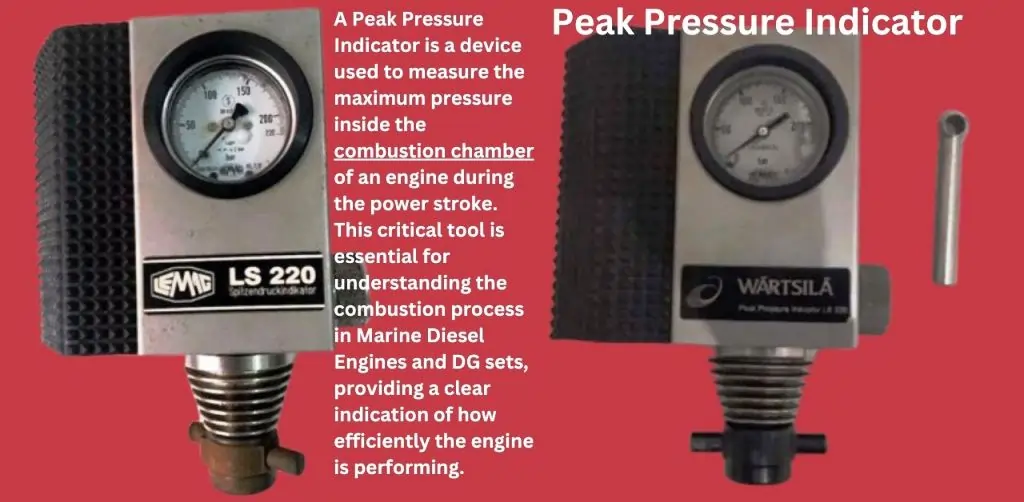

Peak Pressure Indicator

Peak pressure indicators play a vital role in ensuring the smooth operation of Marine Diesel Engines and DG sets by monitoring combustion performance. These devices measure the maximum pressure inside the combustion chamber, providing insights into engine health, fuel efficiency, and potential issues such as improper timing or worn-out components. For engineers and technicians, regularly using a peak pressure indicator can prevent costly breakdowns and ensure optimal engine performance.

In 2024, understanding and utilizing peak pressure indicators is more critical than ever. With advancements in engine technology and the increasing demand for efficiency in marine and industrial sectors, accurate pressure readings are essential for maintaining high-performance standards. Whether using mechanical or electronic versions, mastering these tools is key to preventing engine failures and ensuring long-term reliability. This tutorial will guide you through everything you need to know about peak pressure indicators to enhance engine maintenance and performance.

What is a Peak Pressure Indicator?

A Peak Pressure Indicator is a device used to measure the maximum pressure inside the combustion chamber of an engine during the power stroke. This critical tool is essential for understanding the combustion process in Marine Diesel Engines and DG sets, providing a clear indication of how efficiently the engine is performing.

Function of a Peak Pressure Indicator

The main function of the peak pressure indicator is to record the highest pressure reached during combustion. This measurement helps engineers assess the effectiveness of fuel combustion, detect issues like improper fuel injection timing, and monitor overall engine performance.

Role in Diagnosing Combustion Efficiency and Engine Health

Peak pressure readings offer insights into combustion efficiency, allowing technicians to spot irregularities that could indicate worn-out components, fuel system malfunctions, or other performance issues. By regularly using a peak pressure indicator, engineers can maintain engine health, reduce fuel consumption, and prevent costly repairs or breakdowns.

How Peak Pressure Indicators Work

A Peak Pressure Indicator functions by measuring the maximum pressure inside the combustion chamber during the engine’s power stroke. This pressure is directly related to the combustion process, making it an essential parameter for assessing engine performance and efficiency.

Working Principle of Peak Pressure Indicators

The working principle is simple: the indicator captures and records the highest pressure generated during combustion. This peak pressure is a key indicator of engine health, fuel efficiency, and combustion quality. Variations in this pressure can signal problems like poor fuel injection timing or mechanical wear.

Measuring Peak Combustion Pressure in Diesel Engines

In diesel engines, the indicator is connected to the combustion chamber, where it detects pressure changes during engine operation. The peak pressure is recorded during the power stroke when combustion generates the highest force. This data helps in analyzing the efficiency of the combustion process.

Mechanical vs. Electronic Peak Pressure Indicators

- Mechanical Peak Pressure Indicators: These use a spring-loaded mechanism to capture the peak pressure. When combustion occurs, the pressure compresses the spring, and the peak value is displayed on a gauge. Though reliable, mechanical indicators require manual reading and interpretation.

- Electronic Peak Pressure Indicators: Modern electronic versions use sensors to digitally record peak pressure. These are more accurate and can provide instant, real-time data, which is especially useful for advanced diagnostic purposes. Electronic indicators often feature data logging and can be connected to monitoring systems for detailed analysis.

Types of Peak Pressure Indicators

Peak Pressure Indicators come in two main types: Mechanical and Digital/Electronic. Each type serves the same purpose of measuring combustion pressure but operates through different mechanisms and offers distinct advantages.

Mechanical Peak Pressure Indicators

Mechanical peak pressure indicators are traditional devices that operate using a spring-loaded mechanism to capture and display the peak pressure.

- Working Mechanism: As the combustion pressure increases in the engine, it forces a piston or a diaphragm against a calibrated spring. The maximum pressure compresses the spring, which then holds its position, indicating the highest pressure reached during combustion. The reading is manually observed on a gauge.

- Applications: Mechanical indicators are commonly used in older marine diesel engines and industrial DG sets. They are valued for their durability and reliability, especially in environments where electronic devices may not function well due to extreme conditions.

Digital/Electronic Peak Pressure Indicators

Digital or electronic peak pressure indicators use advanced sensors and digital displays to measure and record combustion pressure with high precision.

- How Modern Digital Indicators Work: These devices use pressure sensors that convert the combustion pressure into an electrical signal. The signal is processed and displayed as a real-time pressure reading on a digital screen. Electronic indicators often come with features such as data logging, trend analysis, and connectivity to other diagnostic systems, making them far more efficient for ongoing engine monitoring.

- Advantages over Mechanical Versions:

- Higher Accuracy: Electronic indicators provide more accurate readings due to their precise sensors.

- Real-Time Monitoring: They allow for instant data capture and analysis, eliminating the need for manual readings.

- Data Logging and Storage: These indicators can store multiple readings over time, making it easier to track engine performance trends and diagnose issues early.

- Ease of Use: Digital indicators are easier to read and use, especially in complex or modern engine systems where quick data access is crucial.

How to Use a Peak Pressure Indicator

Using a peak pressure indicator in marine diesel engines is essential for monitoring combustion efficiency and ensuring engine health. Accurate readings can help diagnose issues early and improve performance. Below is a step-by-step guide on how to measure peak pressure, along with best practices and safety precautions.

Step-by-Step Guide for Measuring Peak Pressure in Marine Diesel Engines

- Prepare the Engine

- Ensure the engine is running at normal operating conditions (temperature and load) to obtain an accurate pressure reading.

- Stop the engine momentarily before inserting the peak pressure indicator.

- Select the Correct Port

- Locate the indicator valve or pressure tapping point on the cylinder head of the marine diesel engine. This is where the peak pressure indicator will be connected.

- Attach the Peak Pressure Indicator

- For mechanical indicators, securely screw the indicator into the pressure tapping point.

- For electronic indicators, connect the sensor to the appropriate valve, ensuring a tight, leak-free fit.

- Restart the Engine

- Start the engine and allow it to reach operational levels again before taking a reading.

- Take the Reading

- Mechanical Indicator: Observe the maximum deflection of the needle on the gauge, which will indicate the peak pressure. Some mechanical indicators may require you to reset or manually note the pressure.

- Electronic Indicator: The digital display will automatically record and show the peak pressure reading in real time.

- Record the Data

- Record the pressure readings for each cylinder, noting any significant variations between them, as this could indicate engine performance issues.

Best Practices for Accurate Readings

- Warm-Up the Engine: Always ensure the engine has reached its normal operating temperature and load before taking measurements.

- Use Proper Equipment: Ensure the peak pressure indicator is well-calibrated and suited for the specific engine type.

- Take Multiple Readings: For increased accuracy, take several readings and average the results, particularly if there are fluctuations.

- Follow Manufacturer’s Guidelines: Always follow the engine and peak pressure indicator manufacturer’s instructions for usage and maintenance.

- Regular Calibration: Periodically calibrate both mechanical and electronic indicators to maintain accurate readings.

Safety Precautions to Follow

- Engine Shutdown: Always stop the engine before attaching or removing the peak pressure indicator to prevent injury from high-pressure gas release.

- Wear Protective Gear: Use appropriate safety equipment such as gloves, safety glasses, and ear protection to safeguard against potential hazards.

- Avoid High-Pressure Exposure: Be cautious when dealing with high-pressure systems, ensuring all connections are secure and leak-free.

- Monitor Temperature: The engine and surrounding components will be hot, so use tools and protective gear to avoid burns.

- Ensure Proper Ventilation: If working in enclosed spaces, ensure adequate ventilation to avoid exposure to exhaust gases.

Common Issues Detected by Peak Pressure Indicators

Peak pressure indicators provide critical insights into the combustion process within marine diesel engines. Abnormal readings, whether too high or too low, often signal underlying engine issues that require immediate attention. By regularly monitoring peak pressure, you can detect these problems early and prevent costly repairs or engine failures.

High Peak Pressure Readings

High peak pressure readings typically indicate excessive pressure inside the combustion chamber. This can lead to mechanical stress and damage to engine components. Common causes of high pressure include:

- Advanced Fuel Injection Timing: When fuel is injected too early, it can cause a more intense combustion, leading to higher-than-normal pressures.

- Carbon Deposits: Accumulation of carbon deposits on valves, piston crowns, or cylinder heads can reduce the combustion chamber volume, raising the pressure.

- Faulty Injector Nozzles: If injectors are delivering too much fuel or creating an improper spray pattern, combustion pressure can rise significantly.

Low Peak Pressure Readings

Low peak pressure readings indicate insufficient combustion pressure, which can result in poor engine performance and fuel inefficiency. Potential causes of low pressure include:

- Worn-Out Piston Rings: Worn or damaged piston rings can cause a loss of compression, reducing the pressure inside the combustion chamber.

- Late Fuel Injection Timing: Injecting fuel too late in the cycle leads to incomplete combustion, resulting in lower pressure.

- Faulty Injectors: Clogged or malfunctioning injectors may not supply enough fuel, causing lower peak pressure readings.

- Leaking Cylinder Head Gaskets: A loss of pressure due to a leaking gasket can cause significant drops in peak pressure readings.

How Abnormal Peak Pressure Readings Indicate Potential Problems

- Worn-Out Piston Rings: Low peak pressure often indicates a loss of compression due to worn or damaged piston rings, allowing combustion gases to escape past the piston.

- Faulty Injectors: Both high and low peak pressure can signal injector problems. If too much fuel is injected, it raises pressure, while too little or improperly atomized fuel lowers pressure.

- Improper Fuel Timing: Incorrect fuel injection timing, whether too early or too late, can cause combustion inefficiency. Advanced timing results in high peak pressures, while delayed timing lowers them.

Maintenance and Calibration of Peak Pressure Indicators

Proper maintenance and regular calibration of peak pressure indicators are essential for ensuring accurate and reliable measurements. Peak pressure readings play a critical role in assessing engine performance and combustion efficiency, so keeping the indicator in optimal condition is vital for consistent engine monitoring.

Importance of Regular Calibration

Calibration is the process of verifying and adjusting the accuracy of a peak pressure indicator. Over time, both mechanical and electronic indicators can experience drift or wear, which leads to incorrect readings. Inaccurate measurements can result in misdiagnoses of engine problems, leading to unnecessary repairs or overlooked issues that could worsen.

- Precision in Engine Monitoring: Regular calibration ensures that the peak pressure indicator provides precise readings, which are critical for maintaining the engine’s performance.

- Preventive Maintenance: Calibrated indicators can help identify early signs of wear or malfunction in the engine, allowing for timely maintenance and repairs.

- Regulatory Compliance: Many marine and industrial sectors have stringent requirements for engine performance monitoring, and ensuring your tools are calibrated keeps you compliant with regulations.

Key Formulas for Peak Pressure and Engine Performance

Understanding the relationship between peak pressure and engine performance is crucial in maintaining marine diesel engines. Below are essential formulas that help diagnose engine efficiency, mechanical output, and combustion effectiveness:

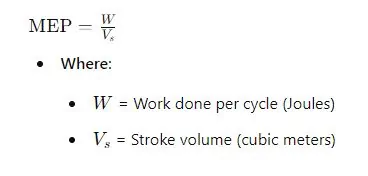

1. Mean Effective Pressure (MEP)

Mean Effective Pressure (MEP) is the average pressure exerted on the piston during one complete engine cycle. It is used to assess the overall efficiency of the engine in converting fuel into work. A higher MEP generally means better engine performance.

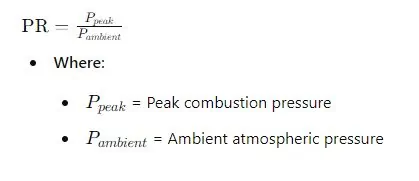

2. Pressure Ratio (PR)

The Pressure Ratio (PR) compares the peak combustion pressure to the ambient atmospheric pressure. This ratio indicates the effectiveness of the combustion process, as a higher pressure ratio typically suggests better engine performance.

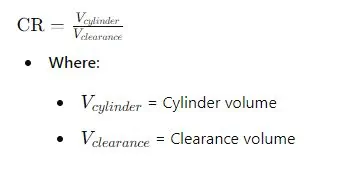

3. Compression Ratio (CR)

Compression Ratio (CR) is the ratio of the volume of the cylinder when the piston is at the bottom of the stroke to the volume when the piston is at the top. A higher compression ratio increases peak pressure and improves thermal efficiency, leading to enhanced engine performance.

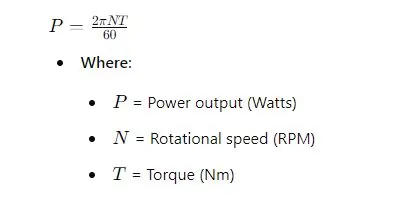

4. Power Output (Indicated Power)

This formula calculates the engine’s power output by using its torque and rotational speed. Power output is a key indicator of engine efficiency and mechanical performance, with greater torque and speed yielding higher power.

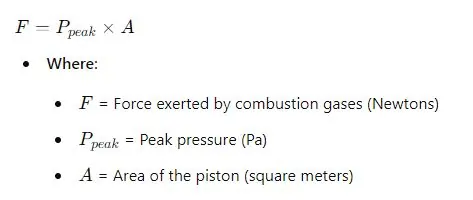

5. Force from Peak Pressure

This formula calculates the force exerted by the combustion gases on the piston at peak pressure. The force produced is a direct result of the pressure generated during combustion and the surface area of the piston, which drives the engine’s output power.

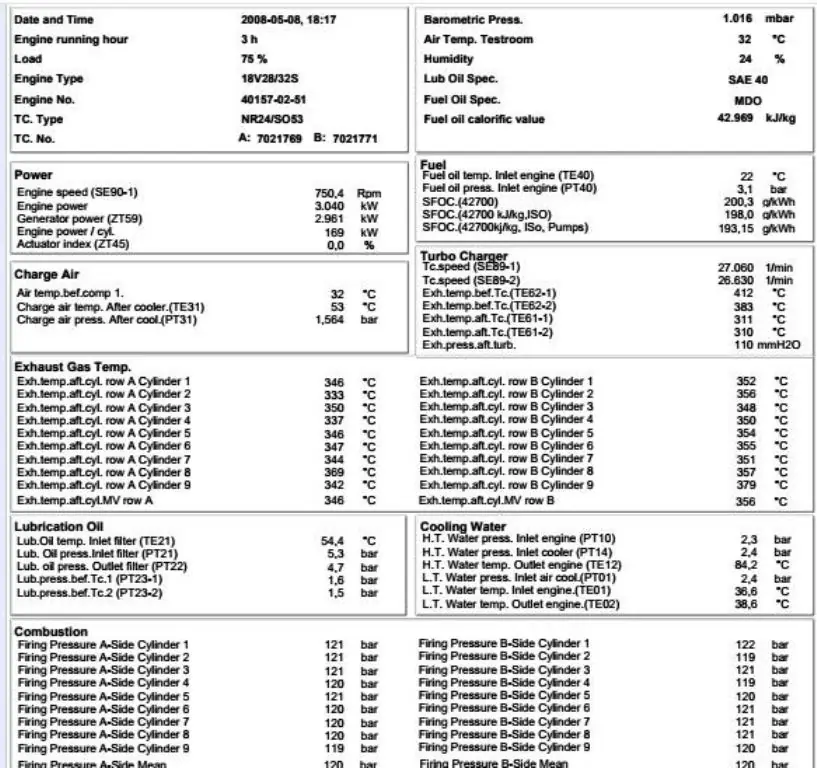

Engine EPD

Tips for Maintaining Mechanical Peak Pressure Indicators

- Regular Cleaning: Mechanical indicators are susceptible to carbon deposits and other contaminants from the combustion chamber. Clean the indicator after each use to prevent debris from affecting the readings.

- Lubrication: Lubricate moving parts like the spring and piston to ensure smooth operation and prevent wear. Use manufacturer-recommended lubricants and avoid over-lubricating.

- Inspect for Wear and Tear: Regularly inspect components such as the spring, diaphragm, and gauge for signs of wear or damage. Any worn parts should be replaced to maintain the accuracy of the device.

- Calibration: Mechanical indicators should be calibrated at least annually, depending on usage frequency. Calibration against a known standard will ensure accurate peak pressure measurements.

Tips for Maintaining Electronic Peak Pressure Indicators

- Sensor Care: The pressure sensors in electronic indicators are delicate and need to be handled with care. Avoid dropping or exposing them to extreme temperatures to prevent damage.

- Software Updates: Ensure that any software or firmware associated with the electronic indicator is up to date. Software improvements can help enhance accuracy and provide new features for monitoring.

- Battery Maintenance: Regularly check and replace the batteries in electronic indicators to avoid power issues during measurement. A low battery can affect the accuracy of readings or prevent data logging.

- Data Storage: Periodically check the memory or storage capacity if the electronic indicator has data logging features. Back up stored data and clear the storage to prevent overflow and maintain device functionality.

- Calibration: Electronic indicators require more frequent calibration than mechanical versions due to the sensitivity of their sensors. It is advisable to calibrate them quarterly or according to manufacturer recommendations.

General Best Practices for Calibration and Maintenance

- Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s instructions for both calibration and maintenance to ensure the longevity and accuracy of the device.

- Use Professional Calibration Services: For critical applications, consider using a professional calibration service to ensure accuracy. This is especially important for electronic indicators, where sensor precision is crucial.

- Track Calibration Schedules: Keep a log of when the indicator was last calibrated and schedule future calibrations to avoid any lapses in accuracy.

When to Replace Your Peak Pressure Indicator

Peak pressure indicators are critical tools for monitoring the performance and health of marine diesel engines. However, like any precision instrument, they have a limited lifespan and may require replacement to ensure accurate readings. Knowing when to replace your peak pressure indicator is crucial to maintain engine efficiency and avoid potential failures.

Signs Your Peak Pressure Indicator Needs Replacement

- Inconsistent or Fluctuating Readings

- If the peak pressure readings vary widely or show erratic spikes without any corresponding engine changes, it could indicate internal wear or damage to the indicator’s components, such as the spring or sensor.

- Difficulty in Calibration

- An indicator that consistently fails to calibrate or holds inaccurate readings after calibration may have reached the end of its functional life. This is especially common in electronic indicators where sensors degrade over time.

- Physical Damage

- Any visible damage to the indicator, such as dents, cracks, or broken parts, can compromise its accuracy. For mechanical indicators, a bent needle or damaged spring can distort readings. In electronic indicators, damaged sensors or displays can render the tool ineffective.

- Frequent Mechanical Failures

- If a mechanical peak pressure indicator frequently jams, sticks, or shows signs of internal friction during operation, it might be nearing the end of its useful life. This can lead to inaccurate pressure readings or even complete device failure.

- Aging Electronic Components

- In electronic indicators, aging sensors and other internal components can lead to gradual deterioration in performance. If the digital display fades or the sensor response slows down, these are strong indicators of the need for replacement.

- Recurring Calibration Issues

- If your peak pressure indicator requires frequent calibration or cannot maintain accurate calibration for long periods, it may be an indication that the device is wearing out and should be replaced to ensure consistent measurements.

Recommended Intervals for Checks and Replacements in Marine Diesel Engines

- Routine Inspection and Calibration

- It’s recommended to inspect and calibrate your peak pressure indicator every 6 to 12 months, depending on usage. Regular checks ensure the device is functioning accurately and that any signs of wear are addressed before they become major issues.

- Mechanical Peak Pressure Indicators

- Mechanical indicators, while durable, should be replaced approximately every 3 to 5 years, depending on usage frequency and environmental conditions. Heavy use or exposure to extreme environments like high humidity, high temperature, or corrosive atmospheres may accelerate wear and require earlier replacement.

- Electronic Peak Pressure Indicators

- Electronic indicators, especially those used frequently, should be replaced every 2 to 4 years. Sensors tend to degrade over time, affecting accuracy. Additionally, advancements in technology may make newer models more efficient, providing better readings and advanced features.

- After Major Engine Overhaul

- Replace or thoroughly inspect your peak pressure indicator following any major engine overhaul or significant maintenance, as such activities can impact the performance of monitoring equipment.

- After Repeated Failures

- If the indicator shows repeated signs of malfunction despite repair attempts, it is more cost-effective and safer to replace it rather than risk inaccurate pressure readings that could lead to engine damage.

Peak Pressure Indicator: Replacement Guide

| Criteria | Details |

|---|---|

| Signs Your Peak Pressure Indicator Needs Replacement | |

| Inconsistent or Fluctuating Readings | Widely varying or erratic readings without engine changes, indicating internal wear or damage. |

| Difficulty in Calibration | Fails to calibrate or holds inaccurate readings even after calibration, especially in electronic indicators. |

| Physical Damage | Visible damage like dents, cracks, or broken parts that compromise accuracy. |

| Frequent Mechanical Failures | For mechanical indicators, signs of jamming, sticking, or internal friction that affect operation. |

| Aging Electronic Components | Fading digital displays or slow sensor response in electronic indicators. |

| Recurring Calibration Issues | Frequent need for calibration or inability to maintain accuracy indicates wear. |

| Recommended Intervals for Checks and Replacements | |

| Routine Inspection and Calibration | Every 6 to 12 months for routine checks and calibration, depending on usage. |

| Mechanical Peak Pressure Indicators | Replace every 3 to 5 years based on usage and environmental conditions. |

| Electronic Peak Pressure Indicators | Replace every 2 to 4 years due to sensor degradation and technological advancements. |

| After Major Engine Overhaul | Replace or inspect thoroughly after any major engine overhaul or significant maintenance. |

| After Repeated Failures | If the indicator malfunctions repeatedly despite repairs, replacement is recommended. |

FAQ on “Peak Pressure Indicator”

Q- What is a peak pressure indicator?

A peak pressure indicator measures the maximum pressure inside the combustion chamber of an engine.

Q- Why is peak pressure important in marine diesel engines?

Peak pressure helps monitor combustion efficiency and detect engine performance issues early.

Q- How often should a peak pressure indicator be calibrated?

A- Calibration should be done every 6 to 12 months, depending on usage.

Q- When should a peak pressure indicator be replaced?

Replace it every 3 to 5 years for mechanical versions and 2 to 4 years for electronic versions.

Conclusion

Understanding and maintaining your peak pressure indicator is essential for ensuring optimal performance and longevity of marine diesel engines and DG sets. Regular calibration, timely replacement, and proper usage help detect potential engine issues early, preventing costly repairs and downtime. Whether you’re using a mechanical or electronic version, staying proactive with maintenance ensures accurate readings, enhances combustion efficiency, and ultimately keeps your engine running smoothly. By following the best practices outlined in this guide, you can extend the life of your equipment and improve overall engine performance.