Marine Engine Monitoring Systems

In the fast-evolving maritime industry, ensuring the optimal performance and reliability of marine engines is paramount. Advanced engine monitoring systems are game-changers, providing real-time data and diagnostics that enhance operational efficiency and safety. These sophisticated systems not only alert operators to potential issues before they escalate but also optimize maintenance schedules, reduce downtime, and extend engine life.

In this blog post, we delve into the top 7 most powerful marine engine monitoring systems available today. Each of these systems offers unique features and capabilities designed to meet the rigorous demands of marine environments, ensuring that your vessel runs smoothly and efficiently. By leveraging these cutting-edge technologies, ship operators can achieve unparalleled reliability and performance, making maritime operations safer and more cost-effective.

Understanding Marine Engine Monitoring Systems

Definition and Purpose Marine engine monitoring systems are sophisticated technological solutions designed to continuously oversee the performance, health, and operational status of marine engines. These systems utilize a network of sensors and data processors to collect real-time information about various engine parameters, such as temperature, pressure, fuel consumption, and vibration levels. The primary function of these systems is to provide detailed insights and diagnostics that enable operators to maintain optimal engine performance, identify and address potential issues before they lead to serious problems, and ensure the overall efficiency and safety of the vessel.

Key Benefits

- Enhanced Safety

- Real-Time Alerts: Monitoring systems provide immediate alerts when engine parameters deviate from normal ranges, allowing operators to take prompt corrective actions and prevent catastrophic failures.

- Diagnostic Capabilities: These systems can diagnose underlying issues, helping to avoid dangerous situations that could arise from undetected engine problems.

- Compliance and Reporting: They assist in ensuring compliance with safety regulations by maintaining detailed records and generating reports necessary for regulatory inspections.

- Improved Efficiency

- Optimized Performance: By continuously monitoring and adjusting engine parameters, these systems ensure that the engine operates at peak efficiency, reducing fuel consumption and minimizing wear and tear.

- Fuel Management: Advanced monitoring systems provide precise fuel consumption data, enabling better fuel management and cost savings through efficient operation.

- Maintenance Scheduling: Predictive maintenance features analyze data trends to forecast when maintenance should be performed, reducing unexpected downtimes and extending the life of engine components.

- Cost Savings

- Reduced Downtime: By identifying potential issues early, monitoring systems help prevent unscheduled repairs and reduce downtime, leading to significant cost savings.

- Lower Repair Costs: Early detection and diagnosis of problems mean that repairs can be made before they escalate into more expensive and complex issues.

- Operational Efficiency: Enhanced engine performance and optimized fuel consumption contribute to lower operational costs, providing a substantial return on investment for monitoring systems.

By implementing marine engine monitoring systems, ship operators can achieve unparalleled levels of safety, efficiency, and cost-effectiveness. These systems represent a critical advancement in maritime technology, transforming how marine engines are managed and maintained. With real-time data and advanced diagnostics at their fingertips, operators can ensure their vessels operate smoothly and reliably, navigating the challenges of the open sea with confidence.

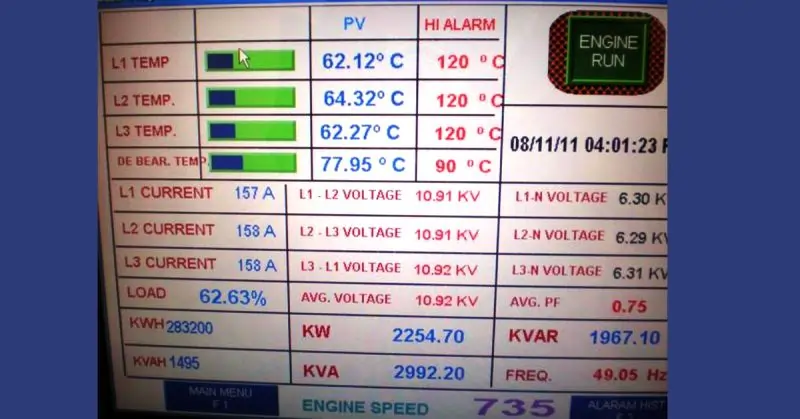

System 1 – Real-Time Data Collection

Features Real-time data collection systems are designed to provide continuous monitoring and instant feedback on various engine parameters. These systems are equipped with an array of sensors that measure critical metrics such as temperature, pressure, fuel flow, exhaust emissions, and vibration levels. The data collected by these sensors is transmitted in real-time to a central processing unit, which analyzes the information and displays it on user-friendly interfaces, such as dashboards or mobile apps. Key features of real-time data collection systems include:

- Instant Data Transmission: Data is collected and transmitted instantly, allowing for immediate analysis and action.

- Comprehensive Monitoring: Coverage includes all vital engine components, ensuring no aspect of engine performance is overlooked.

- User-Friendly Interface: Real-time data is displayed on intuitive interfaces, making it easy for operators to monitor and interpret.

- Alerts and Notifications: Automated alerts and notifications are triggered when parameters deviate from preset thresholds, ensuring timely interventions.

- Data Logging: Historical data is stored for trend analysis, helping in identifying recurring issues and predicting future problems.

Benefits The capabilities of real-time data collection systems translate into several significant benefits for marine engine management:

- Proactive Maintenance: Continuous monitoring allows for the early detection of potential issues before they escalate, enabling proactive maintenance. This approach helps to avoid costly and unexpected repairs, reducing overall maintenance costs.

- Immediate Troubleshooting: Real-time data provides instant feedback on engine performance, allowing operators to quickly diagnose and troubleshoot problems as they arise. This immediate response capability minimizes downtime and ensures the engine operates smoothly.

- Enhanced Engine Performance: By monitoring and optimizing engine parameters in real-time, these systems help maintain optimal engine performance, improving fuel efficiency and reducing wear and tear.

- Informed Decision Making: Access to comprehensive and current data enables better decision-making regarding engine operations, maintenance schedules, and performance improvements.

- Improved Safety: Real-time alerts ensure that any deviations from normal operating conditions are promptly addressed, enhancing the overall safety of the vessel.

Case Study: Improved Performance with Real-Time Data Collection A commercial cargo vessel operating in the North Atlantic experienced frequent engine issues, leading to costly repairs and operational downtime. To address these challenges, the vessel’s management decided to implement a real-time data collection system.

After installing the system, the vessel’s crew immediately began receiving real-time data on critical engine parameters. Within the first month, the system detected abnormal vibration levels that indicated an impending bearing failure. By addressing this issue proactively, the crew was able to replace the faulty bearing during a scheduled port stop, avoiding a potentially catastrophic failure at sea.

Additionally, the real-time data collection system provided detailed insights into fuel consumption patterns. By analyzing this data, the crew identified inefficiencies in the fuel injection system and made necessary adjustments. This optimization led to a 15% reduction in fuel consumption over the next six months, significantly lowering operational costs.

System 2 – Predictive Maintenance Tools

Features Predictive maintenance tools leverage advanced data analytics, machine learning algorithms, and historical data to anticipate and predict maintenance needs before issues become critical. These tools analyze real-time data collected from various engine sensors and compare it with historical performance data to identify patterns and trends that indicate potential failures. Key features of predictive maintenance tools include:

- Data Analytics: Use of sophisticated algorithms to analyze vast amounts of data from engine sensors.

- Machine Learning: Continuous learning from new data to improve the accuracy of predictions over time.

- Condition Monitoring: Constant monitoring of engine conditions to detect anomalies and deviations from normal performance.

- Trend Analysis: Identification of patterns and trends that signal potential issues, allowing for early intervention.

- Automated Alerts: Notifications and alerts generated based on predictive analytics, prompting timely maintenance actions.

- Integration with Maintenance Systems: Seamless integration with existing maintenance management systems to streamline workflows and documentation.

Benefits The implementation of predictive maintenance tools offers numerous advantages that contribute to the overall efficiency and reliability of marine engines:

- Reduction in Unexpected Breakdowns: By predicting potential failures before they occur, these tools help prevent unexpected breakdowns, ensuring continuous and reliable engine operation.

- Lower Maintenance Costs: Early detection of issues allows for scheduled maintenance rather than emergency repairs, significantly reducing maintenance costs and downtime.

- Extended Engine Life: Proactive maintenance based on predictive analytics helps maintain optimal engine conditions, extending the life of engine components.

- Improved Safety: By avoiding sudden failures, predictive maintenance enhances the safety of the vessel and its crew.

- Optimized Maintenance Schedules: Predictive tools enable maintenance to be performed only when necessary, avoiding unnecessary routine checks and focusing resources on critical areas.

Case Study: Success with Predictive Maintenance on a Cargo Ship A large cargo ship operating on transatlantic routes faced frequent engine breakdowns, resulting in significant repair costs and operational delays. To address these challenges, the shipping company implemented a predictive maintenance tool integrated with the ship’s engine monitoring system.

Within a few months, the predictive maintenance tool began identifying subtle anomalies in the engine’s vibration data. The analytics suggested a potential issue with the turbocharger bearings. Based on this prediction, the maintenance team conducted a thorough inspection and discovered early signs of wear that had not yet caused any operational problems.

By addressing the issue early, the team replaced the bearings during a scheduled maintenance window, avoiding a potential in-voyage failure that would have resulted in costly emergency repairs and delays. Additionally, the predictive maintenance tool highlighted irregularities in fuel injection patterns, prompting an adjustment that improved fuel efficiency by 10%.

Over the next year, the cargo ship experienced a 25% reduction in maintenance costs and a significant decrease in unexpected breakdowns. The predictive maintenance tool proved invaluable, allowing the ship to operate more efficiently, safely, and cost-effectively. This success story underscores the transformative impact of predictive maintenance tools in enhancing marine engine reliability and performance.

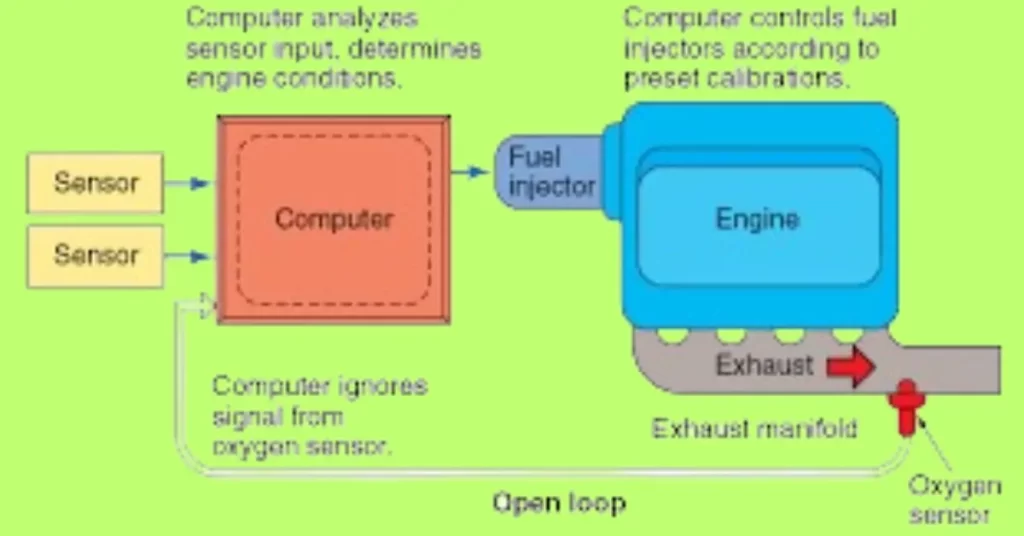

System 3 – Diagnostic Software

Features Diagnostic software for marine engines is designed to provide comprehensive, real-time analysis and troubleshooting capabilities. These tools integrate with the engine’s electronic control units (ECUs) and utilize a range of sensors to monitor various engine parameters. The primary functionalities of diagnostic software include:

- Real-Time Monitoring: Continuously monitors engine performance metrics such as temperature, pressure, fuel consumption, and emission levels.

- Fault Detection: Identifies and logs error codes generated by the engine’s ECUs, pinpointing specific issues and their potential causes.

- Data Visualization: Provides graphical representations of engine data, making it easier to interpret performance trends and identify anomalies.

- Historical Data Analysis: Stores and analyzes historical performance data to detect recurring issues and predict future problems.

- Automated Reporting: Generates detailed diagnostic reports, including error codes, potential causes, and recommended corrective actions.

- User-Friendly Interface: Features an intuitive interface that simplifies the process of accessing and understanding diagnostic information.

Benefits The use of diagnostic software in marine engines offers numerous benefits, enhancing the efficiency and reliability of engine operations:

- Early Issue Identification: By continuously monitoring engine parameters and detecting anomalies, diagnostic software can identify issues before they escalate into major problems, allowing for timely intervention.

- Reduced Downtime: Early detection and diagnosis of potential issues help prevent unexpected breakdowns, minimizing downtime and ensuring continuous operation.

- Cost Savings: Proactive identification and resolution of issues reduce the need for emergency repairs and associated costs, contributing to overall cost savings.

- Improved Maintenance Planning: Detailed diagnostic reports provide valuable insights into engine performance, enabling more effective maintenance planning and resource allocation.

- Enhanced Engine Performance: By ensuring that issues are addressed promptly, diagnostic software helps maintain optimal engine performance and efficiency.

- Safety Assurance: Accurate and timely diagnostics enhance the safety of the vessel and crew by preventing potential engine failures.

Case Study: Diagnostic Software Detecting and Resolving a Critical Issue A commercial fishing vessel operating in the Pacific Ocean experienced intermittent power loss, which significantly impacted its fishing operations. Despite regular maintenance checks, the crew was unable to identify the root cause of the problem. To address this issue, the vessel’s management decided to implement advanced diagnostic software.

Upon installation, the diagnostic software immediately began monitoring the engine’s performance metrics in real-time. Within a short period, the software detected an unusual pattern in the fuel pressure readings, which was not apparent during manual inspections. The software flagged a potential issue with the fuel injection system and generated an error code indicating a possible malfunction in one of the fuel injectors.

Armed with this information, the maintenance team conducted a targeted inspection of the fuel injection system and discovered that one of the injectors was partially clogged, causing inconsistent fuel delivery and power loss. The faulty injector was promptly replaced, and the engine’s performance returned to optimal levels.

The use of diagnostic software not only resolved the critical issue but also prevented further operational disruptions and potential damage to the engine. This proactive approach resulted in significant cost savings by avoiding more extensive repairs and downtime. The successful resolution of the problem highlighted the importance of advanced diagnostic tools in maintaining the efficiency, reliability, and safety of marine engines.

System 4 – Performance Monitoring Systems

Features Performance monitoring systems are advanced tools designed to continuously track and analyze the operational efficiency of marine engines. These systems integrate multiple components and technologies to provide a comprehensive overview of engine performance. Key features include:

- Sensor Network: A network of sensors installed throughout the engine to monitor parameters such as fuel flow, engine load, RPM, temperature, and pressure.

- Data Aggregation: Centralized data collection from all sensors, allowing for real-time and historical performance analysis.

- Analytics Engine: Advanced algorithms that process the collected data to identify performance trends, inefficiencies, and potential issues.

- User Interface: Intuitive dashboards and displays that provide easy access to performance metrics, visualizations, and alerts.

- Reporting Tools: Automated generation of performance reports that summarize key metrics and offer actionable insights.

- Integration Capabilities: Ability to integrate with other ship systems and management software for a holistic approach to vessel operations.

Benefits The deployment of performance monitoring systems offers significant benefits, enhancing both fuel efficiency and overall engine performance:

- Optimized Fuel Efficiency: By continuously monitoring fuel flow and consumption patterns, these systems help identify opportunities for optimizing fuel usage, reducing overall consumption and costs.

- Enhanced Engine Performance: Real-time data and analytics allow for fine-tuning of engine parameters to maintain optimal performance under varying conditions.

- Early Detection of Issues: Performance monitoring systems can detect deviations from normal operation, signaling potential problems before they escalate into more serious issues.

- Informed Decision-Making: Detailed performance data provides the basis for informed decisions regarding engine operation, maintenance scheduling, and operational strategies.

- Reduced Operational Costs: Improved fuel efficiency and early issue detection lead to lower operational costs and extended engine lifespan.

- Environmental Benefits: Optimized fuel consumption reduces emissions, contributing to more environmentally friendly operations.

Case Study: Performance Monitoring Leading to Significant Fuel Savings A large container ship operating on a global trade route faced challenges with high fuel consumption and inconsistent engine performance. To address these issues, the ship’s management implemented an advanced performance monitoring system.

Upon installation, the performance monitoring system began collecting real-time data on fuel flow, engine load, RPM, and other critical parameters. Within a few weeks, the system identified that the engine was frequently operating outside its optimal load range, leading to inefficient fuel consumption.

The analytics engine highlighted specific periods and operational conditions where fuel efficiency could be improved. Based on these insights, the crew adjusted the engine load management strategy, optimizing the engine’s operational profile to maintain it within the optimal range more consistently.

Additionally, the performance monitoring system revealed that certain routes and speed profiles resulted in higher fuel consumption. By adjusting the ship’s sailing speed and route planning based on the performance data, the management was able to further reduce fuel usage.

Over the course of six months, these adjustments led to a remarkable 12% reduction in fuel consumption, translating to significant cost savings and reduced emissions. The success of the performance monitoring system not only improved the ship’s operational efficiency but also demonstrated the value of data-driven decision-making in marine engine management.

This case study underscores the transformative impact of performance monitoring systems in optimizing fuel efficiency and enhancing overall engine performance. By leveraging real-time data and advanced analytics, marine operators can achieve substantial economic and environmental benefits.

System 5 – Alarm and Alert Systems

Features Alarm and alert systems are critical components of marine engine monitoring systems, designed to ensure the safety and reliability of engine operations. These systems integrate various types of alarms and alerts that notify the crew of potential issues in real-time. Key features of these systems include:

- Sensor Integration: Alarms are connected to a wide array of sensors monitoring parameters such as temperature, pressure, fuel levels, and vibration.

- Real-Time Notifications: Instant alerts are sent to the crew via visual and auditory signals, as well as through digital displays and mobile notifications.

- Threshold Settings: Customizable thresholds for different parameters allow for specific and precise monitoring of engine conditions.

- Critical Alerts: Immediate alerts for critical conditions that require urgent attention to prevent severe damage or failure.

- Diagnostic Alerts: Notifications about non-critical issues that need attention during routine maintenance to prevent future problems.

- Event Logging: Detailed logs of all alerts and alarms, which are essential for post-incident analysis and continuous improvement of maintenance protocols.

- Redundancy and Backup: Multiple layers of alert systems to ensure no single point of failure, enhancing reliability.

Benefits Alarm and alert systems play a vital role in maintaining the safety and efficiency of marine engine operations. The primary benefits include:

- Prevention of Damage: Early detection of potential issues through alarms allows the crew to take corrective actions before minor issues escalate into major failures, thereby preventing costly damage to the engine.

- Enhanced Crew Safety: Immediate alerts about hazardous conditions, such as overheating or fuel leaks, ensure that the crew can respond quickly to avoid dangerous situations, thus ensuring their safety.

- Operational Efficiency: By providing timely notifications about engine performance deviations, these systems help maintain optimal operational conditions, thereby enhancing overall efficiency.

- Reduced Downtime: Proactive alerts enable the crew to address issues promptly, minimizing unscheduled downtimes and maintaining continuous operations.

- Regulatory Compliance: Alarm systems help ensure compliance with safety regulations and standards, providing detailed logs and reports that are necessary for regulatory inspections.

Case Study: Emergency Averted Due to Timely Alerts A mid-sized oil tanker was navigating through a busy shipping lane when its engine monitoring system detected a rapid increase in engine temperature, surpassing the preset safety threshold. The alarm system immediately triggered a critical alert, notifying the crew through loud auditory signals and flashing lights on the main control panel. Simultaneously, detailed alerts were sent to the crew’s mobile devices, indicating the specific issue and the affected engine compartment.

The crew swiftly responded to the alerts, initiating emergency protocols to cool down the engine. Upon inspection, they discovered that a cooling system pump had failed, causing the engine to overheat. Thanks to the timely alerts, the crew was able to shut down the engine safely and prevent catastrophic damage. They quickly activated the backup cooling system and replaced the faulty pump.

The entire process, from detection to resolution, took less than 30 minutes, and the ship resumed its journey with minimal delay. The timely intervention not only saved the engine from significant damage but also ensured the safety of the crew and the cargo. The event log provided by the alarm system was later used to analyze the incident and improve the ship’s maintenance protocols, preventing future occurrences.

This case study highlights the critical importance of alarm and alert systems in marine engine monitoring. By providing immediate and actionable alerts, these systems play a crucial role in preventing damage, ensuring crew safety, and maintaining operational efficiency.

System 6 – Remote Monitoring Solutions

Features Remote monitoring solutions for marine engines offer advanced capabilities that allow for the centralized monitoring and management of entire fleets from any location. These systems leverage the power of the internet, satellite communications, and advanced data analytics to provide comprehensive oversight and control over vessel operations. Key features of remote monitoring solutions include:

- Global Connectivity: Continuous data transmission via satellite or cellular networks, ensuring real-time monitoring regardless of the vessel’s location.

- Centralized Dashboard: A unified interface that aggregates data from all vessels in the fleet, providing an overview of their status and performance.

- Real-Time Alerts and Notifications: Instant alerts sent to fleet managers and maintenance teams, enabling immediate response to any issues.

- Historical Data Analysis: Access to historical performance data for trend analysis and predictive maintenance planning.

- Advanced Analytics: Use of AI and machine learning to analyze data, detect anomalies, and provide actionable insights.

- Integration Capabilities: Seamless integration with existing fleet management systems, allowing for cohesive and streamlined operations.

- User Access Control: Secure access controls to ensure that only authorized personnel can view and manage the data.

Benefits The implementation of remote monitoring solutions offers numerous benefits that enhance the efficiency and effectiveness of fleet management:

- Centralized Control: Remote access allows fleet managers to monitor and manage multiple vessels from a single location, providing a holistic view of fleet operations.

- Improved Operational Efficiency: Real-time data and alerts enable proactive management, reducing downtime and optimizing maintenance schedules.

- Cost Savings: Early detection of issues and optimized maintenance schedules lead to significant cost savings by preventing major repairs and reducing fuel consumption.

- Enhanced Safety: Continuous monitoring ensures that any potential safety issues are identified and addressed promptly, protecting both the crew and the vessel.

- Data-Driven Decision Making: Advanced analytics and historical data provide insights that help in making informed decisions about fleet operations and maintenance strategies.

- Regulatory Compliance: Remote monitoring helps ensure compliance with maritime regulations by maintaining detailed logs and reports required for inspections.

Case Study: Enhanced Operational Efficiency with Remote Monitoring A major shipping company operating a fleet of container ships faced challenges in maintaining consistent operational efficiency and reducing downtime. To address these issues, the company implemented a comprehensive remote monitoring solution across its fleet.

With the new system in place, fleet managers gained real-time visibility into the performance and health of each vessel’s engines. The centralized dashboard provided a holistic view of the fleet, highlighting any anomalies or deviations from normal operating conditions. One particular vessel, often experiencing unplanned maintenance due to fuel injector issues, became a focal point.

The remote monitoring system detected irregularities in the fuel injection system’s performance parameters. Advanced analytics flagged the issue and predicted an imminent failure if not addressed. The fleet manager received an immediate alert and scheduled a maintenance stop at the next port. The maintenance team replaced the faulty injectors before a breakdown occurred.

In another instance, the system identified excessive fuel consumption on several vessels. Analysis revealed that certain routes and operating conditions were less fuel-efficient. Using these insights, the company optimized its routing and speed management, resulting in a 15% reduction in fuel costs across the fleet over the next quarter.

The remote monitoring solution also played a critical role in improving the company’s compliance with environmental regulations. Continuous emissions monitoring ensured that all vessels met regulatory standards, and detailed reports were readily available for inspections.

Overall, the implementation of remote monitoring led to a significant improvement in operational efficiency, reduced maintenance costs, and enhanced safety across the fleet. The company’s ability to proactively manage its vessels from a centralized location demonstrated the transformative impact of remote monitoring solutions in modern maritime operations.

System 7 – Comprehensive Engine Management Systems

Features Comprehensive engine management systems are all-in-one solutions that integrate multiple monitoring and management functionalities into a single, cohesive platform. These systems provide a holistic approach to marine engine management by combining real-time data collection, predictive maintenance, diagnostic tools, performance monitoring, and alarm systems. Key features of comprehensive engine management systems include:

- Integrated Monitoring: Consolidates data from various sensors to monitor engine parameters such as temperature, pressure, fuel consumption, and emissions in real-time.

- Predictive Analytics: Utilizes machine learning and data analytics to predict maintenance needs and potential failures before they occur.

- Diagnostic Capabilities: Includes advanced diagnostic tools that identify and troubleshoot issues, providing detailed error codes and suggested corrective actions.

- Performance Optimization: Tracks and analyzes engine performance metrics to optimize fuel efficiency and overall engine operation.

- Alarm and Alert System: Provides real-time alerts and notifications for any deviations from normal operating conditions, ensuring prompt response to potential issues.

- Historical Data Analysis: Stores and analyzes historical data to identify trends and inform maintenance strategies.

- User-Friendly Interface: Features an intuitive interface that offers easy access to comprehensive data and insights through dashboards and reports.

- Remote Access: Allows for remote monitoring and management of engine systems, providing flexibility and control from any location.

Benefits The integration of various monitoring and management functionalities into a single system offers significant advantages:

- Convenience: Centralizes all engine management tasks, reducing the complexity of handling multiple systems and streamlining operations.

- Efficiency: Provides a unified view of engine health and performance, enabling quicker and more informed decision-making.

- Cost Savings: Predictive maintenance and real-time monitoring help prevent costly breakdowns and optimize maintenance schedules, leading to significant cost savings.

- Enhanced Safety: Integrated alarm systems and real-time monitoring ensure that any potential issues are promptly identified and addressed, enhancing the safety of the vessel and crew.

- Operational Optimization: Continuous performance monitoring and optimization ensure that engines operate at peak efficiency, reducing fuel consumption and emissions.

- Flexibility and Control: Remote access capabilities provide the flexibility to manage and monitor engine systems from any location, enhancing operational control.

Case Study: Transformation with a Comprehensive Engine Management System A luxury cruise liner, known for its extensive voyages across the globe, was facing challenges with maintaining engine efficiency and minimizing operational downtime. The vessel’s management decided to implement a comprehensive engine management system to address these issues.

Upon installation, the system integrated data from multiple sensors across the engine, providing real-time monitoring of critical parameters such as temperature, pressure, fuel flow, and emissions. The unified dashboard offered a complete overview of engine health and performance, allowing the crew to monitor and manage operations efficiently.

Within the first few weeks, the predictive analytics component identified irregularities in the engine’s vibration patterns, suggesting a potential issue with the crankshaft bearings. The system generated an alert, and the maintenance team conducted a detailed inspection, confirming early signs of wear. By addressing the issue promptly, they prevented a major breakdown that could have resulted in costly repairs and significant downtime.

The diagnostic tools within the system also played a crucial role in enhancing operational efficiency. During a routine check, the system detected suboptimal fuel injection timing. The diagnostic reports provided detailed insights, enabling the engineers to recalibrate the fuel injectors. This adjustment led to a noticeable improvement in fuel efficiency, with the vessel achieving a 10% reduction in fuel consumption over the next quarter.

Additionally, the integrated alarm and alert system proved invaluable during a voyage in the Mediterranean. The system detected a rapid increase in engine temperature due to a cooling system malfunction. Immediate alerts were sent to the crew, who quickly implemented emergency cooling measures and repaired the faulty component, averting a potential engine overheat and ensuring passenger safety.

The comprehensive engine management system transformed the cruise liner’s operations, delivering significant improvements in engine performance, operational efficiency, and safety. The ability to manage all aspects of engine health and performance through a single, integrated platform demonstrated the immense value of comprehensive engine management systems in modern maritime operations.

FAQ on “Marine Engine Monitoring Systems”

Q: What are marine engine monitoring systems?

A: Marine engine monitoring systems are technologies that track and analyze engine performance and health in real-time.

Q: How do predictive maintenance tools benefit marine engines?

A: Predictive maintenance tools help prevent unexpected breakdowns and reduce maintenance costs by identifying potential issues early.

Q: Can remote monitoring systems improve fleet management?

A: Yes, remote monitoring systems allow centralized control and real-time oversight, enhancing operational efficiency and safety.

Q: What is the advantage of using a comprehensive engine management system?

A: Comprehensive engine management systems integrate various monitoring functions, providing a unified and efficient approach to managing engine performance and maintenance.

Conclusion

Implementing advanced marine engine monitoring systems is essential for enhancing the efficiency, reliability, and safety of your vessel. From real-time data collection and predictive maintenance to diagnostic software and comprehensive engine management systems, these technologies provide powerful tools for proactive engine management. By leveraging these cutting-edge solutions, you can significantly reduce operational costs, prevent unexpected breakdowns, and ensure optimal performance. Embrace these innovative systems to transform your maritime operations and achieve a quieter, safer, and more efficient marine environment.