Potential Transformer

Potential transformers (PTs) are vital components in electrical systems, designed to accurately measure and monitor voltage levels. These devices play a crucial role in ensuring the safety, efficiency, and reliability of power distribution in residential, commercial, and industrial settings. By scaling down high voltages to manageable levels, PTs allow for precise voltage measurement and protection against faults and overloads.

In this blog post, we will delve into the world of potential transformers, exploring seven ultimate facts, types, and uses that highlight their significance. You will learn about the different types of PTs, their specifications, and how to choose the right one for your needs. We will also cover various applications, provide installation guides, and share best practices for usage.

Additionally, we will discuss safety standards, troubleshooting tips, and the latest technological advancements. By the end of this post, you will have a comprehensive understanding of potential transformers and their critical role in modern electrical systems.

Understanding Potential Transformers

What are Potential Transformers?

Definition and Basic Concept Potential transformers (PTs), also known as voltage transformers, are a type of instrument transformer designed to reduce high voltages to lower, more manageable levels. This scaled-down voltage is used for metering, protection, and control in electrical systems. By stepping down high voltages to a standard level, PTs enable safe and accurate measurement and monitoring without directly exposing instruments and personnel to high voltages.

How Do They Work?

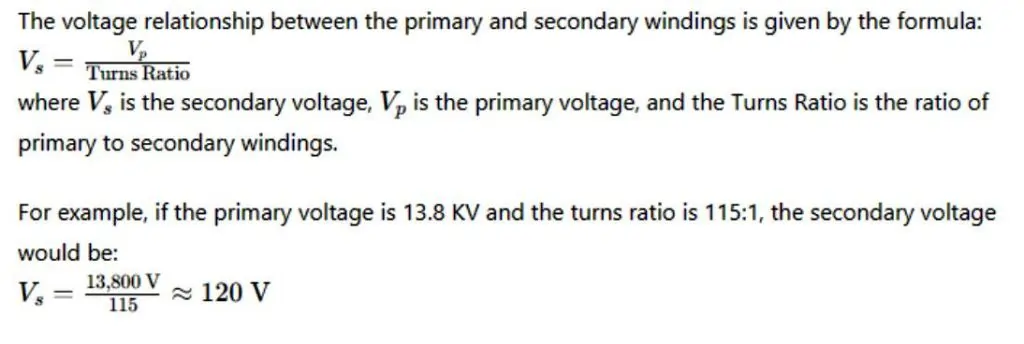

Explanation of the Working Principle Potential transformers operate on the principle of electromagnetic induction, similar to regular transformers. Here’s a detailed explanation of their working using the components:

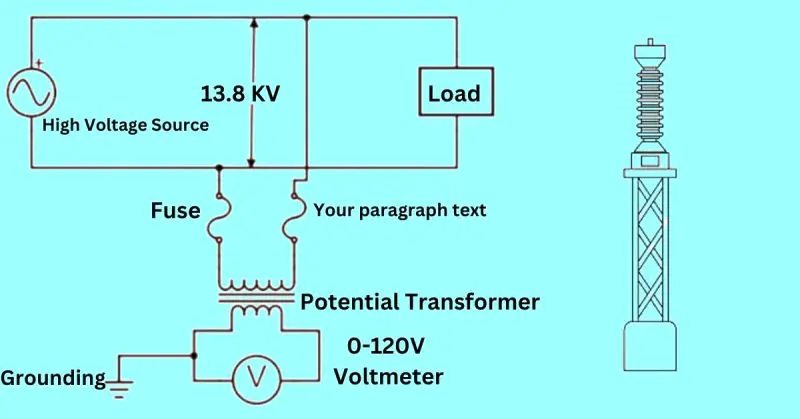

- 13.8 KV High Voltage Input: The high-voltage line (e.g., 13.8 KV) is connected to the primary winding of the PT. This winding is designed to handle high voltages and is typically made of heavy-gauge wire or conductors with high insulation levels.

- Magnetic Core: The PT contains a magnetic core, which is essential for the transfer of energy between the primary and secondary windings. The alternating current flowing through the primary winding generates a magnetic field in the core.

- Secondary Winding: The secondary winding consists of many turns of finer wire compared to the primary winding. The magnetic field in the core induces a voltage in the secondary winding. This induced voltage is a scaled-down version of the primary voltage, determined by the turns ratio between the primary and secondary windings.

0-120V Voltmeter: The secondary side of the PT, which now carries a lower voltage (typically 0-120V), is connected to a voltmeter. This voltmeter displays the scaled-down voltage, which is proportional to the high-voltage line. The readings on this voltmeter can be used to infer the actual high voltage on the primary side using the known transformation ratio.

Fuse: A fuse is placed in series with the primary connection to protect the PT and other downstream equipment. If the current exceeds a certain threshold due to a fault or other issue, the fuse will blow, disconnecting the high-voltage line and preventing damage.

Load: The electrical load is connected to the high-voltage line. The PT measures the voltage supplied to this load.

Grounding: Proper grounding of the PT ensures that any fault currents are safely directed to the earth, preventing electrical shock hazards and protecting the equipment.

Role in Electrical Systems

Importance and Function in Voltage Measurement and Monitoring Potential transformers play a crucial role in electrical systems by providing accurate voltage measurement and monitoring. Their primary functions include:

- Metering: PTs provide a scaled-down voltage that is safe to connect to metering equipment. This allows for accurate measurement of high voltage levels in power systems without the need for direct high-voltage connections.

- Protection: PTs are integral to protection systems in electrical networks. They provide the necessary voltage signals to protective relays, which monitor the system for abnormal conditions such as overvoltages or faults. When a fault is detected, the relays can trigger circuit breakers to isolate the affected section, preventing damage to the system and ensuring safety.

- Control: In control systems, PTs provide voltage feedback for regulating devices such as voltage regulators and automatic voltage controllers. This helps maintain the stability and efficiency of power distribution systems.

- Safety: By reducing high voltages to lower levels, PTs protect both equipment and personnel. Instruments can be safely connected to the secondary side of the PT for monitoring and control purposes without the risk of exposure to dangerous high voltages.

Types and Specifications of Potential Transformers

| Category | Description | Details |

|---|---|---|

| Different Types of Potential Transformers | ||

| Electromagnetic Potential Transformers | Description: Utilize electromagnetic induction to step down high voltage to a lower voltage. Commonly used in power systems for voltage measurement and protection. | Applications: Suitable for standard voltage measurement and protection in residential, commercial, and industrial settings. |

| Capacitor Voltage Transformers (CVTs) | Description: Use capacitive voltage dividers to reduce high voltage. Often used in high-voltage transmission and distribution systems. | Applications: Ideal for high-voltage transmission lines and for applications where phase accuracy is critical. |

| Optical Potential Transformers | Description: Employ optical fibers and sensors to measure voltage. Known for high accuracy and immunity to electromagnetic interference. | Applications: Used in environments with high electromagnetic interference and for precise voltage measurements. |

| Key Specifications | Description | Details |

|---|---|---|

| Ratings | Description: Include primary and secondary voltage ratings. Indicates the maximum voltage the transformer can handle. | Importance: Ensures the transformer operates within safe limits and provides accurate measurements. |

| Sizes | Description: Physical dimensions of the transformer. Influences installation space requirements and compatibility with existing systems. | Importance: Ensures the transformer fits within the designated installation space. |

| Accuracy Classes | Description: Defines the precision of the voltage measurement. Common classes include 0.1, 0.2, 0.5, and 1.0, with lower numbers indicating higher accuracy. | Importance: Determines suitability for applications requiring different levels of measurement precision. |

| Burden | Description: The load connected to the secondary winding of the transformer, typically measured in VA (volt-amperes). | Importance: Ensures the burden is within the transformer’s rated capacity to maintain accuracy. |

| How to Choose the Right One | Description | Details |

|---|---|---|

| Application Requirements | Consideration: Determine the specific application needs, such as measurement, protection, or metering. | Details: Choose a transformer that meets the voltage, accuracy, and application-specific requirements. |

| Voltage Rating | Consideration: Select a transformer with a primary voltage rating that matches or exceeds the system voltage. | Details: Ensures the transformer can handle the maximum expected voltage. |

| Accuracy | Consideration: Select a transformer with an accuracy class appropriate for the application. | Details: Higher accuracy classes (e.g., 0.1 or 0.2) may be necessary for critical measurements. |

| Physical Size | Consideration: Ensure the transformer fits within the available installation space. | Details: Consider the physical dimensions and mounting requirements. |

| Burden Capacity | Consideration: Verify that the transformer can handle the connected burden without exceeding its rated capacity. | Details: Maintains measurement accuracy and prevents overloading. |

| Environmental Factors | Consideration: Assess the environmental conditions, such as temperature, humidity, and exposure to electromagnetic interference. | Details: Choose a transformer with appropriate insulation and protective features. |

| Compliance and Standards | Consideration: Ensure the transformer complies with relevant industry standards and certifications (e.g., IEC, ANSI). | Details: Guarantees the transformer meets safety, performance, and reliability criteria. |

Applications of Potential Transformers

| Application Category | Description | Details |

|---|---|---|

| Residential Applications | Use in home energy monitoring systems and smart grids | Energy Monitoring: Potential transformers are used in home energy monitoring systems to measure and track electricity consumption, helping homeowners manage and reduce their energy usage. |

| Smart Grids: PTs play a crucial role in smart grids by providing accurate voltage measurements, enabling efficient energy distribution and real-time monitoring of the electrical grid. | ||

| Commercial Applications | Implementation in commercial buildings and facilities | Building Management: PTs are used in commercial buildings to monitor and manage the electrical systems, ensuring efficient operation and energy savings. |

| Facility Operations: PTs help in monitoring the electrical consumption of different departments within a facility, enabling accurate billing and energy management. | ||

| Industrial Applications | Role in industrial machinery and large-scale electrical systems | Machinery Monitoring: PTs provide critical voltage measurements for industrial machinery, ensuring safe and efficient operation. |

| Large-Scale Systems: In industrial plants, PTs are essential for monitoring and controlling large-scale electrical systems, helping to maintain stability and prevent overvoltages. |

Installation and Usage of Potential Transformers

| Category | Description | Details |

|---|---|---|

| Installation Guides | Step-by-step instructions for installing potential transformers | Step 1: Preparation: Ensure all necessary tools and safety equipment are ready. Verify that the PT specifications match the application requirements. Step 2: Power Down: De-energize the electrical circuit where the PT will be installed to ensure safety. Step 3: Positioning: Place the PT in its designated location. For primary connections, ensure the PT is mounted securely and that the primary terminals are properly insulated. Step 4: Connecting Primary Side: Connect the high-voltage line (e.g., 13.8 KV) to the primary winding of the PT. Use appropriate fuses to protect the PT and downstream equipment. Step 5: Grounding: Properly ground the PT to ensure any fault currents are safely discharged. Step 6: Connecting Secondary Side: Connect the secondary winding to the measurement instruments, such as a 0-120V voltmeter. Ensure the connections are tight and insulated. Step 7: Power Up and Test: Re-energize the electrical circuit and verify the PT’s operation by checking the secondary voltage readings. Ensure the readings match the expected values based on the primary voltage and turns ratio. |

| Best Practices for Usage | Tips for effective and safe usage | Regular Inspection: Periodically inspect the PT for signs of wear, damage, or loose connections. Proper Rating: Always use a PT with a voltage rating that matches or exceeds the maximum expected voltage in the application. Secure Connections: Ensure all electrical connections are tight and secure to prevent intermittent faults and inaccuracies. Clean Environment: Keep the PT and surrounding area clean and dry to prevent contamination and potential short circuits. Monitor Load: Regularly check the burden on the secondary winding to ensure it remains within the PT’s rated capacity. Temperature Monitoring: Watch for unusual temperature rises, which can indicate overloading or other issues. |

| Common Mistakes to Avoid | Pitfalls and how to prevent them during installation and operation | Incorrect Rating: Using a PT with an incorrect voltage rating can lead to inaccurate measurements and potential damage. Always verify the rating before installation. Loose Connections: Ensure all connections are tight to prevent electrical faults and ensure accurate voltage measurements. Improper Grounding: Failing to properly ground the PT can pose safety hazards and affect performance. Always follow grounding procedures. Ignoring Calibration: Regularly calibrate the PT according to the manufacturer’s guidelines to maintain accuracy. Exceeding Burden Capacity: Do not exceed the PT’s rated burden capacity on the secondary winding to prevent saturation and inaccurate readings. |

Safety and Standards of Potential Transformers

Importance of Safety Standards

Overview of Relevant Safety Standards and Certifications (IEC, ANSI, etc.) Safety standards are critical in ensuring the reliable and safe operation of potential transformers (PTs) in electrical systems. International standards such as those from the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) provide comprehensive guidelines for the design, performance, testing, and certification of PTs.

- IEC Standards: The IEC 61869 series, specifically IEC 61869-1 and IEC 61869-3, covers general requirements and specific requirements for inductive voltage transformers. These standards ensure PTs meet rigorous criteria for accuracy, insulation, and operational safety.

- ANSI Standards: In North America, ANSI/IEEE C57.13 is a widely recognized standard for instrument transformers, including potential transformers. This standard defines the requirements for accuracy, insulation levels, and testing procedures.

- Certifications: Certifications from independent bodies such as Underwriters Laboratories (UL) and Conformité Européenne (CE) indicate that a PT has been tested and verified to meet the highest safety and performance standards.

Adherence to these standards ensures that PTs are capable of performing accurately and safely in various environmental and operational conditions, protecting both equipment and personnel.

Protecting Electrical Circuits

How Potential Transformers Help in Fault Detection and Overload Protection Potential transformers play a crucial role in protecting electrical circuits by providing accurate voltage measurements for monitoring and control purposes. Here’s how they contribute to fault detection and overload protection:

- Fault Detection: PTs provide real-time voltage data to protective relays. When a fault occurs, such as a short circuit or ground fault, the PT detects abnormal voltage levels and sends this information to the relay. The relay then triggers circuit breakers to isolate the affected section, preventing damage to the system and reducing the risk of fire or other hazards.

- Overload Protection: PTs help in monitoring the voltage levels to ensure they remain within safe limits. If the voltage exceeds the specified threshold for an extended period, indicating an overload condition, the PT signals the protective devices to disconnect the affected circuit. This prevents overheating and potential damage to conductors and insulation.

- Accuracy in Measurements: By providing precise voltage measurements, PTs enable accurate monitoring and control of electrical systems. This accuracy is essential for the proper functioning of protective devices, ensuring they respond correctly to any abnormalities.

Regulatory Compliance

Ensuring Compliance with Industry Regulations Regulatory compliance is essential for the safe and effective use of potential transformers. Compliance with industry standards ensures that PTs are designed, tested, and operated in accordance with the highest safety and performance criteria.

- Design and Manufacturing: PTs must be designed and manufactured following the guidelines specified by standards such as IEC and ANSI. This includes adhering to requirements for materials, insulation, and construction to withstand operational stresses.

- Testing and Certification: Manufacturers must subject PTs to rigorous testing to verify their compliance with safety and performance standards. This includes routine tests (such as accuracy and insulation tests) and type tests (such as temperature rise and impulse tests). Certifications from bodies like UL and CE provide additional assurance of compliance.

- Documentation and Audits: Proper documentation of compliance with standards is necessary. Regular audits and inspections help maintain certification and ensure ongoing adherence to standards. This includes keeping records of design, manufacturing processes, and testing results.

Troubleshooting and Maintenance

| Category | Description | Details |

|---|---|---|

| Common Issues and Solutions | Identifying and fixing typical problems with potential transformers | Issue: Inaccurate Readings Solution: Check for loose connections, ensure the PT rating matches the application, and recalibrate if necessary. Issue: Overheating Solution: Verify the burden on the secondary winding is within the rated capacity and ensure proper ventilation around the PT. Issue: Physical Damage Solution: Inspect for cracks, wear, or other physical damage and replace the PT if necessary. Issue: Signal Noise Solution: Ensure the PT is installed away from sources of electrical interference and check grounding connections. Issue: Saturation Solution: Ensure the primary voltage does not exceed the PT’s rated capacity and the burden is appropriate. |

| Maintenance Tips | Regular maintenance practices to ensure longevity and reliability | Regular Inspection: Conduct visual inspections periodically to check for any signs of wear, damage, or corrosion. Clean Environment: Keep the PT and surrounding area clean and dry to prevent dust accumulation and moisture ingress. Tighten Connections: Periodically check and tighten all electrical connections to ensure they are secure. Calibration: Calibrate the PT regularly according to the manufacturer’s instructions to maintain accuracy. Monitor Load: Regularly monitor the burden on the secondary winding to ensure it remains within the rated capacity. Temperature Monitoring: Check for unusual temperature rises, which can indicate overloading or other issues. |

| When to Seek Professional Help | Indicators that professional intervention is needed | Persistent Inaccuracies: If recalibration and basic troubleshooting do not resolve measurement inaccuracies, seek professional help. Severe Physical Damage: When there is significant physical damage such as cracked cores or broken terminals, replacement by a professional is necessary. Unusual Noise or Smell: Any unusual noise or burning smell from the PT should prompt immediate professional inspection. Complex Calibration: For complex calibration procedures or when using advanced PTs, professional expertise ensures proper calibration. Intermittent Faults: If you experience intermittent electrical faults that are difficult to diagnose, a professional can provide a thorough evaluation and solution. |

Comparisons and Reviews

| Category | Description | Details |

|---|---|---|

| Comparing Different Brands and Models | Overview of leading brands and their offerings | Leading Brands: Examine top brands such as Siemens, ABB, Schneider Electric, and GE.<br> Siemens: Known for high reliability and advanced technology. ABB: Offers a wide range of PTs with strong global support. Schneider Electric: Focuses on innovation and energy efficiency. GE: Provides robust and durable PTs suitable for various applications. |

| Performance and Accuracy | Evaluating performance, accuracy, and durability | Performance: Assess the voltage transformation efficiency and stability under different load conditions. Accuracy: Compare accuracy classes (e.g., 0.1, 0.2) to determine suitability for precision applications. Durability: Look at materials and construction quality, insulation ratings, and ability to withstand harsh environmental conditions. |

| Value for Money | Assessing the best options based on cost-effectiveness | Cost-effectiveness: Compare the initial purchase price, installation costs, and long-term operational expenses. Return on Investment (ROI): Evaluate the potential savings from improved energy efficiency and reduced maintenance costs. Warranty and Support: Consider the length and terms of the warranty, and the availability of technical support and service. |

FAQ on “Potential Transformer”

Q: What is the primary function of a potential transformer (PT)?

A: To step down high voltage for measurement.

Q: How do potential transformers enhance electrical safety?

A: By detecting faults and preventing overloads.

Q: What are the main types of potential transformers?

A: Electromagnetic, capacitor voltage, and optical.

Q: Why is regulatory compliance important for potential transformers?

A: It ensures safety and reliability.

Conclusion

Potential transformers are essential components in modern electrical systems, ensuring accurate voltage measurement and protection. By understanding the different types, specifications, and applications, as well as adhering to best practices for installation, maintenance, and safety standards, you can optimize the performance and reliability of your electrical systems. Through careful comparison of brands and models, you can select the most suitable potential transformers that offer the best value for your investment. Properly utilized, potential transformers enhance the safety, efficiency, and longevity of power distribution networks.