By ensuring that the fuel is finely sprayed, injectors promote complete and efficient combustion, which enhances engine performance, fuel efficiency, and reduces emissions.

Components

Several key components make up a fuel injector:

- Injector Nozzle: The nozzle is the part where the fuel is expelled into the combustion chamber. It has tiny holes that ensure the fuel is atomized into a fine mist.

- Solenoid or Piezoelectric Actuator: This component controls the opening and closing of the injector needle. In electronic injectors, a solenoid is used, while in advanced injectors, a piezoelectric actuator is employed.

- Needle Valve: The needle valve regulates the flow of fuel through the nozzle. It opens and closes in response to signals from the actuator.

- Fuel Filter: Located at the injector’s inlet, the filter ensures that any contaminants in the fuel do not clog the injector.

- Fuel Supply Line: This line delivers fuel from the fuel pump to the injector under high pressure

Key Formulas for Fuel Injectors

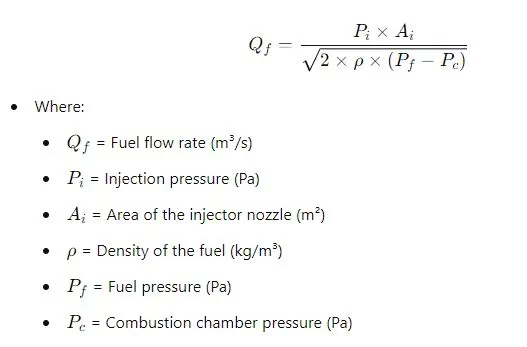

1. Fuel Flow Rate Calculation:

- Description: This formula calculates the rate at which fuel flows through the injector nozzle, crucial for ensuring the correct amount of fuel is delivered to the engine.

- Formula:

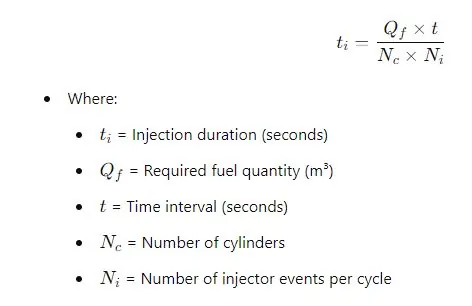

2. Injection Duration:

- Description: This formula determines the duration of fuel injection, ensuring that the engine receives the correct fuel quantity within a specific time interval.

- Formula:

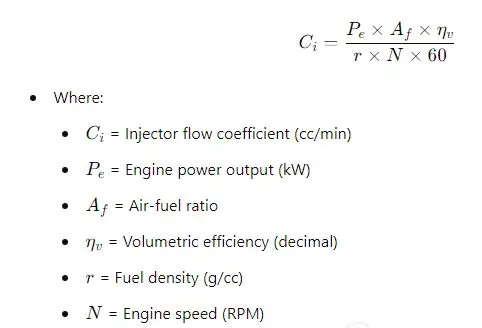

3. Fuel Injector Sizing:

- Description: This formula helps in determining the correct size of the fuel injector needed to deliver the required fuel flow to the engine, based on engine power and other parameters.

- Formula:

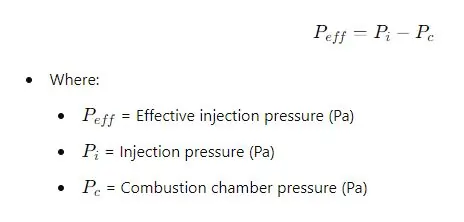

4. Effective Injection Pressure:

- Description: This formula calculates the effective pressure at the injector tip, which is the difference between the injection pressure and the combustion chamber pressure, critical for ensuring proper atomization of the fuel.

- Formula:

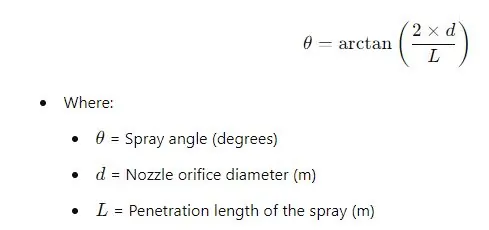

5. Spray Angle:

- Description: This formula calculates the spray angle of the fuel injector, which affects the distribution and penetration of the fuel within the combustion chamber.

- Formula:

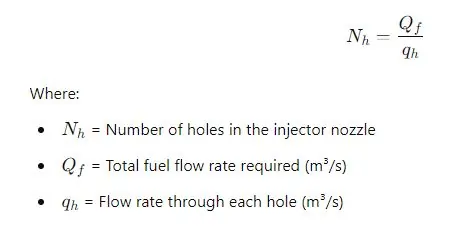

6. Calculating Injector Nozzle Holes

A simplified approach to estimating the number of holes (NhN_hNh) in the nozzle can be expressed as:

Explanation:

- Total Fuel Flow Rate (Qf): This is the amount of fuel that needs to be injected per unit of time to meet the engine’s power requirements.

- Flow Rate Through Each Hole (qh): This is the fuel flow rate that can be achieved through each individual hole in the nozzle, based on the hole size and the injection pressure.

By dividing the total required fuel flow rate by the flow rate through each hole, you can estimate the number of holes needed in the injector nozzle to achieve the desired fuel delivery.

Important Note:

This is a basic formula and assumes uniform flow through each hole. In practical applications, factors such as hole geometry, injection pressure, and desired spray pattern may also influence the final design of the injector nozzle, including the number and arrangement of holes.

Common Fuel Injector Issues

Symptoms

Faulty fuel injectors can manifest through several symptoms that indicate a problem within the system. These include:

- Engine Misfire: Irregular or incomplete combustion caused by inconsistent fuel delivery can result in the engine misfiring.

- Poor Fuel Economy: Inefficient fuel atomization leads to improper combustion, causing the engine to consume more fuel than necessary.

- Rough Idling: Inconsistent fuel delivery can make the engine idle roughly or stall.

- Increased Emissions: Poor combustion efficiency due to faulty injectors can result in higher emissions of unburned fuel.

- Loss of Power: A lack of sufficient fuel reaching the combustion chamber can reduce engine power and performance.

- Engine Knocking: Incorrect fuel-air mixture ratios can cause knocking or pinging noises, indicating pre-ignition issues.

- Fuel Leaks: Visible fuel leaks around the injector area suggest a faulty injector seal or damage to the injector itself.

Causes

Several factors can lead to fuel injector issues:

- Clogging: Dirt, debris, or fuel impurities can clog the tiny nozzle holes, restricting fuel flow and causing uneven atomization.

- Wear and Tear: Over time, the injector components can wear out, leading to leaks, poor sealing, and reduced performance.

- Electrical Failures: Faulty wiring or solenoid failures can prevent the injector from opening and closing correctly.

- Contaminated Fuel: Using low-quality or contaminated fuel can introduce particles that clog or damage the injectors.

- Heat Damage: Excessive engine heat can cause injector seals to degrade, leading to leaks.

- Corrosion: Exposure to moisture and corrosive substances can cause injector components to corrode and malfunction.

- Improper Installation: Incorrect installation or use of incompatible parts can lead to fuel injector problems.

Impact

The issues caused by faulty fuel injectors can significantly affect engine performance and efficiency:

- Reduced Engine Performance:

- Impact: Misfires, loss of power, and rough idling diminish the engine’s overall performance.

- Explanation: Consistent and precise fuel delivery is essential for optimal combustion. Faulty injectors disrupt this process, leading to subpar engine performance.

- Increased Fuel Consumption:

- Impact: Poor fuel economy results in higher operating costs.

- Explanation: Inefficient atomization and combustion mean the engine burns more fuel to achieve the same power output, leading to increased fuel consumption.

- Higher Emissions:

- Impact: Elevated emissions contribute to environmental pollution and may lead to non-compliance with emission regulations.

- Explanation: Incomplete combustion caused by faulty injectors releases more unburned hydrocarbons and other pollutants into the atmosphere.

- Potential Engine Damage:

- Impact: Long-term injector issues can cause severe engine damage.

- Explanation: Continuous misfires and knocking can damage pistons, valves, and other engine components, leading to costly repairs and downtime.

- Operational Inefficiency:

- Impact: Inefficient fuel injectors reduce the overall efficiency of the marine engine.

- Explanation: Optimal engine performance relies on precise fuel delivery. Faulty injectors disrupt this balance, leading to inefficient engine operation and reduced reliability.

Fuel Injector Maintenance

Routine Checks

Regular maintenance of fuel injectors is crucial for ensuring optimal engine performance and longevity. Here’s a checklist for routine checks:

- Visual Inspection:

- Check for visible leaks around the injector area.

- Inspect the injector body and seals for signs of wear or damage.

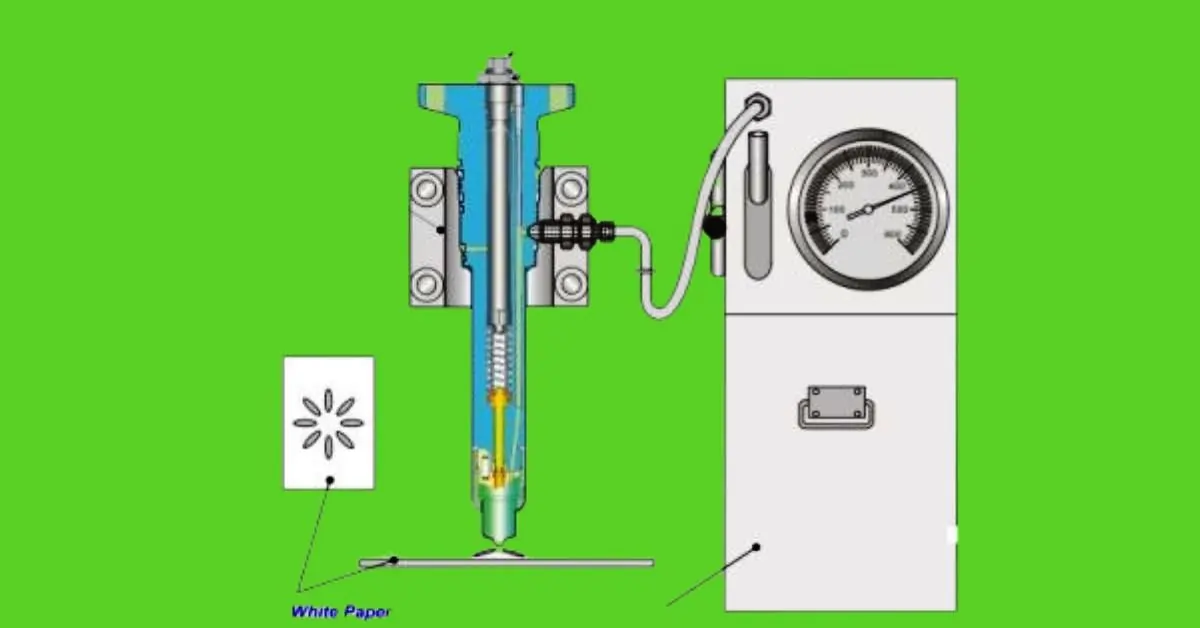

- Fuel Pressure Test:

- Measure the fuel pressure to ensure it is within the manufacturer’s specified range.

- Look for any pressure drops that might indicate a leak or blockage.

- Injector Flow Test:

- Perform a flow test to measure the amount of fuel each injector delivers.

- Ensure uniform fuel delivery across all injectors to avoid imbalances.

- Electrical Testing:

- Use a multimeter to check the resistance of the injector’s solenoid.

- Verify the electrical connections for continuity and proper function.

- Engine Performance Monitoring:

- Monitor engine performance metrics like fuel economy, idle smoothness, and acceleration.

- Look for any irregularities that could indicate injector issues.

Cleaning Methods

Cleaning fuel injectors is essential to maintain their efficiency and prolong their lifespan. Here are some effective cleaning techniques and products:

- In-Tank Fuel Injector Cleaners:

- Method: Add a fuel injector cleaner to the fuel tank as per the product instructions.

- Products: Use high-quality cleaners such as Chevron Techron Concentrate Plus or Sea Foam Motor Treatment.

- Frequency: Use every 3,000 to 5,000 miles or as recommended by the manufacturer.

- Pressurized Cleaning Kits:

- Method: Connect a pressurized fuel injector cleaning kit to the fuel rail. Run the engine with the cleaner solution, bypassing the fuel tank.

- Products: BG 44K Fuel System Cleaner, Liqui Moly Fuel Injection Cleaner.

- Frequency: Perform annually or during scheduled maintenance.

- Ultrasonic Cleaning:

- Method: Remove the injectors and place them in an ultrasonic cleaning machine filled with a cleaning solution. The ultrasonic waves dislodge debris and carbon deposits.

- Products: Use professional-grade ultrasonic cleaners and solutions.

- Frequency: Perform during major engine overhauls or if significant clogging is suspected.

- Manual Cleaning:

- Method: Remove injectors and manually clean the nozzle and components with a specialized brush and cleaning solution.

- Products: Use injector cleaning sprays and brushes designed for this purpose.

- Frequency: As needed, based on visual inspection and performance.

Preventive Measures

Implementing preventive measures can help extend the lifespan of your fuel injectors and maintain engine performance:

- Use High-Quality Fuel:

- Always use fuel from reputable sources to avoid contaminants and impurities.

- Regular Fuel Filter Replacement:

- Replace the fuel filter as per the manufacturer’s schedule to prevent debris from reaching the injectors.

- Add Fuel Stabilizers:

- Use fuel stabilizers, especially in marine environments, to prevent fuel degradation and contamination.

- Avoid Prolonged Idling:

- Minimize prolonged idling, which can cause carbon buildup on the injectors.

- Scheduled Maintenance:

- Stick to a regular maintenance schedule, including periodic injector inspections and cleanings.

- Monitor Engine Performance:

- Keep an eye on engine performance metrics and address any irregularities promptly to prevent injector damage.

- Use Injector-Friendly Additives:

- Use additives specifically designed to keep injectors clean and functioning efficiently.

Upgrading Your Fuel Injectors

Benefits

Upgrading to high-performance fuel injectors offers several advantages, especially for marine diesel engines. Here are the key benefits:

- Enhanced Engine Performance:

- High-performance injectors provide better atomization of fuel, resulting in more efficient combustion. This leads to increased horsepower and torque, enhancing the overall performance of your engine.

- Improved Fuel Efficiency:

- Upgraded injectors deliver the precise amount of fuel needed, reducing wastage and improving fuel economy. This means lower operating costs over time.

- Reduced Emissions:

- Better combustion efficiency results in fewer unburned hydrocarbons and pollutants, helping to meet stringent emission standards and contributing to a cleaner environment.

- Smoother Operation:

- High-quality injectors ensure more consistent and stable fuel delivery, leading to smoother engine operation and reduced vibrations.

- Extended Engine Life:

- Improved fuel delivery and combustion efficiency reduce engine wear and tear, prolonging the lifespan of your engine.

- Adaptability to Upgrades:

- High-performance injectors can complement other engine upgrades, such as turbochargers and advanced fuel management systems, to further boost engine performance.

Considerations

When choosing new fuel injectors, consider the following factors to ensure you select the best option for your needs:

- Compatibility:

- Ensure the injectors are compatible with your specific engine model and configuration. Check manufacturer specifications and consult with experts if necessary.

- Performance Goals:

- Identify your performance goals, whether it’s maximizing power, improving fuel efficiency, or reducing emissions. Choose injectors designed to meet these objectives.

- Flow Rate:

- Select injectors with the appropriate flow rate for your engine. The flow rate should match the engine’s fuel requirements to avoid issues with under or over-fueling.

- Injector Type:

- Decide between mechanical, electronic, or piezoelectric injectors based on your engine’s technology and desired performance characteristics.

- Build Quality:

- Look for injectors made from high-quality materials to ensure durability and reliable performance under marine conditions.

- Brand Reputation:

- Choose injectors from reputable brands known for their quality and performance. Research customer reviews and expert recommendations.

- Cost:

- Consider the cost of the injectors and balance it with the expected benefits. While high-performance injectors may have a higher upfront cost, the long-term benefits can justify the investment.

Top Brands

Here are some of the best brands and models of high-performance fuel injectors available for marine diesel engines:

- Bosch:

- Model: Bosch Diesel Fuel Injectors

- Description: Known for precision engineering and high durability, Bosch injectors offer excellent performance and fuel efficiency.

- Delphi:

- Model: Delphi E3 Diesel Injectors

- Description: Delphi injectors are renowned for their advanced technology and robust construction, ensuring reliable and consistent fuel delivery.

- Denso:

- Model: Denso Common Rail Injectors

- Description: Denso injectors are designed for high efficiency and low emissions, featuring cutting-edge technology for optimal performance.

- Siemens VDO:

- Model: Siemens VDO Piezo Injectors

- Description: These injectors offer rapid response times and precise fuel delivery, ideal for high-performance marine applications.

- Stanadyne:

- Model: Stanadyne Marine Injectors

- Description: Stanadyne injectors are built specifically for marine engines, providing excellent corrosion resistance and reliable performance in harsh environments.

- Cummins:

- Model: Cummins Fuel Injectors

- Description: Cummins offers a range of high-performance injectors designed to maximize the efficiency and power of their marine diesel engines.

Technological Advancements in Fuel Injectors

Latest Innovations

Recent technological advancements in fuel injector design and functionality have significantly enhanced engine performance, fuel efficiency, and emissions control. Here are some of the latest innovations:

- Piezoelectric Injectors:

- Innovation: Utilization of piezoelectric materials that change shape rapidly when an electric current is applied, allowing for more precise control of fuel injection timing and quantity.

- Functionality: These injectors offer faster response times and more accurate fuel delivery compared to traditional solenoid injectors, resulting in better combustion efficiency and reduced emissions.

- Multi-Hole Nozzles:

- Innovation: Development of injectors with multiple small holes in the nozzle for finer fuel atomization.

- Functionality: Enhanced atomization leads to more complete combustion, improving fuel efficiency and power output while reducing unburned hydrocarbons and particulates.

- High-Pressure Common Rail Systems:

- Innovation: Advanced common rail systems that operate at extremely high pressures, up to 2,500 bar or higher.

- Functionality: Higher pressure allows for finer fuel atomization and more precise control over injection timing and quantity, resulting in better fuel efficiency and lower emissions.

- Variable Injection Timing and Quantity:

- Innovation: Injectors capable of varying the timing and quantity of fuel injected during each combustion cycle.

- Functionality: This adaptability allows for optimized performance under different engine loads and conditions, enhancing overall efficiency and responsiveness.

Smart Injectors

The integration of artificial intelligence (AI) and the Internet of Things (IoT) into modern fuel injectors has led to the development of “smart injectors,” which offer numerous benefits:

- Real-Time Monitoring and Adjustment:

- AI Integration: AI algorithms analyze engine data in real-time to optimize fuel injection parameters dynamically.

- IoT Connectivity: Smart injectors communicate with other engine components and external systems, enabling remote monitoring and adjustments.

- Benefits: Enhanced engine performance, fuel efficiency, and reduced emissions through continuous optimization.

- Predictive Maintenance:

- AI Integration: Machine learning models predict potential injector issues before they occur based on historical data and real-time monitoring.

- IoT Connectivity: Alerts and maintenance recommendations can be sent to operators or service centers.

- Benefits: Reduced downtime, lower maintenance costs, and extended injector lifespan through proactive maintenance.

- Adaptive Fuel Management:

- AI Integration: Smart injectors adapt fuel delivery based on driving patterns, engine conditions, and environmental factors.

- IoT Connectivity: Integration with vehicle or vessel management systems for holistic performance optimization.

- Benefits: Improved fuel economy, enhanced engine responsiveness, and optimized emissions control.

Future Trends

As technology continues to advance, several trends are likely to shape the future of fuel injectors and their impact on the automotive and marine industries:

- Increased Adoption of Electric and Hybrid Technologies:

- Trend: As electric and hybrid engines become more prevalent, fuel injectors will be designed to integrate seamlessly with these systems, focusing on optimizing the performance of hybrid powertrains.

- Impact: Enhanced efficiency and reduced emissions in hybrid engines, contributing to the broader adoption of eco-friendly technologies.

- Integration with Autonomous Systems:

- Trend: Fuel injectors will be integrated with autonomous vehicle systems, leveraging AI for optimal fuel management without human intervention.

- Impact: Improved fuel efficiency and performance in autonomous vehicles, supporting the development of self-driving technology.

- Advanced Materials and Manufacturing Techniques:

- Trend: Use of advanced materials such as ceramics and new manufacturing techniques like 3D printing to create more durable and efficient fuel injectors.

- Impact: Longer-lasting injectors with better performance characteristics, reducing the frequency of replacements and maintenance costs.

- Enhanced Emissions Control Technologies:

- Trend: Development of injectors that work in conjunction with advanced emissions control systems to meet increasingly stringent environmental regulations.

- Impact: Lower emissions from both automotive and marine engines, contributing to cleaner air and water.

- Global Connectivity and Data Sharing:

- Trend: Increased connectivity will enable fuel injectors to share performance data globally, allowing for continuous improvement through data-driven insights.

- Impact: Accelerated innovation and optimization in fuel injector technology, leading to more efficient and environmentally friendly engines worldwide.

Environmental Impact and Regulations

Emissions Control

Modern fuel injectors play a crucial role in reducing emissions from marine diesel engines and other combustion engines. Here’s how they contribute to better emissions control:

- Precise Fuel Atomization:

- How It Works: Modern injectors are designed to atomize fuel into extremely fine droplets, ensuring a more complete and efficient combustion process.

- Impact: This reduces the amount of unburned fuel and decreases the emission of hydrocarbons (HC) and particulate matter (PM), contributing to cleaner exhaust gases.

- High-Pressure Injection:

- How It Works: Advanced fuel injectors operate at very high pressures, which enhances the mixing of fuel with air.

- Impact: Improved air-fuel mixture results in more thorough combustion, reducing the formation of nitrogen oxides (NOx) and carbon monoxide (CO).

- Variable Injection Timing:

- How It Works: Modern injectors can vary the timing and duration of fuel injection to match the engine’s operating conditions.

- Impact: This adaptability helps maintain optimal combustion efficiency across different engine loads and speeds, minimizing emissions under all operating conditions.

- Multi-Stage Injection:

- How It Works: Some modern injectors can perform multiple injections per combustion cycle.

- Impact: This technology reduces peak combustion temperatures, which significantly lowers the formation of NOx emissions.

Compliance

Fuel injectors must meet various regulations and standards to ensure they contribute to environmental protection. Here are some important ones:

- International Maritime Organization (IMO) Regulations:

- Regulation: IMO sets global standards for emissions from ships, including NOx and sulfur oxides (SOx) limits under the MARPOL Annex VI.

- Impact: Fuel injectors used in marine engines must help meet these stringent emissions standards to be compliant with international regulations.

- Environmental Protection Agency (EPA) Standards:

- Regulation: In the United States, the EPA sets emissions standards for marine engines under the Clean Air Act.

- Impact: Fuel injectors must be designed to comply with these standards to reduce air pollution and protect public health.

- European Union (EU) Emission Standards:

- Regulation: The EU has set rigorous emission standards for non-road mobile machinery (NRMM), which includes marine engines.

- Impact: Compliance with these standards requires the use of advanced fuel injectors that minimize emissions of NOx, CO, and PM.

- Tier Standards:

- Regulation: Various tiered standards (e.g., Tier 1 to Tier 4) set progressively stricter limits on emissions.

- Impact: Engines equipped with fuel injectors that meet higher-tier standards produce significantly lower emissions, helping to protect the environment.

Eco-Friendly Options

Adopting eco-friendly fuel injector options and practices can further enhance environmental protection:

- Low-Emission Fuel Injectors:

- Option: Invest in injectors specifically designed for low emissions, such as those with advanced multi-hole nozzles and high-pressure capabilities.

- Benefit: These injectors ensure more complete combustion, reducing the emission of harmful pollutants.

- Fuel Additives:

- Option: Use fuel additives that enhance the combustion process and reduce emissions.

- Benefit: Additives can help keep injectors clean and improve fuel atomization, leading to lower emissions and better engine performance.

- Regular Maintenance:

- Practice: Implement a strict maintenance schedule to ensure injectors are functioning optimally.

- Benefit: Well-maintained injectors perform better and emit fewer pollutants, contributing to a cleaner environment.

- Use of Cleaner Fuels:

- Option: Opt for cleaner fuels, such as low-sulfur diesel or biofuels, which produce fewer emissions.

- Benefit: Cleaner fuels reduce the load on fuel injectors and the overall emission of harmful substances.

- Retrofitting Older Engines:

- Option: Retrofit older engines with modern fuel injectors and emissions control technologies.

- Benefit: Upgrading older engines can significantly reduce their environmental impact, bringing them up to current emissions standards.

FAQ on “Fuel Injector”

Q: What is the main function of a fuel injector?

A: A fuel injector delivers precise amounts of fuel into the combustion chamber for optimal engine performance.

Q: What are common symptoms of a faulty fuel injector?

A: Symptoms include engine misfires, poor fuel economy, rough idling, and increased emissions.

Q: How often should fuel injectors be cleaned?

A: Fuel injectors should be cleaned every 3,000 to 5,000 miles or annually, depending on usage and fuel quality.

Q: Can upgrading fuel injectors improve engine performance?

A: Yes, high-performance injectors enhance fuel atomization, improving power, efficiency, and reducing emissions.

Conclusion

Fuel injectors are integral to the performance and efficiency of marine diesel engines. By understanding their function, addressing common issues, and adopting effective maintenance practices, marine engineers can ensure optimal engine performance and longevity. Upgrading to high-performance injectors and staying abreast of technological advancements further enhances fuel efficiency and reduces emissions, contributing to a cleaner environment. As we navigate the future, integrating eco-friendly options and complying with stringent regulations will be key to sustainable marine operations. Embrace these insights to keep your engines running smoothly and efficiently, ensuring your vessels perform at their best.