How to Start a Generator on Board Ship

How to Start a Generator on Board Ship: Navigating the Power of Knowledge

For those setting sail on the vast and unpredictable seas, the heart of a ship lies in its generators. However, starting a Generator on board a ship is not a simple and easy task, as one has to have detailed knowledge of the machine, the Machine’s functioning, and proper starting procedures.

The process is not just turning the key and starting the generator like a car. It involves many complex systems and their functions. Before starting a generator, the step-by-step procedure is followed. By following the correct procedure, you will be able to start the generator on the 1st attempt without any abnormality or failures.

But we don’t stop at the basics. We will also discuss five trusted suggestions for starting a ship’s Generator. Particularly under dire circumstances, these priceless insights can mean the world.

Knowing how to initiate power during emergencies swiftly can be a game-changer at sea.

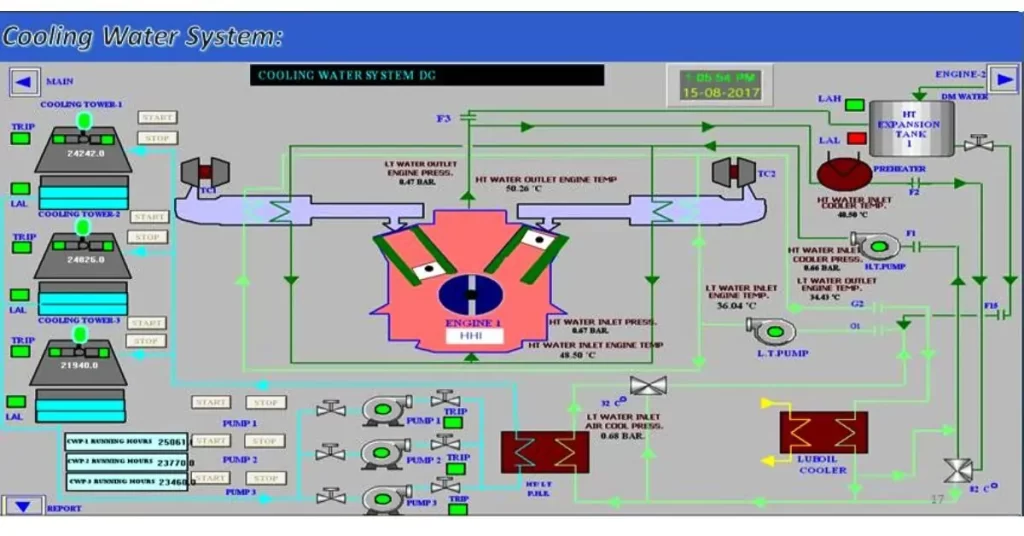

Preparation of Cooling Water System

To ensure the cooling water system is ready to go, follow these steps:

- Check the Cooling Water Tank Level: Check the water level in the cooling water tank. If it’s low, fill it up to the required level.

- Prepare the Cooling Water System: Get the cooling water system ready for startup.

- Valve Position: Change the valve position from “stop” to “operation” to allow water flow.

- Stop Water Leaks: Ensure there are no water leakages in the system. Fix any leaks you find.

- Venting: Check for proper venting in the cooling water system.

- Operating Parameters: Verify that all operating parameters are within the specified range.

- Engine Area Cleanliness: Look around the engine area to ensure it’s clean and free from debris or obstructions.

By following these steps, you’ll prepare the cooling water system effectively for use.

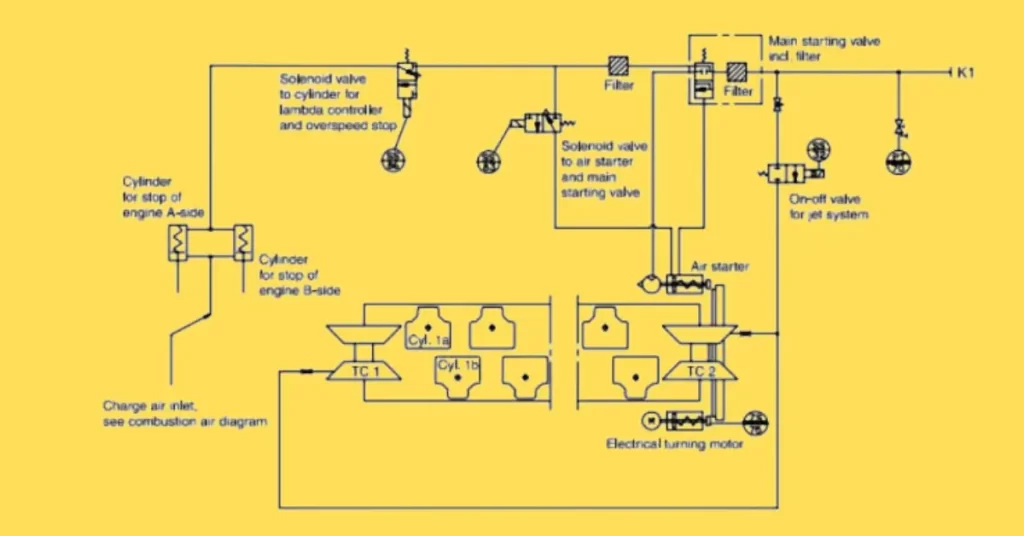

Preparation of Starting Air System for Ship Generator

Before initiating the ship’s generator, it’s essential to prepare the starting air system meticulously. The starting air system is responsible for starting the Diesel Engine, and proper preparation of the system will ensure a smooth and trouble-free starting.

Check Air Receivers: Begin by inspecting the air receivers. These storage tanks hold the compressed air required to start the generator. Ensure they are adequately charged and maintain the recommended pressure, typically around 28 bar.

Inspect Pipes and Valves: Examine the piping and valves connected to the starting air system. Check for the symptoms of leakages, damage, or blockages. Make necessary repairs or replacements as needed.

Non-Return Valves: Check the non-return valves in the system, both automatic and remote-operated ones. Ensure they are in working order and can maintain air pressure without leaks.

Pilot Air Control: Verify the pilot air control system. Ensure the pilot air control valve operates correctly and synchronizes with the engine’s starting air lever.

Engine Start Lever: Check the engine start lever. When activated, it should initiate the flow of pilot air to the appropriate valves, allowing the system to start the generator.

Timing Valves: Inspect the timing valves in the air distributor. These valves are synchronized with the engine’s position to ensure that each starting valve operates in the correct order and timing as the engine rotates.

Safety Measures: Ensure that safety interlocks are in place. For example, an interlock should prevent the remote operating valve from opening when the engine’s turning gear is engaged.

These steps will adequately prepare the starting air system for the ship’s generator.

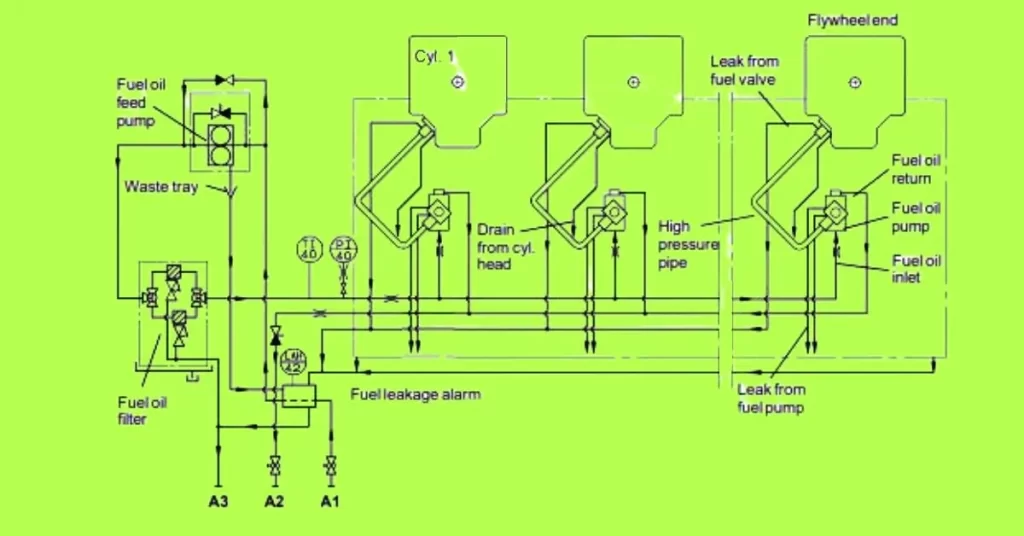

Preparation of Fuel System

Preparing the fuel system properly is crucial before starting the generator on a ship. This ensures a reliable and efficient operation. Here are the steps to follow:

- Drain Water: Begin by draining any water from the fuel system. Water can cause issues with the engine, so it’s essential to remove it.

- Fuel Tank Check: Inspect the fuel tank and ensure it has enough fuel. Top it up if necessary to avoid interruptions during operation.

- Diesel Cooling System: Check the diesel cooling system to ensure it’s functioning correctly. Proper cooling is vital for engine performance.

- Check If Fuel System Is Stopped: If the fuel system was previously stopped or unused, thoroughly check to ensure it’s in good working condition.

- Operate the Fuel System: If the fuel system is stopped, follow the procedures to get it up and running again. This ensures a consistent fuel supply.

- Valve Position: Change the position of valves from “stop” to the “operating” position to allow fuel flow.

- Leakage Check: Examine the entire fuel system for any signs of leakage. If you find any leaks, take immediate corrective action to prevent fuel wastage and potential hazards.

- Air Venting: Check the system for proper air venting. Adequate venting ensures that fuel flows smoothly without airlocks.

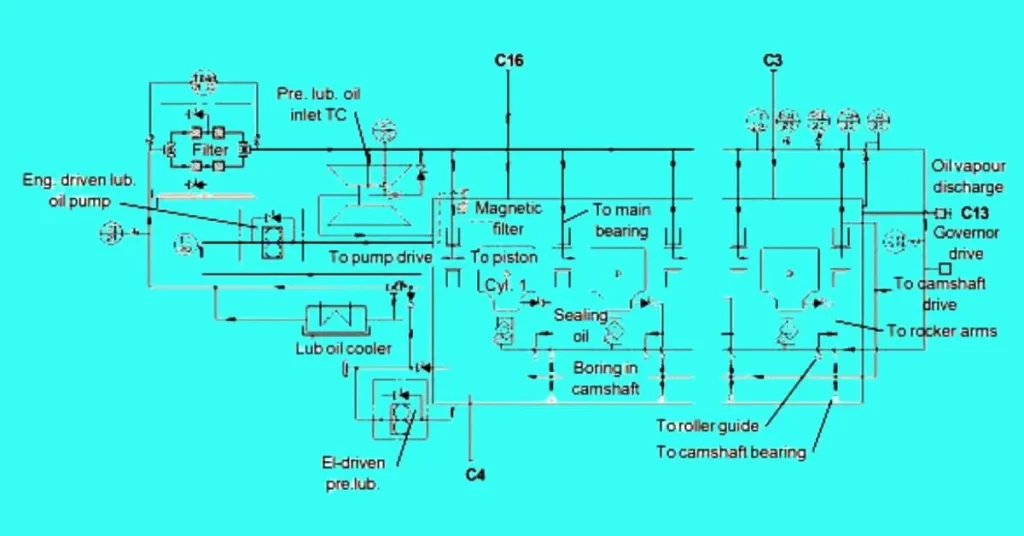

Preparation of Lubricating Oil System

Before starting the engine, it’s essential to ensure that the lubricating oil system is in good shape. Here’s a step-by-step guide:

- Check Sample Date: Verify when the last oil sample for quality check was taken. Regular oil quality checks are crucial for engine health.

- Replace Oil Filters: If the engine has been overhauled or idle for an extended period, replace the oil filters to maintain optimal oil quality.

- Oil Sump Tank Level: Check the oil level in the sump tank. If it’s low, top it up to the required level.

- Valve Position: Change the position of the valve to the “operational” setting. This allows the lubricating oil to flow as needed.

Pre-lubrication of the Engine

Before starting the engine, perform pre-lubrication to ensure proper oil flow and engine health:

- Heat Oil Temperature: A heater raises the lubricating oil temperature to 40⁰C. Proper oil temperature is essential for engine performance.

- Lubricating Oil Pump: If the lubricating oil pump was stopped, operate it to ensure oil circulation.

- Check for Leaks: Inspect the system for any oil leaks and address them promptly to prevent wastage and maintain oil levels.

- Oil Pressure and Condition: Monitor oil pressure and the condition of the pre-lubricating oil to ensure it meets engine requirements.

Pre-Lubrication Timing: Perform pre-lubrication at least 5 to 10 minutes before starting the engine. This is particularly important if the engine has been idle for an extended period or has undergone an overhaul.

Ensure Oil Flow: Confirm that oil flows smoothly from key points, including bearings, pump and valve operating rollers, and remove any maintenance tapes that may have been applied.

By following these steps, you’ll ensure that the lubricating oil system is ready for action, promoting the efficient and reliable operation of the engine.

Intake Air and Exhaust System Preparation

Before starting the engine, it’s vital to prepare the intake air and exhaust system. Here’s a step-by-step guide:

- Open Indicator Valves: Begin by opening the indicator valves.

- Lubricate Liners: Pour 50 CC of oil through the indicator cocks to lubricate the dry surface of the liners. Spray oil under the piston and turn the engine.

- Rotate Engine: Use a shaft-barring arrangement to rotate the engine a few revolutions. This helps check the condition of moving parts and ensures there is no trapped fluid in the combustion chambers. Proper checks during turning prevent hydraulic locks and damage to components.Note: If you notice any escaping fluid through the indicator cock, clean it up with a waste cloth.

- Check Cylinders: Rotate the crankshaft for 2 to 3 revolutions and observe if any fluid emerges from the cylinders.

- Disengage Turning Gear: After the checks, disengage from the turning gear.

Air System Readiness for Emergency Generator Start

For the emergency generator’s air system, follow these steps:

- Remove Condensate: Remove any condensate from the air receiver.

- Check Air Filters: Inspect and clean the air filters to ensure they are clear.

- Air Bottle Pressure: Check and fill the starting air bottle to a pressure of 20-30 bars.

- Control System Pressure: Verify the air pressure for the engine’s control system.

Fuel Regulating System Preparedness

To prepare the fuel regulating system, perform the following checks:

- Governor Operation: Check the regulating rod to ensure smooth and free movement from the governor to all the fuel racks of the high-pressure fuel injection pumps for the emergency generator start.

- Emergency Stop Button: Check and reset the operation of the emergency stop button. Operate it while keeping the fuel control rod at the maximum position to confirm that all fuel racks move to the maximum zero position. This ensures engine shutdown in case of an abnormality.

- Fuel Rack Flexibility: Verify the flexibility of each rack of the fuel injection pump. Check the return of fuel racks to their original position by manually pulling the rack from one position to another.

- Mechanical Fuel Limiter: Check the mechanical fuel limiter for overload (set to 110% load).Note: Setting the mechanical fuel limiter correctly is crucial to prevent potential engine damage.

- Adjust Fuel Limiter: Set the mechanical fuel limiter on the governor to 30-50% of the load limit.

By following these steps, you’ll ensure that the intake air, exhaust system, and fuel regulating system are ready for starting the emergency generator safely and efficiently.

FAQ on ” How to Start a Generator on Board Ship”

Q: What’s the role of the lubricating oil system in generator startup?

A: It ensures engine components are well-lubricated for smooth operation.

Q: Why is pre-lubrication of the engine necessary?

A: Pre-lubrication ensures proper oil flow and engine health before startup.

Q: What should I check before starting the generator’s fuel system?

A: Verify fuel quality, filters, and system integrity to prevent issues during operation.

Q: How do I start a generator on board a ship?

A: Follow the engine’s specific startup procedure and ensure the fuel and air systems are prepared.

Blog Post Conclusion

The Power of Shipboard Generators: Navigating It

On board a ship, starting a generator is an essential task that necessitates accuracy, preparation, and knowledge. Let’s review the most important lessons learned as we come to the end of this guidance on this crucial procedure.

Different onboard systems are powered by generators, which are frequently referred to as the heart of the ship. A properly conducted technique is needed to start them in order to assure a smooth and effective operation.

Preparation is Key: Before even attempting to start the generator, thorough preparation is a must.

Maintenance is Essential: Regular maintenance of the generator and its associated systems is critical for reliability.

Expertise is Valuable: Starting a generator on a ship requires knowledge and expertise. Marine engineers and crew members should be well-trained in the specific procedures for their vessel’s engine to avoid potential mishaps.

In the world of maritime operations, where the ship is both a workplace and a home at sea, the ability to start and maintain generators is a fundamental skill. It ensures that all systems run smoothly, from propulsion to electrical power and emergency backup.