Generator Alignment procedures

In order to increase the efficiency of your generator, it is necessary to align the generators. This is done through the use of alignment procedures. generator alignment procedures can improve the performance of your generator and help to reduce the downtime. By understanding the procedures and using them correctly, you can increase the efficiency of your generator.There are many different Generator alignment procedures. The aim of this blog post is to help the students to understand the different Generator alignment procedures and to help them to use the procedures in a successful manner. By understanding the procedures, the students can create a better Generator alignment system.

Generator alignment procedures will be useful to the readers. Proper alignment of a machine can save a huge amount of money. Misalignment can cause serious problems in a mchine.

- Types of coupling

- Type of Misalignments,

- Symptoms of misalignments,

- Results of misalignments,

- Methods of alignment checks.

Types of coupling

Rigid coupling

In rigid coupling, axial or radial motion is not provided between the driven and driving shaft. A rigid coupling has two flanges mounted on each shaft. In rigid coupling, the alignment should be exact to prevent considerable wear of bearing and seals. The alignment process is simple and easy compared to flexible coupling.

Flexible coupling

The flexible coupling transmits torque from the driving end of the shaft to the driven end with the acceptance of slight misalignment. Misalignment in flexible coupling is expressed in thousands of inches or microns as an order of magnitude.The flexible coupling is designed to accommodate slight misalignment between the shafts and absorption of vibration and shocks. Flexible couplings are expensive as compared to rigid couplings.

Sleeve or muff coupling

Sleeve/Muff coupling is a rigid coupling with a simple design; in this type of coupling, a hollow cylinder is known as a female end, and a shaft end with a similar diameter is known as a male end. Coupling is fitted at the end of two shafts with t help of the gib head key. Power transmission between one shaft to another shaft takes place through a sleeve/ muff and a key.

Split muff coupling

Split muff or compression coupling is also known as Clamp coupling. This coupling is designed in two halves and divided parallel to the plane through the axis of the shaft. Two halves of the muffs are joined together with the help of bolts placed in the recesses.

The best advantage of this coupling is that the coupling can be assembled or disassembled without disturbing the shaft position. This type of coupling is suitable for medium to heavy-duty loads with medium speed.

Flange coupling

Flange coupling has two separate flanges mounted and placed at both ends, held together with nuts and bolts. This coupling brings two end tubes together in a flushed seal manner. Flange couplings can transmit high torque, simple in design, easy to manufacture, and easy to assemble and disassemble.The inventor of flange coupling is Jerome Carden, who invented this coupling in the 16th century.

Gear coupling

Gear couplings are used in mechanical transmission assemblies to connect driving and driven shafts with three-piece couplings.

Gera coupling transmits the torque between two non-collinear shafts. The coupling has two flexible joints fixed at the end of each shaft and connected to a spindle shaft. Each joint of gear coupling has an internal/external gear pair with a 1:1 ratio. The outer diameter of the external gear and the tooth flank is designed to allow angular displacement between the two gears. Gears are equivalent to rotating splines with modified profiles. They are called gears because of the relatively large size of the teeth. Gear couplings are generally limited to angular misalignments of 4 to 5°.

Universal joint (Hooke’s joint)

A universal joint is also known as a universal coupling that connects two rigid shafts with an inclined axis for transmitting the rotary motion. The inclination of the shafts will vary during the transmission of motion. Such couplings are popularly used for power transmission in rear-wheel drive vehicles.

Type of Misalignment

The shaft is the main object of a machine. Shaft alignment occurs when a machine couples with another machine.

During the alignment, we align the centreline of the two shafts in a straight line. On all axes both the shafts should be parallel to each.

Parallel Misalignment

Angular Misalignment

Results of Misalignment.

Misalignment can cause the sudden failure of a machine. In the light of experience i have observed the following major failures in a machine.

- Crankshaft bearing failure

- Break down of major components.

- Fatal to human beings.

- Increase in downtime causing loss of production.

- On board aship a breakdown due to the alignment can cause a huge loss to the shipping company.

- A breakdown in Diesel generator can cause the complete black out in industry and on ships.

Primary Symptoms of Misalignment

Befroe the catastrophic failure, machine will give the misalignment indications . It is necessary for the engineers to know the indications of misalignment by the machine. Listed below are the major initial symptoms.

- Vibration will be with heavy amplitude.

- Temperature of the body will be high.

- There will be frequent loosening of foundation and other bolts.

- Repeated breakage of bolts

- Oil / grease leakage from seals.

- Coupling failure will be very high.

- Bearings will get overheat.

- Frequent failure of bearings

- Overheating of components

- Unbalanced loads on machine

Reason of Misalignment

There are several reasons for the machine needs alignment. Significant causes of misalignment are as below.

- A machine will need the re-alignment if there has been the removal of the machine for. After the repairs it is necessary to carry out the re-alignment.

- during the periodic checks, if the vibration level is more than the specified value.

- Due to the relative movement of the components due to the expansion(Thermal).

- If there is stress on the machine due to the system pipelines and cables of the Motor or Alternator.

- Reason of deformation in the foundation or the base frame of the engine or Alternator or pump.

- Wrong calculations of readings will also need the re-alignment.

- Inaccurate machining of the coupling bores will also need the re-alignment.

The operator should have the basic knowledge of type of alignment and procedures.

Methods of Alignment –

Laser Beam Shaft alignment

- Laser beam shaft alignment method is one of the latest best alignment methods. With this method we can get the accurate measurements. This method is very popular these days. There is reduction in breakdowns and better spares inventory control. advantages of this method are under.

- Laser beams have no effect of vision, gravity or bracket sag

- All the laser shaft tools have software to calculate accurate values. For the correction of alignment in both planes.

- Carry out the measurement and correction of all other shaft alignment issues.

- Always check the corecctness of soft foots.

- Always maintain the records for the alignment readings.

Advantages of Laser beam shaft alignment -*

Comparison between Laser beam alignment and traditional alignment technology

| Sr.No. | Laser beam alignment Technology | Traditional alignment technology |

| 1 | Faster and easier to use | It takes time to adjustments and is complicated to use. |

| 2 | Auto compensation of Thermal growth. Indicates the accurate alignment | Complicated calculations with the need of an experienced person for the calculations |

| 3 | Setting up is done in friction of time with reliable results | Results are not reliable due to the saggy and disturbed movement during the rotation of the shaft |

| 4 | Record or measured reading is by instruments | The complicated manual calculation is not reliable |

| 5 | Laser beam results will not change person to person | Measurement readings will change person to person. |

Tools/Istruments of *a

Traditional alignment tools

- Dial Test gauge

- Thickness gauges

- Micrometers P

- Thermometer

Laser Beam Alignment tools

- We are listing below the important tools for the laser beam.

- Measuring instrument

- Display instrument.

- Shaft fittings with securing arrangements ( Chains)

- Chain tightening rod

- Extension rod

- Adapters for power supply

- Micro USB cables

- Measuring tape

Points to observe for Alignment

-

Maintain the same reference points throughout the procedure.

-

For the perfect correction of alignement, never change the referal points.

Basics of the alignment

We must understand the basics of alignment. While carrying out the alignment, there are two objects. These objects are the base of the alignment procedure.

- Movable Component: – is the Component that will be move during the alignment process. Generally, the Alternator is the movable Component. Since the Prime mover is not easy to move. Prime mover connects with all the Air, Fuel, and Lube Oil, Water, and Exhaust system.

- Fixed Component: – Prime Mover will be the Fixed Component. Shaft becomes the reference point, and prime mover remains a fixed Component

Pre-Alignment checks

- We have to carry out few activities before the final alignment. These activities fall in to the category of pre-alignment.

- Rough alignment

- Shaft run out

- Soft foot check and (r)

- Measure the distance between shaft ends

- Check and relieve the piping strains

- Tightening o foundation bolts

Coupling Arrangements

Alter designs are of the following two types.

- Double bearing (T)

- Single bearing (T)

Double bearing Alternator

Single bearing Design Alternator

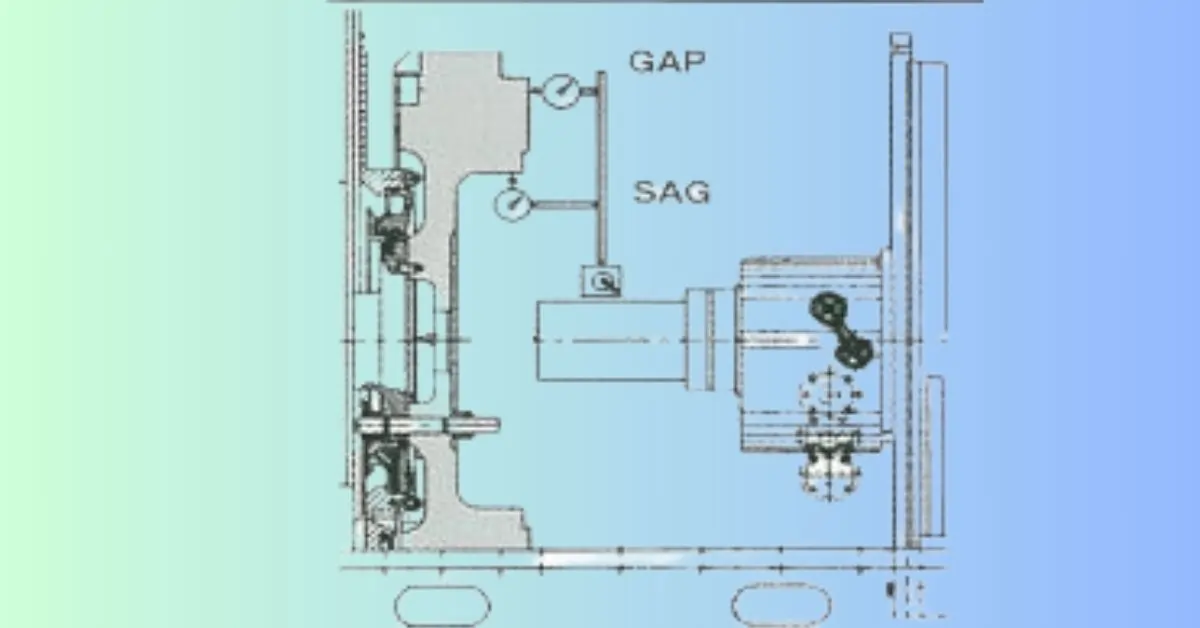

Single bearing Alternator Alignment –

Carry out the following procedure for the alignment of a single bearing alternator.

- Tighten the coupling bolts in sequence with proper specified torque.

- Roughly check the Rotor and Stator of the Alternator air gap. Ensure the rotor pole is not fouling with the stator winding. To carry out this procedure, use the pass the light from one end and look from the opposite end.

- Put the Web deflection dial gauge at the no.1 web of the crankshaft. Rotate the engine and bring the Crankpin of the no.1 web to as close to BDC. The gauge should not touch or foul with the connecting rod.

- Set the needle to zero.

- Turn the engine in a clockwise direction to the starboard side.

- Register the reading

- Again turn the crankshaft to the TDC position of the cylinder.

- Register the readings

- Rotate the crankshaft to Portside and register the reading

- Rotate the crankshaft to 20 deg before the BDC of the Crankpin of the cylinder.

- Register the reading.

- Carry out the calculations as per the following

Generator alignment procedures

Alignment readings prediction

Double Bearing rigid coupling Alignment –

Step-1

- Place the Alternator on the adjusting screws at the base frame. Maintain a distance of approximately 60 mm.

- Adjust the distance from the base frame to the rotor center till. the spigot on the alternator flange fits into the flywheel recess.

- Tighten the coupling bolts between at the specified torque.

- Adjust the axial position of the rotor in the alternator housing and. center it as per the dimensions punched on the casing.

- Mount the dial gauge on the drive end bearing housing and. check the concentricity of the rotor within the tolerance of +/- 0.15mm.

Step 2

- Make the front bearing accessible.

- Loosen the adjusting screws at the front feet and. allow the front end of the alternator housing to rest on the rotor shaft.

- Raise the front end of the Alternator by adjusting screws to. provide the uniform clearance 0f 0.14 mm on each side of the axle. This clearance will center the shaft in the bearing till it has a clearance of 0.28 mm.

- Place the dial gauges on all the Alternator feet to know the. distance between the alternator feet and the base frame at all corners.

- Raise the back end of the Alternator till the achievement of -0.13 mm reding at the top and bottom of the last crank web.

- Check the alignment at the sides also and keep it equal.

- Check the clearance between front end bearing the shaft by top and bottom out leg.

- Carry out step 2 again if the front shaft is touching the bearing.

Step 3

After accomplishing alignment, raise the front bearing by. the change screws till the outlog on the last crank web is 0.00 to +/- 0.01 mm.

Step-4

(Generator alignment procedures)

- Carry out the change of the chokes below the alternator feet and. above and on top until surface contact establishes.

- Tighten the bolts at the feet of the Alternator to the specified torque.

- Carry out the final auto log on the lat crank web and maintain the dimension of 0.00 to +/- 0.02mm.

Laser Beam Generator alignment procedures

Necessary Checks before the Generator alignment procedures

- Isolate the system from external power source.

- Check the mounting surfaces

- Clean the rust and dust.

- Movable component soft foot check;- To avoid the false readings, check the soft foot check. Rectify the soft foot if any soft foot persists.

Alignment Steps (Generator alignment procedures)

- Attach Brackets;- Attach the brackets to the driven and drive shafts.

- Install Laser;- Install the Laser to the stationary and the movable ends.

Alignment Check;-

- Enter the following inputs.

- The dimension of the equipment

- The location points of the Laser and receiver.

- Turn both the equipment 360 degrees.

- Note the reading and follow the steps for the correction of machine position.

- Re-check the alignment after the initial alignment

- Repeat the process till we get the correct alignment.

Top Marine Engineering Books

[table id=30 /]

Blog Conclusion

We hope you enjoyed our blog about the Generator alignment procedures. In this blog, we discussed what the Generator alignment procedures are and how to do them. If you have any questions, please don’t hesitate to contact us by visiting http://sh057.global.temp.domains/~arinedie/contact-us/. Thank you for reading, we are always excited when one of our posts is able to provide useful information on a topic like this!

Good Luck!!