Marine Diesel Engine Troubleshooting

Did you know that marine diesel engine downtime can cost commercial operations thousands of dollars per hour in lost productivity and repair expenses? For senior marine engineers, mastering advanced troubleshooting skills is crucial to maintaining operational efficiency and safety on board. These skills not only minimize downtime but also extend the lifespan of engine components and improve overall vessel performance. In this blog post, we will delve into ten advanced troubleshooting techniques specifically designed for marine diesel engines. These methods are proven to effectively resolve complex engine issues, optimize performance, and ensure reliable operation. Whether you’re a 3rd Marine Engineer or a Chief Marine Engineer, these insights will enhance your ability to diagnose and fix engine problems swiftly and accurately.

The Best 10 Fixes

Advanced Diagnostic Techniques

Comprehensive Diagnostic Tools

Overview of Advanced Diagnostic Tools

- Infrared Thermography:

- Purpose: Infrared thermography is used to detect temperature variations in engine components. It helps identify hot spots, which can indicate areas of excessive friction, electrical faults, or fluid leaks.

- Application: By scanning engine parts with an infrared camera, engineers can quickly pinpoint areas of concern without disassembling the engine. This non-invasive method is crucial for maintaining engine integrity and preventing further damage.

- Benefits: Early detection of potential failures, improved safety, and reduced downtime.

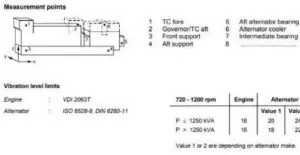

- Vibration Analysis:

- Purpose: Vibration analysis involves measuring and analyzing the vibration patterns of engine components to detect imbalances, misalignments, or wear.

- Application: Sensors placed on key engine parts collect vibration data, which is then analyzed using specialized software to identify anomalies. Engineers can use this data to predict component failures and plan maintenance activities accordingly.

- Benefits: Accurate detection of mechanical issues, extended equipment lifespan, and enhanced operational reliability.

- Engine Performance Software:

- Purpose: Engine performance software monitors and analyzes various engine parameters, such as fuel consumption, power output, and exhaust emissions, in real-time.

- Application: These software tools integrate with the engine’s control systems to provide continuous monitoring and diagnostic capabilities. Engineers can use the software to track performance trends and identify deviations from normal operating conditions.

- Benefits: Optimized engine performance, real-time diagnostics, and informed decision-making for maintenance and repairs.

Data Interpretation

Techniques for Interpreting Diagnostic Data

- Temperature Data Analysis:

- Infrared Thermography: When using infrared thermography, engineers must interpret the thermal images to identify hot spots. These hot spots can indicate potential issues such as overheating components, electrical faults, or fluid leaks.

- Steps:

- Capture thermal images of the engine components.

- Compare the temperature readings to the manufacturer’s specifications.

- Identify any abnormal temperature variations and correlate them with potential issues.

- Example: A hot spot on a bearing may indicate insufficient lubrication or excessive friction.

- Vibration Data Analysis:

- Vibration Analysis: Engineers analyze vibration data to detect imbalances, misalignments, or wear. Different vibration frequencies and amplitudes can indicate specific types of issues.

- Steps:

- Collect vibration data using sensors placed on key engine components.

- Analyze the data to identify patterns and anomalies.

- Compare the findings with baseline vibration levels and industry standards.

- Example: An increase in vibration amplitude at a specific frequency may indicate a misaligned shaft or worn bearings.

- Performance Data Analysis:

- Engine Performance Software: Engineers use engine performance software to monitor and analyze parameters such as fuel consumption, power output, and exhaust emissions. Deviations from normal operating conditions can signal potential issues.

- Steps:

- Continuously monitor engine parameters using performance software.

- Analyze trends and identify deviations from expected performance levels.

- Investigate the root causes of any anomalies detected.

- Example: An unexpected increase in fuel consumption may indicate issues with the fuel injection system or air intake restrictions.

By utilizing these advanced diagnostic tools and techniques for data interpretation, senior marine engineers can effectively identify and address engine issues before they lead to significant failures. This proactive approach not only enhances engine performance and reliability but also reduces maintenance costs and operational downtime.

Fuel System Optimization

Advanced Fuel Contamination Management

Detection: Using Fuel Analysis and Monitoring Systems

- Fuel Analysis:

- Purpose: Fuel analysis is crucial for detecting contaminants such as water, microbial growth, and particulates that can affect engine performance and longevity.

- Application: Regular sampling and laboratory analysis of fuel can identify the presence and concentration of contaminants.

- Benefits: Early detection of contaminants helps in preventing engine damage, reducing maintenance costs, and ensuring optimal engine performance.

- Monitoring Systems:

- Purpose: Advanced monitoring systems continuously assess the quality of fuel in real-time.

- Application: These systems use sensors to detect impurities and provide immediate alerts if contamination levels exceed safe thresholds.

- Benefits: Real-time monitoring allows for prompt corrective actions, minimizing the risk of engine damage and downtime.

Mitigation: Advanced Methods for Fuel Filtration and Treatment

- Fuel Filtration:

- Purpose: Effective fuel filtration systems remove contaminants from fuel before it reaches the engine.

- Types of Filters:

- Primary Filters: Coarse filters that remove larger particulates.

- Secondary Filters: Fine filters that eliminate smaller impurities.

- Benefits: High-quality fuel filtration ensures clean fuel delivery, protecting engine components and enhancing performance.

- Fuel Treatment:

- Purpose: Fuel treatments improve fuel quality by eliminating water and preventing microbial growth.

- Methods:

- Water Separators: Devices that remove water from fuel.

- Biocides: Chemicals added to fuel to kill microbial growth.

- Benefits: Treated fuel reduces the risk of corrosion, clogging, and other issues, leading to better engine efficiency and longevity.

Fuel Injector Calibration

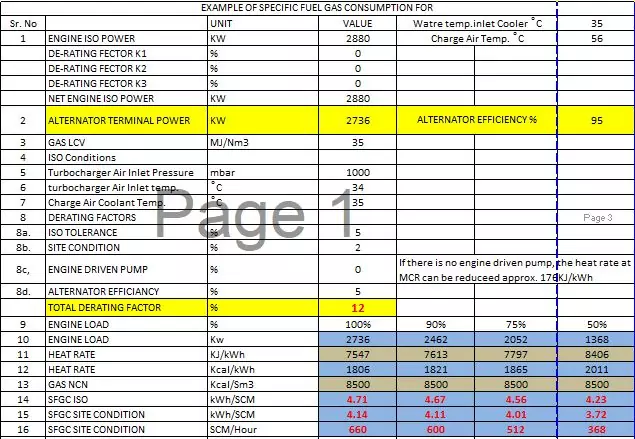

Symptom Analysis: Identifying Issues Through Engine Performance Data and Fuel Consumption Trends

- Performance Data Analysis:

- Purpose: Analyzing engine performance data helps in identifying potential issues with fuel injectors.

- Indicators:

- Increased Fuel Consumption: A sudden rise in fuel usage may indicate injector problems.

- Power Loss: Reduced engine power can be a sign of injector inefficiency.

- Emissions: Higher levels of exhaust emissions can point to injector malfunctions.

- Benefits: Early detection of injector issues allows for timely interventions, preventing more severe engine problems.

Calibration Process: Step-by-Step Guide to Recalibrating Injectors for Optimal Performance

- Preparation:

- Tools and Equipment: Ensure all necessary tools and calibration equipment are available.

- Safety Measures: Follow proper safety protocols to avoid accidents during the calibration process.

- Diagnostic Check:

- Initial Assessment: Use diagnostic tools to assess the current state of the fuel injectors.

- Data Collection: Gather performance data to establish a baseline for calibration.

- Injector Cleaning:

- Cleaning Process: Remove injectors and clean them using appropriate cleaning solutions and tools.

- Inspection: Inspect injectors for wear or damage and replace if necessary.

- Calibration:

- Calibration Bench: Place the injectors on a calibration bench.

- Settings Adjustment: Adjust the injector settings according to manufacturer specifications.

- Flow Testing: Perform flow tests to ensure injectors are delivering the correct amount of fuel.

- Fine-Tuning: Make fine adjustments to achieve optimal injector performance.

- Reinstallation and Testing:

- Reinstallation: Reinstall the calibrated injectors into the engine.

- Performance Testing: Run the engine and monitor performance to ensure the injectors are operating correctly.

- Final Adjustments: Make any necessary final adjustments based on performance data..

Enhancing Air Intake and Exhaust Systems

High-Efficiency Air Filters

Selection Criteria: Choosing the Right High-Efficiency Filters for Specific Engine Types

- Filtration Efficiency:

- Purpose: High-efficiency air filters are designed to remove a greater percentage of airborne particles, including dust, pollen, and other contaminants.

- Criteria: Select filters with high MERV (Minimum Efficiency Reporting Value) ratings, which indicate better filtration performance. Filters with HEPA (High-Efficiency Particulate Air) standards are ideal for capturing fine particles.

- Benefits: Improved air quality leads to better engine combustion, reduced wear on engine components, and enhanced overall performance.

- Compatibility:

- Purpose: Ensure the chosen air filter is compatible with the specific engine type and model.

- Criteria: Refer to the engine manufacturer’s specifications to select filters that fit properly and do not restrict airflow.

- Benefits: Properly fitting filters maintain optimal air intake, ensuring efficient engine operation and preventing potential damage from improper airflow.

- Durability and Materials:

- Purpose: High-quality materials in air filters ensure durability and long service life.

- Criteria: Choose filters made from durable materials like synthetic fibers or specially treated paper that can withstand harsh marine environments.

- Benefits: Durable filters reduce the frequency of replacements, lowering maintenance costs and ensuring consistent engine performance.

Maintenance Schedule: Establishing an Advanced Maintenance Schedule Based on Operating Conditions and Performance Data

- Regular Inspections:

- Frequency: Conduct visual inspections of air filters every 250-500 hours of operation, or as recommended by the manufacturer.

- Procedure: Check for dirt accumulation, damage, and proper fitting. Replace or clean filters as necessary.

- Performance Monitoring:

- Frequency: Continuously monitor engine performance data to identify any signs of reduced airflow or increased fuel consumption, which may indicate a clogged air filter.

- Procedure: Use diagnostic tools to track airflow and engine performance metrics. Adjust the maintenance schedule based on the operating conditions and performance data.

- Cleaning and Replacement:

- Frequency: Depending on the environment and operating conditions, clean or replace air filters every 1,000-2,000 hours, or as specified by the manufacturer.

- Procedure: Follow the manufacturer’s guidelines for cleaning or replacing air filters. Ensure filters are reinstalled correctly to maintain proper airflow.

Exhaust Gas Recirculation (EGR) Systems

Function and Benefits: Understanding the Role of EGR in Reducing Emissions

- Function of EGR:

- Purpose: The EGR system recirculates a portion of the engine’s exhaust gases back into the intake air stream.

- Operation: By mixing exhaust gases with intake air, the EGR system reduces the oxygen concentration in the combustion chamber, lowering combustion temperatures and reducing the formation of nitrogen oxides (NOx).

- Benefits of EGR:

- Emission Reduction: EGR significantly reduces NOx emissions, helping marine engines comply with environmental regulations such as IMO Tier II and Tier III standards.

- Fuel Efficiency: By optimizing combustion, EGR can improve fuel efficiency, reducing operational costs.

- Engine Longevity: Lower combustion temperatures reduce engine wear and tear, extending the engine’s lifespan.

Troubleshooting EGR Issues: Advanced Techniques for Diagnosing and Resolving EGR-Related Problems

- Symptom Identification:

- Common Issues: Symptoms of EGR problems include rough idling, increased fuel consumption, black smoke from the exhaust, and engine knocking.

- Diagnostic Tools: Use OBD-II scanners and engine diagnostic software to read error codes and monitor EGR system parameters.

- Inspection and Cleaning:

- Visual Inspection: Regularly inspect the EGR valve and cooler for signs of carbon buildup or damage.

- Cleaning Procedure: Clean the EGR valve and cooler using specialized cleaning solutions and tools. Ensure all components are free of carbon deposits and functioning correctly.

- Component Testing and Replacement:

- EGR Valve Testing: Test the EGR valve for proper operation using a vacuum pump or diagnostic tool. Replace the valve if it fails to open or close correctly.

- EGR Cooler Testing: Check the EGR cooler for leaks or blockages. Replace the cooler if it is damaged or clogged beyond cleaning.

- Software Updates and Calibration:

- ECU Updates: Ensure the engine control unit (ECU) has the latest software updates, which may include improvements to EGR system management.

- Calibration: Recalibrate the EGR system using diagnostic tools to ensure optimal performance and emission control.

Cooling System Enhancements

Thermal Imaging for Heat Exchanger Efficiency

Implementation: Using Thermal Imaging to Detect Hotspots and Assess Heat Exchanger Performance

- Purpose:

- Thermal imaging is a non-invasive diagnostic tool used to assess the performance of heat exchangers in marine diesel engines. It helps in detecting hotspots that indicate inefficiencies or potential failures in the cooling system.

- Procedure:

- Preparation: Ensure the engine is running under normal operating conditions. Clean the surface of the heat exchanger to remove any dirt or grease that could affect the thermal image.

- Thermal Imaging Camera: Use a high-resolution thermal imaging camera to scan the surface of the heat exchanger. Capture thermal images from multiple angles to get a comprehensive view.

- Analysis: Analyze the thermal images to identify hotspots and temperature variations. Hotspots may indicate areas of reduced coolant flow, fouling, or scaling inside the heat exchanger.

- Benefits:

- Early Detection: Identify potential issues before they lead to significant failures, reducing downtime and maintenance costs.

- Efficiency Improvement: Optimize the performance of the heat exchanger by addressing hotspots and ensuring uniform temperature distribution.

Maintenance Strategies: Advanced Cleaning and Descaling Methods to Enhance Cooling Efficiency

- Chemical Cleaning:

- Chemical Descalers: Use specialized chemical descalers to dissolve mineral deposits and scale inside the heat exchanger. Follow the manufacturer’s guidelines for the correct concentration and application method.

- Circulation Method: Circulate the chemical solution through the heat exchanger for the recommended duration. Ensure proper flushing with clean water afterward to remove any residual chemicals.

- Mechanical Cleaning:

- Plate Cleaning: Disassemble the plate-type heat exchanger and manually clean each plate to remove debris and scale. Use appropriate brushes or scrapers to clean the plates without damaging them.

- Hydroblasting: Employ high-pressure water jets to clean the plates of the heat exchanger. This technique is highly effective for removing tough deposits and ensuring thorough cleaning.

- Preventive Maintenance:

- Regular Inspections: Conduct routine inspections and cleaning of the heat exchanger based on the engine’s operating conditions and manufacturer’s recommendations.

- Water Quality Management: Ensure the cooling water used in the system is of high quality, with minimal impurities that could contribute to scaling and fouling.

Coolant System Integrity Testing

Pressure Testing: Conducting Pressure Tests to Identify Leaks and Weaknesses in the System

- Purpose:

- Pressure testing helps in detecting leaks and assessing the structural integrity of the coolant system. It ensures the system operates efficiently and prevents coolant loss.

- Procedure:

- Preparation: Ensure the engine is cool before starting the test. Isolate the coolant system from the rest of the engine components.

- Testing Equipment: Connect a pressure tester to the coolant system. Gradually increase the pressure to the recommended level specified by the engine manufacturer.

- Inspection: Monitor the pressure gauge for any drops in pressure, which could indicate leaks. Visually inspect the system for signs of coolant leaks, such as wet spots or coolant stains.

- Documentation: Record the results of the pressure test, including any identified leaks and their locations.

- Benefits:

- Leak Detection: Identify and repair leaks early to prevent coolant loss and potential engine overheating.

- System Integrity: Ensure the coolant system maintains its integrity and operates under optimal conditions.

Advanced Coolant Formulations: Selecting and Using Advanced Coolant Formulations for Extended Protection and Performance

- Types of Coolants:

- Ethylene Glycol-Based Coolants: Commonly used for their excellent heat transfer properties and freeze protection.

- Propylene Glycol-Based Coolants: Less toxic than ethylene glycol and safer for the environment, with similar performance characteristics.

- Hybrid Organic Acid Technology (HOAT) Coolants: Provide extended life and improved corrosion protection for mixed-metal engines.

- Selection Criteria:

- Engine Compatibility: Choose coolant formulations that are compatible with the engine’s materials and design.

- Additive Packages: Select coolants with advanced additive packages that provide corrosion protection, prevent scale formation, and enhance heat transfer.

- Operating Conditions: Consider the engine’s operating conditions, such as temperature ranges and environmental factors, when selecting the appropriate coolant.

- Benefits:

- Extended Protection: Advanced coolant formulations offer longer service intervals, reducing the frequency of coolant changes and maintenance.

- Performance Enhancement: Improved heat transfer and corrosion protection ensure optimal engine performance and longevity.

- Environmental Compliance: Using environmentally friendly coolants helps in meeting regulatory requirements and promoting sustainability.

Electrical System Reliability

Battery Management Systems (BMS)

Monitoring and Diagnostics: Utilizing BMS for Real-Time Monitoring and Diagnostics of Battery Health and Performance

- Purpose:

- Battery Management Systems (BMS) are critical for monitoring the health and performance of marine batteries. They provide real-time data on various parameters such as voltage, current, temperature, and state of charge (SOC).

- Components:

- Sensors: BMS utilizes sensors to measure voltage, current, and temperature of individual battery cells.

- Control Unit: The control unit processes sensor data and manages the overall operation of the battery system.

- Communication Interface: Interfaces with the engine’s main control systems to provide real-time data and alerts.

- Functionality:

- Real-Time Monitoring: Continuous tracking of battery parameters to detect anomalies and ensure optimal performance.

- Diagnostics: Analyzing data to identify potential issues such as overcharging, deep discharging, and temperature extremes.

- Alerts and Notifications: Immediate alerts for any critical conditions that could compromise battery health or safety.

- Benefits:

- Preventive Maintenance: Early detection of issues allows for timely interventions, preventing unexpected failures.

- Extended Battery Life: Maintaining optimal operating conditions enhances battery longevity.

- Operational Safety: Real-time monitoring mitigates risks associated with battery malfunctions.

Maintenance Protocols: Developing Advanced Maintenance Protocols to Ensure Battery Longevity and Reliability

- Routine Inspections:

- Visual Checks: Regularly inspect batteries for physical damage, corrosion on terminals, and electrolyte levels (for flooded batteries).

- Connection Integrity: Ensure all connections are tight and free from corrosion.

- Performance Testing:

- Load Testing: Periodically perform load tests to evaluate battery performance under typical operating conditions.

- Capacity Testing: Measure the battery’s capacity to ensure it meets the required specifications.

- Environmental Control:

- Temperature Regulation: Keep batteries within the recommended temperature range to prevent thermal degradation.

- Ventilation: Ensure adequate ventilation to avoid the buildup of harmful gases.

- Charging Protocols:

- Proper Charging: Use chargers compatible with the battery type and follow the manufacturer’s charging recommendations.

- Equalization Charges: Periodically apply equalization charges to balance the charge across all cells (for certain types of batteries).

- Documentation and Record-Keeping:

- Maintain detailed records of all maintenance activities, tests, and performance data. This helps in tracking battery health over time and planning proactive maintenance.

Optimizing Alternator Performance

Performance Testing: Conducting Load and Performance Tests to Ensure Alternator Efficiency

- Purpose:

- Performance testing of alternators ensures they are functioning efficiently and providing adequate power to meet the vessel’s electrical demands.

- Testing Procedures:

- Load Testing: Apply various loads to the alternator and measure its output. This helps in assessing the alternator’s ability to handle different electrical loads.

- Voltage Regulation: Test the alternator’s voltage regulation capabilities to ensure it maintains consistent output voltage under varying load conditions.

- Output Measurement: Measure the alternator’s current and voltage output at different engine speeds to verify its performance across the operational range.

- Equipment Used:

- Multimeter: For measuring voltage, current, and resistance.

- Load Bank: For applying controlled loads to the alternator.

- Oscilloscope: For detailed analysis of voltage and current waveforms.

- Benefits:

- Efficiency Verification: Confirm the alternator is operating at optimal efficiency, which helps in reducing fuel consumption.

- Reliability Assurance: Identify potential issues that could lead to alternator failure, ensuring reliable power supply.

Advanced Troubleshooting: Identifying and Resolving Common Alternator Issues Through Advanced Diagnostic Techniques

- Common Issues:

- Belt Problems: Loose, worn, or broken belts can affect alternator performance.

- Electrical Faults: Issues such as faulty wiring, poor connections, and short circuits.

- Component Failures: Faulty diodes, voltage regulators, or brushes within the alternator.

- Diagnostic Techniques:

- Visual Inspection: Check for physical signs of damage, wear, and loose connections.

- Belt Tension Testing: Use a tension gauge to ensure belts are properly tightened.

- Voltage Drop Testing: Measure voltage drop across connections to identify poor connections or faulty wiring.

- Ripple Voltage Testing: Use an oscilloscope to check for excessive ripple voltage, which can indicate diode failure.

- Resolution Methods:

- Belt Adjustment or Replacement: Adjust the tension or replace worn belts to ensure proper operation.

- Repairing Electrical Faults: Repair or replace faulty wiring and ensure all connections are secure and clean.

- Component Replacement: Replace failed components such as diodes, voltage regulators, or brushes to restore alternator functionality.

- Preventive Measures:

- Regular Maintenance: Implement a routine maintenance schedule for the alternator, including inspections and performance tests.

- Upgrading Components: Consider upgrading to higher-quality components that offer better reliability and performance.

Lubrication System Excellence

Oil Condition Monitoring (OCM)

Implementation: Using OCM Systems to Monitor Oil Quality and Detect Contaminants

- Purpose:

- Oil Condition Monitoring (OCM) systems are essential for maintaining the health and performance of marine diesel engines. They provide real-time data on the quality of the engine oil, including contamination levels, viscosity, and other critical parameters.

- Components:

- Sensors: OCM systems use sensors to measure various properties of the oil, such as particulate contamination, water content, acidity (pH), and viscosity.

- Data Processor: The data collected by the sensors is processed to provide actionable insights into the oil’s condition.

- Display and Alerts: Real-time data is displayed on the engine control panel, and alerts are generated when oil conditions exceed predefined thresholds.

- Implementation Steps:

- Installation: Install OCM sensors at strategic points in the lubrication system where oil quality can be effectively monitored.

- Calibration: Regularly calibrate the sensors to ensure accurate readings.

- Integration: Integrate the OCM system with the engine’s main control system for seamless monitoring and data collection.

- Benefits:

- Early Detection: Detect contaminants and degradation in oil quality early, preventing potential engine damage.

- Cost Savings: Extend the life of the engine oil, reducing the frequency of oil changes and saving on maintenance costs.

- Operational Efficiency: Maintain optimal engine performance by ensuring the lubrication system is functioning correctly.

Predictive Maintenance: Leveraging OCM Data for Predictive Maintenance and Extending Oil Change Intervals

- Data Analysis:

- Trend Analysis: Continuously analyze OCM data to identify trends in oil quality over time.

- Predictive Algorithms: Use predictive algorithms to forecast potential issues based on historical data and current conditions.

- Maintenance Planning:

- Condition-Based Maintenance: Schedule maintenance activities based on the actual condition of the oil rather than fixed intervals. This approach ensures maintenance is performed only when necessary, optimizing resource use.

- Extended Intervals: By accurately monitoring oil quality, it is possible to safely extend oil change intervals, reducing the frequency of oil changes and associated downtime.

- Implementation Steps:

- Data Collection: Collect and store OCM data in a centralized database for analysis.

- Software Tools: Use advanced software tools to analyze the data and generate maintenance recommendations.

- Reporting: Generate regular reports on oil condition and maintenance needs to inform decision-making.

- Benefits:

- Increased Reliability: Reduce the risk of engine failures by performing maintenance based on actual oil conditions.

- Cost Efficiency: Lower maintenance costs by avoiding unnecessary oil changes and extending the service life of the oil.

- Improved Performance: Ensure the engine operates under optimal conditions, enhancing overall performance and efficiency.

Advanced Filtration Techniques

Selection and Maintenance: Choosing High-Efficiency Oil Filters and Establishing Maintenance Schedules Based on Engine Load and Operating Conditions

- Selection Criteria:

- Filtration Efficiency: Select oil filters with high filtration efficiency to remove fine particulates and contaminants from the oil. Look for filters with high Beta ratios, which indicate superior filtration performance.

- Compatibility: Ensure the selected filters are compatible with the specific engine model and the type of oil used.

- Durability: Choose filters made from high-quality materials that can withstand harsh marine environments and prolonged use.

- Types of Filters:

- Primary Filters: Coarse filters that remove larger particles from the oil.

- Secondary Filters: Fine filters that capture smaller particles and provide higher filtration efficiency.

- Bypass Filters: Filters that clean a small portion of the oil continuously, providing additional filtration without restricting flow.

- Maintenance Schedule:

- Regular Inspections: Conduct regular inspections of oil filters to check for signs of clogging or damage. Replace filters as necessary based on their condition.

- Performance Monitoring: Use OCM data to monitor the performance of the filtration system and identify when filters need to be changed.

- Scheduled Replacements: Establish a maintenance schedule for replacing oil filters based on engine load, operating conditions, and the manufacturer’s recommendations.

- Implementation Steps:

- Installation: Properly install high-efficiency oil filters in the engine’s lubrication system.

- Calibration: Ensure filters are correctly calibrated to work with the engine’s operating parameters.

- Monitoring: Continuously monitor filter performance using OCM systems and adjust the maintenance schedule as needed.

- Benefits:

- Improved Oil Quality: High-efficiency filters ensure cleaner oil, which enhances engine performance and longevity.

- Extended Oil Life: Effective filtration extends the life of the oil, reducing the need for frequent changes.

- Reduced Wear and Tear: Cleaner oil reduces engine wear and tear, leading to fewer breakdowns and lower maintenance costs.

Mechanical Integrity and Alignment

Precision Alignment Tools

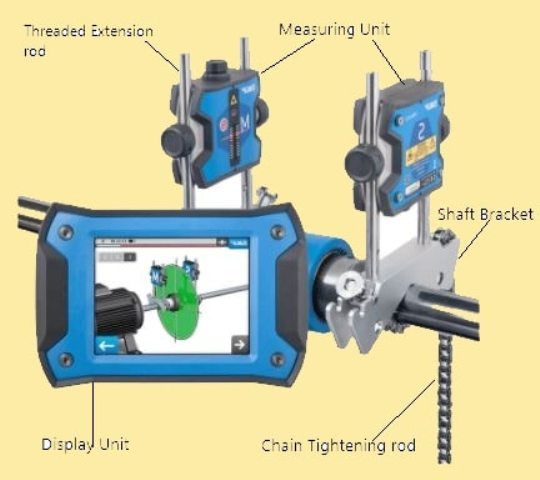

Laser Alignment: Using Laser Alignment Tools for Precise Alignment of Engine Components to Reduce Wear and Improve Efficiency

- Purpose:

- Laser alignment tools are used to ensure precise alignment of engine components, such as shafts, couplings, and bearings. Proper alignment reduces mechanical wear, enhances efficiency, and extends the lifespan of engine components.

- Procedure:

- Preparation: Ensure the engine is stopped and cooled down. Clear the working area of any obstructions.

- Setup: Attach the laser alignment tool to the components that need alignment. Follow the manufacturer’s instructions for setup and calibration.

- Measurement: Activate the laser and take initial alignment readings. The tool projects laser beams that measure the relative positions of the components.

- Adjustment: Use the alignment tool’s feedback to adjust the components until they are perfectly aligned. This may involve moving machinery, adjusting shims, or tightening bolts.

- Verification: Recheck the alignment to confirm accuracy. Repeat the process if necessary until optimal alignment is achieved.

- Benefits:

- Reduced Wear and Tear: Proper alignment minimizes friction and mechanical stress, reducing wear on components.

- Improved Efficiency: Aligning components correctly enhances engine performance and fuel efficiency.

- Extended Component Life: Reduces the likelihood of premature failure and extends the operational life of engine components.

Vibration Analysis: Implementing Vibration Analysis to Detect Misalignment and Mechanical Imbalances

- Purpose:

- Vibration analysis is a diagnostic tool used to detect misalignment, imbalance, and other mechanical issues within the engine. It helps in identifying problems before they lead to significant failures.

- Procedure:

- Installation of Sensors: Attach vibration sensors to key points on the engine, such as bearings, shafts, and housings.

- Data Collection: Operate the engine under normal conditions and collect vibration data over a specified period.

- Analysis: Use specialized software to analyze the vibration data. Look for patterns and anomalies that indicate misalignment or imbalance.

- Diagnosis: Identify the source of the vibration. Common issues include misaligned shafts, unbalanced rotors, and loose components.

- Corrective Action: Implement corrective measures based on the diagnosis, such as realigning components, balancing rotors, or tightening loose parts.

- Benefits:

- Early Detection: Identifies issues early, preventing major failures and downtime.

- Maintenance Planning: Helps in planning targeted maintenance activities, reducing unnecessary inspections.

- Improved Reliability: Enhances the reliability and performance of the engine by ensuring components are operating smoothly.

Component Wear Analysis

Wear Monitoring: Advanced Techniques for Monitoring and Analyzing Component Wear Using Metallurgical Analysis and Ultrasonic Testing

- Purpose:

- Wear monitoring involves using advanced techniques to assess the condition of engine components. This helps in detecting wear and degradation, ensuring timely maintenance and replacement.

- Metallurgical Analysis:

- Sampling: Collect samples of worn components for laboratory analysis.

- Microscopic Examination: Use microscopes to examine the microstructure of the material. Look for signs of wear, such as pitting, cracking, and surface fatigue.

- Chemical Analysis: Conduct chemical analysis to detect changes in material composition that may indicate wear or corrosion.

- Ultrasonic Testing:

- Setup: Place ultrasonic sensors on the component’s surface.

- Data Collection: Emit ultrasonic waves and measure their reflection from the component’s internal structures.

- Analysis: Analyze the ultrasonic data to identify internal flaws, such as cracks and voids, that indicate wear.

- Benefits:

- Accurate Wear Assessment: Provides detailed insights into the condition of components, enabling accurate assessment of wear.

- Timely Maintenance: Ensures maintenance activities are performed based on actual wear conditions, preventing unexpected failures.

- Extended Component Life: Helps in extending the life of components by addressing wear issues proactively.

Proactive Replacement: Developing Proactive Replacement Schedules Based on Wear Analysis Data to Prevent Unexpected Failures

- Purpose:

- Proactive replacement involves replacing components based on wear analysis data rather than waiting for failure. This approach enhances reliability and reduces downtime.

- Procedure:

- Data Collection: Continuously collect wear data using metallurgical analysis and ultrasonic testing.

- Trend Analysis: Analyze trends in wear data to predict the remaining useful life of components.

- Replacement Schedule: Develop a proactive replacement schedule based on the wear data. Replace components before they reach critical wear levels.

- Documentation: Maintain detailed records of wear data and replacement activities to refine the replacement schedule over time.

- Benefits:

- Enhanced Reliability: Prevents unexpected failures by replacing components before they fail.

- Cost Efficiency: Reduces the cost of emergency repairs and downtime.

- Optimal Performance: Ensures the engine operates at peak performance by maintaining components in good condition.

Engine Safeties

Safety Mechanisms: Overview of Critical Safety Mechanisms in Marine Diesel Engines

- Overspeed Protection:

- Purpose: Prevents the engine from running at dangerously high speeds, which can cause mechanical failure or catastrophic damage.

- Mechanism: Utilizes a speed sensor to monitor the engine RPM. If the RPM exceeds the safe limit, the overspeed governor activates to reduce fuel supply or shut down the engine.

- Benefits: Protects engine components from excessive stress and potential failure.

- Oil Pressure Alarms:

- Purpose: Monitors the oil pressure within the engine to ensure it remains within safe operating limits.

- Mechanism: Equipped with pressure sensors that trigger an alarm if the oil pressure drops below the minimum threshold. This can prompt immediate action to prevent engine damage due to insufficient lubrication.

- Benefits: Ensures adequate lubrication of engine parts, preventing wear and overheating.

- Temperature Sensors:

- Purpose: Detects abnormal temperature levels in the engine coolant and exhaust gases.

- Mechanism: Temperature sensors continuously monitor the engine’s operating temperatures. If temperatures exceed safe levels, alarms are triggered, and corrective actions such as cooling system adjustments or engine shutdown are initiated.

- Benefits: Prevents overheating and thermal damage to the engine, ensuring optimal performance and longevity.

- Emergency Shutdown Systems:

- Purpose: Provides a rapid shutdown mechanism in case of severe engine malfunctions or emergencies.

- Mechanism: Integrates with various sensors and safety systems to trigger an immediate engine shutdown when critical conditions are detected.

- Benefits: Protects the engine and crew from dangerous situations by promptly halting operations.

Regular Testing: Procedures for Regular Testing and Verification of Engine Safety Systems

- Scheduled Inspections:

- Frequency: Conduct regular inspections based on the engine manufacturer’s recommendations and operational conditions.

- Procedure: Visually inspect all safety mechanisms for signs of wear, damage, or malfunction. Ensure all sensors and alarms are clean and properly connected.

- Functional Testing:

- Overspeed Protection: Test the overspeed protection system by gradually increasing engine speed to the activation point. Verify that the system activates and reduces speed or shuts down the engine as designed.

- Oil Pressure Alarms: Simulate low oil pressure conditions to ensure the alarm system activates promptly. Check the response time and the accuracy of the pressure sensors.

- Temperature Sensors: Use a controlled heat source to verify that temperature sensors trigger alarms at the correct thresholds. Test both coolant and exhaust temperature sensors.

- Emergency Shutdown Systems: Conduct emergency shutdown drills to ensure the system responds correctly to simulated emergencies. Verify that all sensors and triggers are functioning as intended.

- Documentation and Record-Keeping:

- Maintain detailed records of all testing procedures, results, and any corrective actions taken. Use these records to track the performance and reliability of safety systems over time.

Troubleshooting Safety Systems: Advanced Troubleshooting Methods for Addressing False Alarms and Ensuring System Reliability

- Diagnostic Tools:

- Use advanced diagnostic tools and software to analyze the performance of safety systems. Tools such as multimeters, pressure gauges, and thermal cameras can help identify issues with sensors and alarms.

- System Calibration:

- Regularly calibrate sensors and alarms to ensure accuracy. Follow the manufacturer’s guidelines for calibration procedures and use certified calibration equipment.

- Addressing False Alarms:

- Symptom Analysis: Identify patterns in false alarms to determine potential causes. Check for environmental factors, such as temperature fluctuations or electrical interference, that may trigger false alarms.

- Sensor Inspection: Inspect sensors for dirt, corrosion, or mechanical damage that could affect their performance. Clean or replace sensors as needed.

- Wiring and Connections: Check all wiring and connections for loose or corroded terminals. Ensure that all electrical connections are secure and free from damage.

- System Updates:

- Keep the safety system’s software and firmware up to date. Manufacturers often release updates that improve system reliability and address known issues.

- Training and Awareness:

- Ensure that all crew members are trained on the operation and troubleshooting of engine safety systems. Regularly update training programs to include new technologies and best practices.

Engine Instrumentations

Key Instrumentation: Description of Essential Engine Instrumentation

- Pressure Gauges:

- Purpose: Measure the pressure of various fluids within the engine, such as oil, fuel, and coolant.

- Types:

- Bourdon Tube Gauges: Commonly used for measuring oil and fuel pressure.

- Differential Pressure Gauges: Used for applications where the pressure difference between two points needs to be measured.

- Function: Provide real-time data to ensure that fluid pressures are within the safe operating range, preventing damage and ensuring optimal performance.

- Benefits: Helps in early detection of pressure-related issues, such as leaks or blockages.

- Temperature Sensors:

- Purpose: Monitor the temperature of engine components and fluids, such as the coolant, exhaust gases, and lubricating oil.

- Types:

- Thermocouples: Used for high-temperature measurements, such as exhaust gases.

- Resistance Temperature Detectors (RTDs): Provide precise temperature readings for coolant and oil.

- Function: Ensure temperatures remain within safe limits to prevent overheating and thermal damage.

- Benefits: Enables timely interventions to prevent overheating and maintain engine efficiency.

- Flow Meters:

- Purpose: Measure the flow rate of fluids, such as fuel and coolant, within the engine.

- Types:

- Turbine Flow Meters: Measure the flow rate by detecting the rotation speed of a turbine placed in the flow path.

- Coriolis Flow Meters: Measure mass flow rate directly, providing high accuracy.

- Function: Ensure proper fluid circulation and detect any abnormalities in flow rates.

- Benefits: Helps in maintaining optimal fuel and coolant flow, preventing issues such as fuel starvation or overheating.

Data Analysis: Techniques for Analyzing Instrumentation Data to Detect Trends and Anomalies

- Trend Analysis:

- Purpose: Identify long-term patterns and trends in instrumentation data to predict potential issues before they become critical.

- Technique: Use data visualization tools, such as line graphs and histograms, to track changes in pressure, temperature, and flow over time.

- Implementation: Regularly collect and review data from pressure gauges, temperature sensors, and flow meters. Compare current data with historical records to identify deviations from normal operating conditions.

- Benefits: Early detection of trends, such as gradually increasing oil temperature, allows for proactive maintenance and prevents unexpected failures.

- Anomaly Detection:

- Purpose: Detect sudden deviations from normal operating conditions that could indicate a problem.

- Technique: Use statistical analysis and machine learning algorithms to identify anomalies in the data.

- Implementation: Set thresholds for key parameters based on manufacturer specifications and engine operating conditions. Use real-time monitoring systems to trigger alerts when data exceeds these thresholds.

- Benefits: Immediate identification of issues, such as a sudden drop in oil pressure, enables quick response and minimizes potential damage.

Calibration and Maintenance: Best Practices for the Calibration and Maintenance of Engine Instrumentation to Ensure Accuracy and Reliability

- Calibration:

- Purpose: Ensure that instrumentation readings are accurate and reliable.

- Procedure:

- Regular Calibration: Schedule regular calibration of pressure gauges, temperature sensors, and flow meters based on the manufacturer’s recommendations.

- Calibration Equipment: Use certified calibration equipment to verify the accuracy of the instruments. Adjust the instruments as necessary to correct any deviations.

- Documentation: Maintain detailed records of all calibration activities, including the date, results, and any adjustments made.

- Benefits: Accurate instrumentation ensures reliable data for monitoring and decision-making, enhancing engine performance and safety.

- Maintenance:

- Purpose: Maintain the functionality and longevity of engine instrumentation.

- Procedure:

- Routine Inspections: Regularly inspect instruments for signs of wear, damage, or malfunction. Clean sensors and gauges to ensure they are free from debris and contaminants.

- Functional Testing: Perform functional tests to verify that instruments are operating correctly. For example, use a known pressure source to test pressure gauges or a temperature source to test sensors.

- Replacement: Replace any instruments that are found to be faulty or beyond their service life. Use high-quality replacement parts that meet the manufacturer’s specifications.

- Benefits: Proper maintenance ensures that instruments continue to provide accurate and reliable data, reducing the risk of engine failures and enhancing overall safety.

Engine Control Systems

Overview of Modern Control Systems: Description of Advanced Engine Control Systems

- Electronic Control Units (ECUs):

- Purpose: ECUs are critical components in modern marine diesel engines, responsible for controlling various engine functions to ensure optimal performance and efficiency.

- Functionality:

- Fuel Injection: ECUs precisely control the timing and amount of fuel injected into the combustion chambers, optimizing fuel efficiency and power output.

- Emission Control: They manage exhaust gas recirculation (EGR) systems and other emission control technologies to reduce pollutants.

- Engine Diagnostics: ECUs continuously monitor engine parameters, such as temperature, pressure, and RPM, and provide real-time diagnostics to detect and report faults.

- Benefits: Improved fuel efficiency, reduced emissions, enhanced performance, and early detection of potential issues.

- Integrated Monitoring Systems:

- Purpose: These systems integrate various sensors and control units to provide a comprehensive overview of engine performance and health.

- Components:

- Sensors: Monitor parameters such as temperature, pressure, fuel flow, and exhaust gases.

- Control Panels: Display real-time data and alerts, allowing engineers to monitor engine performance and respond to issues quickly.

- Communication Networks: Enable communication between different engine components and with the vessel’s central monitoring system.

- Benefits: Enhanced situational awareness, improved decision-making, and streamlined maintenance processes.

Troubleshooting Control Systems: Advanced Methods for Diagnosing and Resolving Issues

- Diagnostic Tools:

- OBD-II Scanners: These tools interface with the ECU to read fault codes and provide detailed information about engine performance issues.

- Diagnostic Software: Advanced software solutions analyze data from ECUs and sensors to identify patterns and potential faults.

- Multimeters and Oscilloscopes: Used for testing electrical signals and diagnosing issues with sensors and wiring.

- Common Issues and Solutions:

- Faulty Sensors: Symptoms include incorrect data readings and erratic engine behavior.

- Diagnosis: Use diagnostic tools to identify faulty sensors. Check for physical damage, loose connections, and correct calibration.

- Solution: Replace or recalibrate the faulty sensors. Ensure proper installation and connection.

- ECU Failures: Symptoms include engine misfires, poor performance, and unresponsive controls.

- Diagnosis: Use diagnostic software to analyze ECU performance and identify error codes. Check for software corruption or hardware damage.

- Solution: Update ECU software or replace the unit if hardware damage is detected.

- Wiring Issues: Symptoms include intermittent electrical problems and sensor malfunctions.

- Diagnosis: Use multimeters to test continuity and resistance in the wiring. Look for signs of wear, corrosion, or loose connections.

- Solution: Repair or replace damaged wiring and ensure all connections are secure.

- Faulty Sensors: Symptoms include incorrect data readings and erratic engine behavior.

- Preventive Measures:

- Regular Inspections: Conduct routine inspections of sensors, wiring, and ECUs to detect and address issues early.

- Firmware Updates: Keep ECU firmware up to date to ensure compatibility with the latest diagnostic tools and control algorithms.

- Training: Ensure that engineering staff are trained in the use of diagnostic tools and techniques for effective troubleshooting.

Software Updates and Integration: Importance of Regular Software Updates and Integration with Other Vessel Systems

- Software Updates:

- Purpose: Regular software updates ensure that ECUs and integrated monitoring systems operate with the latest features, bug fixes, and security enhancements.

- Procedure:

- Check for Updates: Regularly check with the engine manufacturer for available updates.

- Backup Data: Before updating, back up current settings and data.

- Install Updates: Follow manufacturer instructions to install updates. Ensure that the engine is not in operation during the update process.

- Benefits: Enhanced performance, improved reliability, and access to new features that improve engine management and diagnostics.

- System Integration:

- Purpose: Integrating engine control systems with other vessel systems, such as navigation and communication, enhances overall vessel performance and safety.

- Components:

- Data Sharing: Share data between the engine control system and other systems to provide a holistic view of vessel operations.

- Centralized Monitoring: Use a centralized monitoring system to oversee all aspects of vessel performance, including engine health, navigation, and safety systems.

- Automated Responses: Implement automated responses to certain conditions, such as adjusting engine power based on navigation data or environmental conditions.

- Benefits: Improved operational efficiency, enhanced safety, and streamlined decision-making processes.

FAQ on “Marine Diesel Engine Troubleshooting”

Q: What causes a marine diesel engine to overheat?

A1: Overheating can be caused by coolant leaks, clogged heat exchangers, or faulty water pumps.

Q: How can I identify fuel contamination in my marine diesel engine?

A: Symptoms of fuel contamination include engine misfires, decreased performance, and visible particles in fuel filters.

Q: Why is my marine diesel engine emitting black smoke?

A: Black smoke often indicates an over-rich fuel mixture, which can be due to clogged air filters, faulty injectors, or turbocharger issues.

Q: What should I do if my marine diesel engine has low oil pressure?

A: Check for oil leaks, ensure proper oil levels, and inspect the oil pump and pressure sensor for faults.

Conclusion

Maintaining and optimizing marine diesel engines requires a comprehensive understanding of advanced systems and techniques. From precision alignment tools and vibration analysis to oil condition monitoring and advanced engine control systems, senior marine engineers must stay informed and skilled in the latest technologies. Regular testing, proactive maintenance, and integration of modern control systems ensure engines run efficiently, reliably, and safely. By following these advanced practices, marine engineers can significantly enhance engine performance, reduce downtime, and ensure the safety and efficiency of marine operations. Continuous learning and adaptation are key to staying ahead in the ever-evolving field of marine engineering.