Marine Engineering

Marine engineering is a comprehensive and multifaceted field that focuses on the design, development, and maintenance of various systems and machinery used in marine vessels. This discipline encompasses a wide range of topics and components essential for the efficient operation of ships and offshore structures. Marine engineers play a crucial role in ensuring the safety, performance, and sustainability of maritime operations.

This blog post delves into the key aspects of marine engineering, covering the main engines, generators, electrical systems, boilers, refrigeration units, air compressors, oil and water separator systems, sewage treatment plants, freshwater generator plants, propulsion systems, marine growth prevention, other auxiliaries, and the use of performance, efficiency, and workshop tools. Additionally, we will explore the importance of ejectors and eductors in marine engineering. Understanding these components and systems is vital for anyone aspiring to excel in this dynamic and challenging profession.

Topics in Marine Engineering

- Main Engines

- Generators

- Electrical Systems

- Boilers

- Refrigeration

- Air Compressors

- Oil and Water Separator Systems

- Sewage Treatment Plants

- Freshwater Generator Plants

- Propulsion Systems

- Pumps, Piping Systems, Pipe Fittings, and Valves

- Marine Growth and Its Prevention

- Other Auxiliary Systems

- Performance, Efficiency, and Workshop Tools

- Ejectors and Educators

- Boat Engines

Main Engines

The main engine is the largest and most critical machine in the engine room, responsible for driving the ship. Aspiring marine engineers must develop a solid understanding of these engines, as they are the heart of the vessel’s propulsion system. Over time, through experience and continuous learning, marine engineers will gain in-depth knowledge of these complex machines. However, having a basic grasp of key terminologies and concepts is essential from the start.

Basic Knowledge of Main Engines

1. Types of Marine Engines:

- Two-Stroke Engines: Commonly used in large vessels due to their efficiency and power output. They complete a power cycle with two strokes of the piston during only one crankshaft revolution.

- Four-Stroke Engines: Typically used in smaller ships. They complete a power cycle with four strokes of the piston during two crankshaft revolutions.

2. Components of a Main Engine:

- Cylinder Block: Houses the cylinders where combustion occurs.

- Piston: Moves up and down within the cylinder, transferring the force of combustion to the crankshaft.

- Crankshaft: Converts the linear motion of the pistons into rotational motion to drive the propeller.

- Camshaft: Controls the timing of the opening and closing of the engine’s valves.

- Fuel Injector: Delivers fuel into the combustion chamber.

- Turbocharger: Increases engine efficiency and power by forcing more air into the combustion chamber.

- Cooling System: Maintains optimal engine temperature to prevent overheating.

- Lubrication System: Ensures all moving parts are adequately lubricated to reduce friction and wear.

3. Engine Operations:

- Starting: Involves the use of compressed air to initiate the engine cycle.

- Running: The engine operates continuously, converting fuel into mechanical energy to propel the ship.

- Stopping: Gradual reduction of engine speed before shutting down to prevent damage.

4. Maintenance of Main Engines:

- Routine Inspections: Regular checks of engine components for wear and tear.

- Overhauling: Detailed disassembly, inspection, repair, and reassembly of engine parts.

- Lubrication: Ensuring all parts are adequately lubricated to reduce friction and prevent overheating.

- Cooling: Monitoring and maintaining the cooling system to ensure the engine operates within safe temperature ranges.

5. Safety Precautions:

- Engine Room Safety: Always follow safety protocols to prevent accidents.

- Emergency Procedures: Familiarize yourself with emergency shutdown procedures and fire safety measures.

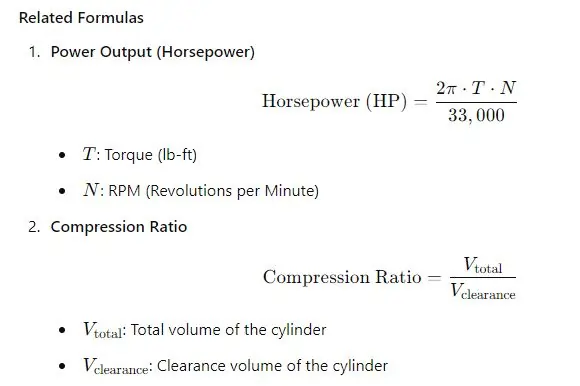

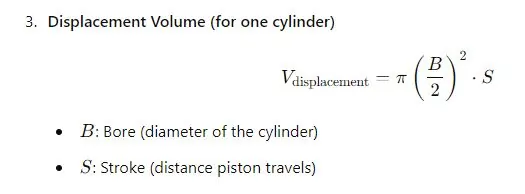

6. Terminology:

RPM (Revolutions Per Minute): The number of times the crankshaft completes a full rotation in one minute.

Bore and Stroke: Bore refers to the diameter of the cylinder, while stroke is the distance the piston travels within the cylinder.

Compression Ratio: The ratio of the volume of the combustion chamber from its largest capacity to its smallest.

Horsepower: A unit of measurement for engine power.

Generators

A diesel generator (DG), also known as a diesel Genset, is crucial for a ship’s operation, combining a diesel engine with an electric generator (alternator) to generate electrical energy. DG sets are often referred to as auxiliary engines and are as vital as the main engines, providing essential power to various systems onboard. Generators are the lifeline of the ship, ensuring continuous and reliable electrical supply.

Components of an Electric Generator (Alternator)

1. Stator:

- Function: The stationary part of the generator that contains windings.

- Role: Generates electricity when the magnetic field of the rotor induces a voltage across the windings.

2. Rotor:

- Function: The rotating part of the generator that produces a magnetic field.

- Role: Induces a current in the stator windings as it rotates.

3. Exciter:

- Function: Supplies the initial magnetic field to start the generation process.

- Role: Ensures that the generator can start producing electricity as soon as the rotor begins to spin.

4. Voltage Regulator:

- Function: Controls the output voltage of the generator.

- Role: Maintains a constant voltage level despite variations in load.

5. Bearings:

- Function: Support the rotor and allow it to rotate smoothly.

- Role: Reduce friction and wear, ensuring the longevity and efficiency of the generator.

6. Cooling System:

- Function: Removes excess heat generated during operation.

- Role: Prevents overheating, ensuring safe and efficient operation.

7. Control Panel:

- Function: Interface for monitoring and controlling the generator.

- Role: Displays critical parameters like voltage, current, frequency, and temperature, and allows for adjustments as needed.

Importance of Electric Generators on Ships

1. Power Supply:

- Primary Power Source: Provides electrical power when the main engine is not running or during emergencies.

- Backup Power: Ensures continuous power supply for critical systems like navigation, communication, and safety equipment.

2. Operational Support:

- Auxiliary Systems: Powers auxiliary systems such as pumps, lighting, and ventilation.

- Essential Services: Supports essential services including heating, air conditioning, and refrigeration.

3. Safety:

- Emergency Situations: Provides power during emergencies, ensuring safety systems remain operational.

- Redundancy: Offers redundancy, ensuring there is always an available power source in case of main engine failure.

Maintenance of Electric Generators

1. Routine Inspections:

- Visual Checks: Regularly inspect for signs of wear, damage, and overheating.

- Performance Monitoring: Check operating parameters like voltage output, current, and frequency.

2. Regular Servicing:

- Winding Inspections: Check stator and rotor windings for insulation damage and cleanliness.

- Bearing Maintenance: Ensure bearings are lubricated and in good condition to prevent friction and wear.

- Cooling System: Inspect and maintain the cooling system to prevent overheating.

3. Overhauling:

- Detailed Inspections: Disassemble, inspect, and repair or replace worn components.

- Testing: Perform comprehensive tests to ensure all parts function correctly after reassembly.

Safety Precautions

1. Electrical Safety:

- Insulation: Ensure all electrical connections and windings are properly insulated.

- Grounding: Verify that the generator is properly grounded to prevent electrical shocks.

2. Operational Safety:

- Load Management: Avoid overloading the generator to prevent damage.

- Regular Testing: Periodically test the generator under load conditions to ensure reliability.

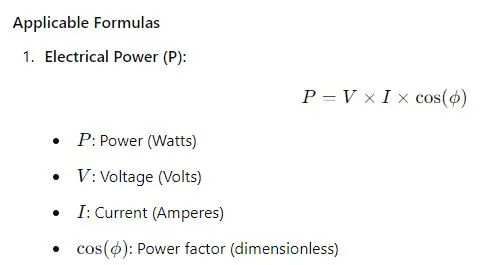

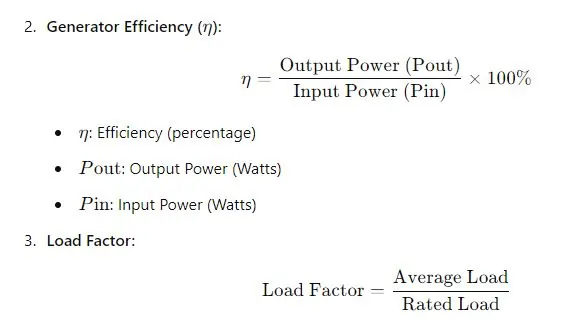

Key Terminology

1. Rated Power: The maximum continuous power output that the generator can deliver under specified conditions.

2. Load Factor: The ratio of the average load to the rated power of the generator over a specific period.

3. Voltage Regulation: The ability of the generator to maintain a constant output voltage despite changes in load.

Electrical Systems on Ships

Marine engineers must possess a comprehensive understanding of the ship’s electrical systems. Adequate knowledge and competency in diagnosing faults, performing troubleshooting, and maintaining ancillary electrical services are essential for ensuring the ship’s safe and efficient operation. This description covers the key aspects of shipboard electrical systems that marine engineers should be familiar with.

Ship’s Electrical System Overview

1. Power Generation:

- Diesel Generators: Primary source of electrical power, converting mechanical energy into electrical energy.

- Auxiliary Generators: Provide backup power and support during peak loads.

- Emergency Generators: Supply power during main generator failures, ensuring critical systems remain operational.

2. Power Distribution:

- Main Switchboard (MSB): Central hub for distributing electrical power to various systems on the ship.

- Distribution Boards: Manage the flow of electricity to different parts of the vessel, such as accommodation, engine room, and deck machinery.

- Circuit Breakers and Fuses: Protect the electrical system from overloads and short circuits.

Competency in Diagnosing Faults and Troubleshooting

1. Fault Diagnosis:

- Visual Inspection: Check for obvious signs of damage, loose connections, and overheating components.

- Use of Multimeters: Measure voltage, current, and resistance to identify electrical faults.

- Insulation Testing: Verify the integrity of electrical insulation to prevent short circuits and electrical shocks.

- Thermal Imaging: Detect hotspots in electrical equipment that may indicate potential failures.

2. Simple Troubleshooting:

- Check Power Supply: Ensure generators and batteries are supplying power.

- Inspect Wiring and Connections: Look for loose, damaged, or corroded wires and connectors.

- Reset Circuit Breakers: Identify and reset tripped breakers and replace blown fuses.

- Test Components: Use appropriate tools to test the functionality of electrical components such as relays, switches, and motors.

Onboard Ancillary Electrical Services

1. Lighting Systems:

- Navigation Lights: Ensure visibility and communication with other vessels.

- Interior Lighting: Provide illumination for accommodation and workspaces.

- Emergency Lighting: Maintain illumination during power failures.

2. Communication Systems:

- Radios: Facilitate ship-to-ship and ship-to-shore communication.

- Intercoms: Enable internal communication within the vessel.

- Satellite Systems: Provide global communication capabilities.

3. Navigation Systems:

- Radar: Detect other vessels and obstacles.

- GPS: Determine the ship’s precise location.

- Autopilot: Assist in maintaining a set course.

4. Battery Care and Upkeep:

- Regular Maintenance: Check electrolyte levels, clean terminals, and ensure proper ventilation.

- Charging Practices: Use appropriate charging methods to extend battery life and prevent damage.

- Testing: Perform regular voltage and load tests to assess battery health.

Electrical Propulsion and High Voltage Safety

1. Electrical Propulsion Systems:

- AC and DC Motors: Convert electrical energy into mechanical energy to drive the ship’s propellers.

- Variable Frequency Drives (VFDs): Control motor speed and torque, enhancing propulsion efficiency.

2. High Voltage Practice Safety Procedures:

- Isolation Procedures: Ensure that electrical systems are de-energized and isolated before maintenance.

- Personal Protective Equipment (PPE): Wear appropriate PPE such as insulating gloves, safety goggles, and protective clothing.

- Lockout/Tagout (LOTO): Implement LOTO procedures to prevent accidental energization during maintenance.

- Safety Signage: Use warning signs and barriers to indicate high voltage areas.

3. Testing Methods:

- Insulation Resistance Testing: Measure the resistance of electrical insulation to identify degradation.

- Dielectric Testing: Apply high voltage to assess the dielectric strength of insulating materials.

- Continuity Testing: Verify that electrical circuits are complete and free from breaks

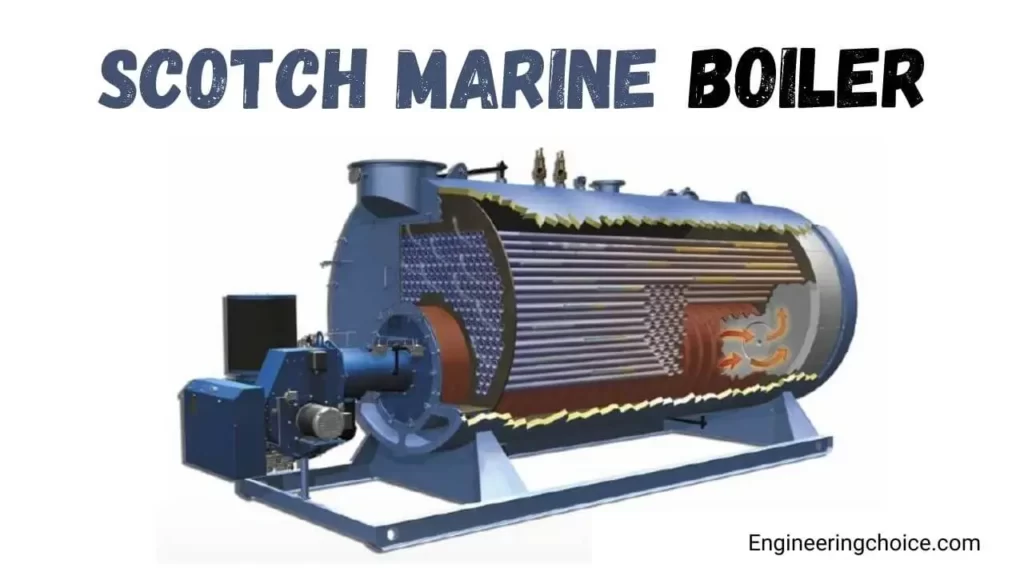

Boilers

Boilers are super important in marine engineering. They make the steam that powers the ship’s engines and other stuff onboard. They turn fuel energy into steam to move the ship.. Marine boilers are designed to withstand the harsh and dynamic environment of the sea and must operate reliably and safely in all conditions.

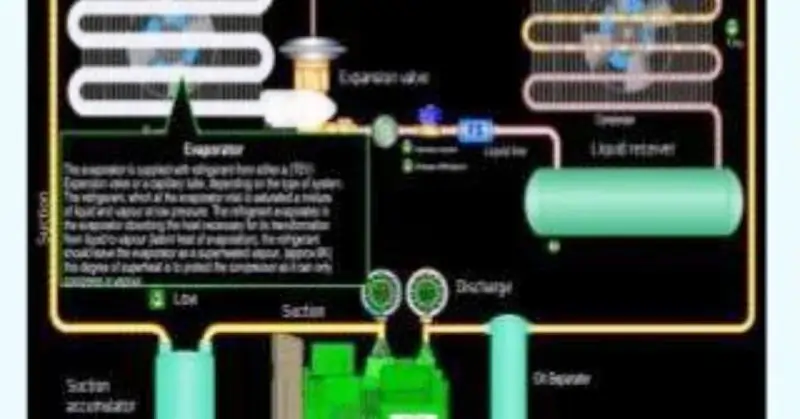

Refrigeration

Refrigeration is super important in marine engineering because it helps keep food and things from spoiling on ships. Shipboard refrigeration systems are built to perform dependably in challenging marine settings and are subject to stringent requirements to protect the environment and the crew.

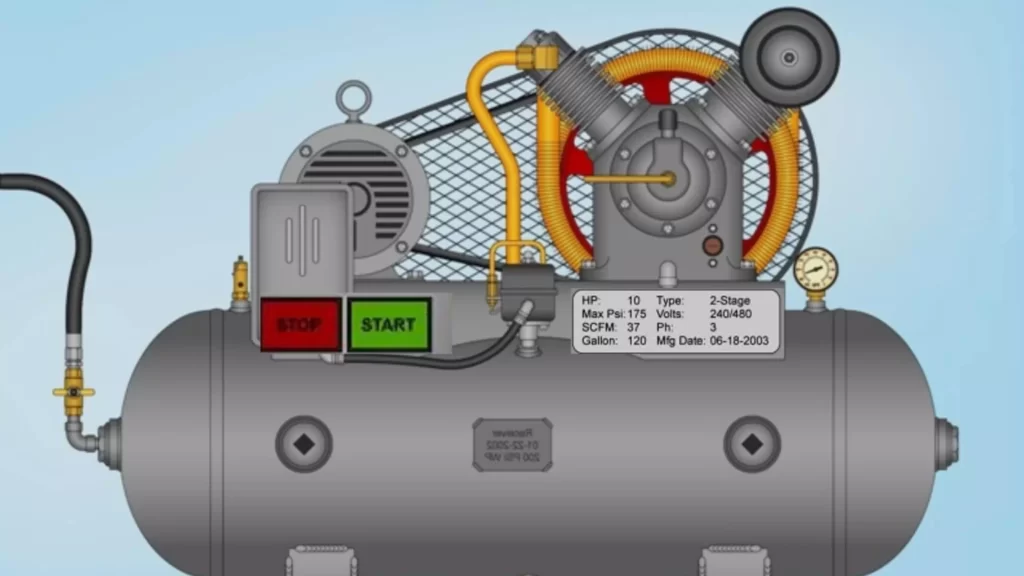

Air Compressor

Air compressors are like super important machines on ships because they provide the compressed air needed to make lots of things work. They help start engines, run tools, and keep different areas on the ship pressurized and well-ventilated.

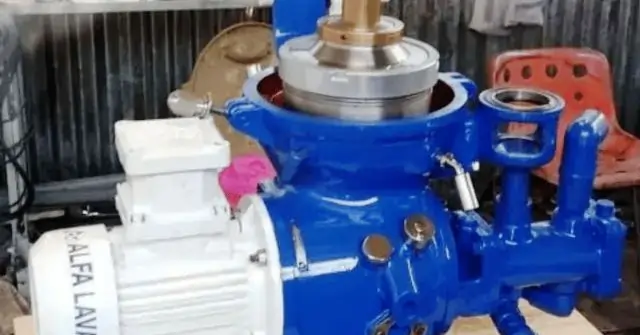

Oil and Water separator system

Oil and Water centrifuging system: – An oily water separator is a piece of equipment specific to the shipping or marine industry. This equipment separates oil and water mixtures into their separate units. This page refers exclusively to oily water separators aboard marine vessels. This equipment is available onboard ships. This equipment will separate oil from oily wastewater, such as bilge water, before discharge into the environment.

Freshwater generator plant

Freshwater production machine: – Freshwater is the essential commodity onboard vessels.

There is a large consumption amount of freshwater onboard a vessel.

Ship staff consumes much water to more than 100ltrs/ per day /staff.

There is a tremendous amount of water requirement In a steamship to run the steam turbine.

Propulsion system

Sips Propulsion: – This is the central system for ships’ movements from one place to another.

This system generates the thrust to move the boat. This system consists of Main Engines or an electric arrangement to move the ship through propellers.

Marine growth and its prevention

Aquatic crop and its avoidance: – Aquatic crop The growth of an Aquatic entity can have an enormous impact on the ship, including its structure.

Other Auxiliaries

Other Equipment: – Marine auxiliaries Machinery, other than the central propulsion unit, are usually called ‘auxiliary’ even though without some auxiliaries, the central machinery would not operate for long. The items considered are air compressors, heat exchangers, distillation equipment, oil/water separators, sewage treatment plants, and incinerators.

Performance, Efficiency, and workshop tools

Achievement, Efficiency, and Workshop Tools: – Marine Engineers should have complete knowledge of all the measuring devices, working tools, measuring instruments, gauges, and other performance analysis tools and instruments.

Ejector and eductor

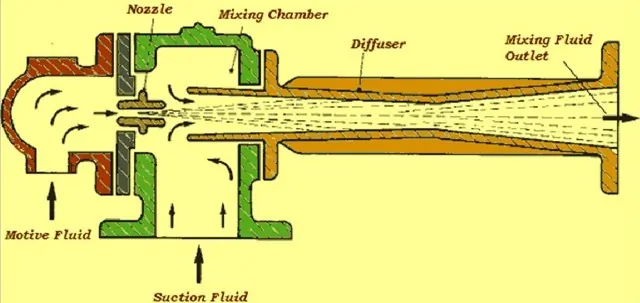

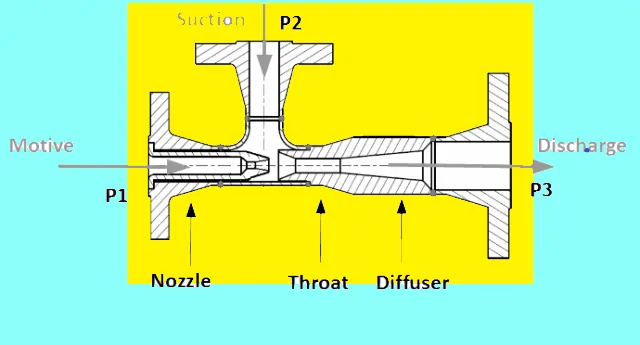

Ejector: They are used to maintain the system vacuum upstream. In contrast, the educator’s main objective is to remove fluid volume from a system by keeping system pressure upstream. The motive fluid used is water; the Ejector sucks the system’s excess volume and maintains the system pressure accurately.

Eductors: The motive fluid used is air. Eductors are used for sucking the muddy water or oily water from the ship’s bilges. Here, the motive fluid is high-pressure water. Hence, the eductor can transfer a considerable fluid volume from low to high pressure.

FAQ on ” Marine Engineering Navy

Q: What is marine engineering in the Navy?

A: Marine engineering in the Navy focuses on ships, engines, and technology to keep naval operations running smoothly.

Q: Why is marine engineering important in the Navy?

A: Marine engineering is crucial for maintaining the Navy’s fleet and ensuring safe and efficient maritime operations.

Q: What do marine engineers in the Navy do?

A: Marine engineers in the Navy design, operate, and maintain naval vessels, including their engines and systems.

Q: What role does technology play in marine engineering for the Navy?

A: Technology is vital in marine engineering, helping the Navy innovate and improve ship performance, safety, and environmental impact.

Blog post Conclusion

We shall appreciate the comments from our readers. We shall also implement the suggestions from our readers to improve this The Best Marine Engineering Tutorials For Marine Engineering Students.