Hydraulic Solenoid Valve

Hydraulic solenoid valves are critical components in modern marine engineering, enabling precise control over fluid dynamics within various systems. These valves operate by converting electrical energy into mechanical motion, allowing for the regulation of flow in hydraulic circuits. Their importance in marine applications cannot be overstated, as they are integral to the efficiency and safety of operations on board ships and other marine vessels. From steering systems to ballast control and engine cooling, hydraulic solenoid valves ensure that these vital functions perform optimally and reliably.

This post aims to highlight the top seven most powerful uses of hydraulic solenoid valves in marine environments, showcasing their versatility and indispensable role in enhancing marine operations. By understanding these applications, marine engineers and enthusiasts can better appreciate the technological advancements that keep our vessels running smoothly and safely on the water.

Detailed Explanation of Hydraulic Solenoid Valves

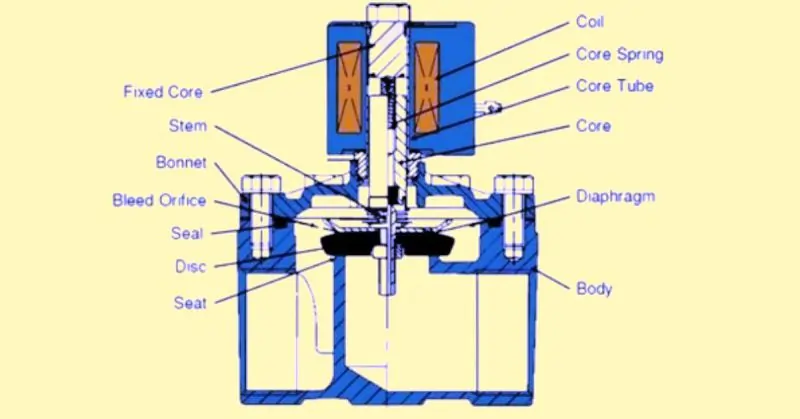

Hydraulic solenoid valves are specialized devices designed to control the flow and direction of hydraulic fluid in various systems. These valves use an electromagnetic solenoid to actuate a spool or poppet within the valve body. When the solenoid is energized, it creates a magnetic field that moves the spool or poppet, changing the flow path of the hydraulic fluid. This operation can either open, close, or redirect the flow, providing precise control over hydraulic systems.

Key components include:

- Solenoid Coil: Generates the magnetic field when energized.

- Spool or Poppet: Moves within the valve body to control fluid flow.

- Valve Body: Houses the internal components and provides the flow passages.

- Spring: Returns the spool or poppet to its default position when the solenoid is de-energized.

- Valve Ports: Inlet and outlet ports for hydraulic fluid to flow through the valve.

How They Operate Under Hydraulic Pressure

Hydraulic solenoid valves operate by controlling the position of the spool or poppet within the valve body. The process can be described in several steps:

- Energizing the Solenoid: An electric current passes through the solenoid coil, generating a magnetic field.

- Actuating the Spool or Poppet: The magnetic field moves the spool or poppet, altering the flow path of the hydraulic fluid.

- Controlling Flow: The movement of the spool or poppet either opens or closes the valve ports, or redirects the fluid to different pathways.

- De-energizing the Solenoid: When the electric current is switched off, the spring mechanism returns the spool or poppet to its original position, resetting the flow path.

Hydraulic solenoid valves are designed to handle high-pressure hydraulic fluids, ensuring reliable performance even in demanding conditions. Their ability to provide precise control under varying pressures makes them essential in hydraulic systems.

Marine Uses

Hydraulic solenoid valves are integral to numerous marine applications, where precise and reliable control of hydraulic fluid is critical for the operation of various systems. Key marine uses include:

Fuel Injection Systems: Enhancing Marine Engine Performance

Fuel injection systems are crucial for the efficient and effective operation of marine engines. Hydraulic solenoid valves play a vital role in these systems by ensuring precise control over fuel delivery. This precision is essential for optimizing engine performance, improving fuel efficiency, and reducing emissions.

Functionality

Hydraulic solenoid valves in fuel injection systems control the timing and amount of fuel injected into the engine’s combustion chambers. When the solenoid valve receives an electrical signal, it opens to allow a precise quantity of fuel to flow through the injector nozzle and into the combustion chamber. This precise control ensures that the right amount of fuel is delivered at the right time, which is critical for efficient combustion.

Precision in Fuel Delivery for Marine Engines

The precision provided by hydraulic solenoid valves is paramount for several reasons:

- Optimized Combustion: Precise fuel delivery ensures that the fuel-air mixture is optimal for combustion, leading to more efficient engine performance.

- Consistent Performance: Accurate fuel injection maintains consistent engine operation, reducing the likelihood of misfires and ensuring smooth performance.

- Adaptability: Solenoid valves can quickly adjust fuel delivery based on engine load and operating conditions, providing flexibility and responsiveness.

Benefits

- Improved Fuel Efficiency: By delivering fuel with high precision, hydraulic solenoid valves help maximize fuel efficiency, reducing overall fuel consumption.

- Reduced Emissions: Precise fuel control minimizes the production of harmful emissions, contributing to a cleaner marine environment.

- Enhanced Engine Longevity: Efficient fuel combustion reduces engine wear and tear, extending the engine’s lifespan and reducing maintenance costs.

Steering Gear Systems

In the realm of marine engineering, steering gear systems are pivotal for the safe and efficient navigation of vessels. At the heart of these systems are hydraulic solenoid valves, which meticulously control the flow of hydraulic fluid to the steering actuators. This control is crucial for achieving the precise and responsive maneuvering necessary in maritime operations.

How Hydraulic Solenoid Valves Work in Steering Gear Systems

Hydraulic solenoid valves operate by converting electrical signals into mechanical motion, regulating the flow of hydraulic fluid. When an electrical current is applied to the solenoid, it creates a magnetic field that moves a plunger or armature, allowing or blocking the flow of fluid. This mechanism enables the steering system to adjust fluid flow with high precision, translating the captain’s commands into exact movements of the vessel’s rudder.

Importance of Reliable Steering Control

Reliable steering control is not just a convenience but a critical safety feature. Precise maneuvering is essential for avoiding obstacles, docking, and navigating through narrow passages or rough seas. Hydraulic solenoid valves ensure that these adjustments can be made quickly and accurately, reducing the risk of steering failures that could lead to accidents.

Benefits of Hydraulic Solenoid Valves in Steering Systems

- Enhanced Responsiveness: Quick and accurate response to steering inputs allows for better handling of the vessel.

- Improved Safety: Reliable operation under varying conditions ensures the safety of the crew and cargo.

- Efficient Navigation: Precision in steering helps in maintaining optimal routes and fuel efficiency.

Hatch Covers

In the operation of cargo ships, hatch covers play a crucial role in protecting valuable cargo from the harsh marine environment. Hydraulic solenoid valves are integral to the functionality of hatch covers, managing the hydraulic cylinders that open and close them. The automated control provided by these valves ensures not only efficient cargo handling but also the secure sealing necessary to prevent water ingress.

How Hydraulic Solenoid Valves Work in Hatch Cover Systems

Hydraulic solenoid valves control the flow of hydraulic fluid to the cylinders responsible for the movement of hatch covers. When activated, these valves regulate the fluid pressure, enabling the smooth and controlled operation of the covers. The precision of this control is essential for the safe and effective opening and closing of hatch covers, particularly under varying load conditions and environmental factors.

Importance of Automated Control

Automated control of hatch covers through hydraulic solenoid valves offers several key advantages:

- Efficiency: Automated systems allow for quick and smooth operation, reducing the time needed for cargo loading and unloading. This efficiency is vital for maintaining tight schedules and optimizing port turnaround times.

- Safety: Precise control minimizes the risk of accidents during hatch cover operation. By ensuring that covers open and close smoothly, the risk of damage to the cargo and the vessel is significantly reduced.

- Security: Secure sealing of hatch covers is essential to protect cargo from water ingress. Hydraulic solenoid valves ensure that hatch covers are tightly closed, safeguarding the cargo from potential water damage during transit.

Benefits of Hydraulic Solenoid Valves in Hatch Cover Systems

- Reliability: Durable and dependable operation under harsh marine conditions ensures consistent performance.

- Ease of Maintenance: Automated systems with hydraulic solenoid valves require less manual intervention, reducing maintenance efforts and costs.

- Enhanced Protection: Secure sealing capabilities protect the cargo from environmental hazards, ensuring safe delivery.

Winch Controls: Ensuring Safe and Efficient Deck Operations

Winch systems are vital for handling heavy loads on marine vessels, facilitating tasks such as lifting, lowering, and moving cargo and equipment. Hydraulic solenoid valves play a critical role in these systems by regulating the hydraulic motors that drive the winches. The precise control provided by these valves is essential for maintaining safety and efficiency in deck operations.

How Hydraulic Solenoid Valves Work in Winch Systems

Hydraulic solenoid valves control the flow and pressure of hydraulic fluid to the motors that power the winches. By modulating this flow, the valves enable precise adjustments in the speed and torque of the winch operations. This precision is crucial for tasks that require careful handling of heavy loads, ensuring that movements are smooth and controlled.

Importance of Precise Control

Precise control in winch systems offers several significant advantages:

- Safety: Accurate control of winch speed and torque minimizes the risk of accidents during lifting and handling operations. This is especially important when dealing with heavy or fragile loads, where any sudden movements could result in damage or injury.

- Efficiency: Hydraulic solenoid valves allow for smooth and efficient winch operations, reducing the time and effort required to complete tasks. This efficiency is vital for maintaining productivity and ensuring timely deck operations.

- Load Management: The ability to finely control winch operations ensures that loads are handled gently and securely, reducing the risk of damage to both the cargo and the vessel’s equipment.

Benefits of Hydraulic Solenoid Valves in Winch Systems

- Reliability: Hydraulic solenoid valves are designed to operate consistently under demanding marine conditions, providing reliable performance.

- Durability: Constructed to withstand the harsh marine environment, these valves offer long-lasting service with minimal maintenance.

- Versatility: Suitable for a wide range of winch applications, from cargo handling to anchor winches and mooring systems.

Applications of Winch Controls

- Cargo Handling: Efficiently moving heavy cargo on and off the vessel.

- Anchor Handling: Precise control during anchor deployment and retrieval.

- Mooring Operations: Ensuring secure and controlled mooring of the vessel.

Stabilizers: Enhancing Vessel Stability in Rough Seas

Stabilizer systems are crucial for improving the stability of marine vessels, particularly in rough seas. These systems rely on hydraulic solenoid valves to control the movement of stabilizing fins or tanks, significantly reducing roll and enhancing the comfort and safety of both passengers and crew.

How Hydraulic Solenoid Valves Work in Stabilizer Systems

Hydraulic solenoid valves regulate the flow of hydraulic fluid to the actuators that control the movement of stabilizing fins or the filling and emptying of stabilizer tanks. By adjusting the position of these fins or the volume of water in the tanks, the system can counteract the rolling motion of the vessel caused by waves and sea conditions. The precise control provided by hydraulic solenoid valves is essential for the effective operation of stabilizers.

Importance of Stabilizers in Marine Vessels

Stabilizers are vital for several reasons:

- Passenger Comfort: By reducing the rolling motion of the vessel, stabilizers significantly enhance the comfort of passengers, especially on cruise ships and passenger ferries.

- Safety: Improved stability reduces the risk of accidents and injuries caused by excessive rolling, ensuring the safety of both the crew and passengers.

- Operational Efficiency: Stabilizers help maintain the vessel’s operational efficiency by providing a smoother ride, which can also protect cargo and sensitive equipment from damage.

Benefits of Hydraulic Solenoid Valves in Stabilizer Systems

- Precision Control: Hydraulic solenoid valves offer precise control over the movement of stabilizing fins or the operation of stabilizer tanks, allowing for quick and accurate adjustments.

- Reliability: Designed to perform consistently under harsh marine conditions, these valves ensure the reliable operation of stabilizer systems.

- Durability: Built to withstand the demanding marine environment, hydraulic solenoid valves provide long-lasting performance with minimal maintenance requirements.

Applications of Stabilizer Systems

- Cruise Ships: Enhancing passenger comfort by minimizing rolling motion during voyages.

- Commercial Vessels: Improving safety and operational efficiency for cargo ships and tankers.

- Naval Ships: Ensuring the stability of military vessels in various sea conditions.

- Yachts and Recreational Boats: Providing a smooth and enjoyable ride for private owners and guests.

Anchor Handling: Ensuring Smooth and Controlled Anchor Operations

Anchor handling is a critical aspect of marine operations, involving the raising and lowering of anchors to secure the vessel. Hydraulic solenoid valves are essential components in this process, as they control the hydraulic windlasses that manage anchor operations. These valves provide smooth and controlled operation, ensuring the safety and efficiency of anchor handling.

How Hydraulic Solenoid Valves Work in Anchor Handling Systems

Hydraulic solenoid valves regulate the flow and pressure of hydraulic fluid to the windlasses, which are mechanical devices used to raise and lower anchors. When activated, these valves control the hydraulic motors that drive the windlasses, allowing for precise adjustments in speed and force. This precise control is crucial for handling heavy anchors smoothly and safely.

Importance of Smooth and Controlled Operation

Smooth and controlled anchor handling offers several significant benefits:

- Safety: Precise control over the raising and lowering of anchors reduces the risk of accidents and equipment damage. Controlled operations prevent sudden movements that could endanger the crew or damage the vessel.

- Efficiency: Hydraulic solenoid valves enable quick and efficient anchor operations, minimizing the time required to secure the vessel. This efficiency is vital for maintaining schedules and ensuring timely operations.

- Durability: Smooth handling reduces wear and tear on the windlasses and other related equipment, extending their service life and reducing maintenance costs.

Benefits of Hydraulic Solenoid Valves in Anchor Handling

- Precision Control: The ability to finely adjust the flow and pressure of hydraulic fluid ensures that anchors are raised and lowered with the utmost precision.

- Reliability: Hydraulic solenoid valves are designed to operate consistently under demanding marine conditions, providing reliable performance.

- Durability: Constructed to withstand the harsh marine environment, these valves offer long-lasting service with minimal maintenance.

Applications of Anchor Handling Systems

- Commercial Vessels: Ensuring secure anchoring for cargo ships, tankers, and other large commercial vessels.

- Offshore Vessels: Managing anchors for offshore supply ships, drilling rigs, and other specialized vessels.

- Naval Ships: Providing reliable anchor operations for military vessels in various sea conditions.

- Yachts and Recreational Boats: Offering smooth and controlled anchor handling for private owners and leisure vessels.

Advantages of Using Hydraulic Solenoid Valves in Marine Environments

- Precision and Accuracy: Hydraulic solenoid valves offer precise control over fluid flow, essential for maintaining optimal performance in critical marine systems.

- High Pressure Handling: Designed to operate under high hydraulic pressures, these valves ensure reliable performance in demanding marine applications.

- Durability and Reliability: Built to withstand harsh marine conditions, including saltwater exposure and extreme temperatures, hydraulic solenoid valves offer long-term durability.

- Automation and Remote Control: Easily integrated with automated control systems, these valves enable remote operation and monitoring, enhancing operational efficiency and safety.

- Energy Efficiency: Hydraulic systems controlled by solenoid valves are typically more energy-efficient, reducing power consumption and operational costs.

FAQ on “Hydraulic Solenoid Valve”

Q: What is a hydraulic solenoid valve used for?

A: It controls hydraulic fluid flow.

Q: How does a hydraulic solenoid valve work?

A: It converts electrical signals to control fluid flow.

Q: What are the benefits of using hydraulic solenoid valves in marine applications?

A: They enhance control, efficiency, and safety.

Q: Can hydraulic solenoid valves help reduce maintenance costs?

A: Yes, they reduce wear and maintenance needs.

Conclusion

In summary, hydraulic solenoid valves are essential for various critical marine applications, including steering gear systems, ballast control, engine cooling, fuel injection, bilge pump systems, anchor handling, and deck machinery operations. Their precise control and reliable performance are vital for enhancing safety, efficiency, and operational effectiveness in the marine industry. By leveraging advanced applications of hydraulic solenoid valves, marine engineers and operators can achieve significant improvements in vessel performance and safety. Consider exploring these advanced uses to optimize your marine operations and stay ahead in the industry.