How to Comply With IMO CII

The International Maritime Organization (IMO) introduced the Carbon Intensity Indicator (CII) regulations to reduce the carbon footprint of the maritime industry. These regulations require vessels to measure and manage their carbon emissions, with a focus on reducing carbon intensity over time. Achieving a CII rating of “C” or better is crucial for compliance, as vessels with lower ratings face fewer restrictions and penalties. For ship owners, this means actively monitoring their emissions and implementing strategies to improve fuel efficiency. By adopting the right practices and technologies, maritime operators can meet these regulations, reduce environmental impact, and ensure long-term sustainability in the industry.

Evaluate Current Status: Assessing Carbon Intensity

Overview of CII Calculation

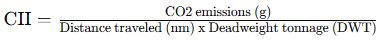

The Carbon Intensity Indicator (CII) is a key metric used to assess the environmental performance of ships. It measures the amount of CO2 emissions produced per unit of transport work (usually expressed as grams of CO2 per nautical mile per deadweight tonnage). The CII is calculated based on the ship’s operational data, including:

- Fuel Consumption: The amount of fuel consumed during a voyage, which is a direct indicator of CO2 emissions produced by the ship’s engine.

- Distance Traveled: The total nautical miles covered during a specific period or voyage.

- Deadweight Tonnage (DWT): The weight a ship can safely carry, including cargo, fuel, and supplies. This helps standardize the measurement of carbon intensity across different vessel sizes.

The formula for calculating CII is typically:

This provides a standardized way to measure how efficiently a ship is operating in terms of carbon emissions per unit of transport work.

Identifying Areas for Improvement

To assess a ship’s current carbon intensity level and pinpoint areas for improvement, consider the following steps:

- Review Operational Data:

- Begin by gathering historical data on fuel consumption, voyage distances, and DWT over a specific period (typically annually). This provides a baseline for understanding the ship’s current performance.

- Calculate the CII:

- Use the gathered data to calculate the CII. Compare it with the IMO’s required CII targets to determine whether the ship meets the compliance threshold (usually a rating of “C” or better).

- Benchmark Against Industry Standards:

- Compare your vessel’s CII with other vessels in the same category or fleet. This benchmarking can reveal whether your ship is underperforming or on track.

- Identify High-Emission Areas:

- Look for specific voyages, periods, or operational patterns where carbon intensity is high. For instance, ships operating at higher speeds or with inefficient routing may produce more CO2.

- Analyze Fuel Consumption Efficiency:

- Evaluate the type of fuel used and consider whether switching to low-carbon alternatives could reduce emissions. For example, using LNG, biofuels, or methanol could significantly lower carbon intensity.

- Evaluate Operational Practices:

- Assess operational efficiency, such as speed management (slow steaming), optimized voyage planning, and just-in-time arrivals. These practices can reduce fuel consumption and improve the ship’s carbon intensity.

Retrofit Energy-Efficient Technologies

Hull Modifications

Reducing Hydrodynamic Resistance

One of the most effective ways to improve fuel efficiency and reduce carbon emissions is by modifying the ship’s hull. By installing advanced hull coatings, air lubrication systems, or appendages, ships can significantly reduce hydrodynamic resistance, which in turn lowers fuel consumption.

- Hull Coatings:

Specially designed coatings, such as anti-fouling and slippery coatings, reduce drag by minimizing the buildup of marine growth and friction between the hull and water. These coatings help the ship move more smoothly through the water, leading to lower fuel usage. - Air Lubrication Systems:

Air lubrication technology injects microbubbles underneath the hull to create a cushion of air between the hull and the water. This reduces friction and drag, allowing the ship to move more efficiently and use less fuel. - Hull Appendages:

Devices like fins, rudders, and bilge keels can be added to a ship’s hull to improve its hydrodynamic performance. These modifications help in reducing energy losses and improving the overall fuel efficiency of the ship.

Fuel-Saving Technologies for Hull Design

In addition to the modifications mentioned above, modern fuel-saving technologies such as bulbous bows or optimized hull shapes are being adopted by shipping companies to improve the efficiency of their vessels. These designs are specifically created to minimize the resistance experienced by the ship, especially at higher speeds, which directly contributes to fuel savings and a reduction in carbon emissions.

Engine Upgrades

Enhancing Engine Efficiency

Another key area for improving carbon intensity and complying with IMO CII regulations is retrofitting engines with modern energy-saving technologies. These upgrades not only improve fuel efficiency but also reduce harmful emissions.

- Variable Valve Timing (VVT):

VVT is an engine technology that adjusts the timing of the valve openings and closings based on the engine’s speed and load. By optimizing fuel combustion, VVT helps to reduce fuel consumption, improve efficiency, and lower emissions, especially during low-load operations. - Turbocharging and Waste Heat Recovery Systems:

Retrofitting engines with turbochargers can improve the engine’s power output and efficiency. Additionally, waste heat recovery systems capture heat from the exhaust gases and convert it into usable energy, helping to power auxiliary systems and reduce fuel consumption. - Exhaust Gas Recirculation (EGR):

EGR systems reduce nitrogen oxide (NOx) emissions by recirculating a portion of the exhaust gas back into the engine to lower combustion temperatures. This reduces the formation of NOx and improves fuel efficiency.

Examples of Engine Retrofit Technologies

- Direct Injection (DI) Systems:

DI technology improves combustion efficiency by directly injecting fuel into the combustion chamber at high pressure, ensuring a more complete burn and reduced fuel consumption. - Hybrid Propulsion Systems:

Some ships are being retrofitted with hybrid propulsion, combining traditional engines with electric motors or batteries. These systems can optimize fuel use by drawing on stored electric energy for low-power operations, reducing reliance on fuel-powered engines.

Renewable Energy Sources

Harnessing Solar and Wind Energy

To further reduce carbon emissions and dependency on traditional fuels, integrating renewable energy sources onboard ships is becoming an increasingly viable option.

- Solar Panels:

Solar panels can be installed on the roofs and decks of ships to generate supplementary power. This energy can be used to power auxiliary systems like lighting, ventilation, and air conditioning, reducing the need to use fuel-powered generators for non-propulsion energy needs. - Wind Power Systems:

Wind propulsion technologies, such as sails or kite systems, have been revisited in modern shipping. These systems harness wind energy to provide auxiliary power, helping ships reduce fuel consumption by supplementing the propulsion provided by conventional engines.

Benefits of Renewable Energy Integration

Using renewable energy sources like solar and wind can contribute significantly to reducing a ship’s carbon footprint. These technologies allow vessels to rely less on fossil fuels, especially during calm weather or when operating in areas with high winds or sunshine, making them an attractive option for long-term sustainability.

Fuel Switching: Transition to Low-Carbon Fuels

Overview of Low-Carbon Fuels

The transition to low-carbon fuels is a crucial step in reducing the maritime industry’s carbon footprint and achieving compliance with environmental regulations such as the IMO CII. Several alternative fuel options are emerging as viable solutions to reduce carbon emissions and help shipowners meet sustainability goals.

- Liquefied Natural Gas (LNG):

LNG is a cleaner fossil fuel alternative that produces significantly less carbon dioxide (CO2) compared to traditional marine fuels like heavy fuel oil (HFO). It also reduces the emission of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter, making it a popular choice for environmentally conscious ship owners. - Methanol:

Methanol is a sustainable liquid fuel with low carbon content and high hydrogen content. It can be derived from renewable sources such as biomass, agricultural waste, and even carbon captured from industrial processes. Methanol combustion results in lower emissions of CO2, sulfur, and nitrogen oxides, making it a promising alternative. - Biofuels:

Biofuels, including biodiesel and bioethanol, are renewable energy sources produced from biological materials. Biodiesel, for example, can be blended with conventional fuels or used directly in marine engines, reducing pollutant emissions. Biofuels are carbon-neutral because the carbon released during combustion is offset by the carbon absorbed during production.

By transitioning to these low-carbon fuels, the maritime industry can significantly reduce its greenhouse gas emissions and move toward a more sustainable future.

Considerations for Fuel Switching

Switching to low-carbon fuels offers numerous benefits, but it also requires careful planning and consideration. The following practical steps should be taken into account when considering a fuel switch:

1. Assess Fuel Availability

Before making a transition to alternative fuels, it’s essential to evaluate the availability of the chosen fuel in the regions where the vessel will operate. Some fuels, such as LNG, have an established bunkering infrastructure in certain regions, while others like biofuels or methanol may still be in the early stages of widespread availability.

- LNG Availability:

LNG has become increasingly accessible in major ports around the world, particularly in Europe and parts of Asia. However, availability can still be limited in more remote regions, which could impact operational efficiency and fuel availability. - Biofuels and Methanol Availability:

Biofuels and methanol are still less widespread than LNG, and their availability at global bunkering stations may vary. It’s important to plan routes and ensure that refueling options are available along the vessel’s regular trade routes.

2. Evaluate Fuel Cost

The financial aspect of switching fuels is a critical consideration for ship owners. While alternative fuels like LNG, methanol, and biofuels can offer long-term savings due to lower emissions and potentially lower fuel costs, the initial investment can be significant.

- Fuel Cost Comparison:

Alternative fuels often come with a higher upfront cost compared to traditional marine fuels. However, many low-carbon fuels, like LNG, are becoming more competitive in terms of pricing, especially as demand increases. It’s essential to consider not only the direct cost of the fuel but also potential savings from lower emissions and reduced regulatory compliance costs.

3. Check Compatibility with Existing Engine Systems

Switching to low-carbon fuels may require modifications to existing ship engines to ensure compatibility and optimal performance. Some fuels, like LNG, require specialized tanks and engine modifications, while others, such as biofuels, may only require minimal adjustments.

- Engine Modifications:

Depending on the fuel type, retrofitting the ship’s engine may be necessary. For example, vessels that transition to LNG may need dual-fuel engines capable of burning both LNG and conventional fuels. Similarly, engines running on biofuels may require modifications to optimize performance and efficiency. - Fuel System Adjustments:

Switching to alternative fuels may also involve upgrading fuel storage and delivery systems. Ships using biofuels or methanol may need specialized tanks and fuel lines designed to handle the properties of these fuels, which could have different viscosity or chemical characteristics compared to traditional fuels.

4. Regulatory Compliance and Certification

As the maritime industry faces increasing environmental regulations, it’s essential to ensure that the chosen alternative fuel complies with international standards such as the IMO’s MARPOL Annex VI, which governs air pollution from ships. Some alternative fuels, like LNG and biofuels, may be easier to certify for compliance, while others may require additional testing and approval.

- IMO Compliance:

Ensure that the selected fuel meets the required sulfur and carbon intensity limits set by IMO regulations, such as the IMO 2020 sulfur cap and the Carbon Intensity Indicator (CII) requirements. Certification bodies may be required to approve the switch and provide documentation for compliance.

5. Monitor Performance and Emissions

Once a fuel switch is made, continuous monitoring is essential to ensure that the ship maintains optimal performance and that emissions are being effectively reduced. This includes tracking fuel consumption, engine efficiency, and emissions data to ensure the ship’s carbon intensity remains within acceptable limits.

- Emission Tracking Tools:

Invest in emission monitoring systems and performance tracking tools that provide real-time data on the ship’s fuel usage and emissions. This data will help ship owners assess the effectiveness of the fuel switch and make necessary adjustments for improved performance.

Implement Operational Changes to Reduce Emissions

The maritime industry can significantly reduce its carbon emissions and improve its Carbon Intensity Indicator (CII) rating by implementing operational changes that focus on improving fuel efficiency. Here are three key strategies that shipowners can adopt to lower carbon intensity:

Slow Steaming: Reducing Ship Speed

Description: Slow steaming refers to the practice of reducing a vessel’s speed to lower fuel consumption and reduce carbon emissions. By operating at slower speeds, ships consume less fuel per mile, which results in reduced CO2 emissions per ton of cargo transported.

- How It Works:

Slow steaming typically involves reducing the vessel’s cruising speed by approximately 10-20%. While slower speeds result in longer voyage durations, the significant reduction in fuel consumption often offsets the increased time. - Benefits:

- Lower Fuel Consumption: Operating at slower speeds reduces the amount of fuel burned per nautical mile, directly decreasing overall fuel costs and carbon emissions.

- Reduced Carbon Intensity: By burning less fuel, slow steaming helps to lower the ship’s carbon intensity, which can improve its CII rating and help comply with regulatory standards.

- Cost Savings: For ships operating on long-haul routes, slow steaming can significantly lower fuel costs, which make up a large portion of operational expenses.

- Challenges:

- Longer Voyage Times: While fuel consumption is reduced, slow steaming results in longer travel times, which may impact shipping schedules and customer delivery timelines.

- Operational Efficiency: Some vessels are designed for higher speeds and may not be optimized for slower cruising speeds, leading to potential efficiency issues or equipment wear.

- Market Pressures: Slow steaming may not always be viable in competitive shipping markets where faster delivery times are critical.

Optimized Voyage Planning: Fuel-Efficient Routes

Description: Optimized voyage planning involves using advanced technology and data analysis to select the most fuel-efficient routes for a vessel. By considering factors such as distance, weather conditions, and sea currents, ships can avoid unnecessary detours and reduce fuel consumption.

- How It Works:

Modern navigation tools and route planning software help ship operators assess various factors (e.g., weather patterns, currents, and congestion in ports) to choose the most efficient route. This ensures that the vessel minimizes its fuel usage while maintaining schedule integrity. - Benefits:

- Fuel Efficiency: By selecting the shortest and least fuel-consuming route, ships can reduce their carbon emissions and improve overall fuel efficiency.

- Time and Cost Savings: Avoiding detours and optimizing routes can save both time and money by reducing fuel consumption and ensuring timely arrivals.

- Reduced Emissions: Fewer detours and more efficient use of fuel directly translate to a reduction in CO2 emissions, improving the vessel’s environmental performance and its CII score.

- Challenges:

- Weather and Environmental Uncertainty: Unpredictable weather conditions, including storms or sudden changes in wind and currents, can sometimes hinder the optimization of routes.

- Advanced Technology Costs: Implementing and maintaining advanced voyage planning software and systems can involve initial investment costs, though these can pay off in long-term fuel savings.

- Dependency on Data Accuracy: Accurate data, such as updated weather forecasts and real-time traffic information, is critical to optimizing voyage planning. Inaccurate or outdated data can undermine the efficiency gains from this strategy.

Just-In-Time Arrivals: Minimizing Port Idle Time

Description: Just-in-time (JIT) arrivals involve coordinating a vessel’s arrival time with port authorities to ensure the ship arrives at port only when a berth is available, reducing the amount of time the ship spends idling at anchor or waiting in line.

- How It Works:

By working closely with port operators, shipping companies can synchronize vessel schedules with port availability, ensuring that the ship arrives at the optimal time to dock and unload. This eliminates the need for the ship to burn fuel while idling or waiting. - Benefits:

- Reduced Fuel Consumption: Minimizing idle time at ports means less time spent using auxiliary engines to maintain power while waiting. This directly reduces fuel consumption.

- Decreased Emissions: Less idling translates to fewer greenhouse gas emissions, improving the vessel’s carbon intensity and helping meet IMO CII targets.

- Improved Efficiency: JIT arrivals contribute to smoother port operations by optimizing berth scheduling, reducing congestion, and increasing turnover rates at ports.

- Challenges:

- Coordination with Ports: Successful implementation of JIT arrivals requires effective coordination with port authorities, which may not always be possible in highly congested or underdeveloped ports.

- Unpredictable Delays: External factors such as weather, congestion, or delays from other vessels can disrupt scheduled arrivals, leading to longer waiting times and fuel wastage.

- Dependence on Real-Time Data: Accurate and timely communication between ship operators and port authorities is essential to execute JIT arrivals effectively. Any miscommunication or lack of real-time data may undermine the strategy’s success.

Crew Training: Empowering Crew for Energy-Efficient Operations

Crew training is a critical component in ensuring that maritime vessels operate at their highest efficiency, helping to reduce carbon emissions and improve compliance with IMO CII regulations. Educating crew members about energy-efficient practices can significantly contribute to lowering fuel consumption, optimizing vessel performance, and minimizing waste. Below are the key areas where crew training can make a tangible difference.

Energy-Efficient Operations: Reducing Fuel Consumption

Importance of Education: Effective crew training helps raise awareness about the importance of energy-efficient operations, which can directly impact a vessel’s carbon intensity. By equipping the crew with the knowledge to implement best practices, ships can operate in a way that minimizes fuel consumption while maintaining operational efficiency.

- Optimized Engine Operation:

Crew members should be trained in the proper use and maintenance of engines, ensuring that they are operating at peak efficiency. This includes managing engine load, reducing unnecessary power use, and avoiding overloading engines. Properly tuning engines and performing regular maintenance checks are also crucial in maintaining optimal fuel efficiency. - Minimizing Energy Wastage:

Small adjustments in daily operations can have a large impact on fuel consumption. Training the crew to minimize energy wastage—such as avoiding unnecessary running of auxiliary engines, managing power use in the galley, and efficiently using onboard lighting and HVAC systems—can significantly reduce the overall fuel consumption of the vessel. - Reducing Idle Time:

Educating the crew about the importance of reducing idle time when in port or waiting for cargo can result in a notable reduction in fuel consumption. By monitoring and managing vessel speeds and idle time, the crew can ensure the ship operates at its most efficient level, minimizing unnecessary fuel use.

Benefits:

- Lower Fuel Consumption: Crew members who are trained to optimize engine performance and reduce energy wastage will help the vessel consume less fuel, thus lowering carbon emissions.

- Operational Efficiency: Energy-efficient operations can enhance the overall performance of the vessel, leading to cost savings and improved performance.

- Regulatory Compliance: Crew training supports compliance with environmental regulations like IMO CII by ensuring that the vessel meets required carbon intensity standards.

Fuel Consumption Monitoring: Tracking Operational Efficiency

Importance of Monitoring: Another vital aspect of crew training is the ability to monitor and analyze fuel consumption data. With the increasing availability of digital tools and performance metrics, crew members can be empowered to make real-time decisions that directly impact fuel usage. Monitoring fuel consumption and operational efficiency provides valuable insights into areas where improvements can be made.

- Digital Tools and Performance Metrics:

Modern vessels are equipped with digital monitoring systems that track fuel consumption, engine performance, and operational parameters. Training the crew to use these tools effectively allows them to track fuel usage in real-time, helping to identify inefficiencies or irregularities in operation. Crew members can then make data-driven decisions to optimize the vessel’s performance. - Regular Reporting and Analysis:

Establishing a routine of monitoring fuel consumption and documenting operational efficiency allows for ongoing analysis. Crew training should emphasize the importance of logging fuel usage and operational data to provide insights into trends, helping identify potential improvements or areas requiring corrective action. - Identifying Inefficiencies:

By continuously tracking fuel consumption and operational metrics, the crew can spot patterns that may indicate inefficiencies, such as excessive idling, suboptimal speeds, or underutilized engines. Early identification of inefficiencies allows for timely intervention, improving overall vessel performance.

Benefits:

- Enhanced Monitoring Capability: Crew members who are trained to use fuel monitoring systems can improve operational decisions, reducing fuel consumption and emissions.

- Increased Accountability: Regular tracking of fuel consumption ensures that crew members are held accountable for energy-efficient operations, promoting a culture of continuous improvement.

- Better Resource Allocation: By identifying inefficiencies and areas for optimization, crews can focus their efforts on areas that will deliver the greatest fuel savings and emissions reductions.

Data Monitoring and Reporting: Ensuring Compliance

In order to comply with the IMO Carbon Intensity Indicator (CII) regulations, it is crucial for ship owners and operators to continuously monitor their vessels’ carbon emissions and track their performance over time. Accurate data collection and reporting are key to demonstrating compliance with the required carbon intensity standards. Below are the essential steps for effectively managing and reporting CII data to ensure ongoing compliance.

Regularly Calculate CII: Monitoring Carbon Emissions

Tracking Carbon Emissions: To monitor the performance of a vessel and its carbon emissions, the CII must be calculated periodically throughout the year. This calculation takes into account various operational parameters, such as fuel consumption, distance traveled, and cargo carried. Regular calculation ensures that the vessel’s carbon intensity remains within the required limits.

- CII Calculation Methodology:

The Carbon Intensity Indicator is calculated using a formula that considers the amount of CO2 emitted per unit of transport work, typically measured in grams of CO2 per nautical mile per ton of deadweight (gCO2/dwt·nm). Monitoring fuel consumption and operational data at regular intervals helps in accurately calculating CII scores. - Continuous Monitoring:

Using digital systems and data loggers, ship operators can track their carbon intensity in real-time. This allows for prompt identification of inefficiencies or deviations from the expected CII performance, enabling corrective actions to be taken before it results in non-compliance. - Identify Areas for Improvement:

By regularly calculating the CII, ship operators can assess whether their emissions reduction strategies, such as slow steaming, fuel switching, and energy-efficient technologies, are effective. If the CII is higher than the target, operators can identify and implement additional measures to improve fuel efficiency and reduce emissions.

Benefits:

- Ongoing Compliance Monitoring: Regular calculation of the CII allows operators to stay ahead of potential non-compliance issues, ensuring that carbon intensity remains within acceptable limits.

- Data-Driven Decision-Making: Frequent CII calculations provide actionable insights that enable ship operators to optimize operations and improve fuel efficiency.

- Proactive Adjustment: By calculating CII data continuously, vessel operators can quickly make necessary adjustments to maintain compliance with IMO regulations.

Submit Compliance Reports: Meeting Regulatory Requirements

Submitting CII Data and Reports: Once the carbon intensity performance data has been tracked, it must be submitted to the relevant authorities as per IMO regulations. This ensures that shipowners demonstrate their commitment to reducing emissions and complying with CII targets.

- Submission Timeline:

Typically, ship owners are required to submit annual reports to the IMO or relevant maritime authorities. These reports must include the vessel’s CII rating, along with a detailed breakdown of fuel consumption, distance traveled, and other operational factors that influence carbon emissions. - Detailed Reporting Format:

The submission must include a comprehensive set of data, such as the ship’s carbon intensity scores over the reporting period, and an analysis of any significant changes or deviations. It’s important that the report is accurate, complete, and formatted according to IMO’s guidelines. - Compliance Documentation:

Along with the CII report, ships may also need to submit additional documentation, such as maintenance records, fuel consumption logs, and details of the energy efficiency measures implemented. Maintaining well-organized records will help demonstrate compliance during inspections and audits.

Benefits:

- Regulatory Compliance: Timely submission of accurate CII reports ensures compliance with IMO regulations and prevents potential penalties or restrictions.

- Transparency and Accountability: Submitting detailed reports creates a transparent record of the ship’s environmental performance and shows a commitment to reducing carbon emissions.

- Avoiding Penalties: Regular, accurate submissions reduce the risk of penalties or restricted access to ports due to non-compliance.

Importance of Maintaining Accurate Records

Ensuring Transparency During Inspections: Accurate and up-to-date records are essential not only for regular CII reporting but also for inspections carried out by port authorities or regulatory bodies. These records serve as proof of compliance and the ship’s environmental performance over time.

- Comprehensive Fuel Consumption Logs:

Keeping detailed logs of fuel usage and operational parameters ensures that the data submitted in CII reports is accurate. These logs should be regularly updated and include all relevant information, such as fuel types, quantities consumed, and voyage details. - Data Storage and Access:

All carbon emissions data, maintenance records, and CII reports should be securely stored and easily accessible. A well-organized digital record-keeping system can simplify the process of providing documentation during inspections. - Audit and Verification:

Regulatory authorities may perform random audits to verify the accuracy of the submitted CII reports. Having comprehensive records helps ships prepare for these audits and ensures that discrepancies, if any, can be promptly addressed.

Benefits:

- Easier Compliance Verification: Accurate records streamline the inspection process and facilitate verification of CII compliance, reducing delays and improving efficiency.

- Mitigating Risks of Non-Compliance: Maintaining detailed and organized records minimizes the chances of errors or omissions, reducing the risk of penalties.

- Proven Environmental Commitment: Well-maintained records demonstrate a vessel’s commitment to sustainability and environmental responsibility, reinforcing a positive reputation in the industry.

Embrace Digitalization and Smart Shipping Solutions

In today’s fast-paced maritime industry, digitalization and smart shipping solutions have become essential in improving operational efficiency, reducing costs, and minimizing environmental impact. By integrating advanced technologies such as Data Analytics, IoT sensors, and automation, shipping companies can significantly enhance their overall performance. This shift towards smart shipping offers greater control, precision, and sustainability in managing shipping operations.

Utilizing Data Analytics and IoT

The Role of IoT Sensors in Monitoring Key Metrics

The Internet of Things (IoT) has revolutionized the shipping industry by enabling real-time monitoring of critical operational data. IoT sensors placed on ships provide constant feedback on various performance parameters such as fuel consumption, emissions, engine health, and other vital operational metrics.

These sensors collect data continuously, enabling fleet managers to track and analyze the condition of each vessel in real time. The integration of IoT technology allows for more accurate forecasting of maintenance needs and better resource management, ultimately reducing costs and downtime.

Real-Time Data for Informed Decision-Making

One of the most significant advantages of IoT integration is the access to real-time data. With the ability to track various operational parameters at any given moment, fleet operators can make more informed decisions. For example, they can adjust speeds or change routes based on weather conditions, traffic, or other factors, ensuring optimal fuel efficiency and reducing the carbon footprint.

Real-time data also enhances predictive analytics, allowing companies to foresee potential equipment failures and address issues before they lead to costly repairs or operational disruptions. This level of visibility boosts overall operational performance, safety, and sustainability.

Automated Efficiency Enhancements

Automating Processes for Engine Control

Smart shipping technologies enable the automation of key processes such as engine control, enhancing both fuel efficiency and operational performance. By implementing automated systems, ships can adjust engine parameters based on current operational conditions, such as load, speed, and environmental factors. These systems optimize fuel consumption and emissions in real time, ensuring that vessels operate at peak efficiency throughout their voyage.

Automation minimizes human error, reduces the need for manual adjustments, and ensures that operational parameters are continuously optimized. By controlling factors such as throttle settings, fuel injection rates, and engine performance, these technologies help maintain the ideal balance between fuel economy and emissions reduction.

Voyage Optimization for Emissions Reduction

Another key area where automation plays a critical role is voyage optimization. Smart shipping technologies use real-time data to determine the most efficient routes, minimizing fuel consumption and environmental impact. By analyzing factors such as wind patterns, currents, and sea conditions, these systems can adjust the ship’s course to save fuel and reduce emissions, all while ensuring timely delivery.

Automated systems can also predict weather disruptions or port delays, enabling ships to adjust their schedules and avoid unnecessary fuel burn. This integration of automation and data analytics is vital in achieving a more sustainable, cost-effective, and efficient shipping industry.

Collaborate with Industry Stakeholders

Collaboration among stakeholders in the shipping industry is essential for advancing sustainability and achieving compliance with evolving regulations. By actively engaging with regulators, industry experts, and key partners, shipping companies can foster innovation, enhance compliance, and contribute to the collective progress toward more sustainable maritime operations. By working together, the industry can overcome challenges and unlock new opportunities to meet environmental goals, such as reducing carbon intensity (CII) and other emissions targets.

Engage with Regulators and Industry Experts

Staying Updated on IMO Regulations

The International Maritime Organization (IMO) plays a critical role in shaping the regulatory landscape for the shipping industry. Staying informed about IMO regulations, including those related to emissions and sustainability, is essential for companies to remain compliant and avoid penalties. As global environmental standards evolve, regulatory frameworks continue to tighten, and shipping companies must keep pace with these changes.

Regularly engaging with regulators and industry experts ensures that companies are aware of the latest updates to policies and regulations. By building strong relationships with these bodies, shipping operators can anticipate shifts in policy and develop proactive strategies for compliance, making it easier to adapt and minimize disruptions in operations.

Collaborating to Improve Compliance and Best Practices

Collaboration between shipping companies, regulators, and industry experts is vital for developing more effective compliance strategies. Engaging in open dialogue with regulatory authorities enables shipping operators to understand the rationale behind certain regulations, leading to more informed decisions about implementation.

Moreover, working together fosters the development of industry-wide best practices. By sharing insights and collaborating on solutions, companies can identify and address common challenges, ensuring that compliance is achievable across the sector. This cooperative approach helps streamline regulatory processes, reduces the risk of non-compliance, and encourages more consistent standards across the industry.

Industry Partnerships for Technological Innovation

Investing in Research and Development for New Fuel Technologies

Technological innovation is key to achieving the shipping industry’s sustainability goals. Investment in research and development (R&D) is crucial to advancing new fuel technologies that can reduce carbon emissions and improve fuel efficiency. By forming strategic partnerships with research institutions, universities, and technology developers, shipping companies can help pioneer the next generation of fuels and energy systems that meet the demands of environmental regulations.

Alternative fuels, such as hydrogen, ammonia, and biofuels, have shown potential to revolutionize the way ships are powered. Collaborative efforts within the industry, alongside government support and private-sector investment, can speed up the commercialization of these technologies, making them more accessible and economically viable for shipping operators.

Energy-Efficient Systems and Emission-Reduction Innovations

Alongside new fuel technologies, energy-efficient systems and emission-reduction innovations also play a pivotal role in helping the industry meet its environmental goals. Collaborating with technology providers to develop and adopt cutting-edge systems, such as energy-saving devices, hull modifications, or advanced air lubrication technologies, can help significantly reduce fuel consumption and emissions.

Investment in emission-reduction technologies such as carbon capture and storage (CCS) systems, scrubbers, and exhaust gas cleaning systems can enable vessels to meet the stringent requirements of the Carbon Intensity Indicator (CII). Moreover, by pooling resources and knowledge, industry stakeholders can accelerate the development and deployment of these technologies across the sector.

Encouraging Industry-Wide Innovation

The shipping industry faces a complex set of challenges, but through collaboration and investment in innovation, companies can address these obstacles more effectively. By forging partnerships with technological innovators, shipping companies can gain access to cutting-edge solutions that promote sustainability while helping to meet global environmental targets.

By working together, stakeholders can make significant strides in reducing the maritime industry’s environmental impact and ensuring compliance with evolving regulations like the CII. This collaborative mindset not only drives technological progress but also strengthens the industry’s collective ability to meet future challenges.

Conclusion

To comply with IMO CII regulations, the maritime industry must focus on embracing digital tools like IoT sensors, collaborating with industry stakeholders, and investing in innovative technologies such as alternative fuels and energy-efficient systems. Proactive compliance is not only crucial for avoiding penalties but also for ensuring the long-term sustainability of the industry. By staying ahead of regulatory changes, continuously improving practices, and investing in cutting-edge solutions, stakeholders can significantly reduce carbon emissions and contribute to a more sustainable future for global shipping. It’s essential that all players—from shipping companies to regulators—work together to drive innovation and achieve lasting environmental goals.