Infrared Sensor

In marine engineering, IR sensors are critical for the efficient operation and safety of engine rooms and ship machinery. These sensors are integral to monitoring systems, ensuring optimal performance and preventing potential hazards.

This comprehensive guide focuses on IR sensors within the marine industry, delving into their types, working principles, and key applications. Designed for marine engineers and professionals, this article provides essential insights into how IR sensors contribute to the maintenance and functionality of shipboard systems. We will explore the components and operations of active and passive IR sensors, their vital features, and their applications in engine rooms and other ship machinery. By the end of this guide, you’ll have a thorough understanding of how IR sensors enhance marine engineering and ensure the smooth operation of maritime vessels.

Understanding Infrared (IR) Sensors in Marine Applications

Definition: What are IR Sensors?

Infrared (IR) sensors are electronic devices that detect and measure infrared radiation emitted by objects based on their temperature. These sensors can either emit infrared radiation and measure the reflection or solely detect the infrared radiation naturally emitted by objects. In the marine industry, IR sensors play a crucial role in various applications, such as monitoring engine room conditions, detecting overheating components, and ensuring the safety and efficiency of ship machinery.

Importance: Why IR Sensors are Essential in Today’s Technology Landscape

IR sensors are vital in modern technology due to their non-contact measurement capabilities, making them indispensable in environments where direct contact is impractical or dangerous. In marine applications, IR sensors help:

- Enhance Safety: By detecting overheating in engines and other machinery, preventing potential fire hazards.

- Improve Efficiency: Monitoring temperatures and machinery conditions to ensure optimal performance and reduce downtime.

- Maintenance: Providing early warnings for maintenance needs, thus extending the lifespan of critical components and reducing repair costs.

History: Brief History and Evolution of IR Sensor Technology

The concept of infrared technology dates back to the early 1800s when Sir William Herschel discovered infrared radiation. The first practical IR sensors were developed during World War II for military applications, including night vision and thermal imaging. Over the decades, advancements in semiconductor technology have significantly improved the sensitivity, accuracy, and affordability of IR sensors.

In the marine industry, the adoption of IR sensors began to gain traction in the late 20th century as the need for more reliable and efficient monitoring systems grew. Today, IR sensors are integral components in the automation and safety systems of modern ships, providing critical data for the safe and efficient operation of maritime vessels.

Types of IR Sensors in Marine Applications

Overview: Classification of IR Sensors

Infrared (IR) sensors are classified into two main types: Active IR Sensors and Passive IR Sensors (PIR). Each type has distinct components and operating principles, making them suitable for various applications within the marine industry.

Active IR Sensors

Components: Active IR sensors consist of an emitter, typically an IR LED, and a detector, such as a photodiode or phototransistor.

Operation: These sensors work by emitting infrared radiation towards an object. The emitted IR light reflects off the object and returns to the detector, which measures the intensity and wavelength of the reflected light. This measurement helps in determining the presence, distance, or movement of objects.

Applications:

- Proximity Sensors: Used in marine automation systems to detect obstacles and ensure safe navigation.

- Obstacle Detection: Essential for robotic systems and automated machinery in the engine room, preventing collisions and accidents.

- Line-Following Robots: Utilized in automated guided vehicles (AGVs) within shipyards and engine rooms to follow designated paths.

Passive IR Sensors (PIR)

Components: Unlike active IR sensors, passive IR sensors do not have an emitter. They consist solely of a detector that senses infrared radiation naturally emitted by objects.

Operation: PIR sensors detect changes in infrared radiation within their field of view. When an object, such as a person or a piece of machinery, emits IR radiation, the sensor measures these changes to detect motion or temperature variations.

Applications:

- Motion Detection: Used in security systems onboard ships to monitor unauthorized access and ensure the safety of personnel.

- Automatic Lighting: Implemented in engine rooms and other ship areas to control lighting based on occupancy, enhancing energy efficiency.

- Security Systems: Integral in surveillance systems, helping to detect intruders or unusual activity in restricted areas.

Active IR Sensors in Marine Applications

Components

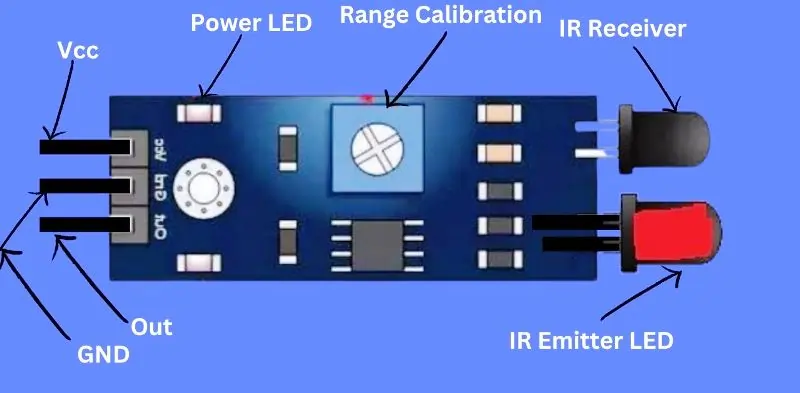

Active IR sensors consist of several key components that work together to detect objects and measure distances. Here’s a detailed description of each component:

- IR Emitter LED:

- Function: Emits infrared radiation towards an object.

- Description: An IR LED that produces light in the infrared spectrum, which is invisible to the human eye but detectable by IR sensors.

- IR Receiver:

- Function: Detects the reflected IR radiation from an object.

- Description: Typically a photodiode or phototransistor that is sensitive to infrared light. It converts the received IR radiation into an electrical signal.

- Distance Adjust (Range Calibration):

- Function: Adjusts the sensitivity and detection range of the sensor.

- Description: A potentiometer or adjustable resistor that allows users to set the desired detection range for the IR sensor.

- Power LED:

- Function: Indicates the power status of the sensor.

- Description: A visible LED that lights up when the sensor is powered on, providing a visual indication that the sensor is active.

- Vcc:

- Function: Provides the operating voltage to the sensor.

- Description: The power supply pin that connects to the positive terminal of the power source, typically 3.3V or 5V.

- GND:

- Function: Provides the ground reference for the sensor.

- Description: The ground pin that connects to the negative terminal of the power source, completing the electrical circuit.

- Out:

- Function: Outputs the signal indicating the detection of an object.

- Description: The signal pin that outputs a high or low voltage, depending on whether an object is detected within the sensor’s range.

- Obstacle LED:

- Function: Indicates the presence of an object within the detection range.

- Description: A visible LED that lights up when the sensor detects an object, providing a visual confirmation of detection.

Working Principle

Active IR sensors operate based on the principles of emission and reflection of infrared light.

- Emission:

- Process: The IR Emitter LED emits infrared light towards an object in its path.

- Details: The emitted IR light travels in a straight line and illuminates the object. This emission is continuous or pulsed, depending on the sensor’s design.

- Reflection:

- Process: The emitted IR light reflects off the surface of the object and returns towards the sensor.

- Details: The IR Receiver detects the reflected IR light. The intensity and angle of the reflected light are measured by the receiver, which converts this light into an electrical signal.

- Signal Processing:

- Process: The electrical signal from the IR receiver is processed to determine the presence and distance of the object.

- Details: The sensor’s circuitry analyzes the signal strength and timing to ascertain if an object is within the detection range. The Distance Adjust component allows fine-tuning of this range, ensuring accurate detection based on the specific application requirements.

Applications in Marine Industry

- Proximity Sensors: Used in marine automation systems to detect obstacles and ensure safe navigation.

- Obstacle Detection: Essential for robotic systems and automated machinery in the engine room, preventing collisions and accidents.

- Line-Following Robots: Utilized in automated guided vehicles (AGVs) within shipyards and engine rooms to follow designated paths.

- Applications

- Proximity Sensors: How they work and where they are used

- Obstacle Detection: Use in robotics and automation

- Line-Following Robots: Role in navigation

Passive IR Sensors (PIR) in Marine Applications

Components

Passive IR sensors (PIR) are designed to detect infrared radiation emitted by objects in their field of view. Unlike active IR sensors, PIR sensors do not emit any radiation; they solely detect the infrared radiation. Here’s a detailed description of the components involved:

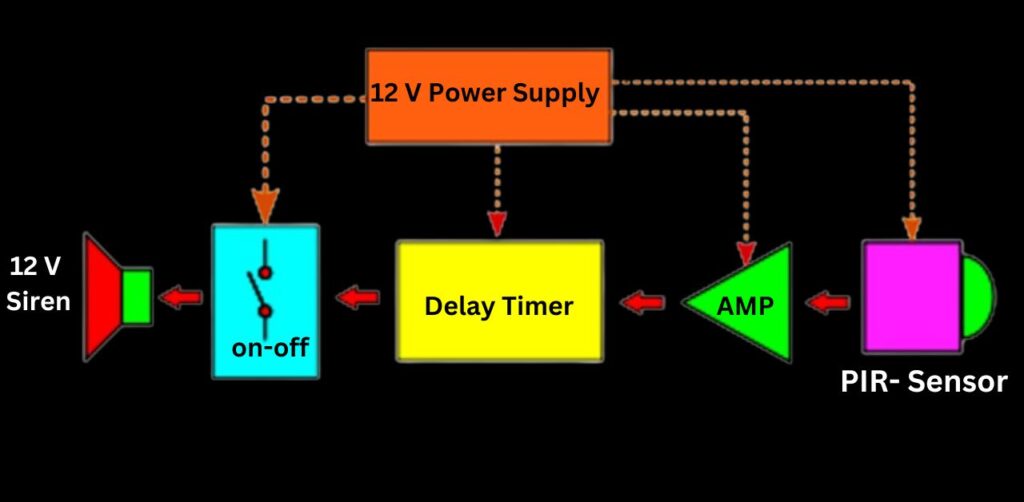

- 12 V Power Supply:

- Function: Provides the necessary operating voltage for the PIR sensor and associated components.

- Description: A stable 12-volt power source that powers the entire PIR sensor system, ensuring consistent performance.

- PIR Sensor:

- Function: Detects infrared radiation emitted by objects.

- Description: The core component that senses changes in infrared radiation within its detection range. It typically consists of a pyroelectric sensor that can detect the levels of IR radiation.

- AMP (Amplifier):

- Function: Amplifies the signal received from the PIR sensor.

- Description: An electronic amplifier that boosts the weak signal from the PIR sensor to a level that can be processed by the control circuit.

- Delay Timer:

- Function: Controls the duration for which the output remains active after detection.

- Description: A timing circuit that allows users to set a delay period, ensuring the sensor output remains active for a specific duration after movement is detected.

- On-Off Switch:

- Function: Manually controls the power to the PIR sensor system.

- Description: A switch that allows the user to turn the PIR sensor system on or off as needed.

- 12 V Siren:

- Function: Emits an audible alert when the PIR sensor detects movement.

- Description: An audible alarm that activates when the sensor detects infrared radiation changes, alerting to the presence of an object or person.

Working Principle

PIR sensors operate based on the detection of infrared radiation emitted by objects. They are particularly sensitive to the heat emitted by living beings.

- Detection:

- Process: The PIR sensor detects infrared radiation emitted by objects in its field of view.

- Details: The pyroelectric sensor within the PIR sensor is sensitive to the IR radiation naturally emitted by objects and living beings. When an object enters the sensor’s detection range, it absorbs the IR radiation and converts it into an electrical signal.

- Movement Detection:

- Process: The PIR sensor measures changes in infrared radiation to detect movement.

- Details: The PIR sensor continuously monitors the IR radiation levels in its field of view. When a moving object causes a sudden change in IR radiation, the sensor detects this variation. The amplified signal from the sensor is processed to determine movement. The delay timer ensures the output remains active for a predetermined duration, providing a stable detection signal.

Applications in Marine Industry

- Motion Detection:

- Use in Security Systems: PIR sensors are widely used in marine security systems to detect unauthorized access and movement in restricted areas. They help enhance the safety of the vessel by providing early warnings of intruders.

- Automatic Lighting:

- Enhancing Energy Efficiency: PIR sensors are used to control lighting systems in engine rooms, hallways, and other areas of the ship. Lights automatically turn on when movement is detected and turn off after a specified period of inactivity, conserving energy.

- Security Systems:

- Importance in Surveillance: PIR sensors are integral components of surveillance systems onboard ships. They trigger alarms and activate security cameras when movement is detected, ensuring continuous monitoring and protection of the vessel.

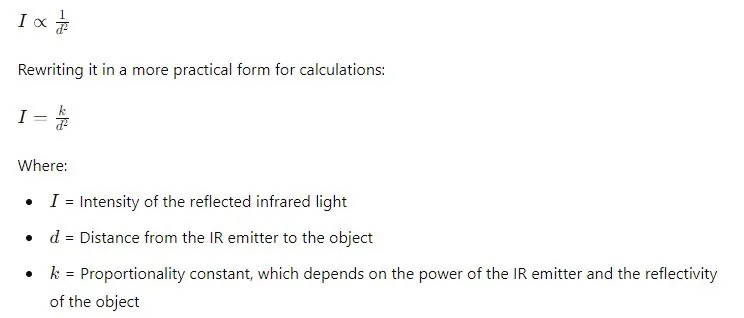

Formula for IR Sensors

One common formula related to IR sensors, especially for calculating the distance of an object based on the intensity of the reflected infrared light, is the inverse square law. This law states that the intensity of light (I) is inversely proportional to the square of the distance (d) from the source:

Key Features of IR Sensors

| Feature | Description |

|---|---|

| Wavelength | IR sensors typically operate within the wavelength range of 700 nanometers (nm) to 1 millimeter (mm). This range allows them to detect infrared radiation emitted by various objects, making them versatile for different applications. |

| Range | The detection capabilities of IR sensors can vary significantly, from a few centimeters to several meters. This variability makes them suitable for both short-range applications, like proximity sensing, and long-range applications, such as motion detection in larger areas. |

| Sensitivity | IR sensors offer adjustable sensitivity, allowing them to be fine-tuned for specific applications. This adjustability ensures that the sensors can accurately detect objects or changes in infrared radiation in different environments, enhancing their reliability and effectiveness. |

Applications of IR Sensors

| Application | Description | Key Points |

|---|---|---|

| Remote Controls | IR sensors are a cornerstone of modern household appliances, primarily used in remote control systems. These sensors facilitate the wireless operation of devices such as televisions, air conditioners, and audio systems. | Ubiquity: Found in nearly every home, providing convenience and ease of use. Functionality: Emit IR signals from the remote, detected by the appliance’s IR receiver, allowing control of functions like power, volume, and settings. Advantages: Offer a reliable, cost-effective solution for wireless communication between devices. |

| Motion Detection | Motion detection is a critical application of IR sensors, particularly in security and automation systems. PIR (Passive Infrared) sensors detect movement by measuring changes in infrared radiation. | Security: Integral to security systems, triggering alarms or activating cameras when movement is detected. Automation: Control lighting, HVAC systems, and other equipment based on presence or absence of people, improving energy efficiency and comfort. Reliability: Provide a non-intrusive and reliable way to monitor and respond to movement. |

| Proximity Sensors | IR sensors are widely used as proximity sensors in various devices, including smartphones, automatic doors, and robots. | Smartphones: Detect when the phone is close to the user’s face, enabling features like turning off the display during calls. Automatic Doors: Ensure automatic doors open and close smoothly, improving accessibility and convenience. Robots: Aid in navigation and obstacle avoidance, enhancing efficiency and safety in robotic operations. |

| Temperature Measurement | IR sensors are crucial in measuring temperature without direct contact, using the principle of detecting infrared radiation emitted by objects. | Thermal Cameras: Detect heat patterns for real-time visualization of temperature variations, essential for surveillance and firefighting. Medical Devices: Non-contact thermometers and other medical devices use IR sensors for accurate, hygienic body temperature measurement. Industrial Processes: Monitor equipment and process temperatures, ensuring optimal performance and preventing overheating or equipment failure. |

Advantages of IR Sensors

| Advantage | Description | Key Points |

|---|---|---|

| Non-contact Measurement | IR sensors can detect objects or measure temperature without requiring physical contact, which is particularly useful in environments where contact is impractical or dangerous. | Safety: Reduces risk in hazardous environments. Hygiene: Ideal for medical applications, ensuring non-invasive measurements. Durability: Less wear and tear on the sensor and objects. |

| Low Cost | IR sensors offer an economical solution for various applications, making them cost-effective for widespread use and easy to integrate into existing systems. | Affordable: Lower production and maintenance costs. Scalable: Easy to implement in large quantities. Accessible: Cost-effectiveness promotes widespread adoption across different sectors. |

| Versatility | IR sensors are suitable for a wide range of industries and applications, from consumer electronics to industrial automation and medical devices. | Wide Application Range: Used in household appliances, security systems, industrial monitoring, and more. Adaptability: Can be customized for specific needs. Innovative: Facilitates advancements in various fields. |

Disadvantages of IR Sensors

| Disadvantage | Description | Key Points |

|---|---|---|

| Limited Range | IR sensors generally have a shorter detection range compared to other sensor types, which can limit their effectiveness in certain applications requiring long-distance detection. | Comparison: Ultrasonic and radar sensors often provide longer detection ranges. Applications: May not be suitable for large open areas or long-range monitoring. |

| Interference | IR sensors can be affected by ambient light and other sources of infrared radiation, which can interfere with their operation and lead to inaccurate readings. | Challenges: Sunlight, artificial lighting, and heat sources can cause interference. Solutions: Requires careful placement and shielding to minimize interference. |

| Accuracy | IR sensors may experience reduced accuracy in certain environmental conditions, such as smoke, fog, or dust, which can scatter infrared radiation and affect sensor readings. | Conditions: Performance can degrade in environments with particulates or vapor. Mitigation: Regular maintenance and calibration can help maintain accuracy. |

FAQ on Infrared Sensors

Q: How do infrared sensors work?

A: They emit or detect IR radiation and convert it to an electrical signal.

Q: What are common applications of IR sensors?

A: Used in remote controls, motion detection, and temperature measurement.

Q: What are the advantages of using IR sensors?

A: They offer non-contact measurement, low cost, and versatility.

Conclusion

Infrared sensors are essential components in modern technology, offering reliable and versatile solutions for a variety of applications, from household appliances to industrial automation and marine engineering. Their ability to provide non-contact measurement, low cost, and adaptability make them invaluable in enhancing efficiency, safety, and performance across numerous fields. Understanding the types, working principles, and applications of IR sensors empowers professionals to leverage this technology effectively, ensuring optimal results in their respective industries.