Introduction

How star delta starter works is a fundamental question for electrical engineers, marine technicians, and industrial electricians. A star delta starter is an electromechanical device that reduces the starting current of three-phase induction motors by initially connecting windings in star configuration, then automatically switching to delta after a preset time. This method reduces inrush current by approximately 66% compared to direct-on-line starting, preventing voltage drops, minimizing mechanical stress, and extending motor lifespan. Understanding the circuit diagram, timer operation, contactor interlocking, and automatic switching sequence is essential for proper motor control in industrial, marine, and commercial applications requiring reliable, efficient motor starting systems.

Understanding the Circuit Components

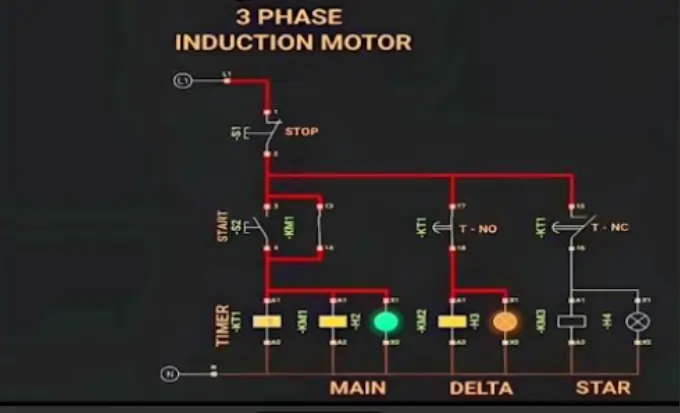

The attached image shows a typical star-delta starter control circuit for a 3 phase induction motor. Here’s what each major part does:

- STOP Button: A normally closed (NC) switch that disconnects the circuit to stop the motor.

- START Button: A normally open (NO) push button that, when pressed, energizes the control circuit to begin the starting sequence.

- TIMER: Automatically switches from star to delta connection after a set time, ensuring the motor starts safely.

- MAIN Contactor (KM1): Controls overall power to the motor.

- STAR Contactor (KM3): Connects the motor windings in star configuration during starting.

- DELTA Contactor (KM2): Connects the windings in delta for normal running after startup.

- Indicator Lamps: Show which mode (main, star, or delta) is active at any point.

How the 3 Phase Induction Motor Star Delta Starter Circuit Works

Step 1: Standby State

- The power supply is ON, but the motor is OFF.

- Only the STOP button allows current to flow in the control circuit.

Step 2: Starting the Motor (Star Connection)

- Press START: The circuit is completed, energizing the MAIN and STAR contactors (KM1 and KM3), as well as the TIMER.

- Motor windings are connected in STAR: This reduces the voltage applied to each winding to about 58% of the line voltage, lowering the starting current and mechanical stress.

- The STAR indicator lamp lights up, showing that the motor is starting in star mode.

Step 3: Automatic Transfer to Delta Connection

- The TIMER runs as soon as START is pressed and after the preset time (usually a few seconds), it de-energizes KM3 (STAR contactor) and energizes KM2 (DELTA contactor).

- Now the motor windings switch from STAR to DELTA configuration. This connects each winding directly across the line voltage for rated performance.

Step 4: Running in Delta Mode

- The DELTA contactor remains energized, and the motor runs at full speed and torque.

- The DELTA indicator lamp lights up.

- The circuit ensures that STAR and DELTA contactors can never be ON simultaneously (electrically interlocked).

Step 5: Stopping the Motor

- Press STOP: The control circuit is interrupted, de-energizing all contactors and stopping the motor.

- All indicator lamps turn off.

Key Points and Safety Features

- Timer Delay ensures smooth transition from STAR to DELTA, preventing electrical or mechanical shock.

- Interlocking prevents both star and delta contactors from closing at the same time, protecting the motor from phase-to-phase short circuit.

- STOP Button provides manual shutdown at any point.

Why Use a Star-Delta Starter for a 3 Phase Induction Motor?

- Reduces starting current to one-third of direct-on-line (DOL) starting.

- Minimizes voltage drop in the power supply.

- Prolongs motor and equipment life.

- Widely preferred for motors rated above 5HP or 3.7kW.

Conclusion

Understanding the star-delta starter wiring and operation is essential for every electrical engineer, technician, and student dealing with 3 phase induction motors. The attached circuit diagram provides a clear, practical example of how safe, efficient, and automated motor starting is achieved. Always follow safety procedures and verify diagrams before use in real installations.