Main Engine Reversing

Main engine reversing in marine diesel engines is a critical function that allows ships to change their direction, ensuring smooth maneuvering in harbors, during docking, or in emergency situations. This process involves altering the engine’s rotational direction, which is essential for controlling the vessel’s movements both forward and backward. Without a reliable reversing mechanism, the ability to safely navigate through tight spaces or respond quickly to hazards would be compromised, making it an indispensable feature in marine operations. Understanding how this system works is crucial for maintaining efficiency and safety on board.

What is Main Engine Reversing?

Main engine reversing is the process of changing the rotational direction of a marine diesel engine to enable the ship to move backward. This function is achieved by adjusting the timing of the engine’s camshaft and fuel injection system, allowing the engine to operate in reverse mode. Reversing is a crucial aspect of a ship’s propulsion system, particularly for maneuvering in confined spaces such as ports or during docking operations.

Definition and Purpose of Engine Reversing in Marine Diesel Engines

The main purpose of engine reversing is to provide ships with the ability to move in reverse, offering full control over the vessel’s direction. This is especially important for large ships that lack independent propulsion mechanisms like bow thrusters for fine-tuned maneuverability.

Why Reversing is Crucial for Ships’ Maneuverability and Safe Operation

Reversing is vital for the safe and efficient operation of ships. It allows vessels to slow down, stop, and move backward when needed, helping the crew avoid collisions and execute precise movements in narrow or congested waters. Without the ability to reverse, a ship’s maneuverability would be severely limited, making operations such as docking, anchoring, and emergency braking difficult and risky.

Main Engine Reversing Mechanism

The main engine reversing mechanism in marine diesel engines is designed to reverse the engine’s rotational direction, enabling the ship to move backward. This is a complex process that involves the precise coordination of several components, including the camshaft, reversing linkage, and control systems, all of which work together to ensure smooth and efficient reversing.

Detailed Explanation of the Reversing Mechanism in Marine Diesel Engines

The reversing mechanism begins with the adjustment of the engine’s camshaft. In normal forward operation, the camshaft controls the timing of the fuel injection and valve operations. When reversing is required, the camshaft’s timing is altered to ensure that fuel is injected at the right moment for the engine to rotate in the opposite direction. This adjustment allows the engine to reverse its rotation while maintaining efficient combustion and performance.

Components Involved: Reversing Linkage, Camshaft, and Control Systems

- Reversing Linkage: The reversing linkage is the mechanical connection that shifts the camshaft’s position, enabling it to change the valve timing for reverse operation. This linkage is often controlled by hydraulic or pneumatic systems to ensure precise movement.

- Camshaft: The camshaft plays a key role in determining when the engine’s intake and exhaust valves open and close. During reversing, the camshaft’s timing is shifted to allow for the reverse operation, ensuring that the engine functions smoothly in both directions.

- Control Systems: Modern control systems manage the entire reversing process, often integrating with the ship’s bridge controls. These systems ensure the correct positioning of the camshaft and fuel injection timing, coordinating the complex actions needed for reversing the engine.

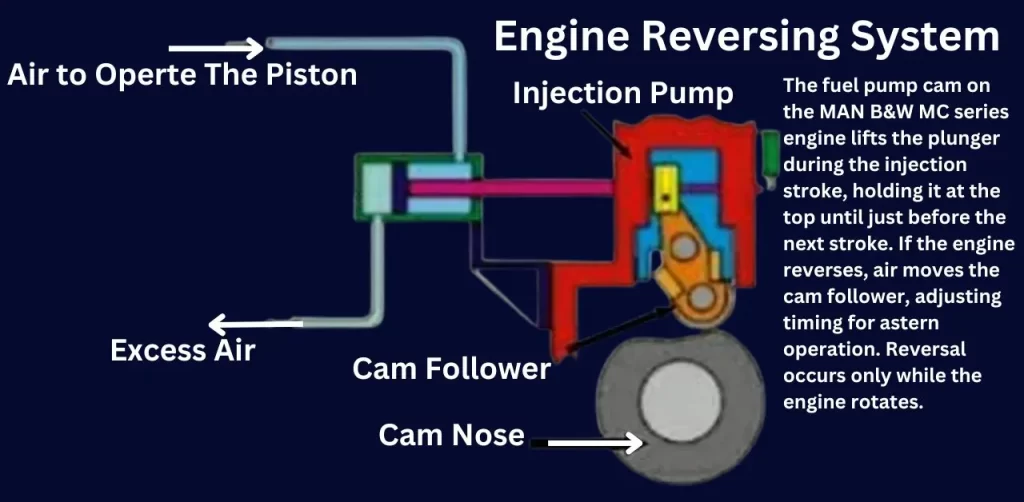

The Role of the Starting Air Distributor in Changing the Engine’s Rotational Direction

The starting air distributor is responsible for directing compressed air into the engine’s cylinders during startup. In the reversing process, it plays a crucial role by controlling the flow of starting air to the appropriate cylinders to initiate rotation in the opposite direction. By directing air to specific cylinders in reverse sequence, the starting air distributor helps the engine begin turning in the desired direction, facilitating smooth reversal of the ship’s movement.

Camshaft Reversing Process

The camshaft reversing process is a crucial element in enabling a marine diesel engine to change its rotational direction, allowing for reverse movement of the ship. The camshaft controls the timing of both the fuel injection and the opening and closing of the engine’s valves, making it central to the reversing operation.

How the Camshaft’s Timing Affects Reversing

In any internal combustion engine, the camshaft determines when the intake and exhaust valves open and close in relation to the movement of the pistons. In marine diesel engines, when reversing is required, the camshaft’s timing must be altered. By shifting the timing, the camshaft ensures that the fuel is injected and the valves operate in sync with the reversed rotational direction of the engine. This adjustment is essential for maintaining the engine’s efficiency and preventing mechanical issues.

Reversing Camshaft and Valve Timing Adjustment for Reverse Operation

In engines designed for reversing, the camshaft is equipped with two sets of cam profiles: one for forward operation and another for reverse. When the engine needs to reverse, the camshaft is mechanically shifted or rotated, bringing the reverse cam profiles into alignment with the valves. This shift modifies the valve timing to match the new direction of the engine’s rotation. As a result, the intake and exhaust valves open and close at different intervals, corresponding to the reversed movement of the pistons. The reversing camshaft thus enables the engine to seamlessly transition between forward and reverse operation.

Importance of Fuel Injection Timing in the Reversing Process

Fuel injection timing is another critical factor in the reversing process. The precise moment when fuel is injected into the cylinder must coincide with the engine’s new rotation to ensure complete combustion and maintain power output. When the camshaft is adjusted for reverse operation, the fuel injection timing is also modified to match the new valve timings. Proper synchronization of fuel injection with valve operation is crucial to prevent engine knocking, misfires, or loss of power during reversing. Without accurate fuel injection timing, the engine’s performance would suffer, leading to inefficiency or potential damage.

By controlling the camshaft’s timing and ensuring the synchronization of fuel injection, the camshaft reversing process allows the engine to operate efficiently in both forward and reverse directions, ensuring smooth ship maneuvering.

Types of Reversing Systems in Marine Engines

Marine diesel engines rely on various reversing systems to change their rotational direction for maneuvering purposes. These systems ensure that the engine can operate effectively in both forward and reverse modes. The main types of reversing systems used in marine engines are mechanical, hydraulic, and pneumatic.

Overview of Common Types of Reversing Systems

Marine engines can be equipped with different reversing mechanisms depending on their design and operational requirements. Each system has its own method of altering the engine’s camshaft and valve timing to facilitate reversing. The choice of system often depends on the size of the engine, its intended use, and the level of automation required.

Mechanical Reversing

Mechanical reversing systems use gears, linkages, or a manually operated mechanism to change the camshaft position and adjust valve timing for reverse operation. In this system, physical movement of components ensures that the engine can reverse its direction.

- Advantages: Simple design, reliable operation, and easy to maintain.

- Limitations: Requires manual intervention, which can lead to slower response times, especially in larger engines.

Hydraulic or Pneumatic Reversing

Hydraulic and pneumatic reversing systems use fluid or air pressure to actuate the reversing mechanism. These systems can automatically shift the camshaft or adjust valve timing by controlling the flow of hydraulic fluid or compressed air to the actuating components.

- Advantages: Faster and more precise operation, ideal for large engines requiring quick response. These systems can also be controlled remotely, improving operational convenience.

- Limitations: More complex and requires regular maintenance of hydraulic or pneumatic lines. Any failure in the system can lead to loss of control during reversing.

Advantages and Limitations of Each System

- Mechanical systems are durable and simple but slower and less suited for large, automated operations.

- Hydraulic and pneumatic systems offer faster, automated control, making them suitable for modern, large-scale engines, but their complexity and maintenance needs are higher.

Steps Involved in Reversing a Marine Diesel Engine

Reversing a marine diesel engine is a carefully coordinated process that involves adjusting various mechanical and control systems to change the engine’s rotational direction. Below is a step-by-step guide to how this process works, as well as key points to check before and during reversing to ensure smooth and safe operations.

Step-by-Step Process to Reverse a Marine Diesel Engine

- Reduce Engine Speed to Idle

Before initiating the reversing process, the engine speed must be reduced to idle or stopped completely. This ensures that the engine components, such as the camshaft and fuel injection systems, can be safely adjusted for reverse operation. - Activate the Reversing System

Depending on the type of reversing system in use (mechanical, hydraulic, or pneumatic), the operator activates the reversing mechanism. This could involve shifting the camshaft using manual linkages or remotely activating hydraulic or pneumatic controls to adjust the timing mechanism. - Adjust the Camshaft for Reverse Operation

The camshaft is shifted to its reverse position, altering the timing of the intake and exhaust valves. This step ensures that the engine’s internal components operate in sync with the reversed rotation. - Reconfigure the Starting Air Distributor

The starting air distributor is adjusted to direct compressed air to the appropriate cylinders in the reverse sequence. This ensures that the engine will start turning in the opposite direction when the start signal is given. - Start the Engine in Reverse

Once the camshaft and air distributor are properly configured, the engine is restarted in reverse mode. Compressed air is injected into the cylinders in the reverse sequence to initiate reverse rotation. - Monitor Engine Performance

After the engine begins operating in reverse, it’s essential to monitor key performance indicators such as fuel injection timing, exhaust temperatures, and pressure levels to ensure the engine is running smoothly and efficiently.

Key Points to Check Before and During Reversing

- Engine Readiness: Ensure that the engine is at idle speed or stopped before attempting to reverse. Never attempt to reverse the engine while it’s running at high speed.

- Reversing Mechanism Functionality: Verify that the reversing linkage, hydraulic or pneumatic controls, and camshaft are in good working order.

- Starting Air System: Check that the starting air system is pressurized and that the distributor is correctly set for reverse operation.

- Fuel Injection Timing: Ensure that the fuel injection timing has been adjusted for reverse operation to avoid misfires or power loss.

- Control System Feedback: Monitor any control system alarms or indicators to detect possible issues during the reversing process.

- Smooth Transition: Once the engine is running in reverse, ensure that there are no unusual vibrations or noises that could indicate mechanical issues.

Common Challenges in Main Engine Reversing

| Common Challenges in Main Engine Reversing | Potential Issues | Solutions |

|---|---|---|

| Failure of the Reversing Mechanism | – Mechanical, hydraulic, or pneumatic system failure. – Mechanical jamming, leaks in hydraulic/pneumatic systems, or worn-out components. | – Regular inspection and lubrication of mechanical parts. – Check hydraulic/pneumatic lines for leaks or pressure loss. – Replace worn-out components proactively to prevent breakdowns. |

| Air System Issues | – Low air pressure or faulty air distributor. – Blockages in air lines preventing reverse operation or causing inefficiency. | – Regularly monitor starting air system pressure. – Clean air filters and remove blockages. – Ensure proper calibration of the air distributor for reverse operation. |

| Timing Misalignment | – Misalignment of camshaft or fuel injection timing. – Causes power loss, engine knocking, or incomplete combustion during reverse operation. | – Regularly check camshaft position and valve timing. – Synchronize fuel injection system with reverse timing. – Recalibrate camshaft and fuel system if misalignment persists. |

| Slow Response or Delayed Reversing | – Sluggish control systems, especially in older mechanical or pneumatic systems. – Delay in reversing response during critical maneuvers. | – Upgrade to modern hydraulic or electronic control systems. – Improve responsiveness and precision of camshaft adjustments. |

| Overheating and Excessive Wear | – Prolonged reversing causes overheating and increased wear. – Long-term engine damage due to poor cooling and lubrication. | – Ensure engine cooling system is functioning properly. – Regularly check and replenish lubricants. – Monitor engine temperatures during reversing and avoid prolonged reverse operation. |

Safety Precautions During Reversing

| Safety Precautions During Reversing | Details |

|---|---|

| 1. Reduce Engine Speed to Idle or Stop | Always ensure the engine is either at idle or completely stopped before initiating the reversing process. High-speed reversing can damage engine components. |

| 2. Ensure Proper Reversing Mechanism Functionality | Verify that the reversing mechanism, whether mechanical, hydraulic, or pneumatic, is in good working condition before reversing. Check for wear, leaks, or mechanical obstructions. |

| 3. Monitor Starting Air Pressure | Ensure that the starting air system has adequate pressure to initiate the reverse rotation. Insufficient pressure may lead to incomplete engine start in reverse. |

| 4. Verify Camshaft Position | Confirm that the camshaft has been fully shifted into the reverse position. A partial shift can lead to timing issues or engine failure. |

| 5. Fuel Injection Timing Check | Make sure the fuel injection system is properly synchronized with reverse timing to avoid misfires or incomplete combustion. |

| 6. Communicate with Bridge and Engine Room Crew | Clear and precise communication between the bridge and engine room is essential. All crew members must be aware of the reversing operation to ensure smooth coordination. |

| 7. Monitor Control Systems for Alarms | Continuously monitor control systems and alarms during reversing for any issues related to timing, pressure, or mechanical systems. Respond immediately to any warnings. |

| 8. Keep Emergency Stop Procedures Ready | Always be prepared to activate emergency stop mechanisms if something goes wrong during reversing, such as a failure in the reversing mechanism or sudden pressure loss. |

| 9. Ensure Proper Cooling and Lubrication | Check that the cooling system is functioning properly and lubricants are at optimal levels to prevent overheating during reversing. |

| 10. Crew Awareness and Coordination | Effective coordination between all crew members involved in reversing is critical to ensure safety and prevent accidents. Crew should be fully aware of their roles during reversing operations. |

Technological Advancements in Reversing Systems

| Technological Advancements in Reversing Systems | Details |

|---|---|

| Electronic and Automated Reversing Systems | – Electronic controls provide precise and automated adjustments to the camshaft and fuel injection timing. – Reduces manual intervention and speeds up the reversing process. – Increases reliability by minimizing human error and mechanical failures. |

| Hydraulic and Pneumatic Actuation | – Advanced hydraulic and pneumatic systems enable faster, smoother, and more responsive reversing operations. – High-performance actuators improve transition time between forward and reverse. – Provides better control during critical maneuvers. |

| Digital Monitoring and Diagnostics | – Digital monitoring tools offer real-time performance assessments. – Detects issues like timing misalignments or pressure drops before failures occur. – Enhances reliability and supports predictive maintenance. |

| Bridge Integration and Automated Control Systems | – Seamless integration with the ship’s bridge controls allows for remote operation of the reversing mechanism. – Enables precise, real-time engine control from the bridge. – Reduces the need for manual intervention in the engine room, improving response time. |

| Safety Enhancements | – Automated systems engage safety protocols during reversing operations. – Automatic adjustments to engine speed and real-time feedback enhance operational safety. – Reduces risks associated with reversing failures. |

| Improved Coordination | – Linked with navigation and propulsion control systems for coordinated maneuvers. – Allows for quicker and more accurate engine direction changes. – Essential for maneuvering in congested or narrow waters. |

Reversing in Different Marine Engine Types

The process of reversing in marine engines varies significantly between 2-stroke and 4-stroke engines due to differences in their design, operation, and timing systems. Both engine types can reverse their rotational direction, but the mechanisms and procedures involved are distinct, reflecting their unique engineering.

Comparison of Reversing Processes in 2-Stroke vs. 4-Stroke Marine Engines

- 2-Stroke Marine Engines

- Simplified Reversing Mechanism: In 2-stroke engines, the reversing process is simpler because these engines do not require separate intake and exhaust strokes. Instead, intake and exhaust processes are managed within a single stroke, making it easier to reverse the engine’s direction by altering valve and fuel injection timing.

- Camshaft Shifting: The camshaft in 2-stroke engines has distinct cam profiles for forward and reverse operations. Reversing the engine involves shifting the camshaft to engage the reverse cam profiles, which modify the timing of the exhaust valves and fuel injection.

- Starting Air Distributor: The starting air system is crucial in reversing 2-stroke engines. The starting air distributor is adjusted to direct compressed air to the appropriate cylinders in reverse sequence, initiating the reverse rotation.

- 4-Stroke Marine Engines

- Complex Reversing Mechanism: Reversing in 4-stroke engines is more complex because they have distinct intake, compression, power, and exhaust strokes. To reverse the engine, the camshaft must be adjusted to ensure that the intake and exhaust valves open and close at the correct intervals for reverse operation.

- Camshaft Adjustment: In 4-stroke engines, the camshaft typically has two sets of cam lobes—one for forward rotation and one for reverse. Shifting the camshaft allows the engine to switch between these lobes, altering the valve timing to accommodate reverse rotation.

- Fuel Injection Timing: In 4-stroke engines, reversing requires not only a change in valve timing but also precise adjustment of fuel injection timing to ensure efficient combustion during reverse operation. The complexity of managing both valve and fuel injection timing makes reversing in 4-stroke engines more intricate than in 2-stroke engines.

Specific Differences in Reversing Procedure

- Camshaft Operation: In 2-stroke engines, the camshaft adjustment is simpler due to the unified nature of the intake and exhaust processes. In contrast, 4-stroke engines require more intricate camshaft shifting due to the separate intake and exhaust strokes.

- Fuel Injection Timing: Both engine types require fuel injection timing adjustment, but the process is more complex in 4-stroke engines because of the need to align with the intake and power strokes.

- Air Distribution: The starting air system plays a more prominent role in reversing 2-stroke engines, where it initiates the reverse motion. While important in 4-stroke engines, the process is typically more reliant on precise mechanical adjustments.

Maintenance of Reversing Systems

| Maintenance of Reversing Systems | Details |

|---|---|

| Importance of Regular Maintenance and Inspection | – Regular maintenance ensures the reliability of reversing systems during critical maneuvers. – Helps identify early signs of wear or malfunction, preventing major breakdowns. – Enhances safety and extends the lifespan of key components. |

| Key Components to Check | Camshaft: – Inspect cam profiles for wear. – Ensure camshaft alignment for smooth shifting between forward and reverse. – Maintain proper lubrication. Control Systems: – Inspect hydraulic/pneumatic lines for leaks and blockages. – Ensure mechanical linkages are well-lubricated and free of wear. – Check electronic controls for sensor and actuator functionality. Starting Air Distributor: – Monitor air pressure to ensure effective engine start in reverse. – Verify air distributor calibration for reverse operation. – Clean air lines to prevent blockages. |

| Preventative Maintenance Strategies | – Scheduled Inspections: Perform regular inspections of camshaft, control systems, and air distributor. – Lubrication and Fluid Checks: Keep components properly lubricated and ensure hydraulic/pneumatic fluid levels are adequate. – Calibration and Testing: Regularly test and calibrate camshaft shifting, air distributor, and control systems. – Proactive Component Replacement: Replace worn cam profiles, hydraulic lines, or mechanical linkages before they cause failures. |

Main Engine Reversing: FAQ

Q- What is reversing of the main engine?

A- Reversing of the main engine changes the engine’s rotational direction to move the ship backward.

Q- How to reverse the ship engine?

A- The ship engine is reversed by shifting the camshaft and adjusting the valve and fuel injection timing.

Q- What is the principle of reversing?

A- The principle of reversing involves altering the camshaft timing and controlling air distribution to initiate reverse rotation.

Q- What is lost motion in the main engine?

A- Lost motion refers to the slack or delay in mechanical linkages during the camshaft’s shift between forward and reverse operation.

Conclusion

Main engine reversing is a critical function in marine diesel engines, enabling ships to change direction and maneuver safely in various conditions. Understanding the reversing mechanism, its components, and the differences between engine types ensures efficient operation and safety. Regular maintenance, crew coordination, and leveraging modern technological advancements are essential for reliable performance. By staying informed and proactive, marine engineers can maintain smooth and efficient engine reversing operations, contributing to overall vessel safety and efficiency.