Indicator Diagram

Indicator diagram play a critical role in monitoring and maintaining marine engine performance. These diagrams graphically represent the pressure changes inside the engine cylinders, helping engineers understand how well the engine is operating. By analyzing these patterns, engineers can diagnose a wide range of issues, from improper fuel injection timing to air leaks and exhaust valve problems. Regularly reviewing indicator diagrams allows for early detection of potential defects, helping prevent costly breakdowns and improving overall engine efficiency. In marine applications, where reliability is paramount, indicator diagrams are an essential tool for ensuring smooth engine operations and timely maintenance.

What is an Indicator Diagram?

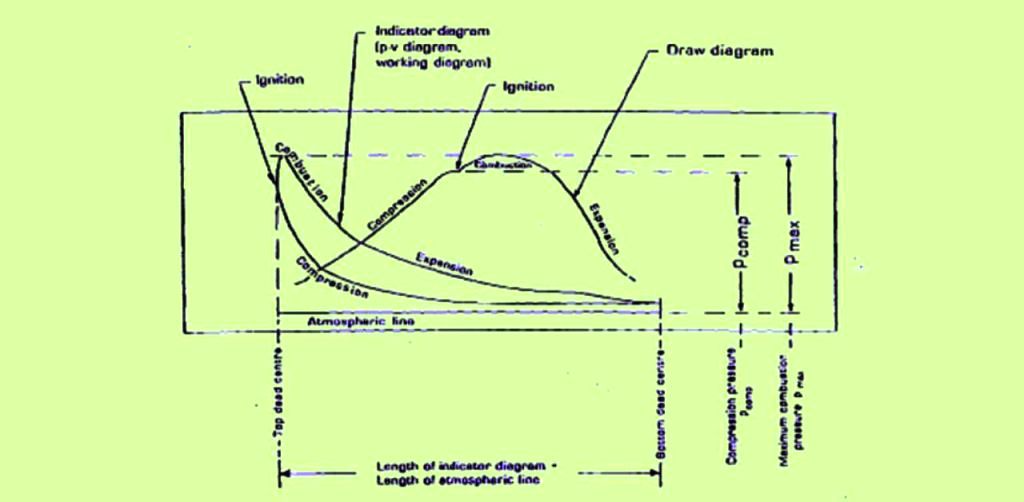

An indicator diagram is a graphical representation of the pressure variations inside an engine cylinder during its working cycle. These diagrams are essential for evaluating engine performance, as they provide a clear visual of how well the engine is functioning in real-time.

Definition and Explanation of an Indicator Diagram

An indicator diagram shows the relationship between the pressure in the cylinder and the position of the piston throughout the engine cycle. The data collected from the cylinder’s pressure is plotted against the piston movement, creating a unique curve that reflects engine health and performance. This curve helps engineers detect abnormalities such as timing issues, leaks, or inefficiencies in fuel combustion.

How Indicator Diagrams Monitor Engine Performance

Indicator diagrams are key in diagnosing engine performance. By analyzing the shape of the diagram, engineers can identify faults like incorrect fuel injection timing, cylinder wear, or valve malfunction. This real-time feedback allows for quick adjustments and efficient maintenance.

Types of Indicator Diagrams

- Power Card: Displays the complete pressure cycle of the engine, showing how the engine generates power during each stroke.

- Compression Card: Focuses on the compression phase of the engine, used to diagnose issues related to the air intake, compression, and valve operation.

Both types provide critical insights into engine performance and are integral to maintaining the health of marine engines.

Purpose of Indicator Cards

Indicator cards serve as a vital tool for diagnosing engine performance by recording the pressure inside a cylinder during various stages of the engine cycle. These cards provide engineers with a detailed insight into how effectively the engine is operating and help in identifying potential issues before they become serious problems.

The Role of Indicator Cards in Engine Diagnostics

The primary role of indicator cards is to assess engine health by visually representing how pressure changes within the cylinder. By analyzing the patterns on the card, engineers can diagnose common engine problems such as fuel injection issues, valve leaks, and compression losses. This helps in fine-tuning the engine for optimal performance.

Understanding the Relationship Between Pressure and Piston Movement

Indicator cards graphically display the pressure generated at different stages of piston movement, allowing engineers to observe how well the engine’s combustion process is functioning. Deviations from the expected pressure curve signal potential engine defects.

Monitoring Engine Efficiency and Detecting Issues Early

Indicator cards are crucial for monitoring engine efficiency. They help engineers identify abnormalities early, ensuring timely maintenance and reducing the risk of severe damage. Regular analysis of indicator cards can improve engine efficiency, extend lifespan, and prevent costly repairs.

How to Detect Defects Using Indicator Diagrams

Indicator diagrams provide valuable insights into engine performance by highlighting deviations from normal pressure patterns. These deviations can help engineers pinpoint specific engine problems quickly and accurately.

How Deviations in the Diagram Can Point to Specific Engine Problems

- Early or Late Injection: If fuel is injected too early or too late, the pressure curve will shift from its normal position, indicating an issue with the fuel timing.

- Exhaust Valve Leaks: A leak in the exhaust valve will cause an abnormal pressure drop in the diagram during the exhaust stroke, signaling a compression loss.

- Scavenge Port Blockages: When scavenge ports are blocked, the air supply to the cylinder is restricted, leading to lower pressure during the intake stroke, which is visible as a flattened curve.

Each of these deviations helps identify specific defects in the engine, allowing for precise diagnostics.

The Importance of Regular Indicator Diagram Monitoring for Maintaining Engine Health

Regular monitoring of indicator diagrams is essential for ensuring that the engine operates at peak efficiency. By consistently analyzing these diagrams, engineers can detect minor issues before they escalate into major failures, thus maintaining engine health, preventing costly breakdowns, and extending the engine’s operational life.

Fault Finding from Draw Card/Indicator Diagram

Indicator diagrams or draw cards are essential tools for diagnosing engine issues. By analyzing deviations in pressure patterns, specific engine problems can be identified. Below are common faults detected through the indicator diagram along with their potential causes.

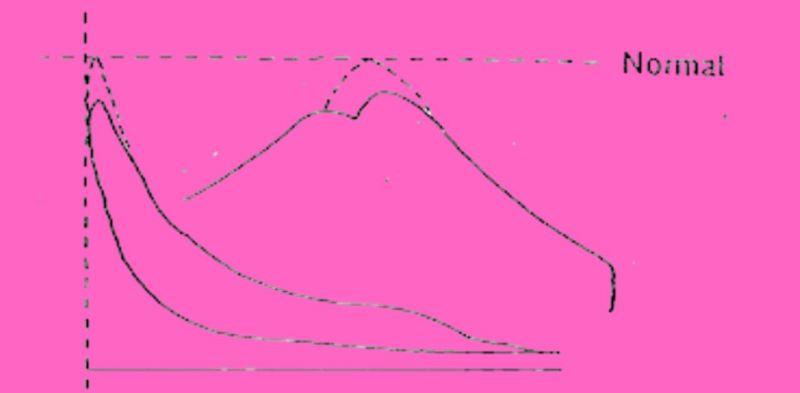

1. Maximum Pressure Too Low, but Compression Pressure is Normal

- Fuel Injection Too Late: If fuel is injected too late, the combustion process occurs after the piston has reached its optimal position, reducing the maximum pressure.

- Fuel Pressure Too Low: Low fuel pressure results in insufficient fuel delivery, which weakens combustion and lowers peak pressure.

- Defective Fuel Valve(s): Faulty fuel valves may cause improper fuel atomization or delayed injection, reducing the efficiency of combustion.

- Defective Fuel Pump Suction Valve: A malfunction in the suction valve can limit fuel delivery, leading to low peak pressure.

- Exceptionally Poor Fuel (Bad Ignition Properties): Low-quality fuel with poor ignition characteristics delays combustion, leading to lower peak pressure.

- Fuel Pump Lead Too Little: If the fuel pump lead is too small, fuel is injected too late, which reduces maximum pressure.

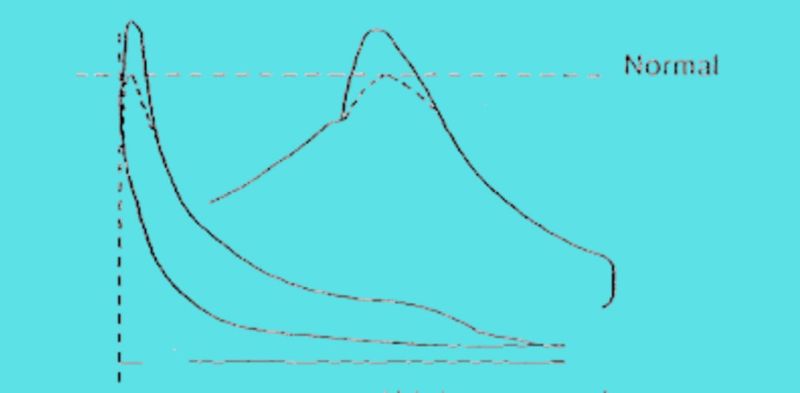

2. Maximum Pressure is High, but Compression Pressure is Normal

- Fuel Injection Too Early (Fuel Pump Lead Too Large): When fuel is injected too early, it ignites prematurely, causing a higher peak pressure before the piston reaches its optimal position. This early combustion increases the maximum pressure without affecting compression pressure.

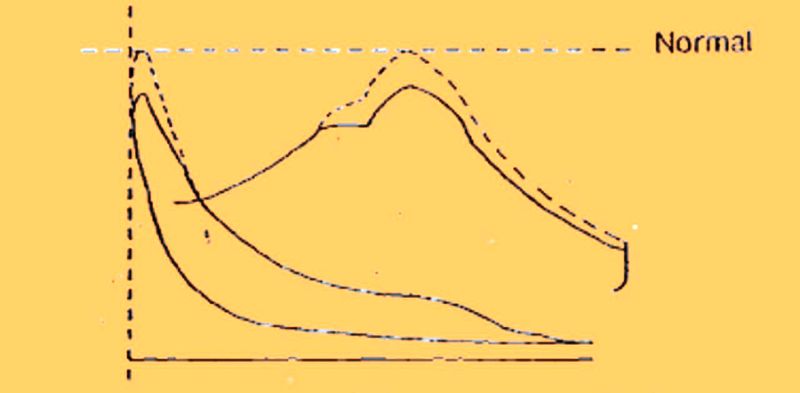

3. Both Maximum Pressure and Compression Pressure are Low

- Leakages, Increased Cylinder Volume, or Fouling: Any leakage in the cylinder (e.g., through the gasket or piston rings), increased cylinder volume, or fouling of the combustion space reduces both compression and peak pressures.

- Piston Ring Blow-by: When piston rings are worn or damaged, combustion gases escape past the rings, reducing compression pressure and causing a lower maximum pressure.

- Exhaust Valve Seat Leakage: A leaking exhaust valve allows gases to escape, resulting in a drop in both compression and maximum pressures.

- Piston Crown Burnt: A damaged or burnt piston crown can reduce the cylinder’s capacity to compress air, lowering both pressures.

- Low Scavenge Pressure: Insufficient scavenge air supply reduces the air-fuel mixture, leading to poor combustion and lower pressures.

- Fouling of Exhaust and/or Air System: Fouled exhaust or air systems restrict airflow, resulting in insufficient compression and lower combustion efficiency, thus lowering both pressures.

Importance of Proper Analysis and Maintenance

Proper analysis and maintenance of marine engines are critical for ensuring optimal performance and preventing costly breakdowns. Indicator diagrams provide a valuable tool for diagnosing engine health and performance, but interpreting these diagrams accurately is essential to derive their full benefits. By following best practices and maintaining a regular schedule of indicator readings, engineers can significantly improve the reliability and longevity of marine engines.

Best Practices for Interpreting Indicator Diagrams

- Regular Monitoring: Perform indicator diagram readings at regular intervals to track engine performance over time.

- Compare with Baseline Data: Always compare current readings with baseline data from the engine’s normal operating condition to identify deviations.

- Analyze Key Parameters: Focus on critical parameters such as maximum pressure, compression pressure, and the shape of the pressure curve to detect issues like fuel injection problems or valve leaks.

- Consult Manufacturer Guidelines: Always interpret the indicator diagram in accordance with the engine manufacturer’s specifications to ensure accurate diagnostics.

The Need for Regular Indicator Diagram Readings to Ensure Engine Longevity

Regular indicator diagram readings help engineers identify issues before they escalate into serious problems. Detecting abnormalities such as poor fuel combustion, air leaks, or valve defects early on ensures that corrective actions can be taken immediately. Consistent monitoring helps maintain engine efficiency, reduce wear and tear on critical components, and prolong engine life.

How to Use Indicator Diagrams to Optimize Maintenance Schedules and Prevent Major Engine Failures

- Predictive Maintenance: By identifying trends in the indicator diagram, engineers can forecast potential failures and schedule maintenance before a breakdown occurs.

- Preventive Actions: Regular analysis helps detect early signs of wear, fuel system issues, or valve problems, allowing for preventive actions to be taken during routine maintenance.

- Reduce Downtime: Addressing issues detected by indicator diagrams during planned maintenance can significantly reduce unplanned engine downtime and avoid major repairs.

FAQs on Indicator Diagram

Q- What is the theory of an indicator diagram?

A- An indicator diagram represents the pressure changes inside an engine cylinder during the engine cycle, helping to analyze performance.

Q- What is the importance of an indicator diagram?

A- Indicator diagrams are crucial for diagnosing engine performance issues, detecting faults early, and ensuring optimal engine efficiency.

Q- What is the indicator diagram plotted between?

A- An indicator diagram is plotted between cylinder pressure and the piston position or volume, helping visualize engine performance.

Q- What is a PV indicator diagram?

A- A PV indicator diagram plots pressure (P) against volume (V) within the engine cylinder, showing how pressure varies during the engine cycle.

Conclusion

Indicator diagrams are invaluable tools in marine engine diagnostics, offering clear insights into engine performance and early detection of potential issues. By carefully analyzing pressure variations within the cylinder, engineers can identify problems like improper fuel injection, valve leaks, and piston ring wear before they escalate into costly repairs. Regular use of indicator cards not only ensures optimal engine efficiency but also helps maintain the engine’s longevity by addressing small defects early on. For reliable marine engine performance and to avoid unexpected breakdowns, it’s essential to incorporate regular indicator diagram monitoring into your maintenance routine.