“Readers can easily navigate this blog post by scrolling through the table of contents to find the topic of their choice. Each section is clearly marked for quick reference, allowing you to jump directly to the information you need.”

MAN Marine Diesel Engines

Welcome to our deep dive into MAN Marine Diesel Engines, renowned for their exceptional performance and reliability. Understanding performance metrics like fuel efficiency, power output, and operational capabilities is crucial for anyone in maritime operations. These metrics impact operational costs, environmental footprint, and engine longevity.

In this post, we explore the top 5 powerful performance metrics of MAN Marine Diesel Engines, translating these metrics into real-world benefits. With 14 years of hands-on experience with MAN engines aboard ships and 20 years as the Service Head with the authorized MAN dealer in India, M/s Powerica Limited, I bring a comprehensive and practical perspective. Join me to uncover the secrets to maximizing your MAN Marine Diesel Engine’s performance.

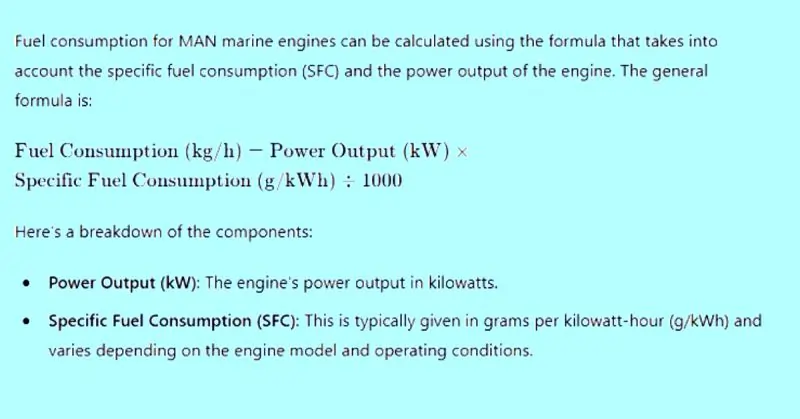

Fuel Efficiency: A Key Performance Metric

Explanation of Fuel Efficiency in Marine Engines

Fuel efficiency in marine engines refers to the engine’s ability to convert fuel into energy with minimal waste. This efficiency is crucial for several reasons:

- Operational Cost Savings: Fuel is one of the largest operational costs for vessels. Improved fuel efficiency directly translates to lower fuel consumption, reducing overall expenses.

- Environmental Impact: Efficient engines produce fewer emissions, helping to meet stringent environmental regulations and reduce the vessel’s carbon footprint.

- Performance and Reliability: Engines that use fuel efficiently tend to run more smoothly and reliably, reducing wear and tear and extending their operational life.

How MAN Marine Diesel Engines Optimize Fuel Consumption

MAN Marine Diesel Engines are renowned for their fuel efficiency, achieved through several advanced technologies and design features:

- Advanced Fuel Injection Systems: MAN engines use state-of-the-art fuel injection systems that ensure precise control of fuel delivery. This precision maximizes the combustion process, ensuring that fuel is burned more completely and efficiently.

- Optimized Combustion Chambers: The design of the combustion chamber in MAN engines is optimized to promote complete combustion of fuel. This reduces unburned fuel residues and maximizes energy output.

- Turbocharging and Aftercooling: MAN engines employ turbochargers and aftercoolers to increase the amount of air entering the combustion chamber. This improves the combustion process, allowing the engine to produce more power with less fuel.

- Electronic Engine Management Systems: These systems continuously monitor and adjust the engine’s performance parameters to ensure optimal fuel efficiency under varying operating conditions.

- Low-Friction Components: MAN engines are designed with low-friction components that reduce energy loss due to friction, further enhancing fuel efficiency.

Real-World Examples and Data Demonstrating Fuel Efficiency

Several real-world cases highlight the fuel efficiency of MAN Marine Diesel Engines:

- Case Study – Cargo Vessel: A cargo vessel powered by MAN engines reported a 10% reduction in fuel consumption compared to its previous engines. This reduction resulted in significant cost savings over a year of operation.

- Data from Sea Trials: In sea trials, MAN engines demonstrated fuel consumption rates that were 5-8% lower than industry averages, showcasing their superior efficiency.

- Environmental Impact: Ships equipped with MAN engines have consistently met and exceeded international emissions standards, thanks to their efficient fuel use and reduced exhaust

Power Output: Unleashing Marine Engine Potential

Definition of Power Output and Its Significance

Power output, in the context of marine engines, refers to the amount of mechanical power an engine can produce. It is typically measured in kilowatts (kW) or horsepower (HP). The power output is a critical performance metric as it directly influences a vessel’s speed, maneuverability, and ability to handle various loads and conditions. High power output is essential for:

- Efficient Navigation: Enabling vessels to travel at desired speeds even under challenging conditions.

- Operational Versatility: Allowing ships to perform a range of tasks, from towing and cargo transport to passenger travel and military operations.

- Reliability and Safety: Ensuring that vessels can operate reliably under full load, reducing the risk of engine failure during critical operations.

Comparison of Power Output Across Different MAN Models

| Model | Power Output | Applications | Features |

|---|---|---|---|

| MAN V12-1900 | 1,397 kW (1,900 HP) | High-performance yachts, fast ferries | Turbocharged, aftercooled, advanced electronic control |

| MAN D2868 LE433 | 588 kW (800 HP) | Commercial vessels, medium-sized yachts | Efficient fuel injection, optimized for fuel economy |

| MAN 51/60DF | 18,000 kW (24,300 HP) | Large cargo ships, cruise liners | Dual-fuel capability, high thermal efficiency, robust construction |

| MAN V32/44CR | 5,400 kW (7,300 HP) | Offshore vessels, larger ferries | Common rail fuel injection, low emissions, high power density |

Benefits of High Power Output in Marine Operations

High power output in marine engines offers several key benefits:

- Enhanced Speed and Performance

- Vessels equipped with high-power engines can achieve greater speeds, crucial for fast ferries, military ships, and high-performance yachts.

- Quick acceleration and deceleration improve maneuverability, essential for navigating tight harbors or avoiding obstacles.

- Improved Load Handling

- High power output allows ships to carry heavier loads without compromising on speed or efficiency.

- This is particularly important for cargo ships and tankers that need to maximize their payload capacity while maintaining operational efficiency.

- Operational Flexibility

- Engines with high power output can perform efficiently under a variety of conditions, including rough seas and high winds.

- This versatility is vital for vessels involved in offshore operations, rescue missions, or towing tasks.

- Increased Reliability and Safety

- High-powered engines are designed to operate under full load without compromising reliability, reducing the risk of engine failure.

- This reliability is crucial for passenger ships, where safety and uninterrupted service are paramount.

- Fuel Efficiency and Environmental Compliance

- Modern high-power MAN engines are engineered to optimize fuel consumption even at high output levels, balancing power with efficiency.

- They also incorporate technologies to minimize emissions, ensuring compliance with stringent environmental regulations.

Durability and Reliability: Cornerstones of MAN Marine Diesel Engines

Importance of Durability in Marine Environments

Durability is a critical factor in the marine industry due to the harsh and unpredictable conditions vessels often face. Marine engines must withstand extreme temperatures, high humidity, saltwater corrosion, and continuous operation for extended periods. The importance of durability in marine environments includes:

- Operational Continuity: Durable engines ensure that vessels can operate without frequent breakdowns, which is essential for maintaining schedules and avoiding costly delays.

- Cost Efficiency: Long-lasting engines reduce the need for frequent repairs and replacements, resulting in significant cost savings over the vessel’s lifetime.

- Safety: Reliable and durable engines are crucial for the safety of the crew and passengers, minimizing the risk of engine failure in critical situations.

- Regulatory Compliance: Durable engines help meet stringent industry standards and regulations, ensuring that vessels remain compliant and can continue to operate in various jurisdictions.

Key Features of MAN Engines that Enhance Durability

MAN Marine Diesel Engines are renowned for their exceptional durability and reliability, thanks to several key features:

- High-Quality Materials

- MAN engines are constructed using high-quality, corrosion-resistant materials that can withstand the harsh marine environment. This includes stainless steel, special alloys, and advanced coatings.

- Robust Design

- The robust design of MAN engines includes reinforced components and structures that ensure longevity and resistance to wear and tear. The engines are designed to handle high loads and continuous operation without compromising performance.

- Advanced Cooling Systems

- MAN engines incorporate advanced cooling systems that maintain optimal operating temperatures, preventing overheating and reducing thermal stress on engine components.

- Effective Lubrication Systems

- These engines are equipped with efficient lubrication systems that minimize friction and wear, ensuring smooth and reliable operation over long periods.

- Stringent Testing and Quality Control

- Each MAN engine undergoes rigorous testing and quality control processes to ensure it meets the highest standards of durability and reliability. This includes endurance testing under real-world conditions.

Testimonials and Case Studies from Long-Term Users

Testimonial 1: Cargo Vessel Operator

“We’ve been using MAN Marine Diesel Engines for over a decade, and their durability is unmatched. Despite operating in some of the toughest maritime conditions, our engines have consistently performed without any major issues. The cost savings from reduced maintenance and downtime have been significant.” — John D., Cargo Vessel Operator

Testimonial 2: Cruise Line Technical Manager

“Our fleet of cruise ships relies on MAN engines for their durability and reliability. The advanced cooling and lubrication systems have kept our engines running smoothly, even on long voyages. The robustness of these engines ensures the safety and comfort of our passengers.” — Sarah M., Technical Manager, Oceanic Cruises

Case Study: Offshore Supply Vessel

Background: An offshore supply vessel equipped with MAN engines has been operating in the North Sea, known for its challenging conditions.

Challenge: The vessel required engines that could handle continuous operation and harsh environmental factors, including saltwater corrosion and extreme temperatures.

Solution: MAN Marine Diesel Engines were chosen for their high-quality materials, robust design, and advanced cooling and lubrication systems.

Outcome: Over five years of operation, the vessel reported minimal engine issues, with significantly lower maintenance costs compared to previous engines. The durability of MAN engines ensured uninterrupted service, even in the harshest conditions.

Emission Control: MAN Marine Diesel Engines Leading the Way

Overview of Emission Regulations in the Marine Industry

The marine industry is subject to stringent emission regulations aimed at reducing the environmental impact of shipping activities. These regulations are enforced by international, regional, and national bodies, and they focus on limiting the emissions of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), particulate matter (PM), and carbon dioxide (CO2). Key regulatory frameworks include:

- International Maritime Organization (IMO): The IMO sets global standards through MARPOL Annex VI, which imposes limits on NOx and SOx emissions from ship exhausts and mandates the use of low-sulfur fuels.

- Emission Control Areas (ECAs): Designated areas where stricter emission limits apply, including the North American ECA, the Baltic Sea ECA, and the North Sea ECA.

- European Union (EU) Regulations: The EU has its own regulations, such as the Sulphur Directive, which mandates the use of low-sulfur fuels in EU waters.

- National Regulations: Various countries have implemented additional emission controls, requiring vessels to adhere to more stringent standards while operating in their territorial waters.

How MAN Engines Meet and Exceed These Standards

MAN Marine Diesel Engines are designed to meet and often exceed these rigorous emission standards, ensuring compliance and contributing to a cleaner environment. Key strategies include:

- Advanced Engine Design: MAN engines are engineered with optimized combustion processes that reduce the formation of NOx and PM.

- Use of Low-Sulfur Fuels: MAN engines are compatible with low-sulfur and alternative fuels, aligning with regulations like those imposed by MARPOL Annex VI and the EU Sulphur Directive.

- Emission Reduction Technologies: Incorporation of cutting-edge technologies that actively reduce harmful emissions.

- Continuous Monitoring and Adjustment: Advanced electronic control systems that monitor and adjust engine parameters in real-time to maintain optimal emission levels.

Specific Technologies Used in MAN Engines for Emission Control

- Selective Catalytic Reduction (SCR)

- Description: SCR technology involves injecting a urea-based solution into the exhaust stream, which reacts with NOx to form harmless nitrogen and water.

- Benefits: This technology significantly reduces NOx emissions, helping vessels comply with the strictest emission limits in ECAs and other regulated areas.

- Exhaust Gas Recirculation (EGR)

- Description: EGR technology recirculates a portion of the engine’s exhaust gas back into the combustion chamber, lowering the combustion temperature and reducing NOx formation.

- Benefits: EGR systems effectively cut NOx emissions, enhancing compliance with international and regional standards.

- Diesel Particulate Filters (DPF)

- Description: DPFs capture and remove particulate matter from the exhaust gases before they are released into the atmosphere.

- Benefits: These filters ensure a significant reduction in PM emissions, contributing to cleaner air quality and compliance with stringent emission limits.

- Common Rail Fuel Injection

- Description: Common rail systems deliver precise amounts of fuel at high pressure directly into the combustion chamber, optimizing the combustion process.

- Benefits: This technology reduces both NOx and PM emissions by ensuring complete and efficient fuel combustion.

- Dual-Fuel Engines

- Description: MAN’s dual-fuel engines can operate on both conventional diesel and cleaner fuels such as liquefied natural gas (LNG).

- Benefits: The use of LNG significantly lowers SOx, NOx, and CO2 emissions, providing an environmentally friendly alternative to traditional marine fuels.

Maintenance and Operational Efficiency: Keeping MAN Marine Diesel Engines at Their Best

Ease of Maintenance and Its Impact on Overall Performance

Maintenance is a critical aspect of marine engine performance and longevity. The ease of maintenance directly influences the engine’s reliability, operational efficiency, and total cost of ownership. MAN Marine Diesel Engines are designed with maintenance-friendly features that simplify routine tasks and repairs, ensuring minimal disruption to operations. Key benefits of ease of maintenance include:

- Reduced Downtime: Quick and straightforward maintenance procedures minimize the time vessels spend out of service, enhancing operational efficiency.

- Lower Costs: Simplified maintenance reduces labor costs and the need for specialized tools or extensive training.

- Improved Reliability: Regular and easy maintenance helps identify and address potential issues before they lead to major failures, ensuring consistent engine performance.

- Enhanced Safety: Properly maintained engines reduce the risk of malfunctions that could compromise the safety of the vessel and crew.

Common Maintenance Practices for MAN Engines

MAN Marine Diesel Engines are designed for ease of maintenance, with several common practices ensuring optimal performance and longevity:

- Regular Inspections

- Description: Routine inspections of critical components such as fuel injectors, turbochargers, and cooling systems help identify wear and potential issues early.

- Frequency: Typically performed monthly or as recommended by the manufacturer.

- Oil and Filter Changes

- Description: Regularly changing the engine oil and filters ensures proper lubrication and prevents the buildup of contaminants that can cause damage.

- Frequency: Oil changes are typically recommended every 250-500 operating hours, depending on the engine model and operating conditions.

- Cooling System Maintenance

- Description: Flushing and refilling the cooling system with the appropriate coolant prevents overheating and corrosion.

- Frequency: Usually performed every 1,000 operating hours or annually.

- Fuel System Maintenance

- Description: Cleaning and replacing fuel filters, and checking fuel lines and injectors ensure efficient fuel delivery and combustion.

- Frequency: Fuel filters are typically replaced every 500 operating hours or as needed.

- Exhaust System Inspections

- Description: Checking the exhaust system for leaks, blockages, and corrosion helps maintain optimal engine performance and emission compliance.

- Frequency: Inspections are usually conducted during regular maintenance intervals.

- Belt and Hose Inspections

- Description: Regularly inspecting and replacing worn belts and hoses prevent failures that could lead to engine damage.

- Frequency: Typically inspected during routine maintenance and replaced as needed.

Tips for Maximizing Operational Efficiency and Reducing Downtime

To ensure maximum operational efficiency and minimize downtime, follow these best practices:

- Adhere to Maintenance Schedules

- Tip: Follow the manufacturer’s recommended maintenance schedule to ensure timely inspections and replacements. This proactive approach prevents unexpected failures and extends engine life.

- Use Genuine MAN Parts

- Tip: Always use genuine MAN parts and consumables for replacements. These parts are specifically designed for MAN engines, ensuring compatibility and reliability.

- Train Your Crew

- Tip: Ensure that your crew is adequately trained in engine maintenance procedures. Regular training updates keep the crew knowledgeable about the latest maintenance techniques and best practices.

- Monitor Engine Performance

- Tip: Use electronic monitoring systems to track engine performance parameters such as temperature, pressure, and fuel consumption. Early detection of anomalies allows for timely interventions.

- Implement Predictive Maintenance

- Tip: Utilize predictive maintenance tools and techniques to anticipate potential issues before they occur. This approach uses data and analytics to predict component failures and schedule maintenance accordingly.

- Maintain Clean Engine Compartments

- Tip: Keep the engine compartment clean and free of debris. A clean environment reduces the risk of contamination and makes it easier to spot potential issues.

- Keep Comprehensive Records

- Tip: Maintain detailed records of all maintenance activities, including dates, tasks performed, and parts replaced. This documentation helps track the engine’s health and identify recurring issues.

FAQ on “MAN Marine Diesel Engines”

Q: What makes MAN Marine Diesel Engines fuel-efficient?

A: MAN engines use advanced fuel injection systems and optimized combustion processes to maximize fuel efficiency.

Q: How do MAN engines comply with emission regulations?

A: MAN engines incorporate technologies like SCR and EGR to meet and exceed international emission standards.

Q: What are the key benefits of high power output in MAN engines?

A: High power output ensures greater speed, better load handling, and enhanced operational flexibility for various marine applications.

Q: How can regular maintenance improve MAN engine performance?

A: Regular maintenance reduces downtime, extends engine life, and ensures reliable and efficient operation.

Conclusion

In conclusion, MAN Marine Diesel Engines stand out for their exceptional performance, fuel efficiency, power output, durability, reliability, emission control, and ease of maintenance. By focusing on these key performance metrics, ship operators can ensure their vessels operate efficiently, safely, and sustainably. Regular maintenance, adherence to emission regulations, and leveraging advanced engine technologies are crucial for maximizing the operational efficiency and longevity of these engines. With decades of expertise and innovative engineering, MAN continues to lead the marine industry, providing reliable and high-performing solutions for maritime operations worldwide. Choose MAN Marine Diesel Engines for unparalleled performance and peace of mind on