Fusible Plug

Fusible plugs are critical safety components used in various applications, from steam engines to high-pressure equipment. Understanding how they function, where they’re used, and their material composition is essential for ensuring the safety and efficiency of the systems they protect. Fusible plugs are designed to prevent catastrophic failures by melting at predetermined temperatures, allowing pressure relief and averting potential disasters.

In this post we will explre five essential facts about fusible plugs, providing you with expert insights to master their use and maximize their benefits. Whether you’re working with steam engines, compressors, or electrical equipment, understanding these key aspects will help you make informed decisions and ensure the reliability of your systems. By the end of this post, you’ll have a comprehensive understanding of fusible plugs, their applications, and how they can enhance safety and performance in various industrial settings.

The History of Fusible Plugs

Fusible plugs originated during the Industrial Revolution to prevent boiler explosions, a common hazard in steam engines. The earliest plugs, made of lead, would melt at high temperatures, releasing steam to reduce pressure. A major advancement came in 1803 when Richard Trevithick, after experiencing a boiler explosion, invented the threaded fusible plug. His design improved installation and reliability, setting a new safety standard.

Throughout the 19th century, advancements in metallurgy allowed for more precise melting points, broadening fusible plugs’ applications. The early 20th century saw the introduction of fusible alloys, offering greater reliability in critical applications, including aircraft and industrial machinery. Modern fusible plugs are engineered with advanced materials, ensuring they perform reliably under extreme conditions, making them essential in various industrial settings.

Applications of Fusible Plugs

What is a Fusible Loop System?

A fusible loop system is a safety mechanism that integrates fusible plugs to detect and respond to high temperatures or pressure conditions. Fusible plugs within these systems are designed to melt at predetermined temperatures, allowing pressure or steam to escape safely. This action triggers a chain of events that either shuts down equipment or activates secondary safety measures, preventing potential damage or catastrophic failure.

Common Uses of Fusible Plugs

Steam Engines:

In steam engines, fusible plugs are crucial for preventing boiler explosions. They are typically placed in the crown sheet of the boiler, where they monitor the temperature. If the water level drops too low, exposing the plug, it melts and releases steam, reducing the pressure and preventing the boiler from overheating and potentially exploding.

Aircraft Wheel Tires:

Fusible plugs are used in aircraft wheel tires to prevent tire blowouts during landing. The intense heat generated during braking can cause the tires to overheat. Fusible plugs melt at a specific temperature, allowing gas to escape and preventing a dangerous pressure buildup within the tires.

Electrical Equipment:

In electrical systems, fusible plugs serve as a safety device in transformers, circuit breakers, and other high-power equipment. They are designed to melt and disconnect the circuit when temperatures rise excessively, protecting the equipment from overheating and preventing fires or other damage.

Compressors:

In compressors, fusible plugs play a vital role in safety and pressure relief. They are installed to protect against overpressure by melting and releasing compressed gas when internal temperatures exceed safe levels. This prevents compressor damage and potential explosions.

High-Pressure Equipment:

Fusible plugs are essential in high-pressure equipment, such as hydraulic systems and pressure vessels, where they prevent overpressure scenarios. By melting at a predetermined temperature, they allow the safe release of pressure, thereby avoiding catastrophic equipment failure and ensuring operational safety.

Advantages of Fusible Plugs

Safety Features

Fusible plugs are indispensable safety components used across various industries to prevent catastrophic failures. Their primary advantage lies in their ability to act as a fail-safe mechanism in high-temperature or high-pressure environments. By melting at a predetermined temperature, fusible plugs allow pressure or steam to escape safely, preventing dangerous buildups that could lead to explosions or severe equipment damage.

This automatic response makes them particularly valuable in critical applications like steam boilers, aircraft tires, and high-pressure systems, where the consequences of failure can be dire. The simplicity and reliability of fusible plugs make them a trusted safety feature in environments where human intervention may not be quick enough to prevent accidents.

Efficiency

Beyond safety, fusible plugs also contribute to the efficient operation of equipment. By mitigating the risk of overpressure and overheating, they help maintain optimal operating conditions, reducing the likelihood of unplanned downtime and costly repairs. Their ability to prevent damage before it occurs ensures that machinery and systems run smoothly and without interruption. This efficiency translates into prolonged equipment life, reduced maintenance costs, and increased operational reliability. In essence, fusible plugs not only protect but also enhance the performance and longevity of the equipment in which they are installed.

Disadvantages of Fusible Plugs

Limitations

While fusible plugs are highly effective safety devices, they do have certain limitations that can impact their performance in specific applications. One of the primary drawbacks is their one-time use nature; once the fusible material melts, the plug cannot be reused and must be replaced. This can lead to operational downtime, especially in critical systems where continuous operation is essential.

Additionally, fusible plugs are sensitive to temperature fluctuations, which can sometimes cause premature activation or failure to activate when needed. In environments with highly variable temperatures, this can be a significant concern. Furthermore, fusible plugs may not always provide precise pressure or temperature relief, especially in systems requiring finely tuned safety responses. This lack of precision can sometimes result in inadequate protection for sensitive equipment.

Maintenance and Replacement

Maintaining and replacing fusible plugs can also present challenges. Since they are typically installed in high-temperature or high-pressure environments, accessing and replacing them can be difficult and time-consuming. This is particularly true in systems where the fusible plugs are located in hard-to-reach areas or integrated deeply within the equipment. Regular inspections are necessary to ensure that the fusible plugs are in good condition and have not been compromised by environmental factors such as corrosion or material degradation. However, these inspections can be labor-intensive and may require shutting down equipment, leading to further operational interruptions. Additionally, sourcing and installing the correct replacement plug is critical, as using an inappropriate plug can result in inadequate safety protection or even system failure.

Formulas and Calculations Related to Fusible Plugs

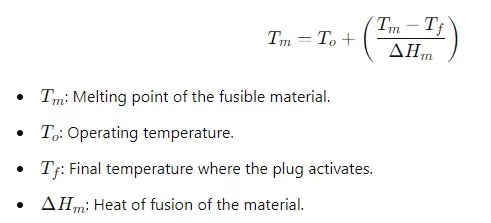

Melting Point Calculation

To determine the melting point of the fusible material used in a plug, the following formula is applied:

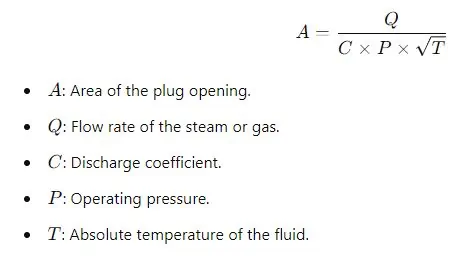

Pressure Relief Capacity

The pressure relief capacity of a fusible plug can be calculated using this formula:

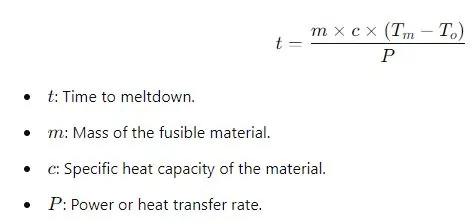

Time to Meltdown

FAQ on “Fusible Plug”

Q: What is the primary function of a fusible plug?

A: A fusible plug prevents overpressure by melting and releasing steam or gas.

Q: Where are fusible plugs commonly used?

A: Fusible plugs are commonly used in steam boilers, compressors, and aircraft tires.

Q: How often should fusible plugs be inspected?

A: Fusible plugs should be inspected regularly, especially during routine maintenance.

Q: Can a fusible plug be reused after it melts?

A: No, once a fusible plug melts, it must be replaced.

Conclusion

In this post, we explored the essential facts about fusible plugs, including their history, applications, advantages, and limitations. We learned that fusible plugs are crucial safety devices used in various high-risk environments, such as steam boilers, compressors, and aircraft tires. They provide a reliable fail-safe mechanism by melting at predetermined temperatures to prevent catastrophic failures. We also discussed the importance of selecting the right materials and understanding the specific applications where fusible plugs offer the most benefit. Additionally, while fusible plugs enhance safety and efficiency, their one-time use nature and the challenges associated with maintenance and replacement must be carefully considered.

As you work with or select fusible plugs for your systems, keep these key points in mind. Understanding their role, advantages, and limitations will help you make informed decisions, ensuring that your equipment remains safe and operational. Fusible plugs are small components, but their impact on safety and efficiency is significant, making them an indispensable part of many industrial applications.