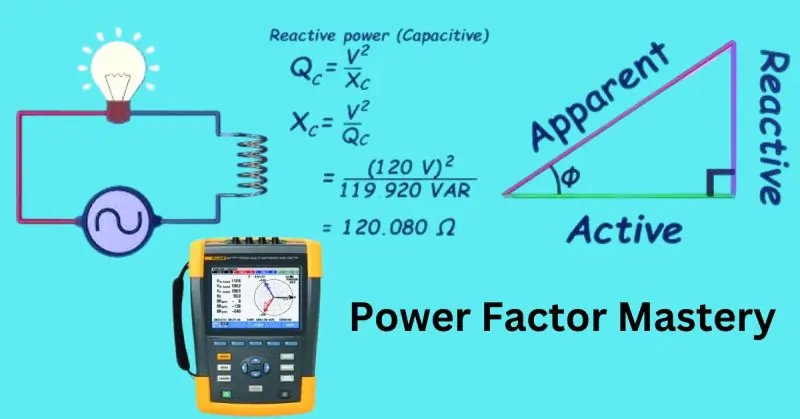

Power Factor Mastery

In the world of electrical systems, power factor is a critical measure of efficiency and reliability. A low power factor can lead to increased energy costs, reduced capacity, and premature equipment failure. It directly impacts the performance and longevity of your electrical infrastructure, making it crucial for both industrial and residential applications.

In this blog post, we will delve into understanding the power factor formula, which is essential for any improvement efforts. We will explore techniques for power factor correction, such as using capacitors, and discuss the benefits of automatic power factor controllers that optimize your system’s performance. Additionally, we will highlight the importance of monitoring with power factor meters to maintain optimal levels.

Furthermore, we will cover improvement strategies and best practices to consistently achieve a high power factor. We will also examine the role of power factor correction capacitors and the optimization of your system using power factor controllers for maximum efficiency.

Understanding Power Factors Formula

Explanation: Detailed Breakdown of the Power Factor Formula

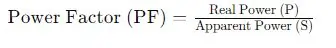

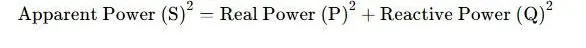

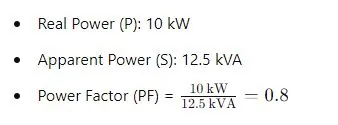

Power factor (PF) is a measure of how effectively electrical power is being used by a system. It is defined as the ratio of real power (P) to apparent power (S) and can be expressed by the formula:

Real Power (P): The actual power consumed by the electrical equipment in watts (W).

Apparent Power (S): The total power supplied to the circuit, measured in volt-amperes (VA), which combines real power and reactive power.

Reactive Power (Q): The power that oscillates between the source and load, measured in reactive volt-amperes (VAR), and does not perform any useful work.

The relationship between these components can also be visualized using the power triangle:

Power factor ranges from -1 to 1. A power factor of 1 indicates that all the power is being effectively converted into useful work, while a power factor of 0 indicates that none of the power is being effectively used.

Importance: Why Knowing the Formula is Crucial for Improvement

Understanding the power factor formula is crucial for several reasons:

- Efficiency: A higher power factor indicates more efficient utilization of electrical power, reducing energy losses.

- Cost Savings: Utility companies often charge higher rates for lower power factors. Improving power factor can reduce electricity bills.

- System Performance: A good power factor improves the performance and lifespan of electrical equipment by reducing overheating and wear.

- Capacity Utilization: Better power factor means less apparent power is needed to achieve the same amount of real power, freeing up capacity in the electrical system for additional loads.

Examples: Practical Examples to Illustrate the Formula in Use

- Example 1: Industrial Motor

This means the motor is operating at 80% efficiency. Improving the power factor to 0.95 would reduce the apparent power to approximately 52.63 kVA, resulting in lower energy costs.

Example 2: Office Building Lighting

By installing power factor correction capacitors, the power factor can be improved to 0.95, reducing the apparent power to 10.53 kVA. This not only reduces electricity bills but also improves the efficiency of the electrical system.

Effective Power Factors Correction Techniques

Definition: What is Power Factor Correction?

Power factor correction (PFC) is a technique used to improve the power factor of an electrical system. The power factor is a measure of how effectively the electrical power is being converted into useful work output. A power factor of 1 (or 100%) means all the power is being used effectively, while a lower power factor indicates inefficient usage. Power factor correction aims to bring the power factor closer to 1 by reducing the phase difference between the voltage and current in an AC power system.

Methods: Different Techniques for Correcting Power Factors

- Capacitor Banks: The most common method, where capacitors are added to the electrical network to offset inductive loads. This reduces the phase difference between voltage and current, thereby improving the power factor.

- Synchronous Condensers: These are synchronous motors running without mechanical load, adjusted to improve the power factor by generating or absorbing reactive power as needed.

- Static VAR Compensators (SVC): These are advanced devices that use a combination of capacitors and reactors, controlled by thyristors, to provide dynamic power factor correction in real-time.

- Phase Advancers: Used primarily for induction motors, phase advancers improve the power factor by providing the necessary excitation current directly to the motor.

- Automatic Power Factor Controllers (APFC): These devices automatically regulate the amount of power factor correction needed by switching capacitors in and out of the circuit based on the load requirements.

Benefits: Advantages of Implementing Power Factor Correction

- Improved Energy Efficiency: By correcting the power factor, the system uses electrical power more effectively, reducing energy losses and improving overall efficiency.

- Cost Savings: Many utility companies charge extra fees for low power factors. Improving the power factor can lower these charges and reduce the overall electricity bill.

- Increased Capacity: With a better power factor, the electrical system can handle more load without requiring an increase in the supply capacity. This is especially beneficial for expanding operations without upgrading infrastructure.

- Reduced Heat and Wear: Improved power factor reduces the current flowing through the electrical system, which decreases heat generation and minimizes wear and tear on equipment, leading to longer lifespan and reduced maintenance costs.

- Enhanced Voltage Stability: Correcting the power factor improves voltage stability in the electrical network, which enhances the performance and reliability of electrical equipment.

- Environmental Benefits: By improving energy efficiency and reducing power wastage, power factor correction contributes to lower greenhouse gas emissions and a smaller carbon footprint.

Utilizing Automatic Power Factor Controllers

Introduction: What are Automatic Power Factor Controllers?

Automatic Power Factor Controllers (APFC) are advanced devices designed to automatically monitor and regulate the power factor of an electrical system. They dynamically adjust the power factor by switching capacitor banks on or off based on the real-time demands of the electrical load. APFCs ensure that the power factor remains within an optimal range, thereby improving the efficiency and stability of the power system.

Functionality: How These Controllers Work

Automatic Power Factor Controllers work by continuously measuring the power factor of an electrical system. Here’s a step-by-step outline of their functionality:

- Monitoring: APFCs are equipped with sensors that measure the power factor by analyzing the phase difference between voltage and current in the system.

- Evaluation: The controller evaluates the measured power factor against a predefined optimal value. If the power factor deviates from the desired range, the APFC determines the amount of reactive power required to correct it.

- Capacitor Switching: Based on the evaluation, the APFC switches capacitor banks on or off to either supply or absorb reactive power. This switching is performed through contactors or solid-state switches to ensure precise control.

- Feedback Loop: The APFC continuously monitors the power factor after each adjustment, creating a feedback loop that maintains the power factor within the optimal range. This real-time correction ensures that the system operates efficiently under varying load conditions.

Benefits: The Impact on System Efficiency and Cost Savings

- Improved Energy Efficiency: By maintaining an optimal power factor, APFCs reduce energy losses in the electrical system. This leads to more efficient use of power and lower energy consumption.

- Cost Savings: Many utility companies impose penalties for low power factors. By keeping the power factor within the optimal range, APFCs help avoid these penalties and reduce overall electricity bills. Additionally, the reduction in energy losses translates to direct cost savings.

- Increased System Capacity: APFCs allow the electrical system to handle additional loads without the need for significant infrastructure upgrades. This increased capacity is particularly beneficial for expanding operations or accommodating new equipment.

- Reduced Equipment Wear and Tear: By minimizing the reactive power in the system, APFCs reduce the strain on electrical components such as transformers, conductors, and generators. This leads to lower maintenance costs and extends the lifespan of the equipment.

- Enhanced Voltage Stability: Maintaining a stable power factor helps stabilize the voltage levels in the system. This results in smoother operation of sensitive equipment and reduces the risk of voltage-related issues.

- Environmental Benefits: By improving the overall efficiency of the electrical system, APFCs contribute to reduced energy consumption and lower greenhouse gas emissions. This makes them an environmentally friendly solution for power factor correction.

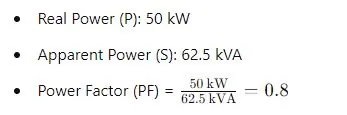

Power Factor Meters: Monitoring and Measuring

| Topic | Details |

|---|---|

| Power Factor Meters: Monitoring and Measuring | |

| Explanation | |

| What is a Power Factor Meter? | A power factor meter is an electrical device used to measure the power factor of an electrical system, indicating the ratio of real power to apparent power. |

| Usage | |

| Installation | Install at key points in the electrical distribution network, ensuring proper connections to voltage and current transformers. |

| Calibration | Calibrate the meter according to manufacturer’s instructions; perform regular calibration checks. |

| Monitoring | Continuously monitor real-time power factor data displayed on the device or remotely through connected systems. |

| Data Logging | Utilize data logging features to record and analyze historical data, identifying trends and potential issues. |

| Alarm Settings | Set alarms for specific power factor thresholds to alert operators when the power factor deviates from the desired range. |

| Maintenance | Regularly check and maintain the meter, inspect connections, clean the device, and update firmware as needed. |

| Selection | |

| Accuracy | Choose meters with high accuracy and precision for reliable readings. |

| Range | Ensure the meter measures the full range of power factors in your system. |

| Features | Consider additional features like data logging, remote monitoring, and alarm settings. |

| Ease of Use | Select a meter with a user-friendly interface and clear display. |

| Compatibility | Ensure compatibility with your existing electrical system, including voltage and current transformers. |

| Durability | Choose durable meters suitable for industrial or harsh environments, with protective casings and resistance ratings. |

| Brand and Support | Opt for reputable brands known for quality and reliability, with good customer support and service options. |

Strategies for Power Factor Improvement

| Topic | Details |

|---|---|

| Strategies for Power Factor Improvement | |

| Overview | Various strategies to improve power factor, including capacitor installation, synchronous condensers, phase advancers, APFC, load management, and harmonic filters. |

| Implementation | |

| Conduct a Power Factor Audit | Measure the current power factor using meters and identify major sources of reactive power and inductive loads. |

| Design a Correction Plan | Determine appropriate correction methods and calculate the required capacitance for capacitor banks. |

| Install Capacitors | Choose suitable locations for capacitor banks, ensure proper connections and safety measures. |

| Implement Synchronous Condensers | Integrate synchronous motors for dynamic reactive power compensation and adjust motor settings for optimization. |

| Apply Phase Advancers | Install phase advancers on large induction motors and adjust settings to achieve desired power factor improvement. |

| Deploy Automatic Power Factor Controllers (APFC) | Install APFCs in the main distribution panel, configure to automatically switch capacitors based on real-time power factor measurements. |

| Optimize Load Management | Schedule large inductive loads during off-peak hours and balance loads to minimize reactive power demand. |

| Install Harmonic Filters | Identify sources of harmonic distortion and install appropriate filters to reduce harmonics and improve overall power factor. |

| Monitor and Maintain | Continuously monitor the power factor using meters and perform regular maintenance on installed equipment to ensure consistent performance. |

| Case Studies | |

| Manufacturing Plant | Problem: Power factor of 0.72 resulting in high energy costs and penalties. Solution: Installed capacitor banks and APFCs. Result: Power factor improved to 0.95, leading to a 15% reduction in energy costs and elimination of penalties. |

| Office Building | Problem: Voltage instability and increased wear on equipment due to a power factor of 0.75. Solution: Installed harmonic filters and capacitor banks. Result: Power factor increased to 0.98, resulting in stable voltage levels and extended equipment lifespan. |

| Textile Industry | Problem: Frequent equipment failures and high operational costs due to a power factor of 0.70. Solution: Implemented synchronous condensers and optimized load management. Result: Power factor enhanced to 0.96, reducing equipment failures and operational costs by 20%. |

The Role of Power Factor Correction Capacitors

Introduction: What are Power Factor Correction Capacitors?

Power factor correction capacitors are electrical devices used to improve the power factor in electrical systems. Power factor is the ratio of real power (useful power) to apparent power (total power), and a low power factor indicates inefficiency. These capacitors work by offsetting the inductive effects caused by certain loads (like motors and transformers) that lead to a lagging power factor. By adding capacitors to the system, the overall power factor can be improved, leading to increased efficiency and reduced energy costs.

Functionality: How They Help in Improving Power Factor

Power factor correction capacitors improve the power factor by providing leading reactive power (capacitive), which counteracts the lagging reactive power (inductive) in the system. Here’s how they function:

- Reactive Power Compensation: Inductive loads, such as motors and transformers, draw reactive power, which creates a phase difference between voltage and current. Capacitors provide leading reactive power that cancels out some of the lagging reactive power, reducing the phase difference.

- Reduction of Apparent Power: By reducing the reactive power component, the apparent power (the vector sum of real and reactive power) is decreased. This leads to a better power factor.

- Improved Voltage Stability: Capacitors help in maintaining stable voltage levels within the system, which is crucial for the smooth operation of electrical equipment.

- Enhanced System Capacity: With an improved power factor, the system can handle more real power without overloading, thereby increasing its capacity.

Installation: Guidelines for Installing and Maintaining These Capacitors

- Pre-installation Assessment

- Conduct a thorough power factor audit to determine the current power factor and identify the required capacitance.

- Analyze the load profile to decide on the optimal placement of capacitors.

- Choosing the Right Capacitors

- Select capacitors based on the system voltage and the amount of reactive power compensation needed.

- Ensure the capacitors have suitable ratings for the specific application and environment.

- Installation Process

- Location: Install capacitors close to inductive loads to maximize their effectiveness. Common installation points include distribution panels, motor control centers, and directly at large inductive loads.

- Connections: Ensure proper electrical connections, adhering to manufacturer guidelines and electrical codes. Use appropriate fuses and protection devices to safeguard the capacitors.

- Safety Measures: Implement safety measures such as grounding and using enclosures to prevent accidental contact with live parts.

- Commissioning

- After installation, test the capacitors to ensure they are functioning correctly. Measure the power factor to verify the improvement.

- Adjust the capacitor settings if necessary to achieve the desired power factor.

- Maintenance

- Regularly inspect the capacitors for signs of wear, such as bulging, leaks, or discoloration.

- Clean and tighten connections periodically to maintain good electrical contact.

- Monitor the system power factor continuously to detect any deviations that may indicate capacitor failure or degradation.

- Replace capacitors at the end of their service life or if they show signs of significant deterioration.

Leveraging Power Factor Controllers for Optimization

Explanation: The Role of Power Factor Controllers in Electrical Systems

Power factor controllers (PFCs) are essential devices used to automatically manage and improve the power factor in electrical systems. They monitor the power factor and adjust the operation of capacitor banks to ensure that it remains within an optimal range. This automatic adjustment helps maintain the efficiency and stability of the electrical system.

Benefits: How They Optimize Power Factor and System Performance

- Improved Energy Efficiency: PFCs reduce energy losses, leading to more efficient use of electrical power.

- Cost Savings: Avoid penalties from utility companies for low power factor, and reduce electricity bills by lowering energy losses.

- Increased System Capacity: High power factor allows the system to handle more load without significant infrastructure upgrades.

- Reduced Equipment Wear and Tear: Minimizing reactive power reduces strain on components, lowering maintenance costs and extending equipment lifespan.

- Enhanced Voltage Stability: Stabilized voltage levels improve equipment performance and reliability.

- Environmental Benefits: Greater energy efficiency and reduced power wastage contribute to lower greenhouse gas emissions.

Best Practices: Tips for Using Power Factor Controllers Effectively

- Regular Monitoring: Continuously check the power factor to ensure it remains within the desired range.

- Proper Sizing: Ensure the PFC and capacitor banks are appropriately sized for the system’s load requirements.

- Routine Maintenance: Regularly maintain PFCs and associated components for optimal performance.

- Alarm Configuration: Set up alarms for specific power factor thresholds to prompt necessary adjustments.

- Data Logging and Analysis: Use data logging features to track power factor trends and analyze performance.

- Integration with Energy Management Systems: Integrate PFCs with existing systems for comprehensive monitoring and control.

- User Training: Train operators and maintenance personnel in the use and maintenance of PFCs.

FAQ on “Power Factor”

Q: What is power factor?

A: It’s the ratio of real power to apparent power in a circuit.

Q: Why is a high power factor important?

A: It boosts energy efficiency and reduces electricity costs.

Q: How can power factor be improved?

A: By using capacitors, synchronous condensers, and automatic controllers.

Q: What are the benefits of power factor correction?

A: Lower energy bills, increased capacity, and reduced equipment wear.

Conclusion

Optimizing your electrical system’s power factor is crucial for improving energy efficiency, reducing costs, and enhancing overall performance. By leveraging power factor controllers, you can automatically manage and maintain an optimal power factor, leading to significant benefits such as cost savings, increased system capacity, reduced equipment wear, and environmental sustainability. Implementing the best practices for using these controllers effectively ensures that your electrical infrastructure operates at peak efficiency, providing a reliable and cost-effective power solution. Investing in power factor correction is a smart move towards a more efficient and sustainable future.