Overload Protection

In today’s world, where electrical systems power everything from our homes to large industrial facilities, overload protection is more critical than ever. Without it, we risk electrical fires, significant equipment damage, and compromised safety. This guide, “Overload Protection: The Best Guide of 2024,” delves into the most essential modern solutions for safeguarding your electrical systems. We’ll explore the importance of overload protection, the various types of protection devices available, and their specific applications, including in marine environments. You’ll also discover the latest advancements in technology, best practices for implementation, troubleshooting tips, and real-world case studies.

By the end of this comprehensive guide, you’ll have a thorough understanding of how to protect your electrical systems effectively and stay ahead with the latest innovations in overload protection.

Explaining Overload Protection in Electrical Systems

Importance of Overload Protection

Overload protection is a critical component in modern electrical systems, designed to prevent electrical fires, equipment damage, and ensure overall safety. By monitoring the current flowing through a system, overload protection devices can detect when the current exceeds safe levels and take action to disconnect the power supply. This prevents excessive heat buildup, which can lead to fires and damage to sensitive equipment. Ensuring that your electrical systems are equipped with reliable overload protection is essential for maintaining operational safety and preventing costly downtimes and repairs.

Fundamental Concepts

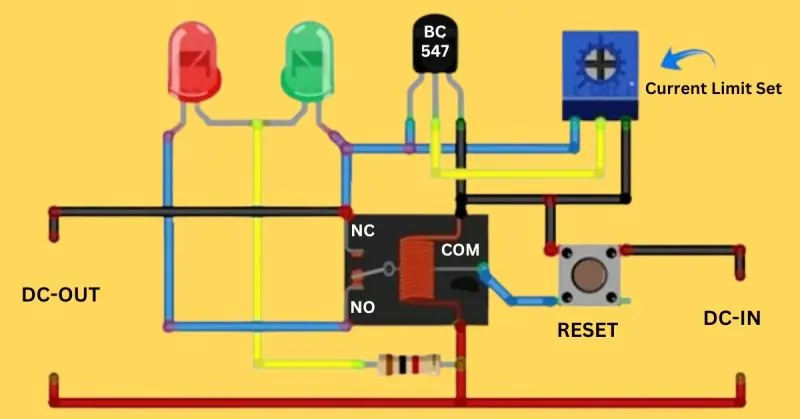

Overload protection operates on the principle of current monitoring and interruption. When the current exceeds a predetermined limit, the protection device intervenes to disconnect the circuit. Here are some key terms and components associated with overload protection:

- Current Limit Set: This is the predefined threshold at which the overload protection device will trigger an interruption. Setting the appropriate current limit is crucial to ensure protection without unnecessary interruptions.

- DC-IN: Direct Current (DC) input refers to the incoming power supply that the overload protection device monitors. It is crucial to understand the specifications of the DC-IN to match the protection device correctly.

- DC-OUT: Direct Current (DC) output is the regulated power supply delivered to the connected load after passing through the protection device. The DC-OUT must be maintained within safe limits to prevent overload.

- RESET: The RESET function is used to reset the protection device after it has been triggered. This allows the system to resume normal operation once the overload condition has been resolved.

- NC (Normally Closed): In a normally closed configuration, the circuit is complete, and current flows until the overload protection device is activated, opening the circuit to stop the current flow.

- NO (Normally Open): In a normally open configuration, the circuit is incomplete, and no current flows until the overload protection device is triggered, closing the circuit to allow current flow.

- COM (Common): This is the common terminal that can be connected to either NC or NO terminals, depending on the desired configuration for the protection device.

How Overload Protection Operates

When the electrical current flowing through a system exceeds the set current limit, the overload protection device detects this excess current. It then acts to interrupt the current flow by opening the circuit (in NC configuration) or closing the circuit (in NO configuration). This interruption prevents further current flow, protecting the system from potential damage. Once the overload condition is addressed, the device can be reset using the REST function to resume normal operation.

Types of Overload Protection Devices

Circuit breakers are essential devices in electrical systems designed to protect circuits from damage caused by overloads or short circuits. When an overload is detected, the circuit breaker interrupts the flow of current, preventing potential hazards. There are several types of circuit breakers:

- Standard Circuit Breakers: These are the most common type, used in residential and commercial buildings to protect electrical circuits from overloads and short circuits.

- Ground Fault Circuit Interrupters (GFCIs): These are used to protect against electrical shock by breaking the circuit when a ground fault is detected.

- Arc Fault Circuit Interrupters (AFCIs): These are designed to prevent fires by detecting and interrupting arc faults, which are high-power discharges of electricity between conductors.

- Smart Breakers: These advanced circuit breakers offer features like remote monitoring, control via mobile devices, and integration with smart home systems. They can provide real-time data on energy usage and circuit status, enhancing both safety and convenience.

Fuses

Fuses are one-time-use devices that protect electrical circuits by breaking the connection when the current exceeds a specific limit. They are widely used due to their simplicity and effectiveness. Various types of fuses include:

- Glass Tube Fuses: Commonly used in electronics and appliances, these fuses provide visible confirmation of a blown fuse.

- Blade Fuses: Often used in automotive applications, these fuses are easy to replace and come in standard sizes.

- Ceramic Fuses: These are used in high-voltage applications and provide superior durability and resistance to high temperatures.

- Resettable Fuses (PTC): Unlike traditional fuses, these can reset themselves after an overload condition is cleared, making them ideal for applications where continuous protection is needed.

Thermal Overload Relays

Thermal overload relays are used primarily to protect electric motors and other equipment from overheating due to excessive current. They operate based on the principle of thermal expansion:

- Bimetallic Thermal Relays: These contain a bimetal strip that bends when heated by excess current, triggering the relay to open the circuit and stop the current flow.

- Electronic Thermal Relays: These use electronic sensors to detect temperature changes and provide more precise protection compared to bimetallic relays.

- Application in Motors: Thermal overload relays are crucial for protecting motors from prolonged overload conditions, preventing damage and ensuring longevity.

Comparative Analysis

While all these devices serve the purpose of protecting electrical systems from overloads, they differ in their mechanisms and applications:

- Circuit Breakers vs. Fuses: Circuit breakers can be reset and reused after tripping, making them more convenient for frequent use. Fuses, however, are typically cheaper and simpler but need to be replaced after they blow.

- Fuses vs. Thermal Relays: Fuses provide immediate protection by blowing, while thermal relays offer delayed protection to account for temporary overloads, making them suitable for motors that experience inrush currents.

- Circuit Breakers vs. Thermal Relays: Circuit breakers offer broader protection and can handle both overloads and short circuits, while thermal relays are specialized for motor protection against overloads due to their ability to tolerate brief surges.

Overload Protection in Marine Applications

Significance in Marine Engineering

Overload protection is crucial in marine engineering due to the unique and demanding environments in which marine vessels operate. Ships face constant exposure to harsh conditions such as saltwater corrosion, high humidity, and extreme temperatures, which can all impact the reliability and safety of their electrical systems. The confined spaces and complex wiring aboard ships also increase the risk of electrical faults and fires. Therefore, robust overload protection is essential to safeguard electrical systems, ensure operational reliability, and prevent catastrophic failures at sea.

Shipboard Electrical Systems

Shipboard electrical systems are highly specialized and require tailored overload protection solutions to meet their specific needs. These systems power a wide range of equipment, from navigation and communication systems to propulsion and auxiliary machinery. Key considerations for overload protection in these environments include:

- Voltage and Current Ratings: Shipboard electrical systems often operate at higher voltages and currents than residential or commercial systems, necessitating overload protection devices that can handle these demands.

- Redundancy and Reliability: Marine applications demand high reliability and redundancy to ensure continuous operation. Overload protection devices must be able to provide reliable protection without frequent false trips.

- Environmental Protection: Devices must be resistant to corrosion, moisture, and vibration to maintain their effectiveness in marine environments.

- Compatibility with Marine Standards: Overload protection solutions must comply with marine standards and regulations, such as those set by the International Maritime Organization (IMO) and classification societies like Lloyd’s Register and the American Bureau of Shipping (ABS).

Marine Safety

The role of overload protection in ensuring marine safety cannot be overstated. Properly implemented overload protection helps prevent electrical fires, equipment damage, and system failures that could lead to dangerous situations at sea. Key aspects include:

- Fire Prevention: Overload protection devices detect and interrupt excessive current flow before it can generate sufficient heat to start a fire. This is critical in the confined and often flammable environments aboard ships.

- Equipment Protection: By preventing overloads, these devices protect vital shipboard equipment from damage, ensuring that navigation, communication, and propulsion systems remain operational.

- Accident Prevention: Reliable overload protection minimizes the risk of electrical accidents that could harm crew members or passengers. For instance, ground fault protection reduces the risk of electrical shocks.

- Emergency Preparedness: In the event of an overload or short circuit, effective protection systems ensure that critical systems can be quickly and safely restored, maintaining the ship’s operational readiness and safety.

Modern Technologies in Overload Protection

Advancements in Technology

Overload protection has seen significant technological advancements, enhancing the safety and reliability of electrical systems. One of the most notable developments is the advent of smart breakers. Unlike traditional circuit breakers, smart breakers offer advanced features such as remote monitoring and control, energy usage tracking, and integration with smart home systems. These breakers can provide real-time data on electrical loads, allowing for more precise management and quicker response to overload conditions.

Another key advancement is the development of IoT-enabled devices. These devices leverage the Internet of Things (IoT) to enhance overload protection capabilities. By connecting overload protection devices to the internet, users can monitor and manage their electrical systems remotely, receiving alerts and updates in real time. This connectivity not only improves safety but also enhances the overall efficiency of electrical systems.

IoT Integration

Integrating IoT into overload protection systems brings numerous benefits. One of the primary advantages is real-time monitoring. IoT-enabled devices can continuously monitor electrical loads and conditions, providing instant alerts if an overload or fault is detected. This allows for immediate intervention, preventing potential damage and ensuring the safety of the system.

Another benefit is predictive maintenance. IoT devices can analyze data trends over time, identifying patterns that may indicate potential issues before they become critical. This proactive approach enables timely maintenance, reducing the risk of unexpected failures and extending the lifespan of electrical equipment.

Moreover, IoT integration facilitates remote control and automation. Users can manage their overload protection systems from anywhere, using smartphones or computers. This remote access allows for quick adjustments to settings and immediate response to alerts, even when not physically present at the location. Automation features can also be set up to automatically adjust load distributions and settings based on real-time data, optimizing the performance and safety of the electrical system.

Future Trends

Looking ahead, several emerging trends and innovations are set to further revolutionize overload protection technology. One such trend is the increased use of artificial intelligence (AI) and machine learning. AI can enhance the predictive capabilities of overload protection systems by analyzing vast amounts of data to predict potential overloads and faults more accurately. Machine learning algorithms can continuously improve the system’s response based on historical data and evolving patterns.

Another promising trend is the development of advanced materials and components that offer higher reliability and durability. Innovations in materials science are leading to overload protection devices that can withstand harsher conditions and provide more consistent performance over longer periods.

Best Practices for Implementing Overload Protection

Design Guidelines

Implementing effective overload protection begins with a robust design tailored to the specific needs of residential, commercial, and industrial settings. Here are some best practices:

- Residential Settings:

- Load Assessment: Start with a thorough assessment of the electrical load requirements. Identify all critical and non-critical loads to ensure appropriate protection for each circuit.

- Zoning: Divide the electrical system into zones based on usage patterns (e.g., kitchen, living room, HVAC). Each zone should have dedicated overload protection to isolate faults without affecting the entire system.

- Smart Breakers: Consider incorporating smart breakers for enhanced monitoring and control, particularly in homes with high-tech appliances and smart home systems.

- Commercial Settings:

- Load Calculation: Perform detailed load calculations to account for diverse electrical needs, including lighting, HVAC, office equipment, and specialized machinery.

- Redundancy: Design with redundancy to ensure critical operations remain unaffected during an overload. This might include using dual power sources or backup circuits.

- Scalability: Ensure the design is scalable to accommodate future expansions or increased load demands without compromising protection.

- Industrial Settings:

- Detailed Load Analysis: Conduct an exhaustive load analysis to identify peak demand periods and high-load equipment. This is crucial for environments with heavy machinery and continuous operations.

- Custom Solutions: Implement custom overload protection solutions for specific machinery, considering factors like motor starting currents and operational cycles.

- Environmental Considerations: Design for harsh environments, ensuring devices are protected against dust, moisture, and extreme temperatures.

Installation Tips

Proper installation is key to ensuring the effectiveness of overload protection devices. Here are some practical tips:

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s installation guidelines for each overload protection device. This ensures proper operation and avoids voiding warranties.

- Proper Sizing: Ensure that circuit breakers, fuses, and relays are correctly sized according to the load they protect. Oversized or undersized devices can fail to protect or cause nuisance tripping.

- Secure Connections: Make sure all electrical connections are tight and secure to prevent loose connections, which can cause overheating and arcing.

- Labeling: Clearly label all overload protection devices and associated circuits. This simplifies maintenance and troubleshooting.

- Testing: Conduct thorough testing of all installed devices to verify their functionality. Periodic testing should be part of the maintenance routine to ensure continued reliability.

Compliance and Standards

Adhering to safety standards and regulations is critical in implementing overload protection systems:

- Local Codes: Ensure compliance with local electrical codes and regulations, which may vary by region and jurisdiction. These codes provide the minimum safety requirements for electrical installations.

- National Standards: Follow national standards such as the National Electrical Code (NEC) in the United States, the Canadian Electrical Code (CEC), or the International Electrotechnical Commission (IEC) standards. These standards set the benchmarks for safe electrical design and installation.

- Industry-Specific Regulations: For commercial and industrial settings, comply with industry-specific regulations such as those from the Occupational Safety and Health Administration (OSHA) or relevant industry bodies.

- Regular Inspections: Schedule regular inspections by qualified professionals to ensure ongoing compliance and identify any potential safety issues.

- Documentation: Maintain detailed records of all overload protection systems, including design specifications, installation details, and maintenance logs. This documentation is essential for compliance audits and future reference.

Troubleshooting Overload Protection Issues

| Section | Details |

|---|---|

| Common Problems | Nuisance Tripping: Devices trip frequently without an apparent cause, leading to unnecessary downtime. Failure to Trip: Devices do not activate during an overload condition, posing a serious safety risk. Worn Out Components: Mechanical parts in circuit breakers and relays can wear out, affecting performance. Incorrect Settings: Improperly set current limits or incorrect device ratings can cause malfunction. Environmental Damage: Exposure to dust, moisture, or extreme temperatures can impair functionality. Loose Connections: Poor electrical connections can lead to overheating and arcing. |

| Step-by-Step Guide | Identify the Problem: Check if the device has tripped and note the circumstances. Inspect for visible signs of damage or environmental impact. Nuisance Tripping: Inspect load conditions and ensure they do not exceed device capacity. Verify and adjust current limit settings. Examine wiring for short circuits or ground faults. Failure to Trip: Test the device under simulated overload conditions. Inspect the mechanism for jams or wear. Confirm device rating matches system requirements. Worn Out Components: Regularly inspect mechanical components. Test device functionality periodically. Replace worn or damaged parts. Incorrect Settings: Review user manual for correct settings. Adjust settings per manufacturer’s guidelines. Environmental Damage:<br> – Inspect for corrosion, dust, or moisture ingress. Clean and protect the device. Consider relocating or using protective enclosures. Loose Connections: Tighten all electrical connections. Inspect and replace damaged wiring. Use proper tools for secure connections. |

| Maintenance Tips | Routine Inspections: Schedule regular inspections for wear, damage, or environmental impact. Include visual and functional testing. Periodic Testing: Test operation under controlled conditions. Simulate overload conditions to ensure proper tripping. Clean Environment: Keep the area around devices clean and free of dust, debris, and moisture. Use protective covers or enclosures in harsh environments.<br> Documentation: Maintain detailed records of inspections, tests, and maintenance activities. Document changes in settings, replacements, or repairs. Training: Ensure personnel are properly trained. Provide ongoing training to keep up with new technologies and best practices. |

FAQ on “Overload Protection”

Q: What is the primary purpose of overload protection?

A: To prevent electrical fires and equipment damage.

Q: How do smart breakers enhance protection?

A: Through remote monitoring and real-time alerts.

Q: Why is overload protection crucial in marine applications?

A: It ensures shipboard safety and reliability.

Q: What indicates an overload device needs maintenance?

A: Frequent tripping and visible damage.

Conclusion

In this guide, we’ve highlighted the essential aspects of overload protection, from understanding its importance and exploring various types of devices to discussing best practices and troubleshooting. Staying updated with the latest technologies and implementing robust protection systems is crucial for ensuring safety and efficiency in all electrical environments. We encourage you to assess your current setup and consider modern solutions to enhance your system’s reliability and prevent potential hazards. By prioritizing overload protection, you safeguard your equipment and contribute to a safer and more efficient electrical infrastructure.