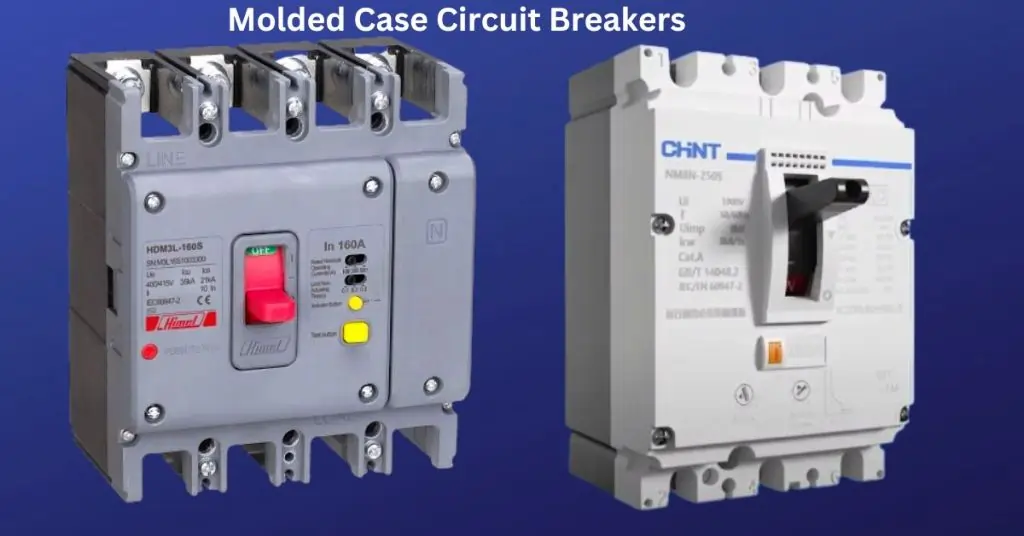

Molded Case Circuit Breakers

Molded Case Circuit Breakers (MCCBs) are essential components in modern electrical systems, designed to protect circuits from overloads and short circuits. Their robust construction and adjustable settings make them versatile for various applications, from residential to industrial settings. The importance of MCCBs lies in their ability to safeguard electrical infrastructure, ensuring safety and reliability.

In this post, we delve into the key features and functions of MCCBs, helping you understand their critical role in maintaining electrical system integrity. You’ll learn about the different types of MCCBs and their specific applications, providing insights into how to choose the right one for your needs. We’ll also cover practical aspects such as installation and maintenance tips, troubleshooting common issues, and understanding industry standards and compliance requirements.

By the end of this post, you’ll have a comprehensive understanding of MCCBs, enabling you to make informed decisions to enhance the safety and efficiency of your electrical systems.

Understanding Molded Case Circuit Breakers (MCCBs)

Definition of MCCBs and Their Role in Electrical Systems

Molded Case Circuit Breakers (MCCBs) are essential devices in electrical systems designed to protect circuits from damage caused by overcurrent, which includes both overload and short circuit conditions. Unlike standard circuit breakers, MCCBs offer adjustable trip settings and a higher current rating, making them suitable for a wide range of applications from residential to industrial settings. MCCBs are crucial in ensuring the safety and reliability of electrical systems by automatically disconnecting the electrical flow in abnormal conditions.

How MCCBs Operate to Protect Against Overloads and Short Circuits

MCCBs function by monitoring the current flowing through a circuit. They are equipped with two main protective mechanisms:

- Thermal Protection: This is designed to protect against overloads. When the current exceeds a preset limit for a certain period, a bimetallic strip inside the MCCB heats up and bends, triggering the trip mechanism. This disconnects the circuit, preventing overheating and potential damage to the electrical components.

- Magnetic Protection: This protects against short circuits. A short circuit causes a sudden surge in current, which generates a strong magnetic field. This magnetic field activates a solenoid, which trips the breaker almost instantaneously, disconnecting the circuit to prevent severe damage and fire hazards.

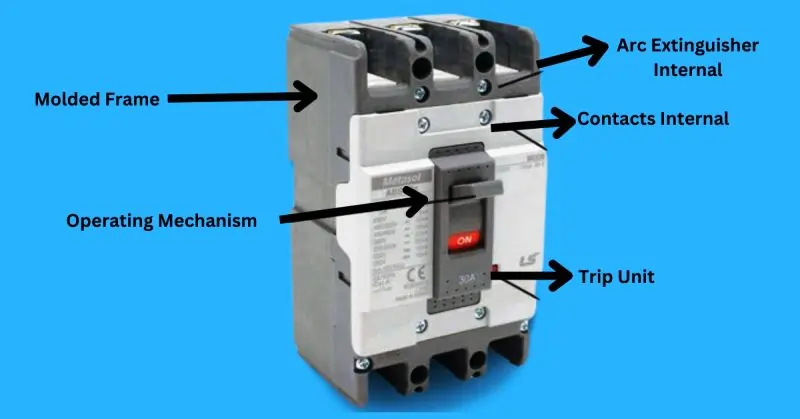

Key Components and Their Functions

- Frame: The frame provides the structural support for the MCCB and houses all the internal components. It is made from durable, heat-resistant materials to withstand high temperatures and physical stress.

- Operating Mechanism: This component allows the manual operation of the MCCB. It includes the handle and internal linkages that move the contacts open or closed.

- Contacts: The contacts are the conductive parts that allow current to flow when closed and interrupt the flow when opened. MCCBs have both fixed and movable contacts that separate to break the circuit when a fault is detected.

- Trip Unit: The trip unit is the brain of the MCCB, determining when to open the contacts. It includes both thermal and magnetic trip elements for detecting overloads and short circuits. Advanced MCCBs may have electronic trip units that offer more precise control and additional features like remote monitoring.

- Arc Extinguisher: When the contacts open to interrupt the current, an electrical arc is formed. The arc extinguisher is a series of metal plates that split and cool the arc, safely extinguishing it to prevent damage to the breaker and maintain safety.

- Terminal Connectors: These are the points where the MCCB connects to the electrical circuit. They ensure a secure and stable connection for the incoming and outgoing wires.

Key Features and Specifications of MCCBs

Molded Case Circuit Breakers (MCCBs) are designed with several powerful features that make them essential for safeguarding electrical systems. Here, we provide a detailed overview of these key features and the specifications to consider when selecting an MCCB.

Detailed Overview of the Most Powerful Features of MCCBs

- Adjustable Trip Settings

- Flexibility: MCCBs come with adjustable trip settings that allow users to fine-tune the breaker’s response to overcurrent conditions. This flexibility ensures the breaker can be precisely matched to the specific requirements of the electrical system it protects.

- Customization: Users can adjust the trip settings to accommodate different load conditions, enhancing both protection and efficiency.

- High Interrupting Capacity

- Safety and Reliability: High interrupting capacity refers to the MCCB’s ability to safely interrupt high fault currents without damaging the breaker or the electrical system. This is crucial in industrial and commercial applications where large currents are common.

- Protection: This feature ensures that even in the event of a severe short circuit, the MCCB will function correctly to prevent damage to electrical equipment and maintain system integrity.

- Thermal-Magnetic Protection

- Dual Protection Mechanism: MCCBs are equipped with both thermal and magnetic protection mechanisms. Thermal protection guards against prolonged overcurrent (overload) situations, while magnetic protection responds instantly to short circuits.

- Comprehensive Safety: This dual mechanism ensures comprehensive protection for electrical systems, making MCCBs suitable for a wide range of applications.

- Advanced Electronic Trip Units

- Precision and Control: Advanced MCCBs may feature electronic trip units that offer more precise control over the trip settings and provide additional functionality, such as remote monitoring and diagnostics.

- Enhanced Features: These trip units can include features like ground fault protection, programmable trip characteristics, and communication capabilities, which are valuable for complex electrical systems.

Specifications to Consider When Selecting an MCCB

- Current Rating

- Definition: The current rating indicates the maximum continuous current that the MCCB can carry without tripping.

- Selection Tip: Choose an MCCB with a current rating that matches or slightly exceeds the normal operating current of the circuit to ensure reliable protection.

- Interrupting Capacity

- Definition: This is the maximum fault current that the MCCB can interrupt safely.

- Selection Tip: Ensure the interrupting capacity is higher than the highest possible short circuit current in the system to provide adequate protection.

- Trip Unit Type

- Options: MCCBs can come with thermal-magnetic or electronic trip units.

- Selection Tip: For basic applications, thermal-magnetic units are sufficient. For advanced applications requiring precision and additional features, electronic trip units are preferable.

- Frame Size

- Definition: The frame size refers to the physical dimensions of the MCCB and its maximum current-carrying capability.

- Selection Tip: Select a frame size that fits within the space available in the panel and meets the current requirements of the circuit.

- Adjustability

- Feature: Look for MCCBs with adjustable trip settings to provide flexibility in protecting different load conditions.

- Selection Tip: Adjustable settings are crucial for systems with variable loads or where future expansion is anticipated.

- Environmental Ratings

- Consideration: Check the MCCB’s ratings for temperature, humidity, and other environmental factors.

- Selection Tip: Ensure the MCCB is rated for the environmental conditions it will operate in, especially for outdoor or harsh industrial environments.

Types and Applications of MCCBs

| Type of MCCB | Definition & Operation | Industrial Applications | Commercial Applications | Residential Applications |

|---|---|---|---|---|

| Thermal-Magnetic MCCBs | Definition: Combine thermal element for overload protection and magnetic element for short circuit protection. Operation: Thermal element bends to trip on overcurrent; magnetic element trips instantaneously on short circuit. | Manufacturing plants, heavy machinery, large motor control centers | Office buildings, shopping centers, hotels (HVAC systems, lighting circuits, power distribution panels) | Main service panels, subpanels |

| Electronic MCCBs | Definition: Use electronic sensors and microprocessors for precise protection settings. Operation: Advanced features such as ground fault protection, adjustable trip curves, and remote monitoring. | Facilities with complex systems requiring precise protection and monitoring (data centers, chemical plants, automation systems) | Hospitals, high-rise buildings, campuses (detailed monitoring and advanced protection features) | Smart homes with advanced electrical systems (detailed monitoring and remote management) |

| Microprocessor-Based MCCBs | Definition: Enhanced digital features and programmable settings. Operation: Customizable protection settings and detailed data logging. | Critical infrastructure (power plants, refineries, large-scale manufacturing) | Large commercial complexes (real-time monitoring and diagnostics) | High-end residential settings with complex electrical demands and smart home integration |

| Adjustable MCCBs | Definition: Allow user to set trip parameters within a range for flexibility. Operation: Both thermal-magnetic and electronic MCCBs can be adjustable. | Flexible manufacturing systems, facilities with varying load requirements (food processing plants, assembly lines) | Buildings with changing electrical loads (convention centers, entertainment venues) | Custom-built homes with unique electrical demands |

Examples of MCCB Usage

| Setting | Example Use |

|---|---|

| Industrial | Manufacturing Plants: Thermal-magnetic MCCBs protect machinery from overloads and short circuits. Data Centers: Electronic MCCBs offer precise protection and real-time monitoring to ensure uninterrupted operations. Power Plants: Microprocessor-based MCCBs provide detailed diagnostics and customizable settings for critical equipment protection. |

| Commercial | Office Buildings: Thermal-magnetic MCCBs safeguard HVAC systems and lighting circuits. Hospitals: Electronic MCCBs ensure reliable protection and monitoring of critical medical equipment .Shopping Centers: Adjustable MCCBs adapt to varying electrical loads from different shops and seasonal changes. |

| Residential | Homes: Thermal-magnetic MCCBs are used in main service panels for general protection. Smart Homes: Electronic MCCBs provide advanced protection and remote monitoring capabilities. Custom-Built Homes: Adjustable MCCBs cater to unique and changing electrical |

Selection and Sizing of MCCBs

Selecting and sizing the right Molded Case Circuit Breaker (MCCB) is crucial for ensuring the safety, efficiency, and reliability of your electrical system. This guide provides a step-by-step approach to selecting the appropriate MCCB, considering key factors for correct sizing, and tips for ensuring compatibility and optimal performance.

Step-by-Step Guide on How to Select the Right MCCB for Specific Applications

Identify the Application Requirements

Determine the specific application and the role of the MCCB within the electrical system (e.g., protecting a motor, feeder circuit, or entire distribution panel).

Calculate the Load Current

Calculate the total load current by summing up the currents of all connected devices. This will help in selecting an MCCB with an appropriate current rating.

Determine the Maximum Short Circuit Current

Assess the maximum possible short circuit current at the point of installation. This helps in choosing an MCCB with a sufficient interrupting capacity to handle fault conditions.

Select the MCCB Type

Choose between thermal-magnetic, electronic, microprocessor-based, or adjustable MCCBs based on the application requirements and desired features.

Consider Environmental Conditions

Evaluate the environmental conditions where the MCCB will be installed, such as temperature, humidity, and exposure to dust or corrosive elements. Select an MCCB with appropriate environmental ratings.

Check Compliance and Standards

Ensure the selected MCCB complies with relevant industry standards (e.g., UL, IEC) and has the necessary certifications for your application.

Review Manufacturer Specifications

Compare the specifications of different MCCBs from reputable manufacturers to find one that meets your requirements.

Installation Requirements

Consider the physical size and mounting options of the MCCB to ensure it fits within the available space in the panel or enclosure.

Factors to Consider for Correct Sizing Based on Electrical Load and System Requirements

Current Rating

The current rating of the MCCB should match or exceed the continuous operating current of the circuit it protects. This ensures the breaker can handle the load without tripping under normal conditions.

Interrupting Capacity

Select an MCCB with an interrupting capacity that exceeds the maximum short circuit current expected in the system. This ensures the breaker can safely interrupt high fault currents without damage.

Trip Settings

For adjustable MCCBs, set the trip parameters (e.g., long-time, short-time, and instantaneous trip settings) to match the protection requirements of the specific application.

Voltage Rating

Ensure the MCCB’s voltage rating is compatible with the system voltage. This is critical for safe and reliable operation.

Thermal and Magnetic Trip Curves

Understand the thermal and magnetic trip characteristics of the MCCB to ensure it provides adequate protection for both overload and short circuit conditions.

Frequency

Verify that the MCCB is rated for the operating frequency of the electrical system (e.g., 50Hz or 60Hz).

Tips for Ensuring Compatibility and Optimal Performance

Consult with Manufacturers

Engage with MCCB manufacturers or distributors to get recommendations and technical support for selecting the right breaker for your application.

Use Sizing Tools and Software

Utilize online sizing tools and software provided by manufacturers to accurately determine the appropriate MCCB size and settings based on your specific load and system conditions.

Consider Future Expansion

When selecting an MCCB, consider the potential for future load expansion. Choose a breaker with some margin above the current requirements to accommodate additional loads.

Regular Maintenance and Testing

Schedule regular maintenance and testing of MCCBs to ensure they continue to operate correctly and provide reliable protection.

Professional Installation

Ensure the MCCB is installed by qualified personnel following manufacturer guidelines and industry standards to avoid improper installation and potential safety hazards.

Installation and Maintenance of (MCCBs)

Proper installation and maintenance of Molded Case Circuit Breakers (MCCBs) are crucial for ensuring their effectiveness and reliability in protecting electrical systems. This guide provides detailed instructions for installing MCCBs, best practices for maintaining and testing them, and common installation mistakes to avoid along with troubleshooting tips.

Detailed Instructions for the Proper Installation of MCCBs

| Step | Description |

|---|---|

| Preparation | Ensure you have necessary tools and equipment, including a torque wrench, screwdrivers, and PPE. Verify that the MCCB specifications match the system requirements. |

| Turn Off Power | Ensure that the power supply to the circuit where the MCCB will be installed is completely turned off. |

| Mount the MCCB | Securely mount the MCCB in the designated location within the electrical panel using provided hardware. Ensure it is firmly attached. |

| Connect the Wires | Connect incoming and outgoing wires to the MCCB terminals, ensuring tight and secure connections. Use a torque wrench to apply correct torque as specified by the manufacturer. |

| Check Alignment | Verify that all connections are properly aligned and there is no strain on the wires. |

| Inspect Installation | Conduct a thorough inspection to ensure all connections are secure, the breaker is properly mounted, and there are no signs of damage or loose components. |

| Restore Power and Test | Restore the power supply and test the MCCB to ensure it operates correctly. Perform a functional test to verify the breaker trips under fault conditions. |

Best Practices for Maintaining and Testing MCCBs to Ensure Longevity and Reliability

| Practice | Description |

|---|---|

| Regular Inspection | Conduct regular visual inspections of the MCCB and its connections for signs of wear, damage, or overheating. Ensure connections remain tight and secure. |

| Cleaning | Keep the MCCB and its surrounding area clean and free from dust, dirt, and debris. |

| Functional Testing | Periodically test the MCCB using a test kit to simulate fault conditions and verify proper operation. Record and compare test results to manufacturer’s specifications. |

| Thermal Imaging | Use thermal imaging equipment to check for hotspots or abnormal temperature rises in the MCCB and its connections. Address any issues promptly. |

| Lubrication | Apply appropriate lubrication to moving parts if specified by the manufacturer to ensure smooth operation and prevent wear. |

| Replacement of Worn Parts | Replace any worn or damaged parts immediately using genuine manufacturer parts for compatibility and reliability. |

Common Installation Mistakes to Avoid and Troubleshooting Tips

| Common Installation Mistakes | Description |

|---|---|

| Loose Connections | Ensure all connections are tight and secure to prevent overheating and electrical faults. |

| Improper Torque | Use a torque wrench to apply correct torque to all connections as specified by the manufacturer. Over-tightening or under-tightening can cause connection failures. |

| Incorrect Alignment | Verify that all connections are properly aligned and there is no strain on the wires to avoid mechanical stress and potential failure. |

| Inadequate Clearance | Ensure there is adequate clearance around the MCCB for ventilation and heat dissipation. Overcrowding can lead to overheating. |

| Troubleshooting Tips | Description |

|---|---|

| Breaker Trips Frequently | Cause: Overload or short circuit in the circuit. Solution: Check the load current and compare it with the MCCB rating. Inspect the circuit for faults and rectify any issues. |

| Breaker Does Not Trip | Cause: Faulty trip mechanism or incorrect settings. Solution: Test the MCCB using a test kit and verify the trip settings. Replace the breaker if necessary. |

| Overheating | Cause: Loose connections or inadequate ventilation. Solution: Tighten all connections and ensure proper ventilation around the MCCB. |

| Physical Damage | Cause: Mechanical stress or impact. Solution: Inspect the MCCB for signs of damage and replace any affected parts or the entire breaker if needed. |

Troubleshooting and Safety Tips for (MCCBs)

This guide provides an overview of common issues with MCCBs, step-by-step troubleshooting instructions, and important safety tips for working with and around MCCBs.

Common Issues with MCCBs and How to Identify Them

| Issue | Identification |

|---|---|

| Frequent Tripping | MCCB trips frequently under normal load conditions. |

| Failure to Trip | MCCB does not trip during an overload or short circuit. |

| Overheating | MCCB and its connections feel unusually hot to the touch. |

| Physical Damage | Visible signs of wear, cracks, or damage to the MCCB housing or components. |

| Loose Connections | Wires connected to the MCCB are not securely fastened. |

| Abnormal Noise | Unusual buzzing or humming sounds coming from the MCCB. |

Step-by-Step Troubleshooting Guide for Diagnosing and Resolving Issues

| Step | Description |

|---|---|

| 1. Identify the Issue | Observe and note the specific problem (e.g., frequent tripping, overheating, etc.). |

| 2. Inspect Visually | Perform a thorough visual inspection of the MCCB and its connections. Look for loose wires, physical damage, or signs of overheating. |

| 3. Test the Load Current | Use a clamp meter to measure the load current and compare it to the MCCB’s rating. |

| 4. Check Trip Settings | Verify the trip settings on the MCCB and adjust if necessary to match the load requirements. |

| 5. Test the MCCB | Use a test kit to simulate fault conditions and ensure the MCCB trips correctly. Record the results for comparison. |

| 6. Inspect the Circuit | Check the entire circuit for faults or issues that could cause the MCCB to trip or fail. |

| 7. Tighten Connections | Ensure all wire connections are tight and secure to prevent loose connections and overheating. |

| 8. Replace Faulty Parts | Replace any damaged or worn components of the MCCB. Use genuine replacement parts for compatibility. |

| 9. Re-Test After Repairs | After making any repairs or adjustments, retest the MCCB to ensure it is functioning correctly. |

Important Safety Tips for Working with and Around MCCBs

| Safety Tip | Description |

|---|---|

| Turn Off Power | Always ensure the power is turned off before working on or near the MCCB to avoid electrical shocks. |

| Use Appropriate PPE | Wear personal protective equipment such as gloves, safety glasses, and insulated tools. |

| Verify Voltage Absence | Use a voltage tester to confirm that no voltage is present before starting work. |

| Follow Manufacturer Guidelines | Adhere to the manufacturer’s installation and maintenance instructions to ensure safety and compliance. |

| Avoid Overloading | Ensure that the MCCB is not overloaded by checking and adhering to its current rating. |

| Keep Area Clean | Maintain a clean and organized workspace to avoid accidents and ensure easy access to the MCCB. |

| Regular Maintenance | Schedule regular maintenance and inspections to identify and address potential issues early. |

| Stay Informed | Stay updated with the latest safety standards and best practices for working with MCCBs. |

FAQ on “Molded Case Circuit

Q: What are Molded Case Circuit Breakers (MCCBs)?

A: MCCBs protect electrical circuits from overloads and short circuits.

Q: How do MCCBs differ from standard circuit breakers?

A: MCCBs have adjustable trip settings and higher current ratings.

Q: What are the main types of MCCBs?

A: Thermal-magnetic, electronic, microprocessor-based, and adjustable.

Q: How often should MCCBs be tested and maintained?

A: Annually, during regular maintenance checks.

Conclusion

Proper installation, maintenance, and troubleshooting of Molded Case Circuit Breakers (MCCBs) are essential for ensuring the safety and reliability of electrical systems. By understanding common issues, following a step-by-step troubleshooting guide, and adhering to safety tips, you can effectively manage and maintain MCCBs. Regular inspections and timely interventions not only prevent potential failures but also extend the lifespan of your electrical infrastructure. Stay informed and proactive to keep your systems running smoothly and safely.