Pneumatic Solenoid Valve

Did you know that over 70% of modern ships rely on pneumatic solenoid valves for critical operations? These essential components play a pivotal role in ensuring the smooth and efficient functioning of marine systems. From controlling fuel flow to maintaining safety protocols, pneumatic solenoid valves are indispensable in the maritime industry.

In this post, we delve into the significance of pneumatic solenoid valves and their vital applications on marine vessels. These valves not only enhance the performance and reliability of ship systems but also contribute to safety and environmental compliance.

Our goal is to highlight the seven most powerful uses of pneumatic solenoid valves in marine settings. By understanding these key applications, marine engineers and enthusiasts can better appreciate the versatility and importance of these valves in modern maritime operations. Join us as we explore how these small but mighty components make a big impact on the high seas.

Understanding Pneumatic Solenoid Valves

Definition and Functionality

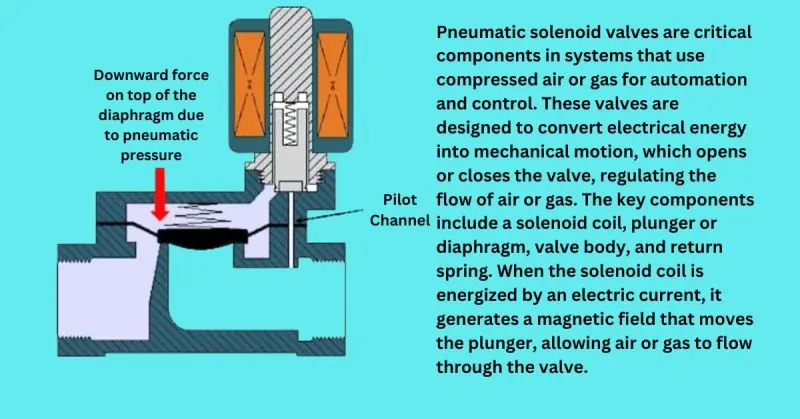

Pneumatic solenoid valves are electromechanical devices used to control the flow of air or gas in a pneumatic system. They consist of a solenoid, which is an electrically energized coil, and a valve that controls the flow of air. When the solenoid is energized, it generates a magnetic field that moves a plunger or an armature, opening or closing the valve. This action allows or restricts the flow of air, thus controlling the operation of pneumatic devices downstream.

These valves are designed to provide precise control over pneumatic systems, enabling automation and regulation of various processes. They can be normally open (allowing flow until actuated to close) or normally closed (blocking flow until actuated to open), providing flexibility in controlling pneumatic circuits.

Importance in Marine Systems

Pneumatic solenoid valves are critical components in marine applications for several reasons:

- Engine Control: These valves play a crucial role in managing engine operations by controlling air intake, exhaust, and fuel injection systems. Their precise control capabilities ensure optimal engine performance and efficiency.

- Automation and Safety: Pneumatic solenoid valves are integral to automated control systems on ships, enhancing operational efficiency and safety. They are used in various automated processes, such as ballast water management, cargo handling, and fire suppression systems.

- Fuel Management: In marine fuel systems, these valves regulate the flow of fuel to ensure proper combustion and engine performance. They help maintain the correct fuel-air mixture, which is vital for efficient and safe engine operation.

- Environmental Control: Marine vessels are subject to strict environmental regulations. Pneumatic solenoid valves aid in maintaining environmental control systems, such as HVAC systems and pollution control devices, ensuring compliance with regulations.

- Reliability and Durability: Marine environments are harsh, with exposure to saltwater, humidity, and varying temperatures. Pneumatic solenoid valves are designed to withstand these conditions, offering reliable performance and long service life.

Engine Control Systems

Role of Valves in Engine Control

Pneumatic solenoid valves play a crucial role in the efficient control of marine engine systems. These valves are responsible for regulating the flow of air, fuel, and exhaust gases, which are essential for optimal engine performance. By precisely controlling these flows, pneumatic solenoid valves ensure that the engine operates at peak efficiency, reducing fuel consumption and emissions.

In marine engines, pneumatic solenoid valves are used to manage various functions such as air intake, fuel injection, and exhaust gas recirculation. They help maintain the correct air-fuel ratio, which is vital for combustion efficiency. Additionally, these valves are used to control the timing and amount of fuel injected into the engine cylinders, directly impacting engine power and performance.

Case Study/Example

Case Study: Pneumatic Solenoid Valves in Large Container Ships

In large container ships, pneumatic solenoid valves are integral to the operation of the main engine’s fuel injection system. For instance, consider the engine control system of a Maersk Triple-E class container ship. These vessels are among the largest in the world and are powered by two-stroke diesel engines, which require precise control over fuel injection to achieve optimal performance.

In the Maersk Triple-E class ships, pneumatic solenoid valves are used to control the timing and duration of fuel injection into each cylinder. The engine control unit (ECU) sends signals to the solenoid valves, which then open or close to allow the precise amount of fuel to be injected at the right moment. This precise control is critical for achieving the high efficiency and low emissions required for these massive vessels.

By using pneumatic solenoid valves, the engine can adjust to varying load conditions and maintain optimal combustion efficiency. This not only improves fuel economy but also reduces the ship’s overall environmental impact by minimizing emissions of pollutants such as nitrogen oxides (NOx) and sulfur oxides (SOx).

Automation and Safety Systems

Enhancing Automation

Pneumatic solenoid valves are essential components in the automation of marine systems, significantly improving the safety and efficiency of ship operations. These valves provide precise control over the flow of air and gases, enabling automated systems to function smoothly and reliably. By integrating pneumatic solenoid valves into various ship systems, shipbuilders and operators can achieve higher levels of automation, reducing the need for manual intervention and minimizing the risk of human error.

In automated marine systems, pneumatic solenoid valves are used to control a wide range of functions, including ballast water management, cargo handling, and engine control. For instance, in ballast water management systems, these valves regulate the flow of ballast water to maintain the ship’s stability and ensure compliance with environmental regulations. Automated cargo handling systems also rely on pneumatic solenoid valves to control the movement of cargo, enhancing loading and unloading efficiency while ensuring the safety of the crew and cargo.

Safety Applications

Pneumatic solenoid valves play a vital role in various safety systems on ships, providing quick and reliable responses to potential hazards. Some of the key safety applications that rely on pneumatic solenoid valves include:

- Fire Suppression Systems: Pneumatic solenoid valves are used in fire suppression systems to control the release of fire extinguishing agents, such as CO2 or water mist. These valves ensure that the agents are quickly and accurately delivered to the affected areas, minimizing damage and protecting the crew.

- Emergency Shutoff Systems: In the event of an emergency, pneumatic solenoid valves can be used to quickly shut off fuel lines, ventilation systems, and other critical systems to prevent the spread of fire or hazardous materials. This rapid response capability is crucial for maintaining the safety of the ship and its crew.

- Gas Detection Systems: Pneumatic solenoid valves are also employed in gas detection systems to isolate sections of the ship where hazardous gases are detected. By controlling the flow of air and gases, these valves help prevent the spread of toxic or flammable substances, ensuring a safe environment on board.

- Life-Saving Equipment: Many life-saving systems, such as inflatable life rafts and life jackets, use pneumatic solenoid valves to control the inflation process. These valves ensure that the equipment is deployed quickly and reliably in emergency situations, providing vital support for the crew and passengers.

- Pressure Relief Systems: Pneumatic solenoid valves are used in pressure relief systems to maintain safe pressure levels in various ship systems, such as fuel tanks and pipelines. By automatically relieving excess pressure, these valves prevent equipment failure and potential hazards.

Fuel Management Systems

Fuel Flow Regulation

Pneumatic solenoid valves are pivotal in the precise regulation of fuel flow within marine fuel management systems. These valves control the delivery of fuel from storage tanks to the engine, ensuring that the right amount of fuel is supplied at the correct pressure and time. By integrating with the ship’s fuel management system, pneumatic solenoid valves enable real-time adjustments to fuel flow, adapting to varying engine demands and operational conditions.

In practice, pneumatic solenoid valves operate by opening and closing in response to electrical signals from the engine control unit (ECU). When the ECU determines that the engine requires more fuel, it sends a signal to the solenoid valve, which opens to allow more fuel to flow. Conversely, when less fuel is needed, the valve closes to restrict the flow. This precise control mechanism helps maintain optimal fuel levels for combustion, contributing to efficient engine operation and performance.

Efficiency and Performance

The use of pneumatic solenoid valves in fuel management systems significantly enhances the overall fuel efficiency and performance of marine engines. Here’s how:

- Optimal Combustion: By ensuring the accurate delivery of fuel, pneumatic solenoid valves help maintain the ideal air-fuel mixture required for efficient combustion. This results in more complete fuel burn, reducing fuel wastage and lowering emissions of unburned hydrocarbons and other pollutants.

- Improved Fuel Economy: Precise fuel flow regulation minimizes fuel consumption, contributing to better fuel economy. By preventing overfueling and ensuring that only the necessary amount of fuel is used, ships can achieve longer voyages on the same amount of fuel, reducing operational costs.

- Enhanced Engine Performance: Consistent and accurate fuel delivery ensures that the engine operates smoothly and reliably. Pneumatic solenoid valves help maintain stable engine performance, reducing the likelihood of misfires, engine knock, and other issues that can affect engine health and longevity.

- Adaptability to Load Changes: Marine engines often experience varying load conditions, such as changes in speed or power demand. Pneumatic solenoid valves allow the fuel management system to quickly adapt to these changes by adjusting fuel flow in real-time. This adaptability ensures that the engine can respond efficiently to different operational demands, maintaining optimal performance across a range of conditions.

- Emission Control: Efficient fuel management through pneumatic solenoid valves contributes to lower emissions of harmful pollutants, such as nitrogen oxides (NOx) and sulfur oxides (SOx). By supporting cleaner combustion, these valves help ships comply with stringent environmental regulations, enhancing their sustainability profile.

- System Reliability: The robust design and reliable operation of pneumatic solenoid valves ensure the long-term stability and performance of the fuel management system. Their durability in harsh marine environments reduces the need for frequent maintenance and repairs, enhancing the overall reliability of the ship’s propulsion system.

Bilge and Ballast Systems

Bilge Systems

Pneumatic solenoid valves play a critical role in the management of bilge water on ships. Bilge systems are designed to collect and remove water that accumulates in the lowest part of the ship, known as the bilge. This water can come from various sources, such as leaks, condensation, and routine operations. Efficient removal of bilge water is essential to maintain the ship’s safety and integrity.

Role of Pneumatic Solenoid Valves in Bilge Water Management:

- Automatic Control: Pneumatic solenoid valves are integrated into bilge pumping systems to automate the process of bilge water removal. These valves are controlled by sensors and switches that detect the water level in the bilge. When the water level reaches a certain point, the solenoid valve opens, allowing the bilge pump to discharge the water overboard or into a holding tank.

- Preventing Backflow: Solenoid valves help prevent backflow, ensuring that discharged water does not return to the bilge. This is crucial in maintaining a dry and safe bilge area, as backflow can cause flooding and potential damage to the ship’s structure and equipment.

- Environmental Compliance: Many modern bilge systems are equipped with oily water separators to comply with environmental regulations. Pneumatic solenoid valves control the flow of water through these separators, ensuring that only clean water is discharged overboard, while oily residues are retained for proper disposal.

Ballast Operations

Ballast water systems are essential for maintaining the stability and balance of a ship, especially when it is not fully loaded with cargo. Ballast water is taken on board or discharged to adjust the ship’s weight distribution, ensuring optimal stability and safe navigation. Pneumatic solenoid valves are integral to the efficient operation of ballast water systems.

Importance of Pneumatic Solenoid Valves in Ballast Water Systems:

- Precise Control: Pneumatic solenoid valves provide precise control over the intake and discharge of ballast water. This allows for accurate adjustment of the ship’s trim, list, and draft, ensuring stability under various loading conditions.

- Automation and Efficiency: By automating the opening and closing of ballast valves, pneumatic solenoid valves enhance the efficiency of ballast operations. Automated systems can quickly respond to changes in the ship’s load and environmental conditions, making necessary adjustments without manual intervention.

- Stability and Safety: Maintaining proper ballast levels is critical for the ship’s stability, especially in rough seas or during cargo operations. Pneumatic solenoid valves ensure that ballast adjustments are made swiftly and accurately, reducing the risk of capsizing or structural stress.

- Compliance with Regulations: Ballast water management is subject to international regulations aimed at preventing the spread of invasive marine species. Pneumatic solenoid valves are used in ballast water treatment systems to control the flow of water through filtration and disinfection units, ensuring compliance with environmental standards.

- Redundancy and Reliability: Ships often have multiple ballast tanks and a network of solenoid valves to provide redundancy. This ensures that even if one valve fails, others can maintain the necessary ballast operations, enhancing the overall reliability and safety of the ship.

HVAC and Environmental Control

Climate Control

Pneumatic solenoid valves are essential components in the heating, ventilation, and air conditioning (HVAC) systems on ships. These systems are crucial for maintaining a comfortable and safe environment for crew and passengers, as well as for protecting sensitive equipment.

Use of Pneumatic Solenoid Valves in HVAC Systems:

- Temperature Regulation: Pneumatic solenoid valves control the flow of refrigerants, hot water, or steam in HVAC systems. By opening or closing these valves, the system can regulate the temperature of different areas on the ship, ensuring optimal comfort levels in living quarters, workspaces, and recreational areas.

- Airflow Control: These valves are also used to manage airflow within the HVAC system. By adjusting the position of dampers and vents, pneumatic solenoid valves help distribute conditioned air evenly throughout the ship, maintaining consistent air quality and temperature in all zones.

- Humidity Control: In conjunction with other components, pneumatic solenoid valves control the flow of humidification and dehumidification agents. This is particularly important in preventing condensation and corrosion in sensitive areas like engine rooms and electronics compartments.

- Energy Efficiency: By precisely controlling the flow of heating and cooling agents, pneumatic solenoid valves contribute to the energy efficiency of HVAC systems. Efficient regulation reduces energy consumption and operational costs, which is crucial for the economic operation of a ship.

Environmental Compliance

Ensuring environmental control and compliance with regulations is a critical aspect of modern maritime operations. Pneumatic solenoid valves play a significant role in helping ships meet these requirements.

Role of Pneumatic Solenoid Valves in Environmental Compliance:

- Pollution Control: Pneumatic solenoid valves are used in various pollution control systems, such as exhaust gas cleaning systems (scrubbers). These valves regulate the flow of cleaning agents and water, ensuring that exhaust gases are treated to remove harmful substances before they are released into the atmosphere.

- Ballast Water Treatment: As part of ballast water management systems, pneumatic solenoid valves control the flow of water through filtration and disinfection units. This ensures that ballast water is treated to remove invasive species and pathogens, complying with international regulations such as the Ballast Water Management Convention.

- Waste Management Systems: On ships, waste management systems often use pneumatic solenoid valves to control the treatment and discharge of wastewater. These valves ensure that only treated water meeting environmental standards is released overboard, preventing marine pollution.

- Air Quality Management: Pneumatic solenoid valves help maintain air quality by regulating the flow of fresh air and removing contaminants from enclosed spaces. This is particularly important in areas where hazardous materials are stored or processed, ensuring compliance with safety and environmental regulations.

- Energy Management: By enhancing the efficiency of HVAC systems, pneumatic solenoid valves contribute to the overall energy management strategy of the ship. Reduced energy consumption translates to lower greenhouse gas emissions, helping ships meet stringent environmental standards and carbon reduction targets.

Installation and Maintenance

Installation Best Practices

Proper installation of pneumatic solenoid valves is crucial for their optimal performance and longevity in marine environments. Here are some best practices to ensure correct installation:

- Choose the Right Valve: Select pneumatic solenoid valves that are specifically designed for marine environments. Ensure they are corrosion-resistant and rated for the operating conditions they will encounter, such as temperature, pressure, and fluid type.

- Prepare the Installation Site: Ensure the installation site is clean and free of debris. The area should be accessible for future maintenance and protected from physical damage and harsh environmental conditions.

- Correct Orientation: Install the valve in the correct orientation as specified by the manufacturer. Incorrect installation can lead to improper functioning or damage to the valve.

- Secure Mounting: Use appropriate mounting brackets or supports to secure the valve firmly. Avoid placing stress on the valve body or connections to prevent leaks and mechanical failure.

- Proper Connections: Ensure all pneumatic and electrical connections are secure and properly sealed. Use thread sealants or Teflon tape where appropriate, but avoid over-tightening which can damage threads or the valve body.

- Electrical Wiring: Follow the manufacturer’s guidelines for electrical wiring. Ensure that the electrical supply matches the voltage and current requirements of the solenoid. Use appropriate wire gauge and insulation for marine environments to prevent corrosion and electrical faults.

- Testing and Calibration: After installation, test the valve for proper operation. Check for leaks, proper opening and closing, and correct response to control signals. Calibrate the valve as necessary to ensure it operates within the desired parameters.

Maintenance Tips

Regular maintenance is essential to ensure the longevity and reliability of pneumatic solenoid valves in marine applications. Here are some maintenance tips to follow:

- Routine Inspections: Conduct regular visual inspections of the valves for signs of wear, corrosion, or damage. Check for leaks around connections and seals.

- Cleanliness: Keep the valves and surrounding areas clean. Remove any debris, dirt, or marine growth that could interfere with valve operation. Clean the valve internals periodically, following the manufacturer’s recommendations.

- Lubrication: Lubricate moving parts as recommended by the manufacturer. Use lubricants that are compatible with the valve materials and suitable for marine environments.

- Check Electrical Connections: Inspect electrical connections for signs of corrosion or loose wires. Ensure that all connections are tight and that insulation is intact.

- Test Functionality: Regularly test the valves to ensure they are operating correctly. Cycle the valves through their full range of motion to check for proper opening and closing.

- Seal and Gasket Replacement: Periodically replace seals and gaskets to prevent leaks. Use replacement parts that are designed for the specific valve model and suitable for marine conditions.

- Monitor Performance: Keep records of valve performance, including any issues encountered and maintenance performed. Monitoring performance trends can help identify potential problems before they lead to valve failure.

- Spare Parts Inventory: Maintain an inventory of critical spare parts, such as seals, gaskets, and solenoids. Having spare parts on hand can reduce downtime in case of valve failure.

- Training: Ensure that personnel responsible for valve maintenance are properly trained. They should understand the specific requirements of pneumatic solenoid valves and follow the manufacturer’s maintenance guidelines.

- Manufacturer Support: Consult the valve manufacturer for any specific maintenance recommendations or support. Utilize their resources for troubleshooting and obtaining genuine replacement parts.

FAQ on “Pneumatic Solenoid Valve”

Q: What is a pneumatic solenoid valve?

A: It controls air or gas flow in a pneumatic system.

Q: How do they enhance marine engine performance?

A: By regulating fuel and air flow precisely.

Q: Why are they important in ballast systems?

A: They control ballast water flow for ship stability.

Q: What maintenance is required?

A: Regular inspections, cleaning, and lubrication.

Conclusion

Pneumatic solenoid valves are vital components in the marine industry, playing crucial roles in engine control, automation, safety systems, fuel management, bilge and ballast operations, HVAC systems, and environmental compliance. Their precise control and reliability enhance the efficiency and safety of ship operations, making them indispensable in modern maritime applications. By adhering to proper installation practices and regular maintenance, these valves can deliver long-lasting performance even in the harshest marine environments. As technology advances, pneumatic solenoid valves will continue to be at the forefront of innovation, ensuring the smooth and efficient functioning of marine vessels.