Fuel Injector and How it Works

Diesel generators are like backup power superheroes used in different places to keep things running when the main power goes out. They use a part called a fuel injector, which is like a power booster for the engine.

We’ll talk about diesel generator fuel injectors in this blog post. We’ll learn about their purpose, the available several kinds, and why they’re so important for a generator’s efficiency. We’ll also discuss maintaining your generator to keep it in good working order and frequent injector problems.

Whether you’re a marine engineer on a ship or someone who looks after a building, knowing about fuel injectors can help you make sure your generator stays strong and doesn’t break down when you need it most.

What is a Fuel Injector?

A fuel injector is a critical component in the fuel delivery system of an internal combustion engine. Its primary function is to spray fuel into the engine’s combustion chamber at a specific time and in a precise quantity. Fuel injectors are commonly used in gasoline and diesel engines and alternative fuel engines like those that run on ethanol or propane.

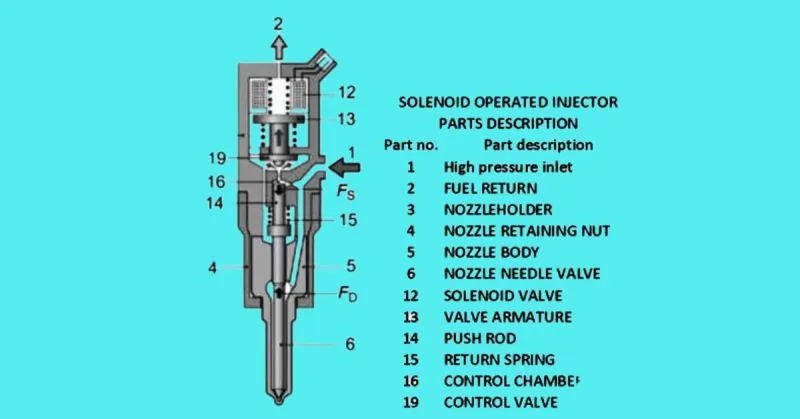

Fuel injectors are like tiny fuel delivery systems for engines. They have a nozzle, a valve, and an electromagnet called a solenoid. The solenoid opens and closes the valve, controlling how much fuel goes into the engine. The nozzle turns the fuel into a fine mist, spreading it evenly in the engine’s combustion chamber.

Engine satisfactory and efficient operation is possible by the proper functioning of Fuel injectors. Fuel injectors supply the correct quantity of fuel in mist and the correct pressure to form the homogenous mixture of air and fuel.

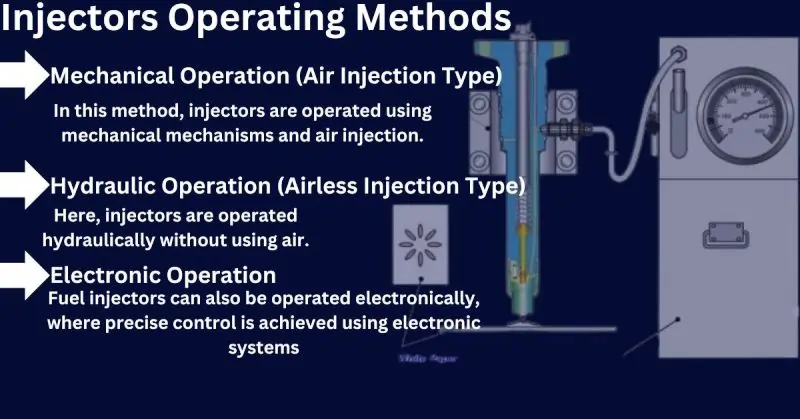

Injectors Operating Methods

Methods of Operating Fuel Injectors:

Fuel injectors can be operated using different methods:

- Mechanical Operation (Air Injection Type): In this method, injectors are operated using mechanical mechanisms and air injection.

- Hydraulic Operation (Airless Injection Type): Here, injectors are operated hydraulically without using air.

- Electronic Operation: Fuel injectors can also be operated electronically, where precise control is achieved using electronic systems.

These methods offer various ways to control and manage fuel injection in engines, each with its own advantages and applications.

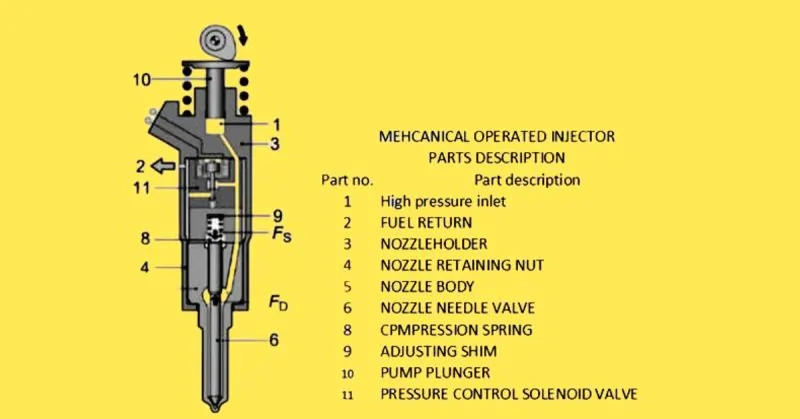

Mechanically Operated (Air injection type)

A mechanical fuel injector is an older type of fuel injection system used to deliver fuel into an internal combustion engine. Unlike modern engines that use electronic fuel injection, older vehicles often rely on these mechanical systems.

In a mechanical fuel injection system, fuel travels through a set of pumps, valves, and nozzles. These components are controlled by mechanical parts like linkages and springs, often driven by a camshaft or similar mechanism. This setup determines when and how much fuel is delivered.

The basic operation involves building pressure in a fuel line, which opens a needle valve. This valve allows fuel to flow through a nozzle into the engine’s intake manifold. The amount of fuel delivered depends on the nozzle’s size and how long the injection event lasts, all regulated by the mechanical setup.

While mechanical fuel injection systems can be reliable, they lack the precision and flexibility of modern electronic systems. Electronic systems can finely control the timing and volume of fuel delivery, adapting to changing engine conditions more effectively.

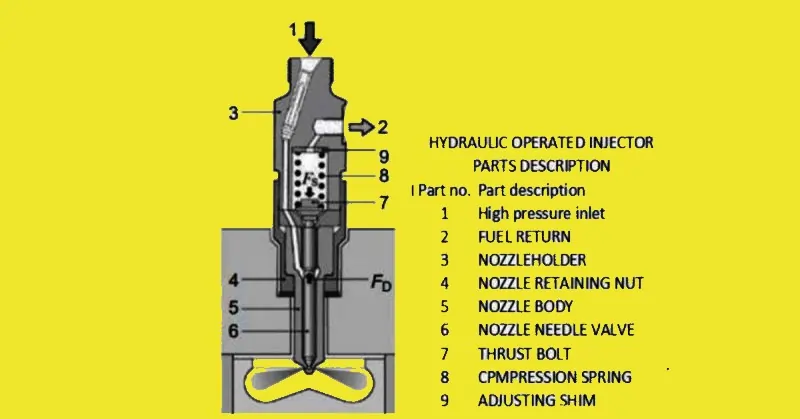

Hydraulically (Airless Injection type)

Hydraulically operated fuel injectors are a specific type of fuel injection system used primarily in diesel generators.

Here’s how they work: High-pressure fuel from the injection pump travels through a fuel line to reach the injector. Once there, a hydraulic mechanism comes into play.

To control the injector’s timing and how long it stays open, a mechanical device like a camshaft is typically employed.

These special injectors use a hydraulic system to control how much fuel goes into the engine, making sure it’s just right for the engine to work its best and use fuel efficiently. You can usually find them in big diesel engines like the ones in large generators, trains, and boats. They might be a bit more complicated than some other injectors, but they make engines work better and pollute less.

Electronically operated injector

Modern diesel generators use a special fuel injector controlled by a computer-like system called an electronic control unit (ECU).

Here’s how it works: High-pressure fuel from the injection pump is sent through a fuel line to the injector. The injector is controlled by an electronic part called a solenoid, which opens and closes the valve. The ECU figures out the perfect timing and how long the injector should stay open based on info from sensors that check things like engine speed, how hard it’s working, and how hot it is.

This electronic control is super precise. It helps the engine run its best and pollute less. These special injectors can adjust the amount of fuel they spray as the engine’s needs change, helping it use fuel wisely and run better.

What’s even cooler is that these injectors can be set to give the engine a few shots of fuel in each cycle. This is something you’ll find in many modern diesel engines nowadays.

Principle of Nozzle Needle Control

An injector controls fuel delivery by using a nozzle and a needle valve. These parts work together to ensure the right amount of fuel goes into the engine, depending on how the engine runs.

Here’s how it works: Fuel in the fuel line gets pushed into the injector and flows through the nozzle. The nozzle is designed to have a small opening that turns the fuel into a fine mist, which is better for burning in the engine.

Inside the nozzle, there’s a needle valve held down by a spring. When the fuel pressure in the injector gets high enough, the needle valve lifts off its seat, allowing fuel to flow through the nozzle and into the engine.

The injector decides how much fuel enters the engine by adjusting how long the needle valve remains open. This control is usually done by a mechanical or electronic system.

This helps the injector ensure that the engine receives the correct amount of fuel, taking into account factors such as the engine’s speed and temperature.

This way of controlling fuel delivery is super important because it helps the engine run better, emit fewer pollutants, and make the most power it can.

Needle opening process

Referring to the above figures, the needle opens during the start of fuel injection as soon as the hydraulic force FD becomes higher than the closing force FS.

Mechanically and hydraulically controlled injectors are operated by cams, and common rail system injectors are operated by solenoid controlling the fuel through pressure accumulator with lift control needle.

Nozzle design;- A nozzle consists of a nozzle body, high inlet pressure, needle guide, seat, and spray holes. All the modern direct injection engines use multi-hole type nozzles. The nozzle converts pressure energy into kinetic energy with maximum efficiency. Nozzles spray the fuel with the ability to penetrate, break up to adjust with the combustion space.

Nozzle Seat;- Seat is designed to seal the combustion chamber and the opening pressure will depend upon the diameter of the seat.

Needle guide;- The function of the needle guide is to guide the needle during the injection period and separates the high and low-pressure zones. The clearance between the needle and guide is normally in the range of 1-5 micron.

The clearance will be smaller for the higher injection pressure to reduce the leakages.

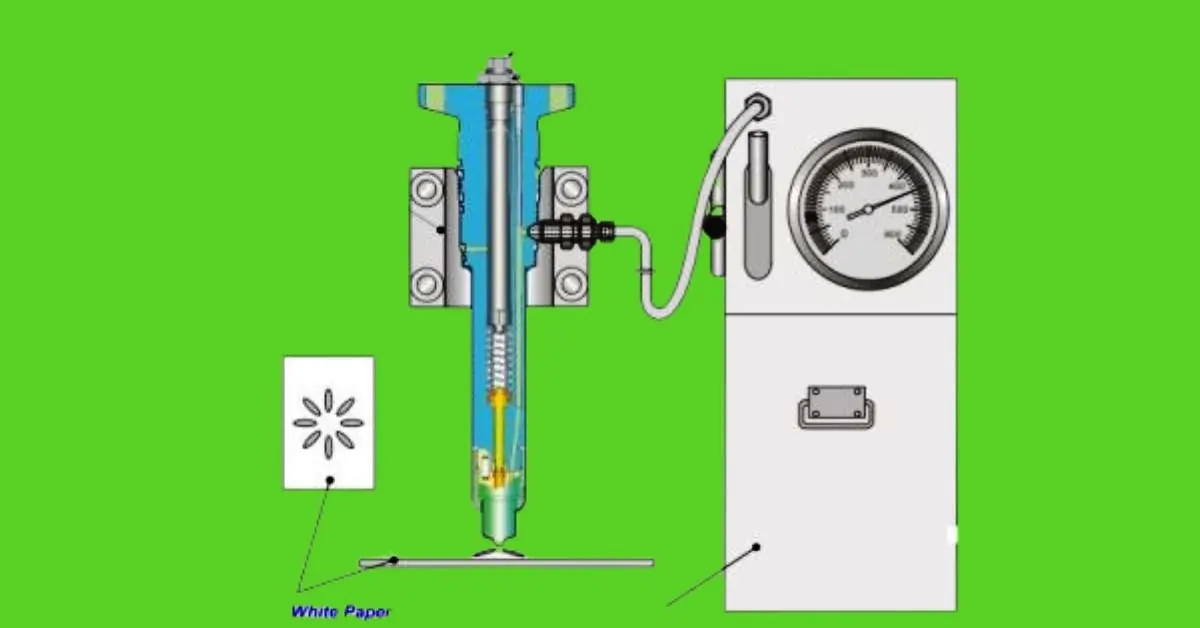

How to Perform the Fuel Injection Pressure Test

Performing a fuel injection pressure test on marine diesel engine fuel injectors (or fuel valves) is crucial to ensuring that the engine runs efficiently and smoothly. The correct injection pressure ensures optimal fuel atomization, resulting in better combustion and fuel efficiency. Here’s a step-by-step guide on how to conduct the test:

Step 1: Safety Precautions

- Shut down the engine and ensure it has cooled down before starting the test.

- Wear protective gear, including gloves and goggles, as you will be working with high-pressure fuel lines.

- Ensure proper ventilation in the work area to avoid inhalation of fuel fumes.

Step 2: Gather the Required Tools and Equipment

- Injector test bench or a specific fuel injector pressure tester for marine diesel engines.

- High-pressure gauge for fuel injection pressure.

- Wrenches and necessary tools for removing injectors.

- Cleaning materials to handle any fuel spillage.

Step 3: Remove the Fuel Injector/Fuel Valve

- Carefully remove the fuel injectors (also referred to as fuel valves in marine engines) from the engine cylinder head. This requires loosening the injector from its mounting location using appropriate tools.

- Be cautious of any high-pressure fuel lines and make sure to relieve fuel system pressure if applicable.

Step 4: Prepare the Injector for Testing

- Attach the fuel injector or fuel valve to the injector test bench or pressure tester.

- Ensure that the injector is properly secured to prevent leakage and that it is positioned in a way that allows for clear observation of the pressure reading.

Step 5: Perform the Injection Pressure Test

- Use the hand lever on the test bench to pump fuel through the injector.

- Observe the pressure at which the injector opens and sprays fuel. This is the fuel injection opening pressure.

- The fuel should spray in a fine, misty pattern, which indicates proper atomization.

Step 6: Compare the Pressure Reading to Specifications

- Compare the measured injection opening pressure to the manufacturer’s recommended pressure for the specific engine model. This information is typically available in the engine’s maintenance manual.

- If the injector pressure is too low or too high, it can indicate problems with the injector’s internal components such as the needle valve, spring, or seating surface.

Step 7: Inspect Spray Pattern and Atomization

- In addition to checking the pressure, carefully observe the spray pattern of the injector. It should be even and well-atomized, with no dribbling or inconsistent spray. Poor atomization may result in incomplete combustion and engine performance issues.

- If there are irregularities in the spray pattern, the injector may require cleaning, repair, or replacement.

Step 8: Adjust or Replace the Injector if Necessary

- If the injection pressure is not within the specified range, you may need to adjust the pressure setting on the injector by tightening or loosening the adjusting screw (if applicable) or replacing the spring.

- If the injector is severely worn or damaged, replacement may be necessary to restore optimal fuel injection performance.

Step 9: Reinstall the Fuel Injector

- Once the testing and any necessary adjustments or repairs are completed, reinstall the injector into the engine.

- Tighten all connections securely to avoid any fuel leakage during operation.

Step 10: Final Testing and Inspection

- After reinstalling the injectors, perform a test run of the engine to ensure proper operation.

- Monitor the engine’s performance to check for any signs of rough idling, misfires, or excess smoke, which could indicate ongoing fuel injection issues.

The factors affecting the injector performance

Spray Pattern ( FUEL CONSEQUENCES ON | DIESEL INJECTOR )

Fuel Injector injects the fuel broken up into excellent spray in the form of mist. Oxidization of the tiny droplets starts during the initial combustion. The bigger the specific are smaller the droplets. Smaller droplets will inject the fuel at faster rate with perfect combustion.

There is trend of using the smaller fuel droplets and fine spray in the high injection pressure. Modern Diesel Engines use this popular system of fuel injection.

In the perfect combustion, oil small droplets are burned out completely before they approach the cylinder liner.Fuel valves inject the fuel in spray form into combustion chamber formed between the top of the piston and cylinder head bottom surface. In the compression stroke of the piston, Injected fuel spray penetrates deep in to the combustion chamber space and the efficient burning of fuel takes place, before the droplet reaches to the cylinder walls.

However, if the spray pattern produced by the fuel injector is not enormity as the above description, droplets enlarge to a more prominent size and delay in burnout.

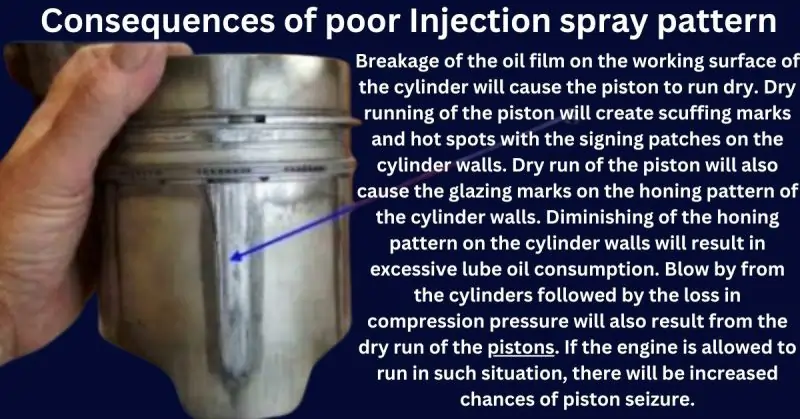

Consequences of Poor Spray Pattern

The following phenomenon takes place due to the poor spray pattern of the injected fuel, which has an adverse effect in the efficient burning of fuel, and other effects are mentioned in the following paragraph.

The oil film’s breakage on the cylinder’s working surface will cause the piston to run dry. Dry piston running will create scuffing marks and hot spots with the signing patches on the cylinder walls. Dry run of the piston will also cause the glazing marks on the honing pattern of the cylinder walls. Diminishing of the honing pattern on the cylinder walls will result in excessive lube oil consumption. Blow by from the cylinders followed by the loss in compression pressure will also result from the dry run of the pistons. If the engine is allowed to run in such situation, there will be increased chances of piston seizure.

Dribbling

Leaky needle will cause the Fuel drip from the nozzle tip due to the imporper seating, will directly drip on the piston crown in the form of drops. Fuel in droplets form dripping from the dribbling nozzle will get collected at the piston crown. This accumulated fuel will create the fuel burning on the crown and metal of the piston crown will melt down.

Lubricants diluted with fuel.

In some instances where the fuel droplets are more significant than normal, it will lead to improper combustion. Droplets of the fuel will remain unburned and will reach the lubricating oil through the cylinder liner walls. Diluted lubricating oil will lose viscosity and result in poor parts lubrication. The hydrodynamic film of lubricating oil will change into boundary lubrication. The boundary lubrication will be the cause of crankshaft bearing failure.

Piston rings will wear rapidly. This abnormal wear of the piston ring will not create the sealing effect in the combustion chamber and will be the cause of blow-by.

Many failures have been where blow has caused the hot spots and subsequently a crankcase explosion.

Fuel Properties

Following fuel properties are desired apart from the perfect combustion

Excellent Lubrication qualities

Lubricating oil must lubricate the high-precision moving parts in the nozzle. There is no external lubrication available. The presence of sulfur performs the function of lubrication in the nozzle. Earlier fuel used to have 0.5 % sulfur, but in modern engines, due to obvious reasons, the amount of sulfur has been reduced to 0.05. Fuel with less than 0.3% sulfur loses its inherent lubrication properties and is unsuitable for lubricating the nozzle components. With this condition of poor lubrication of the needle and fuel passage, the problem will start manifesting. The presence of water is also the cause of insufficient lubrication inside the nozzle moving parts and stationary parts.

To maintain the lubrication properties of the fuel, the use of additives is recommended. These additives will also provide the detergent properties in the nozzle.

The Fuel cleanliness

Due to the acceptable clearances in the nozzle moving parts, clean fuel prevents sticking the needle in the fuel passage. Dirty fuel will cause jamming and damage to the needle in the barrel. Dirt particles will also act as abrasive and speed up the enlargement of the nozzle holes. The growth of the nozzle holes will result in fuel injection in jet form. This jet form will make the piston run hot, and if continued, it will cause the melting away of material from the piston crown.

FAQ on ” Fuel Injector and How it Works

Q: What is a fuel injector?

A: A fuel injector is a device that delivers fuel into an engine’s combustion chamber

Q: How does a fuel injector work?

A: It works by spraying a fine fuel mist into the engine’s combustion chamber for efficient combustion.

Q: What role does the electronic control unit (ECU) play in fuel injectors?

A: The ECU monitors engine conditions and adjusts fuel delivery for optimal performance.

Q: Why is proper fuel injector maintenance important?

A: Regular maintenance ensures fuel injectors work efficiently, improving engine performance and reducing emissions.

Blog Conclusion

Fuel injectors are essential to modern internal combustion engines, including those used in diesel generators. These injectors control fuel delivery into the engine’s combustion chamber based on engine speed, load, and temperature. There are several types of fuel injectors, including mechanical, hydraulically operated, and electronically operated injectors, each with its own advantages and limitations.

The principle of nozzle needle control is central to the operation of a fuel injector, and involves the use of a nozzle and a needle valve to control the amount of fuel delivered to the engine precisely. By controlling the atomization and delivery of fuel, the injector can help to optimize engine performance, improve fuel efficiency, and reduce emissions.

Overall, fuel injectors are an important component of modern diesel generator systems, providing precise control over fuel delivery and helping to optimize engine performance and efficiency. As engine technology continues to evolve, it is likely that fuel injectors will continue to play an important role in the development of more efficient and sustainable diesel engines.