Marine Diesel Engine Safety Devices

Marine diesel engines are critical machines on ships and boats, and their safe operation is paramount to ensure the safety of the crew, passengers, and vessels. To help mitigate risks, several safety devices are essential for marine diesel engines. In this blog post, we will explore some of the most important safety devices, such as the Crankcase Relief Door, Oil Mist Detector, Scavenge Relief Valve, Starting Air Relief Valve, Cylinder Head Safety Valve, Starting Airline Flame Trap, and Cylinder Relief Valve.

In addition to these safety devices, we will also discuss safety alarms such as low oil pressure alarms, high water temperature alarms, fuel filter alarms, exhaust gas temperature sensors, and emergency shut-off switches. By understanding the role of these safety devices and maintaining them properly, you can help ensure the safe and reliable operation of your marine diesel engine.

Safety Devices on Marine Engines

The purpose of safety devices on marine engines is to ensure safe and reliable operation of the engine and to protect the Marine engines from potential hazards. Marine engines are often subject to harsh conditions, such as overloading, high temperatures, and heavy vibrations, which can lead to various mechanical and electrical failures.

Safety devices are designed to detect and alert Marine engineers to potential issues before they can cause serious damage to the engine or compromise the safety of the vessel. For example, an overheat alarm can alert the operator if the engine temperature rises above a safe level, while a low oil pressure alarm can warn of a potential engine failure due to insufficient lubrication.

In addition to alarms, safety devices may also include automatic shut-off switches that can quickly shut down the engine in an emergency, such as a fire or flooding. By installing and maintaining safety devices on marine engines, ship owners and operators can help ensure the safe and reliable operation of their vessels and protect their crew and passengers from potential hazards.

Relief Door on Crankcase

The Crankcase relief doors are also fitted to prevent any damage to the crankcase and ingress of fresh air inside the crankcase. The crankcase doors are spring-loaded valves that lift up in case there is any rise of pressure inside the crankcase. This is a non-return valve that allows the crankcase pressure to release from the Crankcase. It doesn’t allow the outside air to enter the Crankcase.

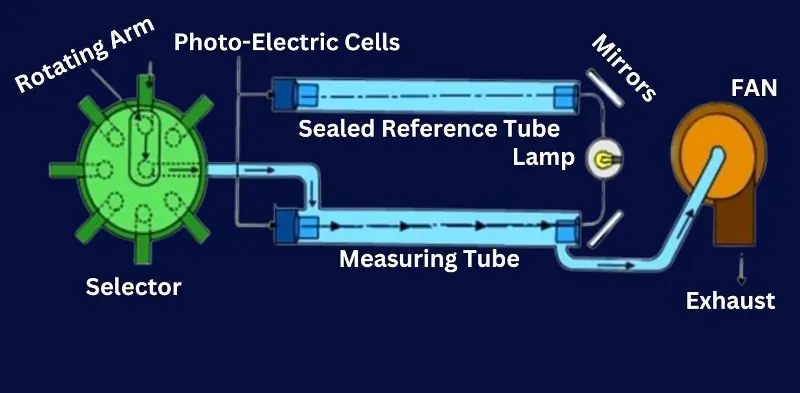

Oil Mist detector

Oil Mist Detectors protect large diesel, gas, and dual-fuel engines of all applications. They protect against heavy consequential damage due to oil mist explosions, a result of overheating of bearings or moving parts. The oil mist detector is the essential device fitted on Marine Diesel Engines for the safety of Engines. The oil mist detector will check and monitor the mist in the crankcase.

Scavenge Relief Valve

A Scavenge Relief Valve (SRV) is a safety valve used in marine diesel engines to prevent excessive pressure buildup in the scavenge air system. The scavenge air system is responsible for removing exhaust gases from the engine’s cylinders and delivering fresh air to the cylinders for combustion.

During operation, the scavenge air pressure can increase due to factors such as a blockage in the air ducts, incorrect scavenge air pressure adjustment, or malfunctioning of the turbocharger. If the scavenge air pressure exceeds the maximum allowable limit, it can cause damage to the engine’s components such as pistons, cylinder liners, or connecting rods.

The SRV is designed to open when the scavenge air pressure exceeds the maximum allowable limit, allowing excess air to escape and maintain the pressure within safe limits. The SRV is typically located in the scavenge airline, close to the turbocharger, and is spring-loaded to remain closed until the scavenge air pressure exceeds the set limit. Once the valve opens, the excess air is vented to the atmosphere, and the scavenge air pressure is reduced to a safe level.

The SRV is an essential safety feature in marine diesel engines, as it helps to prevent damage to the engine’s components and ensure safe and reliable operation. Regular maintenance and inspection of the SRV are necessary to ensure that it is functioning correctly and within the required pressure range.

Relief Valve for starting air

A Relief Valve for starting air is a safety valve used in marine diesel engines to prevent excessive pressure buildup in the starting air system. The starting air system is responsible for providing compressed air to the engine’s cylinders to start the engine.

During engine startup, the starting air pressure can increase due to factors such as incorrect starting air pressure adjustment or malfunctioning of the starting air compressor. If the starting air pressure exceeds the maximum allowable limit, it can cause damage to the engine’s components and can severely blow the starting air line.

The Relief Valve for starting air is designed to open when the starting air pressure exceeds the maximum allowable limit, allowing excess air to escape and maintain the pressure within safe limits. The Relief Valve is typically located in the starting air line and is spring-loaded to remain closed until the starting air pressure exceeds the set limit. Once the valve opens, the excess air is vented to the atmosphere, and the starting air pressure is reduced to a safe level.

Regular maintenance and inspection of the Relief Valve are necessary to ensure that it is functioning correctly and within the required pressure range.

Safety valve for cylinder head

A Safety Valve for Cylinder Head is a safety device used in marine diesel engines to prevent excessive pressure buildup in the engine’s combustion chambers or cylinders. The combustion process generates high pressures and temperatures within the cylinders, and if the pressure exceeds the maximum allowable limit, it can cause damage to the engine’s components such as cylinder liners, pistons, and valves.

The Safety Valve for Cylinder Head is typically located on the cylinder head cover or on the cylinder block and is designed to open when the cylinder pressure exceeds the maximum allowable limit. The valve is spring-loaded and remains closed until the pressure in the cylinder exceeds the set limit. Once the valve opens, the excess pressure is vented to the atmosphere, and the cylinder pressure is reduced to a safe level.

Regular maintenance and inspection of the Safety Valve are necessary to ensure that it is functioning correctly and within the required pressure range. The valve should also be checked and adjusted during engine overhauls or after any significant changes to the engine’s operating conditions.

Starting airline flame Trap

A Starting Airline Flame Trap is a safety device used in marine diesel engines to prevent the propagation of fire or explosion from the engine’s starting air system to the surrounding environment. The starting air system provides compressed air to the engine’s cylinders to start the engine, and during operation, the compressed air can become hot and potentially ignite any flammable gases or vapors present in the surrounding environment.

The Starting Airline Flame Trap is typically located at the inlet of the starting air system and is designed to prevent any flames or sparks generated within the starting air system from escaping to the surrounding environment. The flame trap consists of a fine mesh screen that is designed to absorb any flames or sparks generated within the starting air system and prevent them from passing through the screen.

The Starting Airline Flame Trap is an essential safety feature in marine diesel engines, as it helps to prevent the propagation of fire or explosion and ensures safe and reliable operation. Regular maintenance and inspection of the flame trap are necessary to ensure that it is functioning correctly and not clogged with debris or other contaminants. The flame trap should be cleaned or replaced as necessary during routine maintenance intervals or if there is any indication of reduced airflow.

Cylinder Relief Valve

The cylinder relief valve is designed to relieve pressures in excess of 10% to 20% above normal. The operation of this device indicates a fault in the engine which should be discovered and corrected. As a practical safeguard against explosions that occur in a crankcase, explosion relief valves or doors are fitted

Main Engine Alarms and tripping devices

Main engines are guarded against any abnormality in the engine by alarm and tripping devices. The following nineteen types of alarm and tripping devices are popularly installed on the engines.

- Low Lubricating oil pressure trip

- Engine over-speed tripping device

- Low jacket cooling pressure trip

- Main bearing high-temperature trip

- Piston cooling low-pressure trip

- camshaft Low lube oil pressure trip

- The high-temperature thrust-bearing trip

- Oil mist alarm

- Emergency manual trip

- Low sump oil level alarm

- Lubricating pump tripping alarm

- High jacket water alarm

- High piston cooling alarm

- Low-control air pressure alarm

- Low starting air pressure alarm

- High exhaust gas temperature alarm

- Engine turning gear engaged alarm

- High turbocharger gas temperature alarm

- High scavenge temperature alarm

Starting Interlocks

| Sr No. | Description |

| 1 | Turning gear Engaged |

| 2 | Auxiliary Blower off |

| 3 | Pre-Lube oil Pump and cooling water Pump not running |

| 4 | Interlock for rotating direction |

A typical Alarm System will have a sensing device such as

- A level sensor

- Thermocouple

- Pressure sensor.

These sensing devices are connected to display devices which may have minimum and maximum values marked on them. When this value reaches, a switch is activated an electrical or pressure signal is sent to the sips alarm panel and audiovisual warning devices.

The panel’s indicating light will remain on or continue flashing till the duty engineer acknowledges the alarm and the condition that caused the alarm to activate has been removed.

It is a protection circuit as well warning circuit. The activation of the limit switch will also activate the shutdown procedure of the machine.

The protective system activates one or more switches or valves, causing the machine to come to an unscheduled halt in a controlled manner. Safety trips and critical alarms for the Engine safety.

Important Guide Lines

- Carry out the alarm system maintenance periodically for the proper functioning of the sensors and alarms.

- If the alarm indication appears, ascertain the cause of alarm and then press the reset button.

While adjusting temperature and pressure switches, follow the following.

- Use the calibrated instruments when adjusting the switches. And the direction of change is taken into account.

- After the adjustment, constantly repeat the test at two different values.

- Whenever an automatic restart set is involved, in the machine control room, always switch the automatic restart circuit to manual and off before re-set.

- Never restart the equipment or put it back into service without rectifying the cause of alarm.

- Always investigate any abnormal run indication even if the equipment is running smoothly.

- The watch-keeping engineer must have enough confidence in the alarm system and protection devices in the engine room. He must be sure all the time that he will be given a timely warning to take immediate action.

Main Engine Shutdown Safety Devices

1. Over-speed trip: An over-speed device will cut off the fuel supply in the speeding Engine event more than the predetermined value. Set the overspeed setting by manual setting It will not allow the Engine to restart as the reason for overspeeding still exists, and the Engine might run over speed again.

To ensure the correct operation, maintenance staff should check it periodically.

As per the practice following two types of over-speed devices are installed.

- Mechanical over Speed Trip is set at 18% more than the nominal operating RPM (Speed).

- The setpoint of an Electro-pneumatic device is 15% above the Engine’s Nominal RPM (speed).

2. Jacket water high-temperature Alarm and Trip:- Jacket cooling Water removes the waste heat. Failure of jacket water to remove the heat away, seizure of the components will take place due to expansion. The alarm will indicate the abnormal temperature at the initial stage and will trip the engine in the event of ignoring the alarm.

3. L.O low-pressure Trip, alarm and Trip:- There will be instant engine damage due to the low Lube oil pressure. A standard lube oil pressure device will stop the Engine. The low lube oil pressure will cause the seizure of components. There will be the failure of Major components like the Crankshaft, Bearings, and Pistons due to the Low lube oil pressure

Usually, oil pressure stops the Engine. There are two set points for low lubricating oil pressure.

- First, setpoints will give the alarm of low Lube oil pressure.

- The second set point will stop the Engine to prevent significant damage to the Engine.

4. High Exhaust gas Temperature:- High exhaust gas temperatures are too critical and can provide information regarding the Engine operation. High Exhaust Temperature will indicate the symptoms of overloading of the Engine. High exhaust temperature will also display insufficient scavenging in the machine. Severe damage may take place if the Engine continues to operate at High exhaust temperature. Therefore High exhaust temperature alarm is provided.

High-Pressure Crankcase Alarm

Crankcase pressure will rise high due to the blow-by of gases from the combustion chamber. The high blow-by occurs due to the leaky piston rings into the Crankcase. High pressure in the crankcase indicates the poor condition of engine piston rings, Cylinder liners and Pistons.

Types of safety Devices

Basic Terminology

1. Alarm: An Audible and visual alarm will ring if there is any deviation in the Parameter. The notice will give a pre-warning of the problem.

2. Slow down: In this process, if the action taken by the Engineer is not appropriate then the device will slow down the engine.

3. Shut down: For any higher fluctuating parameter that could be the cause of harm to other engine systems, the shutdown protective device will cut off the fuel system and stop the Engine.

4. Starting Interlock: Starting Interlock will not allow the Engine to start if the Engine’s crucial system hasn’t been operated. It will also interlock the system if the turning gear is appropriately arranged.

Safety Items Fitted to the Main Engine and How They Work

Typical Safety alarms

Operation Data and Set Points

Different Engine Slow Down Situations (Critical alarms and safety trips)

Under the slowdown situation, Engine speed will fall below the minimum rate but above critical speed.

Slowdown conditions

| Sr. No. | Situation | Set Point for slowdown |

| 1 | Lube Oil Pressure | 1.5 Bar |

| 2 | Camshaft Oil Pressure | 2 Bar |

| 3 | Piston Cooling Media | No flow |

| 4 | Oil Mist Detector | If has activated |

| 5 | Main bearing Sensor | If has activated |

| 6 | Lube Oil Inlet Temperature | > 60 0 C |

| 7 | Piston Cooling Temperature | > 75 0 C |

| 8 | Jacket Cooling Water Temperature | > 88 0 C |

| 9 | Cylinder Exhaust temperature | > 450 0 C |

| 10 | Scavenge Air Temperature | > 65 0 C |

| 11 | Thrust Block Temperature | > 75 0 C |

| 12 | Flow of cylinder Lube oil | Low |

| 13 | Control Air Pressure | < 6 bar |

Shutdown conditions

| Sr. No. | Situation | Set Point for shutdown |

| 1 | Inlet Low Lube Oil Pressure | <1 Bar |

| 2 | Low Camshaft Lube Oil pressure | <1.5 Bar |

| 3 | cooling water pressure low | <.1 Bar |

| 4 | High Jacket Cooling Water Temp. | >950 C |

| 5 | Flow of cylinder Lube oil | No Flow |

| 6 | High Thrust Block Temperature | >900 C |

| 7 | Turbocharger Inlet Oil Pressure | <.8 Bar |

| 8 | High Lube Oil Temperature | >850 C |

Frequently Asked Questions

Blog Conclusion

In conclusion, marine diesel engines are powerful and efficient machines that require careful maintenance and operation to ensure safe and reliable performance. Fortunately, there are several safety devices designed to protect the engine and crew from potential hazards.

Among the most important safety devices are the engine shutdown system, emergency stop button, overheat protection, and relief door on the crankcase. These devices can help prevent engine damage, fires, and other emergencies, and give crew members the means to quickly stop the engine if needed.

Regular maintenance and testing of these safety devices is essential to ensure they are functioning properly and can provide the protection they were designed for. By taking a proactive approach to engine safety, operators can minimize the risk of accidents and keep their vessels operating safely and efficiently for years to come.

Please feel free to contact us if you have any further questions or comments at http://sh057.global.temp.domains/~arinedie/contact-us/. Thank you for reading this blog post, we would love to hear from you!