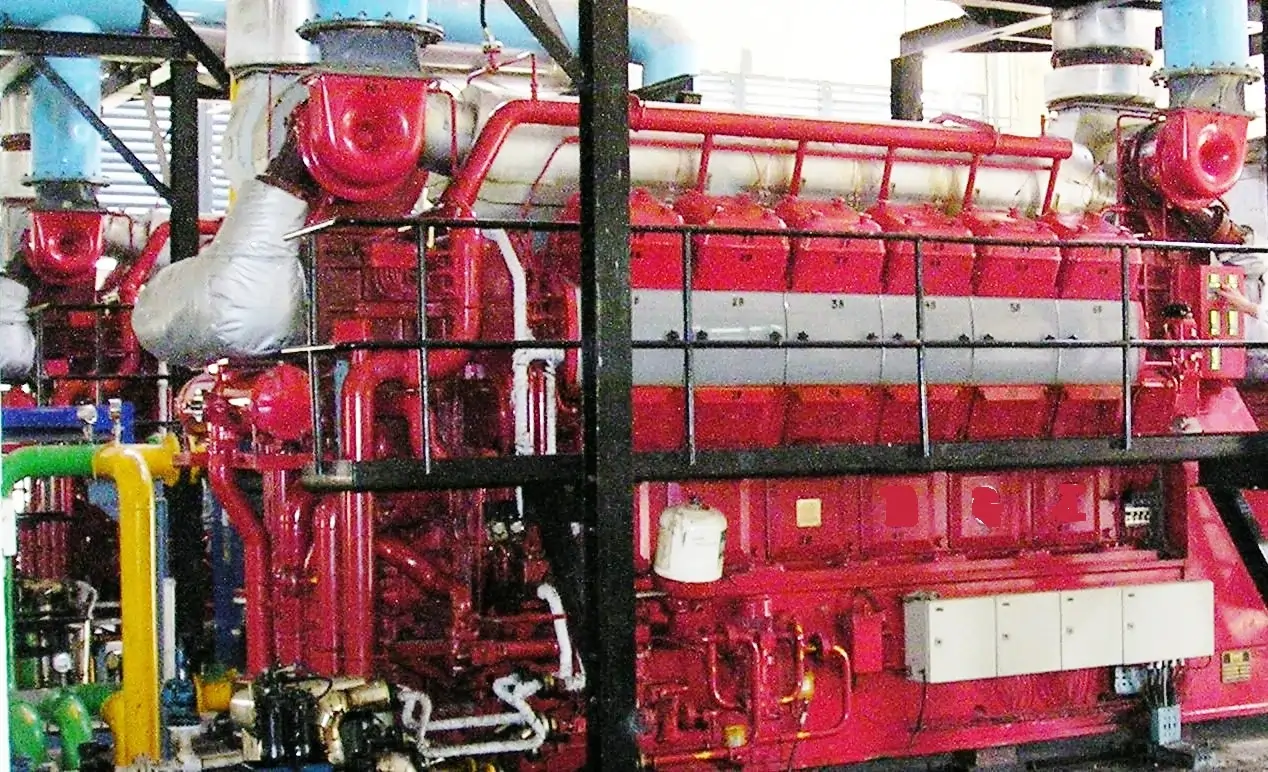

MAN B and W Diesel Engine

Did you know that MAN B&W Diesel Engines power over 50% of the world’s largest vessels? As industry leaders, these engines are renowned for their reliability and efficiency. However, even the best engines can benefit from advancements in technology. Upgrading and retrofitting your MAN B&W Diesel Engine is essential to maintain peak performance, meet environmental regulations, and extend the lifespan of your investment.

In this post, we’ll explore the seven most powerful upgrades and retrofits available for MAN B&W Diesel Engines. From advanced fuel injection systems and turbocharger enhancements to cutting-edge electronic control units and propulsion system upgrades, each option is designed to boost efficiency and performance. We’ll also look at exhaust gas recirculation systems, advanced cooling systems, and emissions compliance retrofit kits. By the end of this guide, you’ll have a clear understanding of how these upgrades can transform your engine’s capabilities.

Understanding MAN B&W Diesel Engines

History and Background

MAN B&W Diesel Engines have a storied history dating back to the early 20th century. Founded as Burmeister & Wain in Denmark, the company merged with MAN SE, a German engineering giant, to create MAN B&W Diesel. This merger brought together decades of expertise and innovation, making MAN B&W a leading name in marine propulsion. Today, these engines are synonymous with durability, efficiency, and cutting-edge technology, powering some of the largest vessels across the globe.

Core Features

MAN B&W Diesel Engines are known for their robust design and advanced engineering. Key features include:

- High Efficiency: Optimized for fuel efficiency, these engines reduce operating costs and minimize environmental impact.

- Reliability: Built to withstand harsh marine environments, they offer unparalleled reliability and longevity.

- Advanced Control Systems: Integrated electronic control units (ECUs) enhance performance monitoring and diagnostics.

- Modular Design: Their modular construction allows for easy maintenance and customization.

- Emission Compliance: Equipped with technology to meet stringent global emission standards.

Importance of Upgrades

Regular upgrades and retrofits are crucial for several reasons:

- Enhanced Performance: Upgrades can significantly improve engine performance, increasing power output and fuel efficiency.

- Compliance with Regulations: Emission standards are continually evolving. Retrofitting your engine ensures compliance with the latest environmental regulations.

- Cost Savings: Upgrades can reduce fuel consumption and maintenance costs, providing long-term savings.

- Extended Lifespan: Regularly updating engine components can extend the overall lifespan of your engine, protecting your investment.

- Technological Advancements: Embracing new technologies can provide competitive advantages, such as improved diagnostics and more efficient operations.

Upgrade 1 – Advanced Fuel Injection Systems

Description

Advanced fuel injection systems, such as electronic fuel injection (EFI) and common rail injection, are at the forefront of marine diesel engine technology. These systems enhance the precision of fuel delivery to the engine cylinders, optimizing the combustion process. EFI systems use electronic controls to adjust injection parameters in real-time, while common rail systems maintain high-pressure fuel delivery for consistent combustion efficiency.

Benefits

Upgrading to advanced fuel injection systems offers numerous advantages:

- Improved Fuel Efficiency: Precise fuel delivery reduces overall fuel consumption, leading to significant cost savings.

- Reduced Emissions: Optimized combustion processes lower emissions of pollutants, helping vessels meet stringent environmental regulations.

- Enhanced Engine Performance: These systems provide smoother and more responsive engine operation, with improved power output and acceleration.

- Extended Engine Life: Efficient combustion reduces engine wear, extending the operational lifespan of the engine.

- Advanced Diagnostics: Modern systems include diagnostic tools that monitor performance and detect issues early, preventing costly breakdowns.

Case Study

Real-World Example: MV Asuka II

The MV Asuka II, a luxury cruise ship, recently underwent an upgrade to its fuel injection system. The ship’s MAN B&W Diesel Engines were retrofitted with a state-of-the-art common rail injection system. Before the upgrade, the ship faced challenges with fuel efficiency and emission compliance.

Post-upgrade, the MV Asuka II experienced a 12% improvement in fuel efficiency, resulting in substantial fuel cost savings. Emissions of NOx and particulate matter were reduced by 20%, enabling the vessel to meet the latest International Maritime Organization (IMO) environmental standards. The enhanced engine performance also led to smoother voyages and fewer maintenance issues.

This successful upgrade highlights the transformative impact of advanced fuel injection systems on marine diesel engines. By adopting such technologies, shipowners can achieve significant operational improvements, cost savings, and environmental benefits (MDPI).

Upgrade 2 – Turbocharger Enhancements

Description

Advanced turbocharger options for MAN B&W Diesel Engines include variable geometry turbochargers (VGT), sequential turbocharging, and electric-assisted turbocharging. VGTs adjust the turbo’s vane angles to optimize airflow at various engine speeds, improving efficiency and performance. Sequential turbocharging involves using multiple turbochargers that operate in stages to boost power at different engine loads. Electric-assisted turbocharging integrates an electric motor to eliminate turbo lag and enhance acceleration.

Benefits

Upgrading to advanced turbochargers offers several performance and efficiency benefits:

- Increased Power Output: Enhanced turbocharging significantly boosts engine power and responsiveness.

- Improved Fuel Efficiency: Optimized air-fuel mixture reduces fuel consumption, leading to cost savings.

- Reduced Emissions: Better combustion efficiency lowers emissions, aiding compliance with environmental regulations.

- Enhanced Engine Durability: Efficient turbocharging reduces engine strain and wear, extending engine life.

Installation Tips

For a successful turbocharger upgrade:

- Compatibility Check: Ensure the new turbocharger is compatible with your engine model.

- Professional Assessment: Have a certified marine engineer assess your engine’s current state and recommend the best turbocharger option.

- Quality Components: Use high-quality parts and components to avoid potential failures.

- Proper Calibration: Calibrate the turbocharger correctly to match your engine’s specifications.

- Regular Maintenance: Follow a strict maintenance schedule to keep the turbocharger in optimal condition.

- Monitor Performance: Use advanced diagnostic tools to monitor the turbocharger’s performance and make adjustments as needed.

Upgrade 3 – Exhaust Gas Recirculation (EGR) Systems

Description

Exhaust Gas Recirculation (EGR) systems work by recirculating a portion of an engine’s exhaust gas back to the engine cylinders. This process dilutes the air-fuel mixture with inert gases, lowering combustion temperatures and reducing the formation of nitrogen oxides (NOx), which are significant pollutants. EGR systems are crucial for achieving cleaner combustion and meeting stringent emission standards.

Benefits

Implementing EGR systems provides several key benefits:

- Environmental Impact: EGR systems significantly reduce NOx emissions, contributing to a cleaner environment and improving air quality.

- Regulatory Compliance: By reducing NOx emissions, EGR systems help vessels comply with international emission regulations set by organizations like the International Maritime Organization (IMO).

- Fuel Efficiency: In some cases, EGR systems can also improve fuel efficiency by optimizing the combustion process, leading to cost savings.

Technical Insights

Technical Details:

- Components: An EGR system typically includes an EGR valve, cooler, and control unit. The EGR valve controls the flow of exhaust gases, while the cooler lowers the temperature of the recirculated gases.

- Operation: The control unit regulates the EGR valve based on engine load and speed, ensuring optimal performance.

- Installation Advice: Proper installation and calibration are essential for effective EGR system operation. Here are some tips:

- Professional Installation: Have a certified marine engineer install the EGR system to ensure it is integrated correctly with your engine.

- High-Quality Components: Use components that are specifically designed for your engine model to ensure compatibility and reliability.

- Regular Maintenance: EGR systems require regular maintenance to prevent clogging and ensure efficient operation. Schedule periodic inspections and cleanings.

- Software Updates: Keep the EGR system’s control unit software updated to take advantage of the latest advancements in emission control technology.

- Monitoring and Diagnostics: Use advanced diagnostic tools to monitor the performance of the EGR system and make necessary adjustments.

Upgrade 4 – Electronic Control Units (ECUs)

Description

The latest advancements in Electronic Control Units (ECUs) have revolutionized marine diesel engine management. Modern ECUs integrate advanced microprocessors and sensors to provide real-time monitoring and precise control over various engine parameters. These systems utilize algorithms to optimize fuel injection, turbocharging, and emission control processes, ensuring peak performance and efficiency under all operating conditions.

Benefits

Upgrading to advanced ECUs offers several key benefits:

- Improved Engine Management: Enhanced control over fuel injection, ignition timing, and air-fuel ratios results in more efficient and responsive engine performance.

- Advanced Diagnostics: ECUs continuously monitor engine health, providing early warnings of potential issues and reducing downtime through predictive maintenance.

- Fuel Efficiency: Optimized engine operation leads to significant fuel savings, reducing operating costs.

- Emission Control: ECUs help maintain compliance with stringent emission regulations by precisely managing exhaust systems and other emission-related components.

- Customization: ECUs can be tailored to specific vessel requirements, allowing for customized performance tuning and optimization.

Success Story

Success Story: MV Seabourn Sojourn

The MV Seabourn Sojourn, a luxury cruise ship, underwent an ECU upgrade to improve its engine performance and compliance with new emission regulations. The ship’s MAN B&W Diesel Engines were equipped with state-of-the-art ECUs featuring advanced diagnostic and control capabilities.

Following the upgrade, the Seabourn Sojourn experienced notable improvements:

- Fuel Efficiency: A 10% reduction in fuel consumption was achieved, leading to substantial cost savings.

- Performance: Engine responsiveness and overall performance were significantly enhanced, providing a smoother and more efficient cruising experience.

- Emission Reduction: The upgrade resulted in a 15% decrease in NOx emissions, ensuring compliance with the latest IMO standards.

The success of the ECU upgrade on the MV Seabourn Sojourn demonstrates the transformative impact of modern electronic control technology on marine diesel engines. By investing in advanced ECUs, shipowners can achieve superior engine management, cost savings, and regulatory compliance.

Upgrade 5 – Advanced Cooling Systems

Description

Advanced cooling technologies for MAN B&W Diesel Engines include closed-loop cooling systems, charge air coolers, and advanced heat exchangers. Closed-loop systems recirculate coolant, maintaining optimal temperatures without continuous freshwater intake. Charge air coolers reduce the temperature of compressed air before it enters the engine, improving combustion efficiency. Advanced heat exchangers use efficient materials and designs to maximize heat transfer and maintain stable engine temperatures.

Benefits

Implementing advanced cooling systems offers significant benefits:

- Enhanced Engine Longevity: Consistent and optimal cooling prevents overheating, reducing wear and tear and extending engine life.

- Improved Performance: Stable operating temperatures ensure efficient combustion, leading to better performance and fuel efficiency.

- Reduced Maintenance Costs: Efficient cooling minimizes thermal stress and associated maintenance needs, lowering overall operating costs.

Maintenance Tips

To maintain advanced cooling systems:

- Regular Inspections: Conduct routine checks for leaks, corrosion, and blockages in the cooling system components.

- Coolant Quality: Use high-quality, manufacturer-recommended coolants to prevent corrosion and scale buildup.

- Cleaning: Periodically clean heat exchangers and charge air coolers to remove debris and maintain efficiency.

- Monitor Temperatures: Continuously monitor engine and coolant temperatures using diagnostic tools to detect and address issues early.

- Replace Worn Parts: Timely replacement of worn-out components, such as hoses and seals, ensures the system’s reliability.

Upgrade 6 – Retrofit Kits for Emissions Compliance

Description

Retrofit kits for MAN B&W Diesel Engines are designed to help existing engines meet stringent emission standards. These kits include components such as Selective Catalytic Reduction (SCR) systems, Diesel Particulate Filters (DPF), and Exhaust Gas Recirculation (EGR) systems. SCR systems use a urea-based solution to reduce NOx emissions, while DPFs capture particulate matter. EGR systems recirculate exhaust gases to lower combustion temperatures and reduce NOx formation.

Benefits

Implementing retrofit kits offers several advantages:

- Regulatory Compliance: Retrofit kits ensure engines meet international emissions standards, such as those set by the International Maritime Organization (IMO).

- Environmental Impact: By reducing emissions of NOx and particulate matter, these kits contribute to a cleaner environment.

- Operational Efficiency: Enhanced combustion processes can lead to improved fuel efficiency and engine performance.

- Extended Service Life: Retrofitting older engines with modern emission control technologies can extend their operational life and delay the need for complete engine replacements.

Case Study

Case Study: MS Europa

The MS Europa, a luxury cruise ship, underwent a retrofit to meet the latest IMO Tier III emission standards. The retrofit included the installation of a Selective Catalytic Reduction (SCR) system and a Diesel Particulate Filter (DPF).

Post-retrofit, the MS Europa achieved:

- NOx Reduction: A significant reduction in NOx emissions, bringing them within the stringent limits required by IMO.

- Particulate Matter Reduction: A substantial decrease in particulate matter emissions, improving air quality around the vessel.

- Fuel Efficiency: An improvement in fuel efficiency due to optimized combustion processes facilitated by the retrofit systems.

Upgrade 7 – Propulsion System Upgrades

Description

The latest propulsion technologies for MAN B&W Diesel Engines include hybrid propulsion systems, electric propulsion, and advanced propeller designs. Hybrid systems combine traditional diesel engines with electric motors, allowing for flexible operation and reduced fuel consumption. Electric propulsion systems, powered by batteries or fuel cells, offer zero-emission capabilities. Advanced propeller designs, such as contra-rotating propellers and ducted propellers, enhance thrust and efficiency.

Benefits

Upgrading propulsion systems provides several significant benefits:

- Improved Efficiency: Advanced propulsion technologies optimize fuel usage, reducing operating costs.

- Increased Power: Enhanced propulsion systems deliver greater thrust, improving vessel speed and maneuverability.

- Environmental Compliance: Electric and hybrid systems significantly reduce emissions, meeting stringent environmental standards.

- Operational Flexibility: Hybrid systems allow for different operational modes, optimizing performance for various conditions.

Implementation Guide

Step-by-Step Guide to Implementing Propulsion System Upgrades:

- Assessment and Planning

- Evaluate Needs: Assess the vessel’s operational requirements and identify the most suitable propulsion technology.

- Feasibility Study: Conduct a feasibility study to understand the technical and economic implications of the upgrade.

- Selection of Technology

- Choose the System: Select the appropriate propulsion system (hybrid, electric, advanced propellers) based on the assessment.

- Procure Components: Source high-quality components from reputable manufacturers.

- Installation Preparation

- Engine Room Modification: Prepare the engine room to accommodate new components, including additional space for batteries or electric motors.

- Electrical System Upgrade: Upgrade the vessel’s electrical system to support new propulsion technology.

- Installation

- Professional Installation: Hire certified marine engineers to install the new propulsion system.

- System Integration: Ensure seamless integration of the new system with existing engine controls and monitoring systems.

- Testing and Calibration

- Initial Testing: Perform initial testing to ensure the system is functioning correctly.

- Calibration: Calibrate the propulsion system for optimal performance.

- Training and Documentation

- Crew Training: Provide comprehensive training for the crew on operating and maintaining the new propulsion system.

- Documentation: Maintain detailed documentation of the installation process, system specifications, and maintenance procedures.

- Maintenance and Monitoring

- Regular Inspections: Schedule regular inspections and maintenance to ensure the propulsion system remains in optimal condition.

- Performance Monitoring: Continuously monitor system performance and make adjustments as necessary.

FAQ on “MAN B&W Diesel Engine”

Q- What are the benefits of advanced fuel injection systems?

A- Improved fuel efficiency and reduced emissions.

Q- How do EGR systems reduce emissions?

A- They lower NOx emissions by recirculating exhaust gases

Q- Why is regular maintenance crucial for cooling systems?

A- It prevents overheating and extends engine life.

Q- What does upgrading to modern ECUs provide?

A- Better engine management and diagnostics.

Conclusion

In this post, we explored seven powerful upgrades and retrofits for MAN B&W Diesel Engines to enhance performance, efficiency, and compliance with modern standards.

- Advanced Fuel Injection Systems: Improved fuel efficiency and reduced emissions through precise fuel delivery.

- Turbocharger Enhancements: Increased power and better fuel efficiency with advanced turbocharger options.

- Exhaust Gas Recirculation (EGR) Systems: Lower emissions and improved environmental compliance.

- Electronic Control Units (ECUs): Enhanced engine management and diagnostics for optimal performance.

- Advanced Cooling Systems: Increased engine longevity and performance with modern cooling technologies.

- Retrofit Kits for Emissions Compliance: Meeting current emission standards and improving operational efficiency.

- Propulsion System Upgrades: Improved efficiency and power with the latest propulsion technologies.

By considering these upgrades, you can ensure your MAN B&W Diesel Engine operates at peak performance, remains compliant with regulations, and achieves long-term cost savings. For more detailed information and related articles, explore our other posts on advanced marine engine technologies and maintenance tips. Enhance your engine’s capabilities today and stay ahead in the maritime industry!