The maritime industry is in the midst of a profound transformation, driven by the latest trends in marine engineering. The era of being solely about mechanical repairs and fabrication is giving way to a new age defined by digitalization, sustainability, and hyper-efficiency. From the shipyard to the high seas, innovative technologies are reshaping how vessels are designed, operated, and maintained.

Staying competitive in this evolving landscape requires a forward-thinking approach, embracing the technologies that promise smarter, cleaner, and safer marine operations. Here are five key trends steering the future of the industry.

1. Artificial Intelligence and Predictive Analytics

From Reactive Repairs to Proactive Intelligence

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is moving the industry beyond basic sensor data. These powerful systems analyze vast, real-time datasets—encompassing engine performance, fuel consumption, weather conditions, and hull resistance—to generate actionable insights.

Key Benefits:

- Optimized Performance: AI algorithms can autonomously adjust course and speed for maximum fuel efficiency, considering variables like weather and ocean currents.

- True Predictive Maintenance: ML models predict equipment failures weeks in advance by recognizing subtle patterns and anomalies, allowing for planned interventions and eliminating unexpected downtime.

- Enhanced Decision-Making: Captains and engineers receive data-driven recommendations to optimize everything from cargo loading to route planning.

2. The Green Fuel Revolution: Decarbonizing propulsion

Powering the Shift to a Sustainable Future

With stringent International Maritime Organization (IMO) regulations and a global push for net-zero emissions, the quest for alternative fuels is accelerating. This is more than a trend; it’s a fundamental overhaul of marine propulsion.

The Contenders:

- Green Methanol & Biofuels: Offering a lower-carbon footprint and easier integration with existing engine technology.

- Liquid Hydrogen & Ammonia: Positioned as the ultimate zero-emission solutions for the long term, though challenges in storage and handling remain at the forefront of engineering research.

- Battery-Electric & Hybrid Systems: Becoming standard for short-sea shipping, ferries, and port vessels, significantly reducing noise and air pollution in coastal areas.

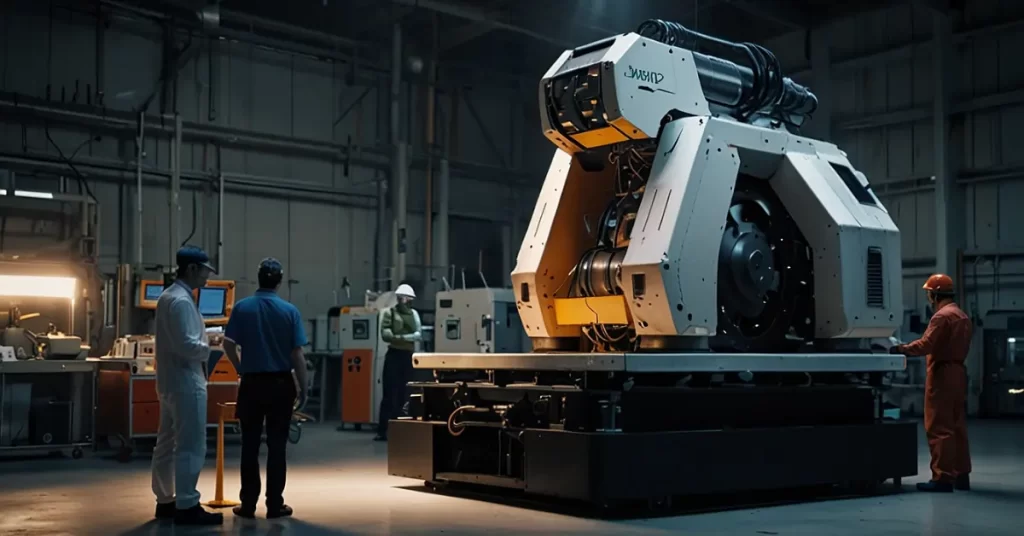

3. Robotics, Automation, and Advanced Fabrication

Enhancing Precision, Safety, and Efficiency

Automation is revolutionizing marine operations, both in construction and maintenance. This trend encompasses everything from the shipyard floor to underwater inspections.

Applications in Action:

- Automated Guided Vehicles (AGVs) & Robotic Welding: In modern shipyards, these technologies ensure unparalleled precision in fabrication, leading to stronger structures and faster build times.

- Unmanned Inspection Vehicles: Drones and remotely operated vehicles (ROVs) conduct hazardous hull and infrastructure inspections, enhancing crew safety and providing high-definition data without dry-docking.

- 3D Printing/Additive Manufacturing: Enables the on-demand production of complex, obsolete, or custom parts directly in port, drastically reducing supply chain delays and inventory costs.

4. Digital Twin Technology

Creating a Virtual Replica of the Physical World

A Digital Twin is a dynamic, virtual model of a physical asset—like a ship or an offshore platform. This technology allows for simulation, analysis, and control in a risk-free digital environment.

Why It’s Transformative:

- Design & Prototyping: Engineers can test new systems and modifications in the digital twin first, identifying potential issues long before physical installation.

- Crew Training: Personnel can be trained on complex operations and emergency scenarios using the virtual model, ensuring preparedness without impacting the actual vessel.

- Lifecycle Management: The twin evolves with the physical asset, providing an invaluable historical record and a platform for testing the impact of future changes.

5. Advanced Materials and Smart Coatings

Building Smarter, Lighter, and More Durable Vessels

Innovation in materials science is directly contributing to greater efficiency and longer asset lifecycles. The goal is to build vessels that are stronger, lighter, and more resistant to the harsh marine environment.

Breakthrough Areas:

- High-Strength Composites & Alloys: These materials reduce the overall weight of vessels, leading to significant gains in fuel efficiency and payload capacity.

- Smart Hull Coatings: Next-generation coatings do more than just prevent fouling. Some are designed to “self-polish” more effectively, while others can indicate coating wear or even repair minor damage autonomously.

- Corrosion-Resistant Innovations: New alloys and treatment processes are extending the service life of critical components exposed to seawater, reducing maintenance frequency and costs.

Navigating the Future

The horizon of marine engineering is bright with innovation. The convergence of digital technology and a steadfast commitment to sustainability is creating a new paradigm for the industry. Success in this new era will belong to those who embrace these trends, adopting smarter processes and cleaner technologies.

For shipowners and operators, the message is clear: the future is not just about maintaining assets but about continuously evolving them. By partnering with engineering services that are fluent in both robust traditional practices and these transformative advancements, you can ensure your fleet is not just ready for the future, but leading it.

Conclusion: Navigating the Future with the Latest Trends in Marine Engineering

The horizon of marine engineering is bright with innovation. The latest trends in marine engineering—from AI-driven analytics and green fuel systems to advanced robotics and digital twins—are not merely incremental changes; they represent a fundamental shift towards a more intelligent, efficient, and sustainable maritime industry. Success in this new era will belong to those who proactively embrace these technologies, adopting smarter processes and cleaner solutions.

For shipowners and operators, the message is clear: the future is not just about maintaining assets but about continuously evolving them. By partnering with engineering services that are fluent in both robust traditional practices and these transformative advancements, you can ensure your fleet is not just ready for the future, but leading it. The journey of innovation is continuous, and staying ahead means committing to the ongoing integration of these cutting-edge trends.